Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

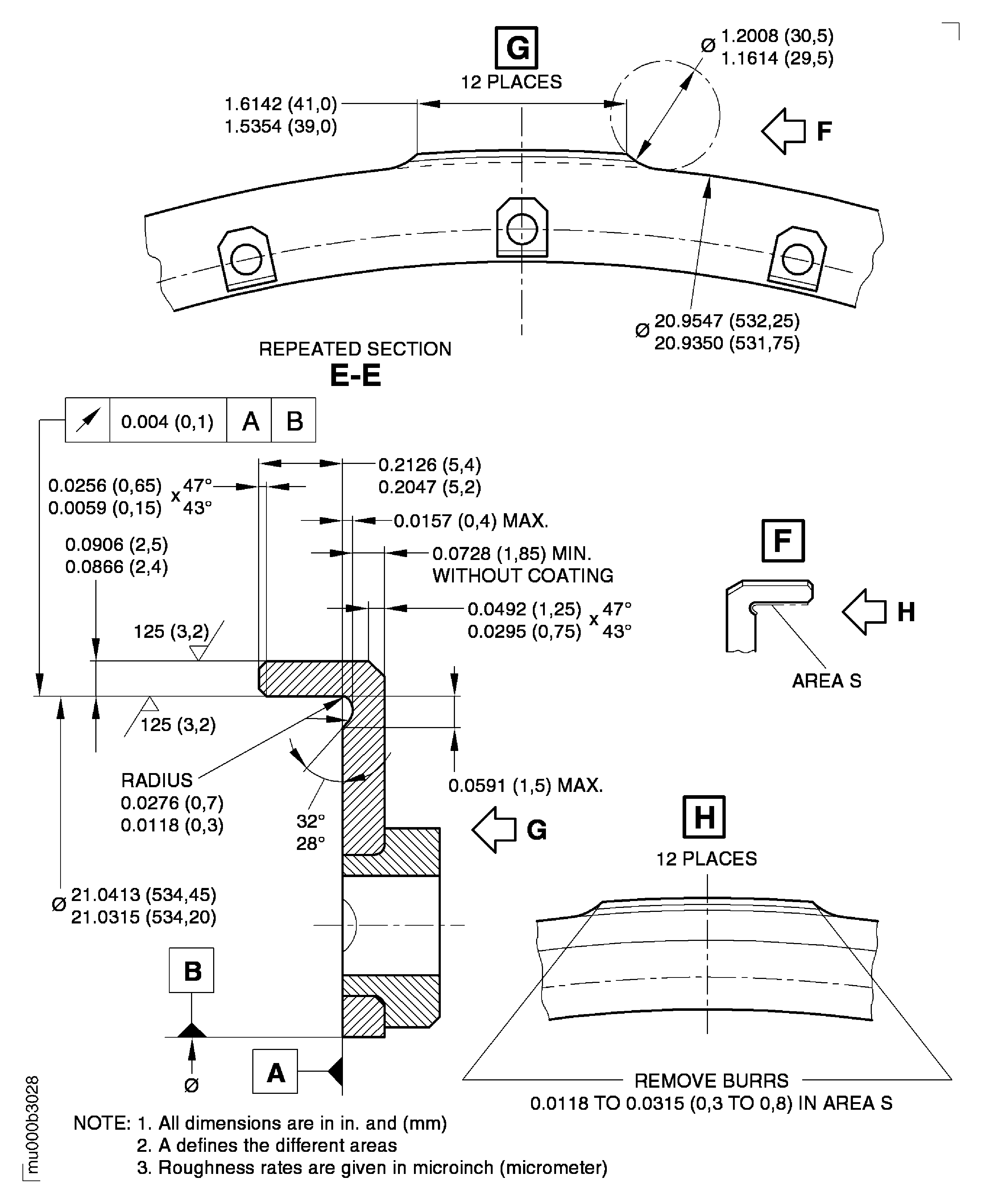

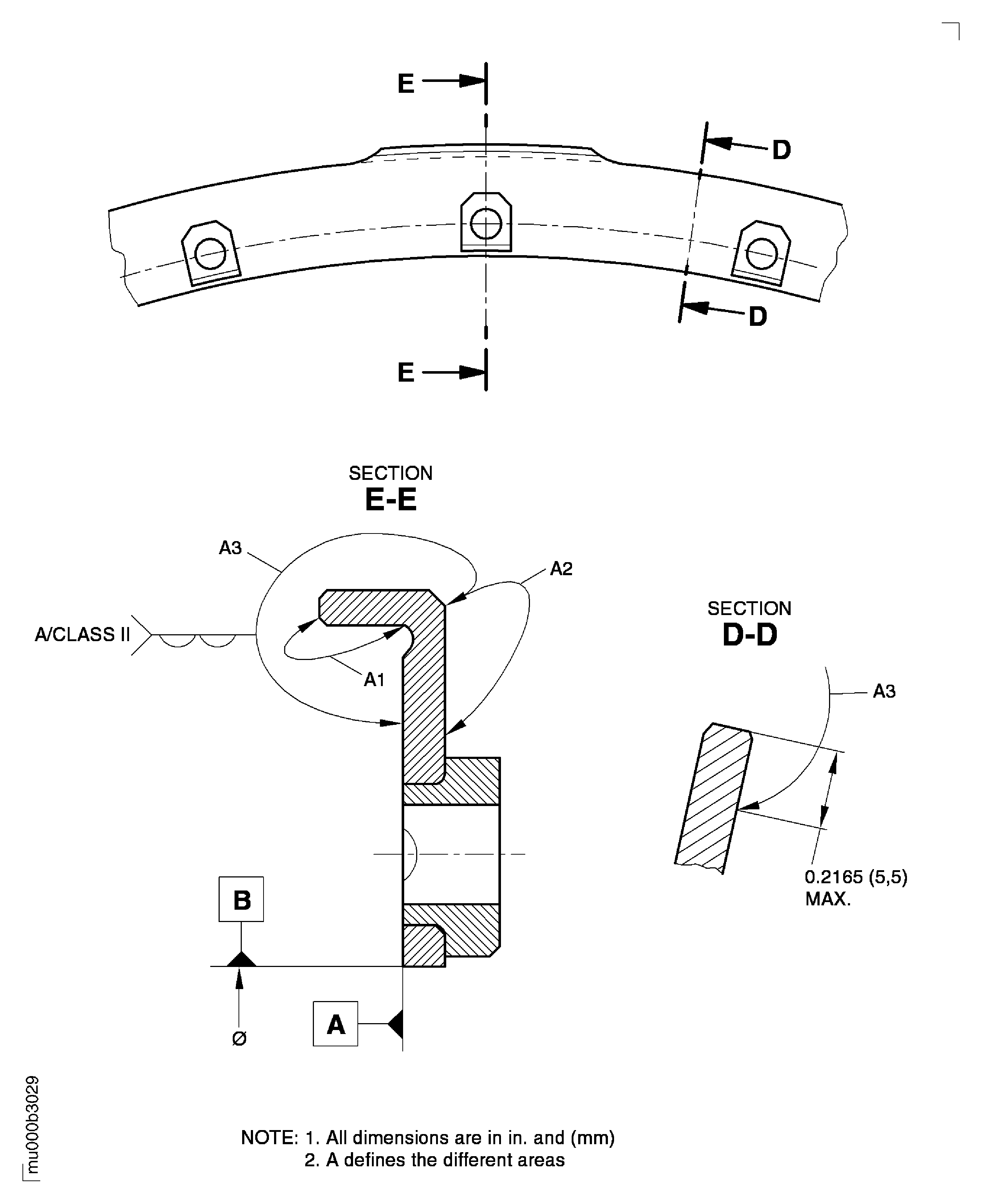

TASK 72-50-24-300-060 LPT Inner Diffuser Duct Support Ring - Weld Repair Front Faces, Repair-060 (VRS4551)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

If the locating diameter in area A1 was plasma sprayed before, remove the old coating fully. Refer to VRS4128 TASK 72-50-24-300-022 (REPAIR-022).

If the rear face in area A2 was plasma sprayed before, remove the old coating fully and replace after repair. Refer to VRS4129 TASK 72-50-24-300-023 (REPAIR-023).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Turning lathe | LOCAL | Turning lathe | ||

| Grinding machine | LOCAL | Grinding machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-170 Clean the Support Ring Assembly

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501.

Use CoMat 03-184 WELDING FILLER WIRE, NICKEL. Make sure that there is sufficient material to do last machining. To prevent distortion, several weld passes must be made. Prevent too much temperature build-up.

Gas tungsten arc weld the front faces area A3.

SUBTASK 72-50-24-310-077 Weld Repair the Support Ring Assembly

Refer to Figure.

SUBTASK 72-50-24-320-082 Machine the Welded Areas

Refer to the SPM TASK 70-37-00-370-501.

Put the part in an oven for eight hours at 1450 to 1500 deg F (788 to 816 deg C).

Use argon or vacuum.

Cooling rate equivalent to air cooling.

Heat treat the support ring assembly.

SUBTASK 72-50-24-370-072 Heat Treatment after Weld Repair

Refer to Figure.

SUBTASK 72-50-24-220-232 Examine the Machined Areas

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions