Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-300-031 LPT Stage 3 Blade - Restore Shroud Pre-Twist, Repair-031 (VRS4209)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Only one pre-twist repair is permitted per part. A "W" marking adjacent to the part number shows that the part was repaired before.

Before repair remove the Aluminide Coating, refer to VRS4208 TASK 72-50-32-300-030 (REPAIR-030).

After repair replace the Aluminide Coating, refer to VRS4208 TASK 72-50-32-300-030 (REPAIR-030).

NOTE

For more equipment and materials necessary to do this repair, refer to:

Equivalent materials can be used.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3M14481 Fixture check and correct | 0AM53 | IAE 3M14481 | 1 | |

| IAE 3M14482 Blade holder | 0AM53 | IAE 3M14482 | 1 | or |

| IAE 3M14495 Bladeholder | 0AM53 | IAE 3M14495 | 1 | |

| IAE 3M14483 Handle twist | 0AM53 | IAE 3M14483 | 1 | |

| IAE 3M14493 Gage, inspection | 0AM53 | IAE 3M14493 | 1 | |

| IAE 3M14494 Gage, master | 0AM53 | IAE 3M14494 | 1 | or |

| IAE 3M14543 Gage, master | 0AM53 | IAE 3M14543 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-031 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-031 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 11851 | CoMat 05-138 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 |

Spares

NONESafety Requirements

NONEProcedure

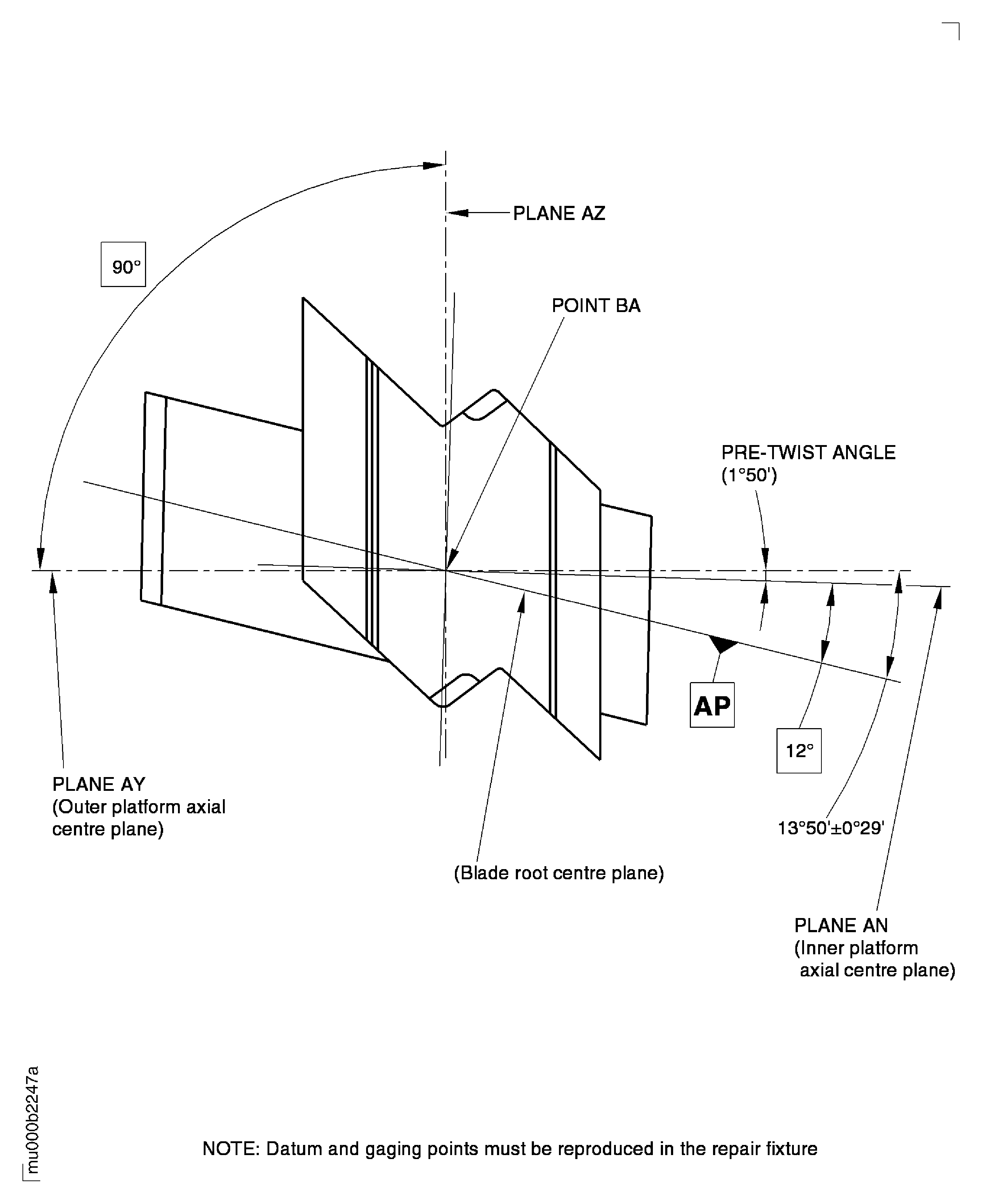

Refer to Figure.

NOTE

Use a test piece to evaluate amount of twist necessary to get a permanent set of necessary pre-twist value. Twist-back of outer shroud is not permitted if achieved pre-twist is out of limits.Use IAE 3M14481 Fixture check and correct 1 off, IAE 3M14482 Blade holder 1 off or IAE 3M14495 Bladeholder 1 off, IAE 3M14483 Handle twist 1 off, IAE 3M14493 Gage, inspection 1 off and IAE 3M14494 Gage, master 1 off or IAE 3M14543 Gage, master 1 off.

Do not bend outer shroud and airfoil section axially or circumferentially.

Twist the stage 3 turbine blade.

SUBTASK 72-50-32-350-102 Restore Pre-Twist on Outer Shroud

Do the stress-relief after all weld operations.

This SUBTASK is optional.

Refer to the SPM TASK 70-37-26-370-501, Stress-Relief Cycle 18.

Stress-relieve the turbine blade.

SUBTASK 72-50-32-370-110 Heat Treatment after Twisting

NOTE

Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-32-110-159 Clean the Stage 3 Turbine Blade

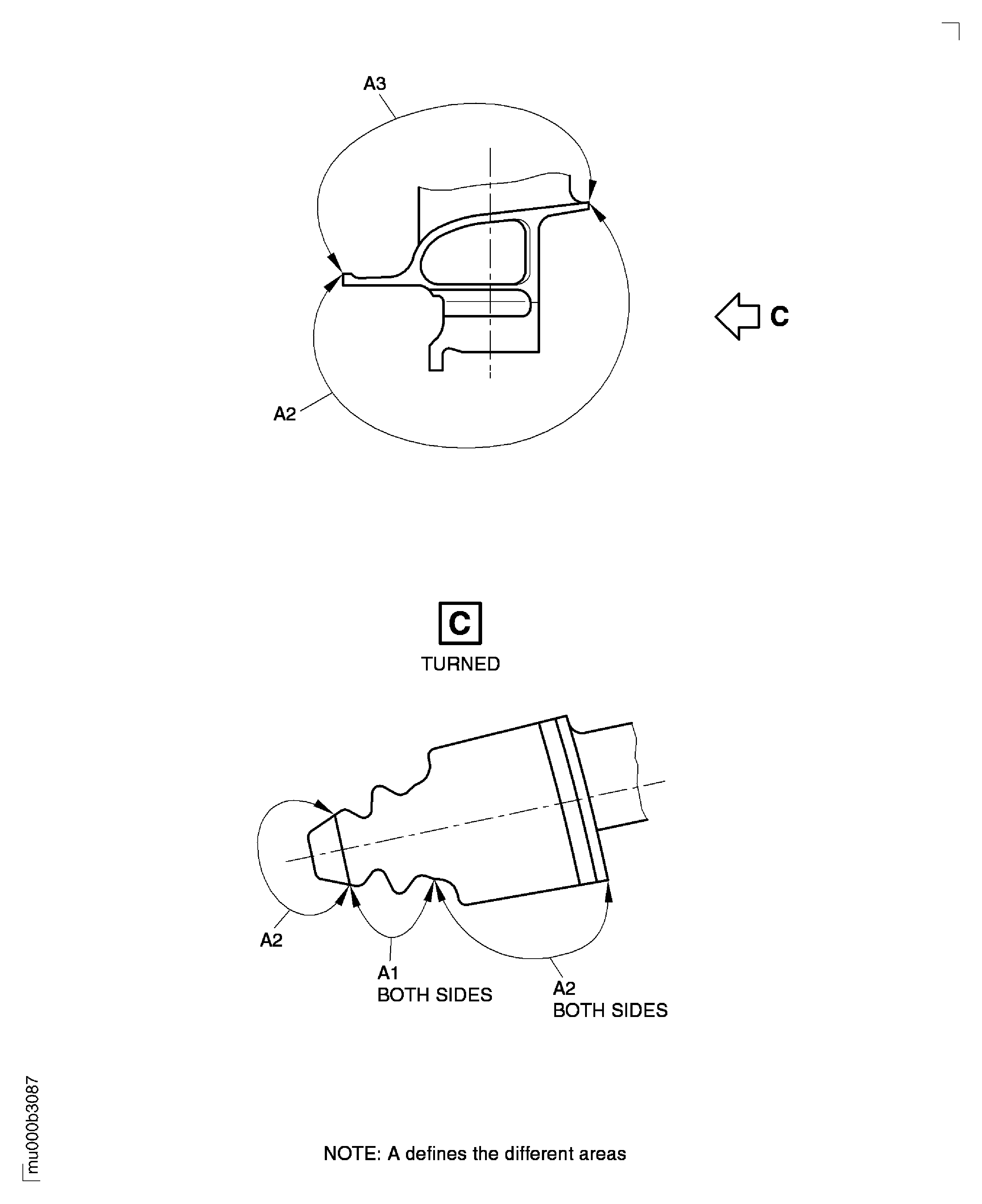

Refer to Figure.

Refer to the SPM TASK 70-38-13-380-501.

Use CoMat 05-029 CAST STEEL SHOT, S110 or CoMat 05-138 SHOT, CAST STEEL, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14 to an intensity of 6A.

Shotpeen blade root flanks plus corner radii to end faces.

Shotpeening is permitted in area A2.

Shotpeen area A1.

SUBTASK 72-50-32-380-107 Shotpeen the Surface A1 of the Stage 3 Turbine Blade

NOTE

Do the shotpeening after all weld and coating operations.If you cannot read any of these, make new marks.

Use the roll stamp method.

Refer to the SPM TASK 70-09-00-400-501.

Examine the markings of part number and serial number.

SUBTASK 72-50-32-220-467 Examine the Stage 3 Turbine Blade Markings

Refer to the SPM TASK 70-09-00-400-501.

Vibropeen VRS4209 and symbol "W" adjacent to the part number.

SUBTASK 72-50-32-350-103 Make a Mark to Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions