Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-300-069 LPT Stage 3 Blade - Weld Build Up Repair The Knife Edge Seals, Repair-069 (VRS4510)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

A ** following any repair referenced in this inspection indicates that the repair is not yet published in the current revision of this manual and the part must be rejected.

Contact IAE for additional information concerning FAA approved data.

NOTE

NOTE

NOTE

NOTE

If repair of pre-twist is also required, then do VRS4511 TASK 72-50-32-300-065 (REPAIR-065)** first, before start of this repair.

Do not repair turbine blades that have cracks extending into the outer shroud.

Before repair, write down the turbine blade part number and serial number.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| External grinding machine | LOCAL | External grinding machine | ||

| Tridimensional measuring unit | LOCAL | Tridimensional measuring unit | ||

| DELETED | 0AM53 | DELETED | ||

| IAE 3M14411 Welding fixture | 0AM53 | IAE 3M14411 | 1 | |

| IAE 3M14524 Grinding mounting block | 0AM53 | IAE 3M14524 | ||

| IAE 3M14467 Grinding fixture | 0AM53 | IAE 3M14467 | ||

| IAE 2M14195 Inspection mounting block | 0AM53 | IAE 2M14195 | ||

| IAE 3M14466 Welding mounting block | 0AM53 | IAE 3M14466 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-031 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-031 | ||

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 11851 | CoMat 05-138 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 |

Spares

NONESafety Requirements

NONEProcedure

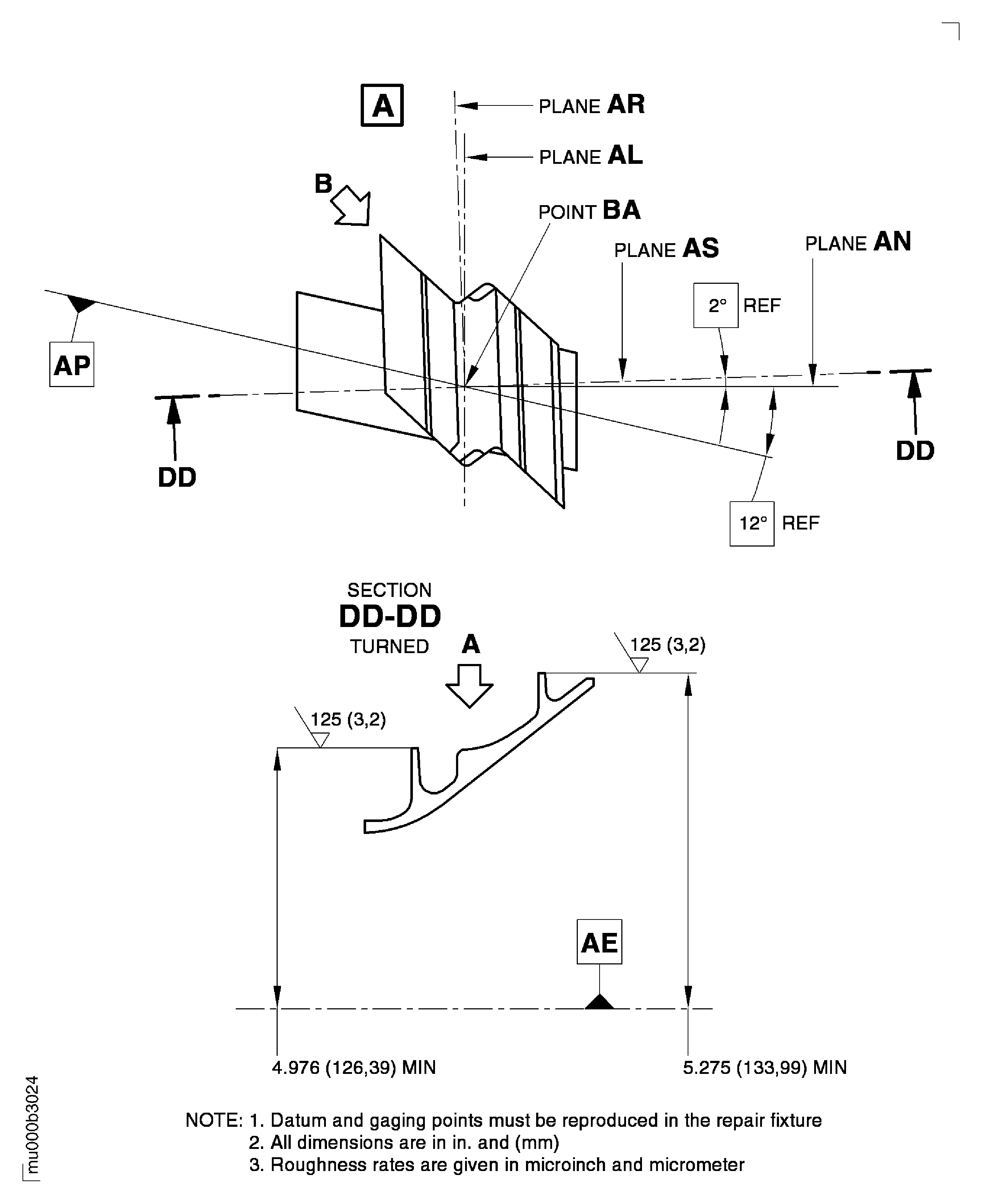

Refer to Figure.

Use IAE 3M14524 Grinding mounting block 1 off, IAE 3M14467 Grinding fixture 1 off, and External grinding machine.

Keep material removal to a minimum.

Grind the knife edge seals.

Remove coating from the knife edge weld area for a minimum distance of 0.040 in. (1.00 mm) all around.

Use CoMat 05-075 WATERPROOF SILICON CARBIDE or similar.

Remove the aluminide coating locally.

SUBTASK 72-50-32-324-057 Machine the Knife Edge Seals

Refer to Figure.

SUBTASK 72-50-32-220-439 Examine the Machined Areas

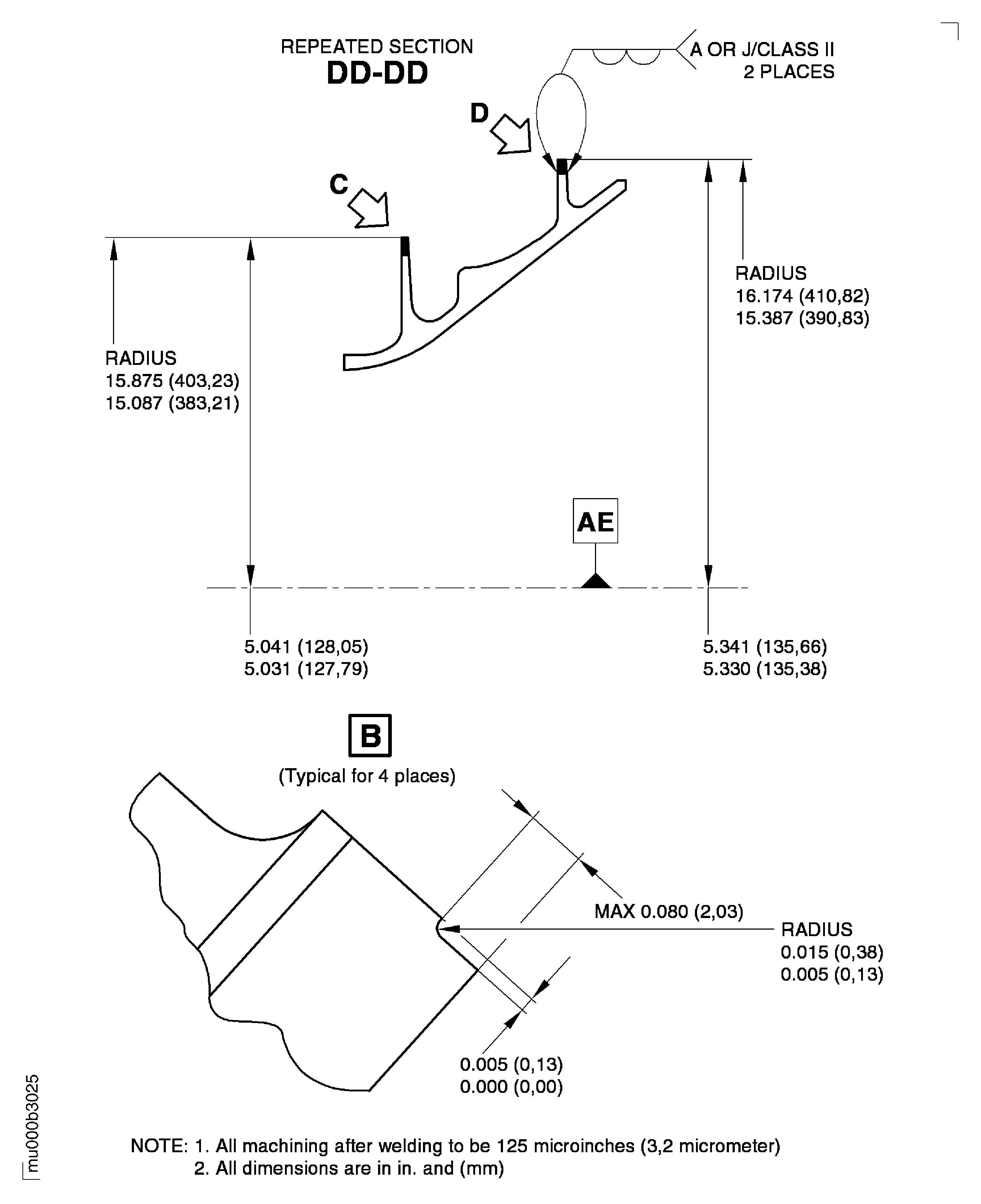

Use IAE 3M14466 Welding mounting block 1 off and IAE 3M14411 Welding fixture 1 off.

Make sure that there is sufficient material to do last machining.

Refer to the SPM TASK 70-31-13-310-501.

Decrease temperature of the turbine blade to reduce heat affected zone to a minimum.

Gas tungsten arc weld build-up seal fins.

SUBTASK 72-50-32-310-084 Weld Build-Up Repair the Knife Edge Seals

Do the stress-relief after all weld operations.

This SUBTASK is optional if aluminide coating will be completely removed and re-applied per VRS4300 TASK 72-50-32-300-049 (REPAIR-049) after weld repair.

Refer to the SPM TASK 70-37-10-370-501, Stress-Relief Cycle 5.

Stress-relieve the turbine blade.

SUBTASK 72-50-32-370-098 Heat Treatment after Weld Repair

NOTE

Refer to the SPM TASK 70-23-04-230-501.

Repair cracks in knife edge welds if they do not extend into the outer shroud.

Do the test for cracks.

SUBTASK 72-50-32-230-185 Examine the Welded Areas for Cracks

Refer to Figure and Fig 72-32-50-990-300-002.

Use IAE 3M14524 Grinding mounting block 1 off, IAE 3M14467 Grinding fixture 1 off, and External grinding machine.

Grind the welded areas.

SUBTASK 72-50-32-324-058 Machine the Welded Areas

Refer to the SPM TASK 70-23-05-230-501.

Use high sensitivity level.

Repair cracks in knife edge welds.

For limits refer to VRS4204 TASK 72-50-32-300-026 (REPAIR-026).

Do the test for cracks.

SUBTASK 72-50-32-230-186 Examine the Machined Areas for Cracks

Refer to the SPM TASK 70-38-13-380-501. Use CoMat 05-029 CAST STEEL SHOT, S110 or CoMat 05-030 CAST STEEL SHOT DELETED or CoMat 05-031 CAST STEEL SHOT DELETED or CoMat 05-138 SHOT, CAST STEEL, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14 to an intensity of 6A.

Shotpeen blade root flanks plus corner radii to end faces.

Shotpeening is permitted in area A2.

Shotpeen area A1.

SUBTASK 72-50-32-380-087 Shotpeen the Surface A1 of the Stage 3 Turbine Blade

If you cannot read any of these, make new marks.

Use the roll stamp method.

Refer to the SPM TASK 70-09-00-400-501.

Examine the markings of part number and serial number.

SUBTASK 72-50-32-220-440 Examine the Stage 3 Turbine Blade Markings

Refer to the SPM TASK 70-09-00-400-501.

Vibropeen VRS4510 adjacent to the part number.

SUBTASK 72-50-32-380-088 Make a Mark to Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions