Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-300-041 LPT Stage 4 Blade - Touch Up, Repair-041 (VRS4294)

General

Price and availability - none

An ** following any repair referenced in this repair indicates that the repair is not yet published in the current revision of this manual and the part must be rejected. Contact IAE for additional information concerning FAA approved data.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Shot peen system | LOCAL | Shot peen system | ||

| Gas furnace | LOCAL | Gas furnace | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Illuminated comparator magnifier | LOCAL | Illuminated comparator magnifier | ||

| Vapor blast cabinet | LOCAL | Vapor blast cabinet |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

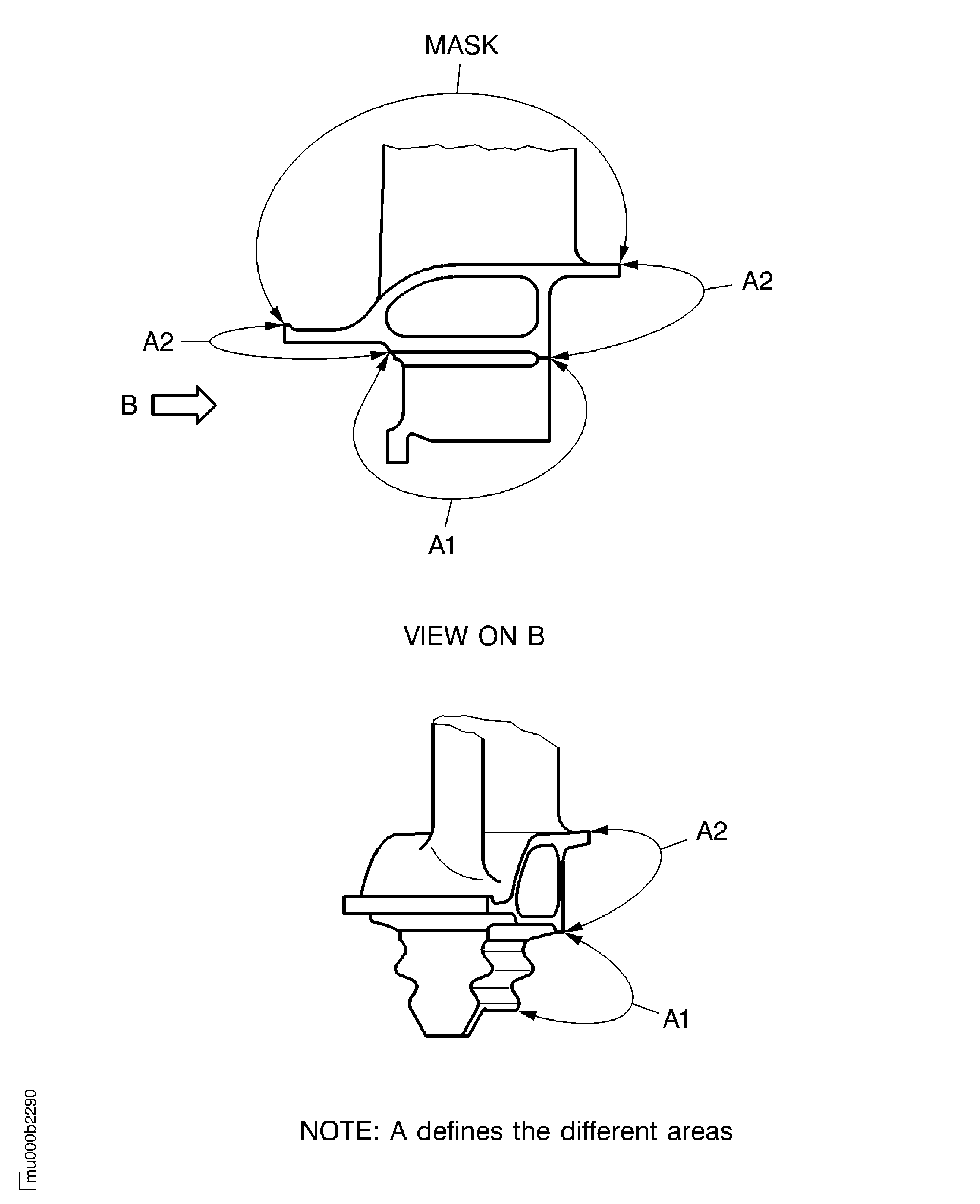

Refer to Figure.

NOTE

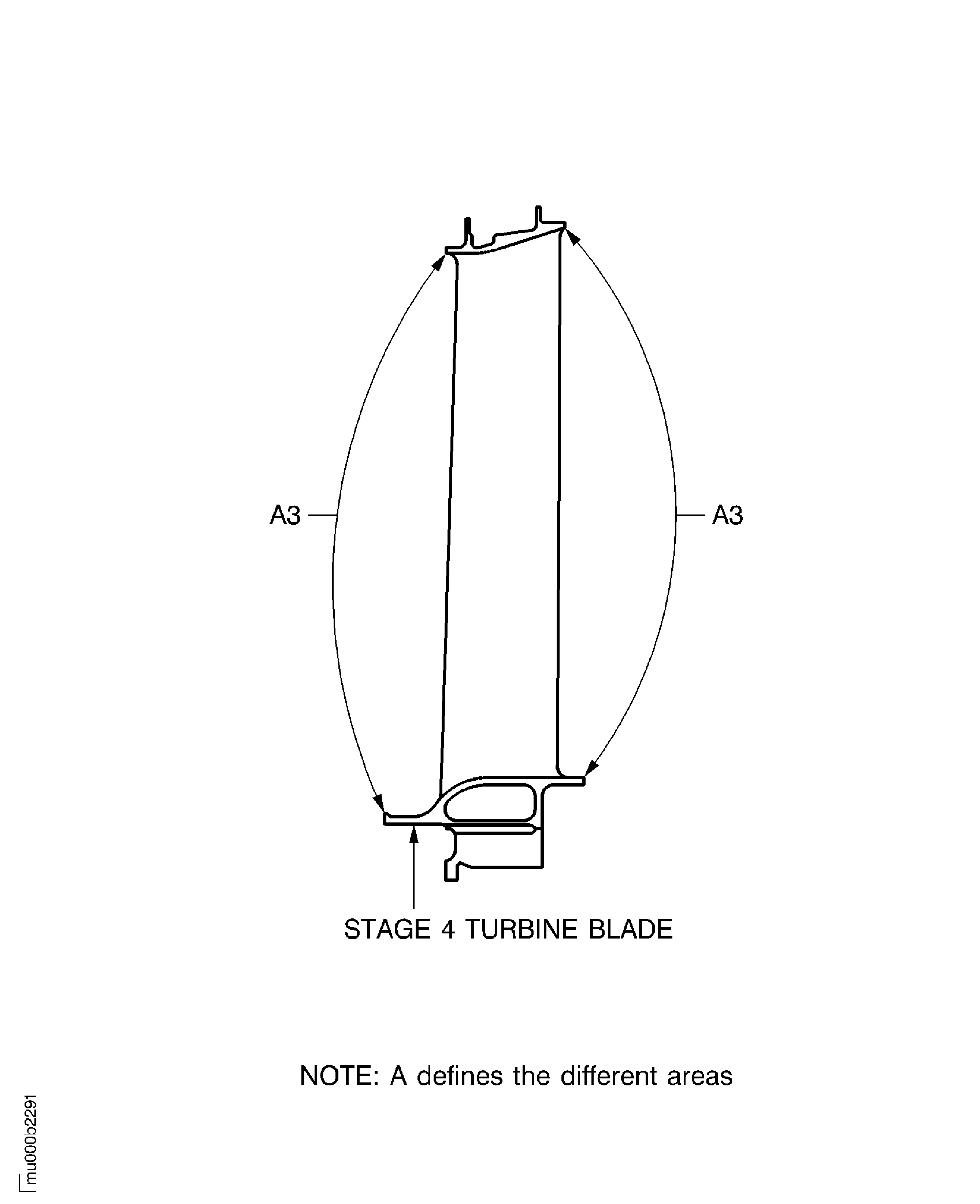

This repair is only required after blend repair in connection with VRS4292, refer to TASK 72-50-32-300-044 (REPAIR-044).If the coating is damaged, refer to VRS4295, TASK 72-50-32-300-042 (REPAIR-042) or VRS4296, TASK 72-50-32-300-043 (REPAIR-043).Touch up is only permitted in areas A3, refer to Figure.Record the part number, the heat code and the blade life figure, if these are marked on the blade root.Optional standard diffusion heat treatment of 1975 plus or minus 25 deg F (1080 plus or minus 14 deg C) for 4 hours can be used. This diffusion heat treatment gives slightly more corrosion protection. The blades have to be placed in an oven for 8 hours at 1652 deg F (900 deg C) for precipitation heat treatment before shot peening.Refer to the SPM TASK 70-38-14-380-501.

Do the touch-up coating.

SUBTASK 72-50-32-380-063 Touch Up the Coating of the Stage 4 Turbine Blade after the Blend Repair

Refer to the SPM TASK 70-38-14-380-501.

Heat treat for 2 hours at 1575 to 1625 deg F (857 to 885 deg C).

Use gas furnace.

Diffuse the coating of the stage 4 turbine blade by heat treatment.

SUBTASK 72-50-32-370-060 Do the Diffusion Heat Treatment of the Coated Stage 4 Turbine Blade

Refer to: Figure

Refer to the SPM TASK 70-38-04-300-503 and Figure.

Prepare the stage 4 turbine blade for shot peening.

Refer to the SPM TASK 70-38-04-300-503.

Use S110 shot, shot peen system and shot peen to an intensity of 6A.

NOTE

Shot peening in area A2 is acceptable but need not be complete.

Shot peen the area A1.

SUBTASK 72-50-32-380-064 Shot Peen the Stage 4 Turbine Blade in Area A1

If the marking is not readable, it must be renewed by the roll stamp method on the blade root.

Refer to the SPM TASK 70-09-00-400-501.

Part numbers, heat code.

If the marking is not readable, it must be renewed by the vibration marking pencil.

Refer to the SPM TASK 70-09-00-400-501.

Part life.

SUBTASK 72-50-32-220-184 Examine the Markings on the Blade Root

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions