Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-076 Turbine Exhaust Case (TEC) - Add Drain Holes On The Outer Case, Repair-076 (VRS3655)

General

Price and Availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Drill | LOCAL | Drill | ||

| Aluminum oxide rag wheel | LOCAL | Aluminum oxide rag wheel | ||

| Welding equipment | LOCAL | Welding equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-378 WELDING WIRE | LOCAL | CoMat 03-378 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Safety Requirements

NONEProcedure

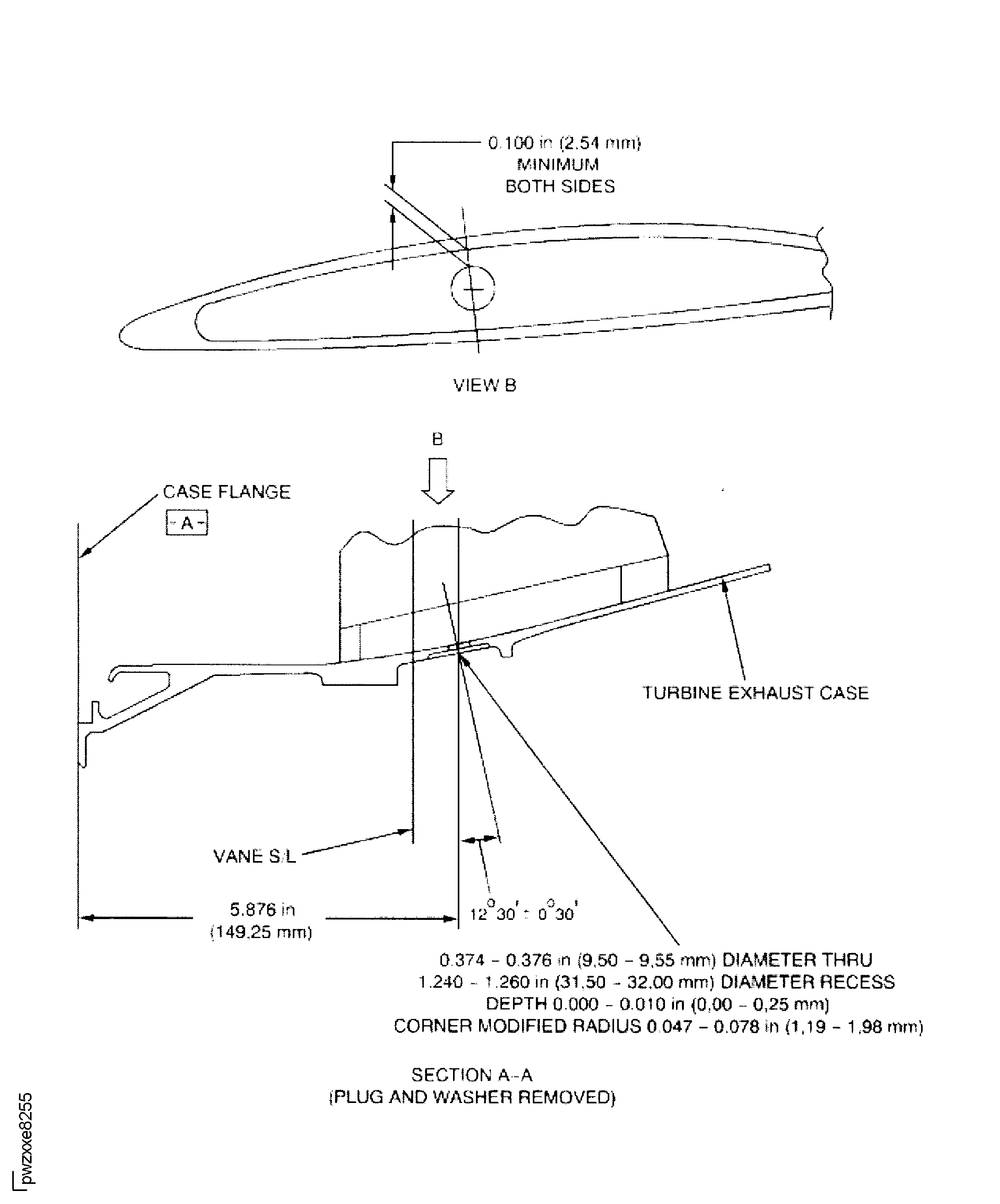

Remove steps or incorporate a 1.240-1.260 in (31.50-32.00 mm) diameter recess. See Figure.

Machine the outer case surface if necessary to remove steps.

SUBTASK 72-50-53-320-125 Install Drain Holes in the Outer Case at Struts No 4, 7, 8 and 10

Refer to the SPM TASK 70-11-26-300-503. Areas must be clean and dry from drained fluid before welding.

Clean the areas to be welded.

SUBTASK 72-50-53-110-130 Clean the Areas to be Welded

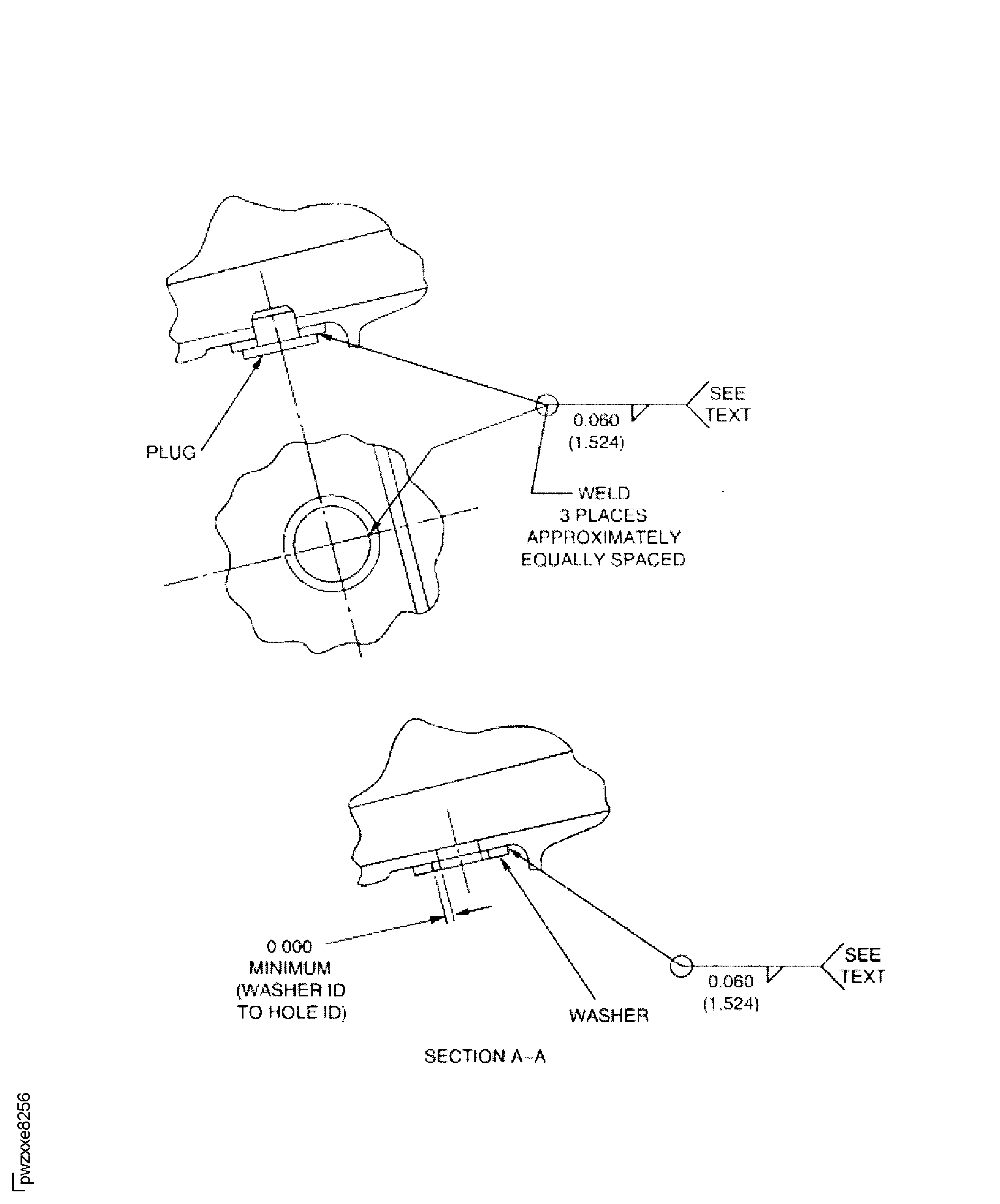

Refer to the SPM TASK 70-31-13-310-501. Use the manual gas tungsten arc method and CoMat 03-378 WELDING WIRE. See Figure.

Weld the washers to the outer case.

Refer to the SPM TASK 70-31-13-310-501. Use the manual gas tungsten arc method and CoMat 03-378 WELDING WIRE. Refer to Figure for location and dimensions.

Fillet weld the plugs to the washers.

SUBTASK 72-50-53-310-079 Weld the Washers to the Outer Case

Refer to the SPM TASK 70-37-12-370-501, Cycle 6.

Locally stress-relieve the repaired areas.

SUBTASK 72-50-53-370-086 Locally Stress-Relieve the Repair Areas

Refer to the SPM TASK 70-23-05-230-501. Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY).

No cracks are permitted.

Do a fluorescent penetrant inspection of the repaired areas.

SUBTASK 72-50-53-230-113 Do a Fluorescent Penetrant Inspection of the Repaired Areas

Refer to the SPM TASK 70-11-26-300-503.

Areas must be clean and dry from drained fluid before welding.

Clean the areas to be welded.

SUBTASK 72-50-53-110-131 Clean the Areas to be Welded

Refer to the SPM TASK 70-31-13-310-501. Use the manual gas tungsten arc method and CoMat 03-378 WELDING WIRE. See Figure.

Plug weld the holes.

SUBTASK 72-50-53-310-080 Plug Weld the Holes

Refer to the SPM TASK 70-37-12-370-501, Cycle 6.

Locally stress-relieve the repaired areas.

SUBTASK 72-50-53-370-087 Locally Stress-Relieve the Repaired Areas

Refer to the SPM TASK 70-23-05-230-501. Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY).

No cracks are permitted.

Do a fluorescent penetrant inspection of the repaired areas.

SUBTASK 72-50-53-230-114 Do a Fluorescent Penetrant Inspection of the Repaired Areas

Make a line through the existing "-01", then mark "-001" on the turbine exhaust case adjacent to the part number. Refer to the SPM TASK 70-09-00-400-501. Use the vibration peen method.

NOTE

Do not mark the part again if the part number has been previously identified to "-001".

Re-identify the part number.

Refer to the SPM TASK 70-09-00-400-501. Use the vibration peen method.

NOTE

If the VRS repair number is marked on the part, do not mark the part again.

Mark the repair number VRS3655 on the turbine exhaust case adjacent to the part number.

SUBTASK 72-50-53-320-128 Identify the Repair

Refer to the SPM TASK 70-11-26-300-503.

Areas must be clean and dry from drained fluid before welding.

Clean the areas to be welded.

SUBTASK 72-50-53-110-132 Clean the Areas to be Welded

You can use the old plugs again if they have no damage.

Refer to the SPM TASK 70-31-13-310-501. Use the manual gas tungsten arc method and CoMat 03-378 WELDING WIRE. Refer to Figure.

Fillet weld the plugs to the washers.

SUBTASK 72-50-53-310-081 Fillet Weld the Plugs to the Washers

Refer to the SPM TASK 70-23-05-230-501. Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY).

No cracks are permitted.

Do a fluorescent penetrant inspection of the repaired areas.

SUBTASK 72-50-53-230-115 Do a Fluorescent Penetrant Inspection of the Repaired Areas

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4