Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-00-430-001 External Gearbox Module - Assemble The Module, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

Transportation covers/blanks must be removed immediately before the installation of the components.

After assembly apply CoMat 07-012 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to TASK 70-38-06-380-501 .

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10011 Handling fixture | 0AM53 | IAE 1F10011 | 2 | |

| IAE 1F10021 Storage stand | 0AM53 | IAE 1F10021 | 1 | |

| IAE 1F10023 Gearbox adapter | 0AM53 | IAE 1F10023 | 1 | |

| IAE 5F10048 Gearbox handling adapter | 0AM53 | IAE 5F10048 | 1 | |

| IAE 1F10154 Build stand | 0AM53 | IAE 1F10154 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-012 AIR DRYING ENAMEL | 0AM53 | CoMat 07-012 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Safety Requirements

NONEProcedure

Refer to Figure.

WARNING

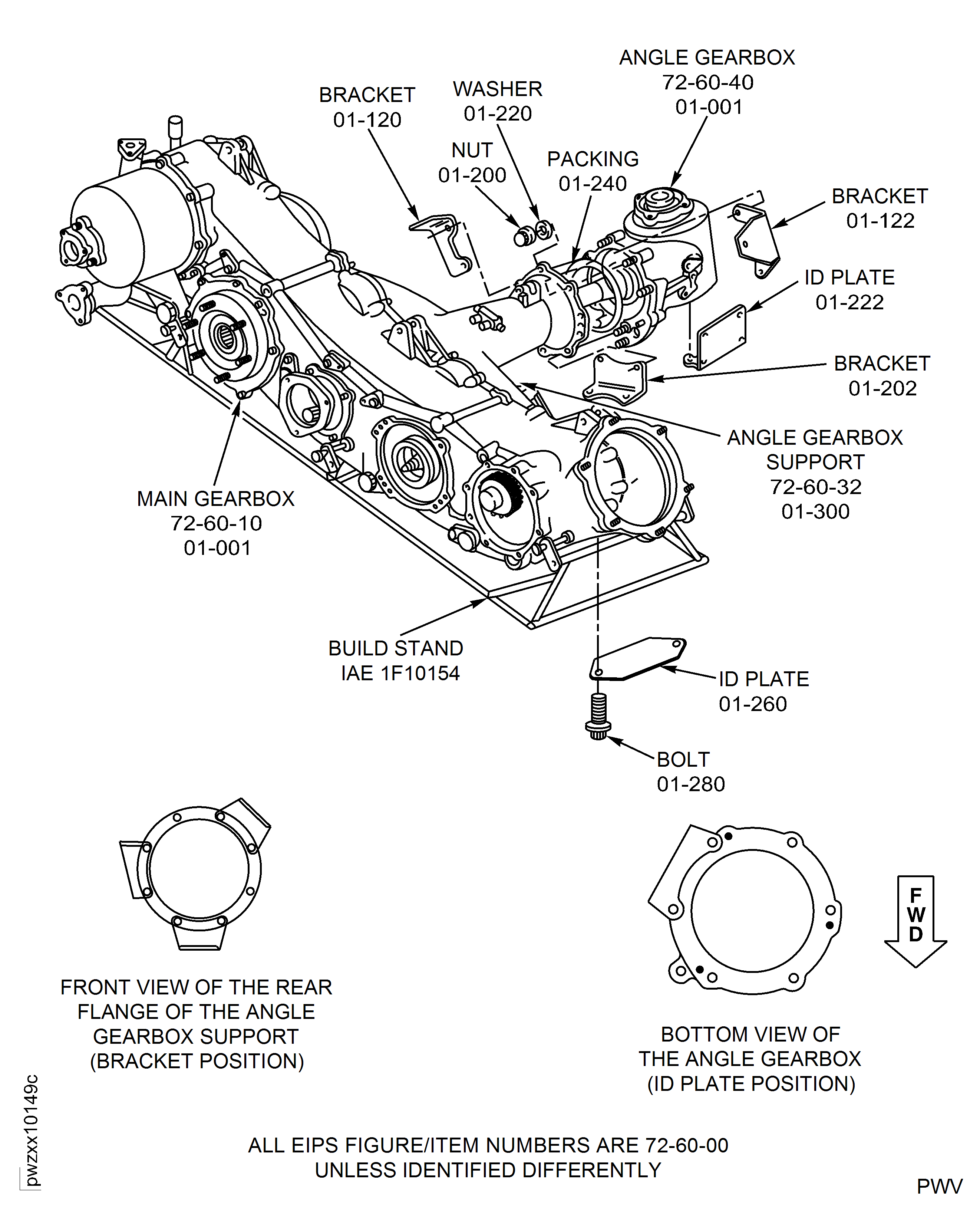

MAKE SURE THAT IAE 1F10154 BUILD STAND 1 OFF, WITH THE MAIN GEARBOX INSTALLED, IS SAFETIED TO THE WORK BENCH. THE WEIGHT OF THE ANGLE GEARBOX CAN TURN OVER THE BUILD STAND.Install External Gearbox Module (72-60-00, 01-240) packing 1 off in to the groove on the flange of the angle gearbox support.

Apply CoMat 10-077 APPROVED ENGINE OILS on the flange of the angle gearbox support.

SUBTASK 72-60-00-430-051 Install the Angle Gearbox to the Main Gearbox

Refer to Figure.

Use two bolts ENGINE-EXTERNAL GEARBOX MODULE (72-60-00, 01-280) to secure the identification plate ENGINE-EXTERNAL GEARBOX MODULE (72-60-00, 01-260) to the bottom of the gearbox casing.

SUBTASK 72-60-00-430-062 Install Identification Plate

Refer to Figure.

Remove two fasteners ENGINE-ANGLE GEARBOX ASSEMBLY (72-60-40, 01-055) and washers that secure the radial gear support ENGINE-ANGLE GEARBOX DRIVING BEVEL GEAR ASSEMBLY (72-60-42, 01-230) to the bottom of the angle gearbox.

Install the module identification plate External Gearbox Module (72-60-00, 01-222) to the bottom of the angle gearbox using the removed fasteners and washers.

SUBTASK 72-60-00-430-063 Install Module Identification Plate

Refer to Figure.

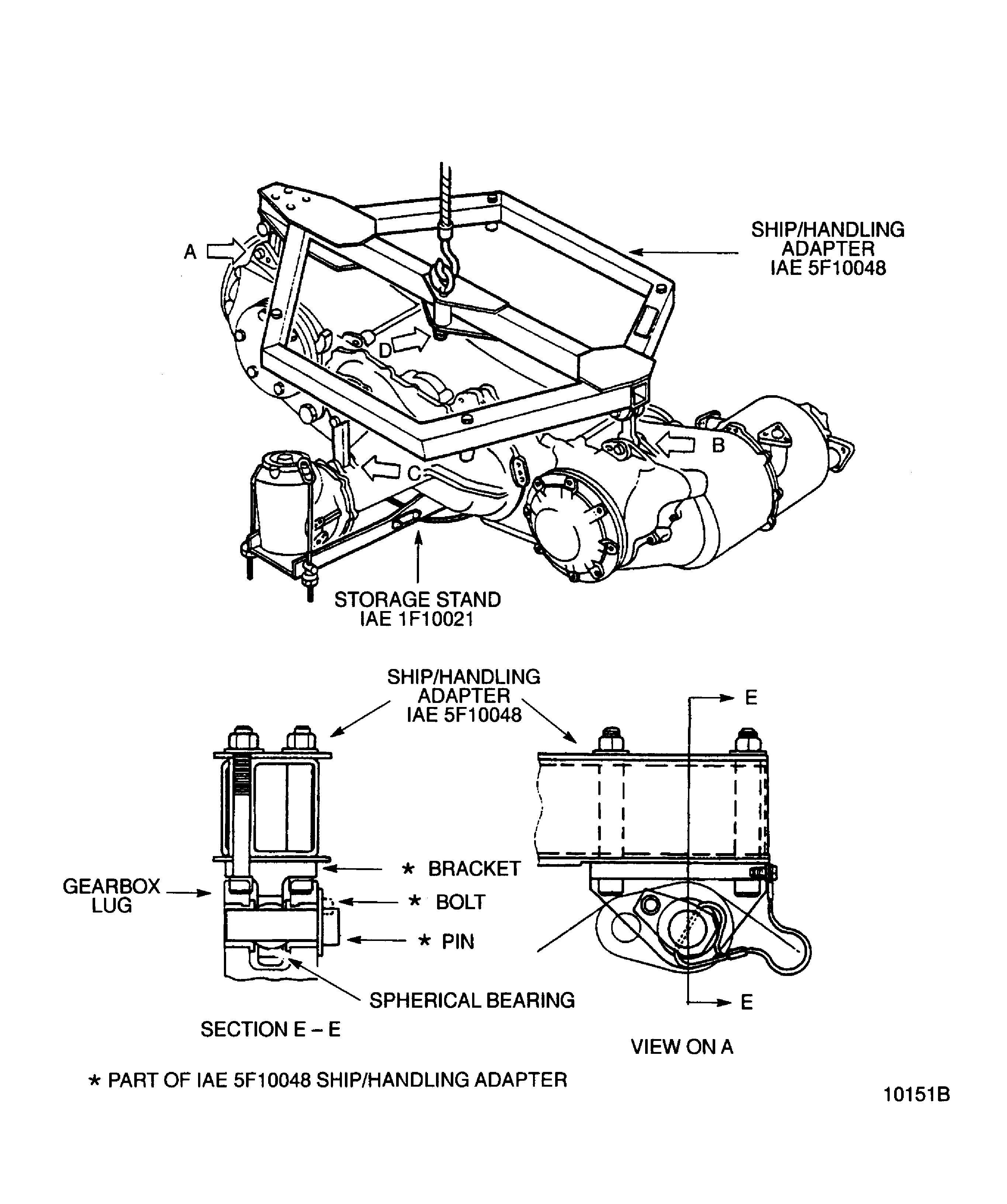

Install the IAE 5F10048 Gearbox handling adapter 1 off on the external gearbox.

Release the six knobs of IAE 1F10154 Build stand build stand 1 off and lift the external gearbox from the supports of the build stand.

SUBTASK 72-60-00-430-060 Remove the External Gearbox from the Build Stand

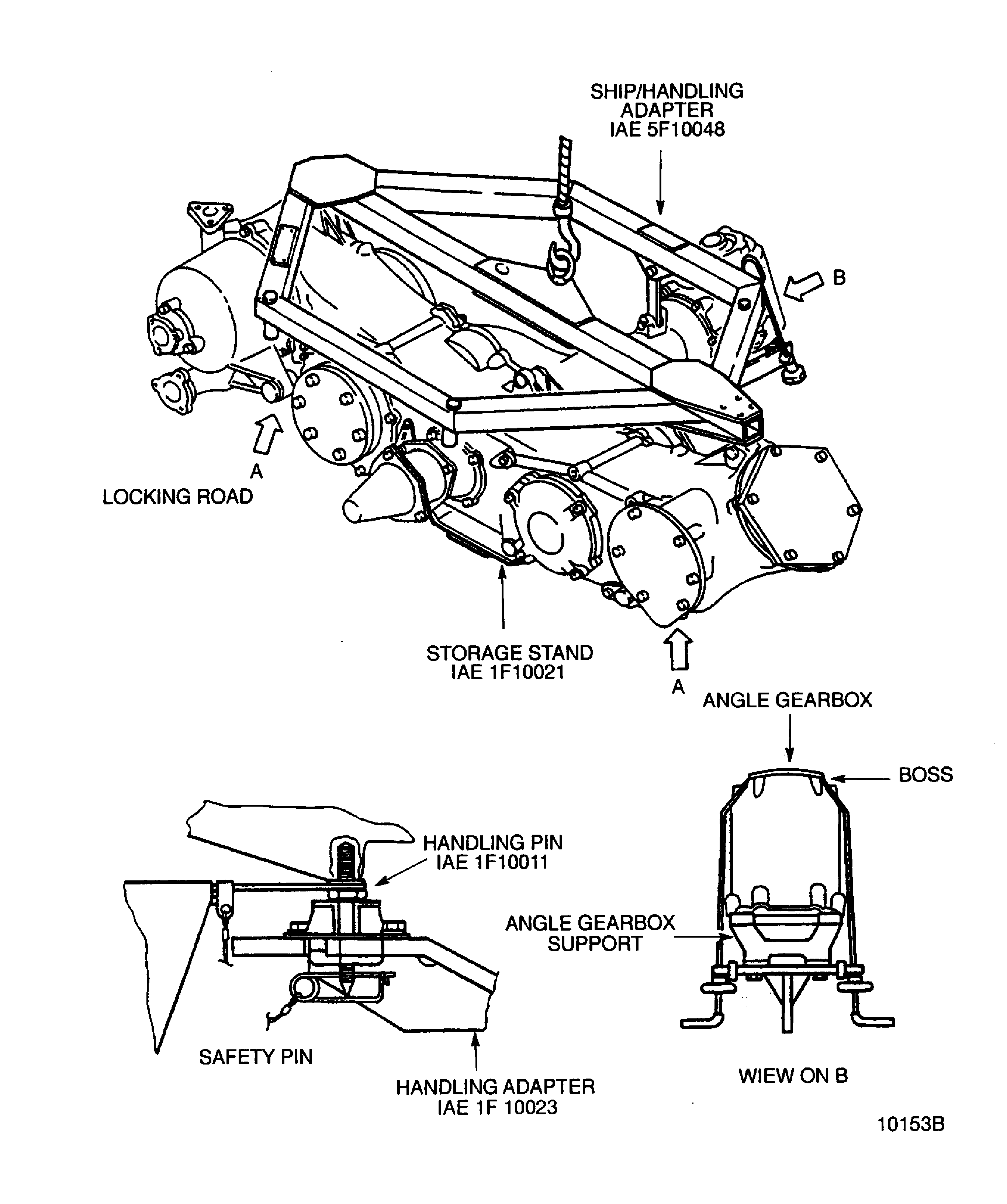

Refer to Figure.

Move the external gearbox on IAE 1F10021 Storage stand 1 off.

Install the IAE 1F10011 Handling fixture 2 off on the ground handling bosses on the bottom of the gearbox.

Align the two handling pins with the holes of IAE 1F10023 Gearbox adapter 1 off on the storage stand. Align the angle gearbox with the angle gearbox support of the gearbox adapter.

Put again the shipping adapter into the shipping container.

Remove the IAE 5F10048 Gearbox handling adapter 1 off from the external gearbox, refer to Figure.

SUBTASK 72-60-00-430-061 Install the External Gearbox on the Storage Stand

Refer to Figure.

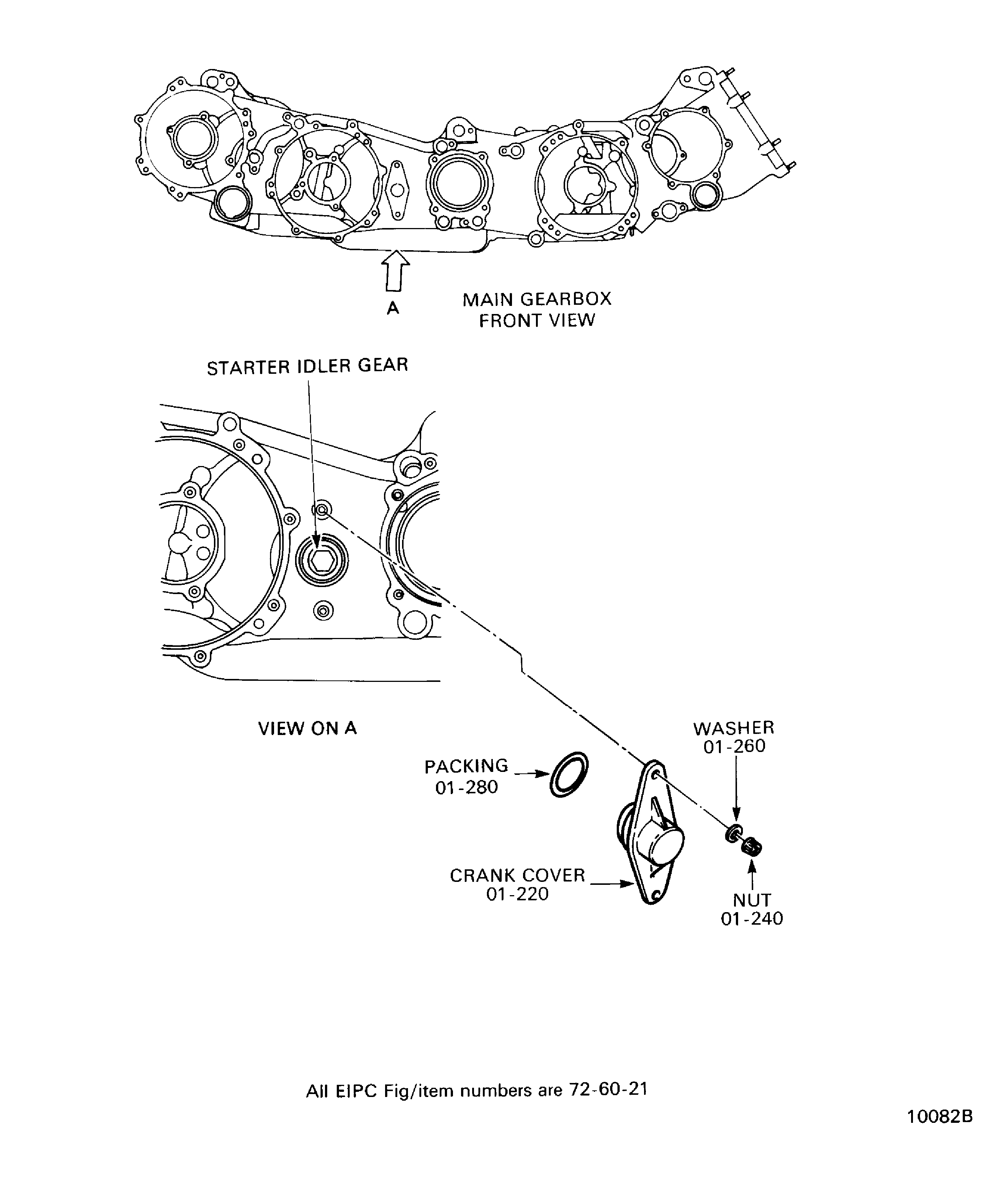

Install ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-280) packing 1 off on the flange of the crack cover.

Lubricate with CoMat 10-077 APPROVED ENGINE OILS the crack cover seat on the gearbox casing.

SUBTASK 72-60-00-430-057 Install the Crank Cover

Figure: Install the angle gearbox

Install the angle gearbox

Figure: Install the oil tank

Install the oil tank

Figure: Install the oil scavenge filter assembly

Install the oil scavenge filter assembly

Figure: Remove and install the cover crank

Remove and install the cover crank

Figure: Install the oil scavenge pump assembly

Install the oil scavenge pump assembly

Figure: Install the oil pressure pump assembly

Install the oil pressure pump assembly

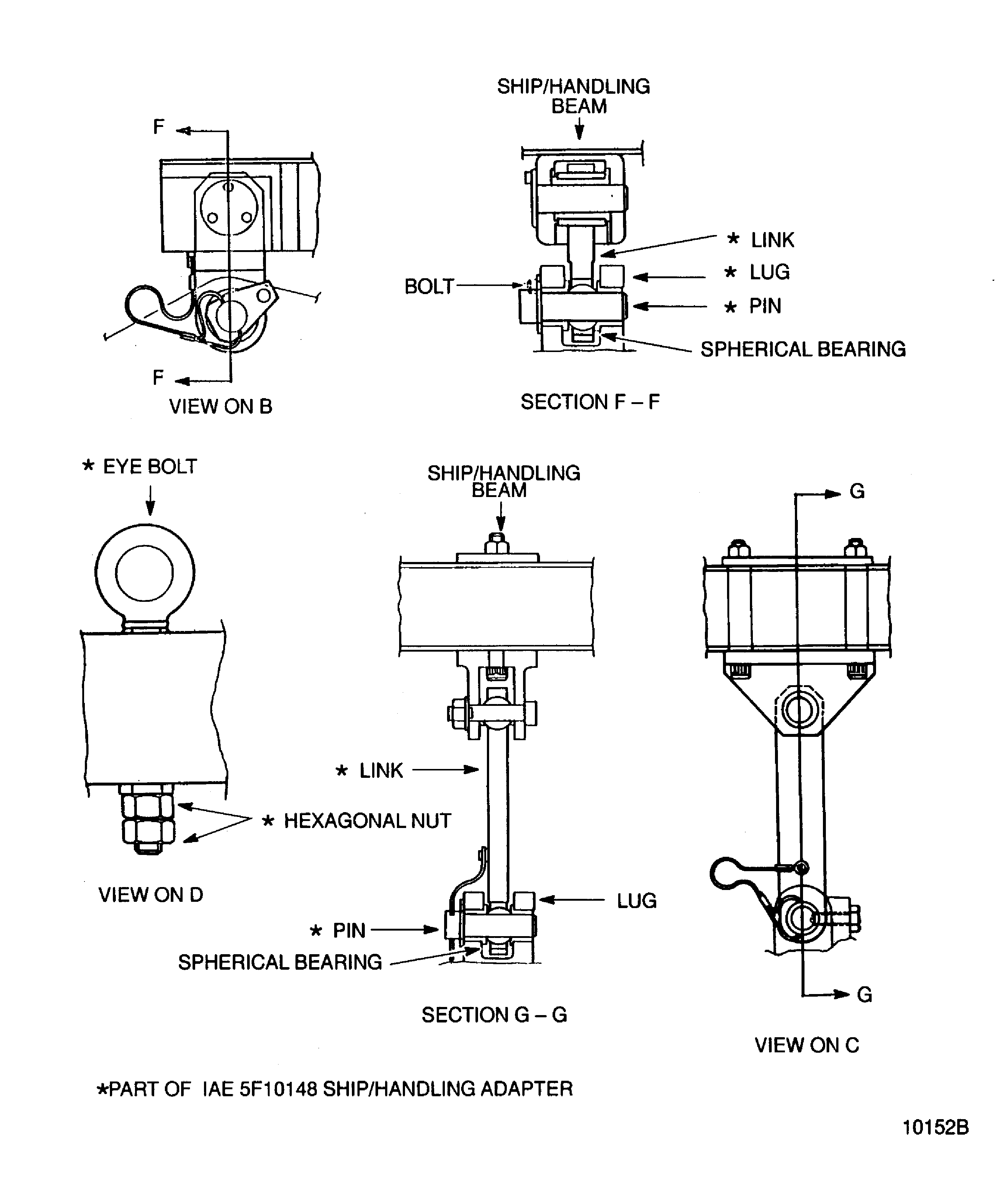

Figure: Install/Remove the shipping adapter on/from the external gearbox

Install/Remove the shipping adapter on/from the external gearbox

Figure: Install/Remove the shipping adapter on/from the external gearbox

Install/Remove the shipping adapter on/from the external gearbox

Figure: Install the external gearbox to the storage stand

Install the external gearbox to the storage stand