Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-22-41-300-007ACAC Inlet Duct - Replace The Bush, Repair-007 (VRS1651)

General

Price and availability - Refer to IAE.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Fluorescent penetrant inspection equipment | 0AM53 | Fluorescent penetrant inspection equipment | ||

| Heat Protective Gloves | LOCAL | Protective Gloves, Heat | ||

| Milling machine | LOCAL | Milling machine | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Vibroengraving equipment | LOCAL | Vibroengraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-026 LIQUID NITROGEN | LOCAL | CoMat 03-026 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

Secure in position for safe machining.

Use a boring machine.

Install the ACAC Inlet duct onto the machine.

Machine to remove all the damage and wear. Only remove the minimum amount of material.

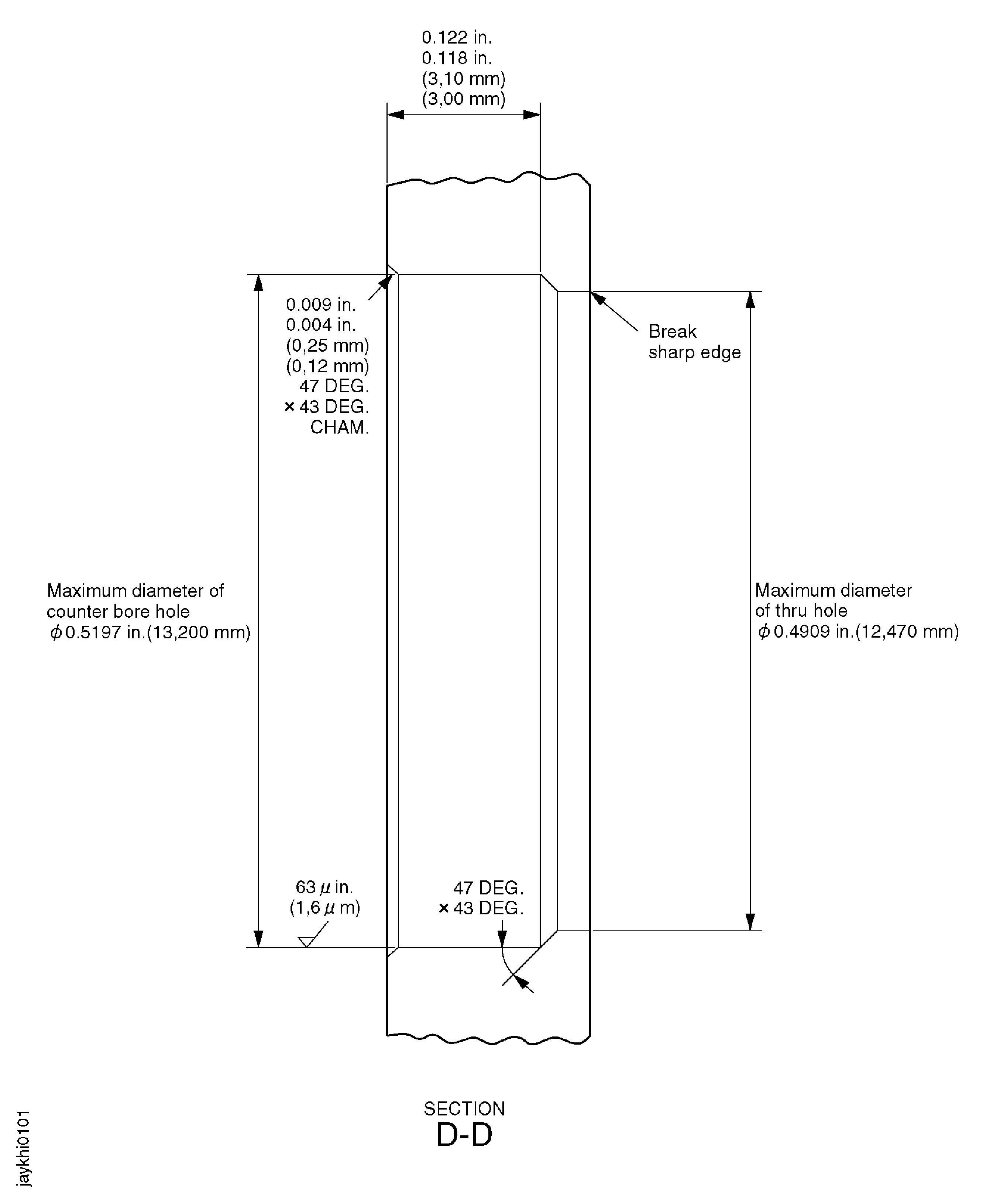

Maximum diameter of the thru and counter bore are 0.4909 in. (12.470 mm) and 0.5197 in. (13.200 mm).

Use suitable boring machine, with standard workshop equipment.

NOTE

A bore that does not clean up to give the necessary finish and correct interference limit on the diameter, when you install the bush, must be machined to the next oversize, refer to Figure.

Machine the bore oversize.

Use standard workshop equipment.

Remove the sharp edges.

SUBTASK 75-22-41-320-001 Machine the Bore Oversize

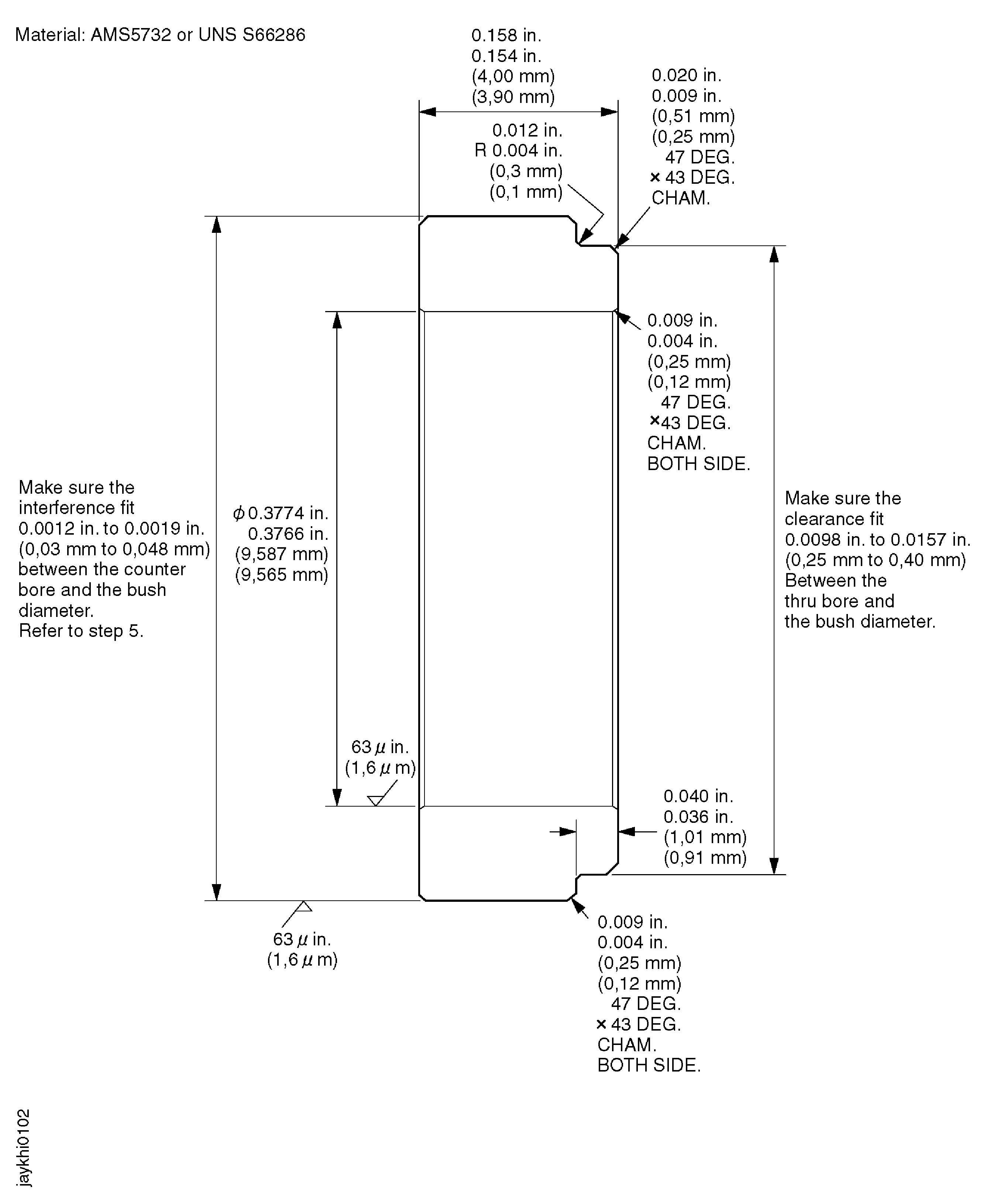

Make sure that all dimensions of manufactured bush are given in Figure are met.

Remove all sharp edges.

Make the bush.

Resultant interference fit between machined hole and bush diameter to be 0.00012 to 0.00189 in. (0.003 to 0.048 mm).

Refer to Figure.

Measure the dimensions of the bush.

SUBTASK 75-22-41-320-002 Make the Repair Part

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Crack test of the bush.

Do Step again.

Cracked

SUBTASK 75-22-41-230-001 Examine the Repair Part

Refer to SPM TASK 70-11-26-300-503.

Clean the duct.

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Do Step again. Machine bore to the next oversize.

Cracked

Crack test on the bush location bore.

SUBTASK 75-22-41-220-001 Examine the Machined Area

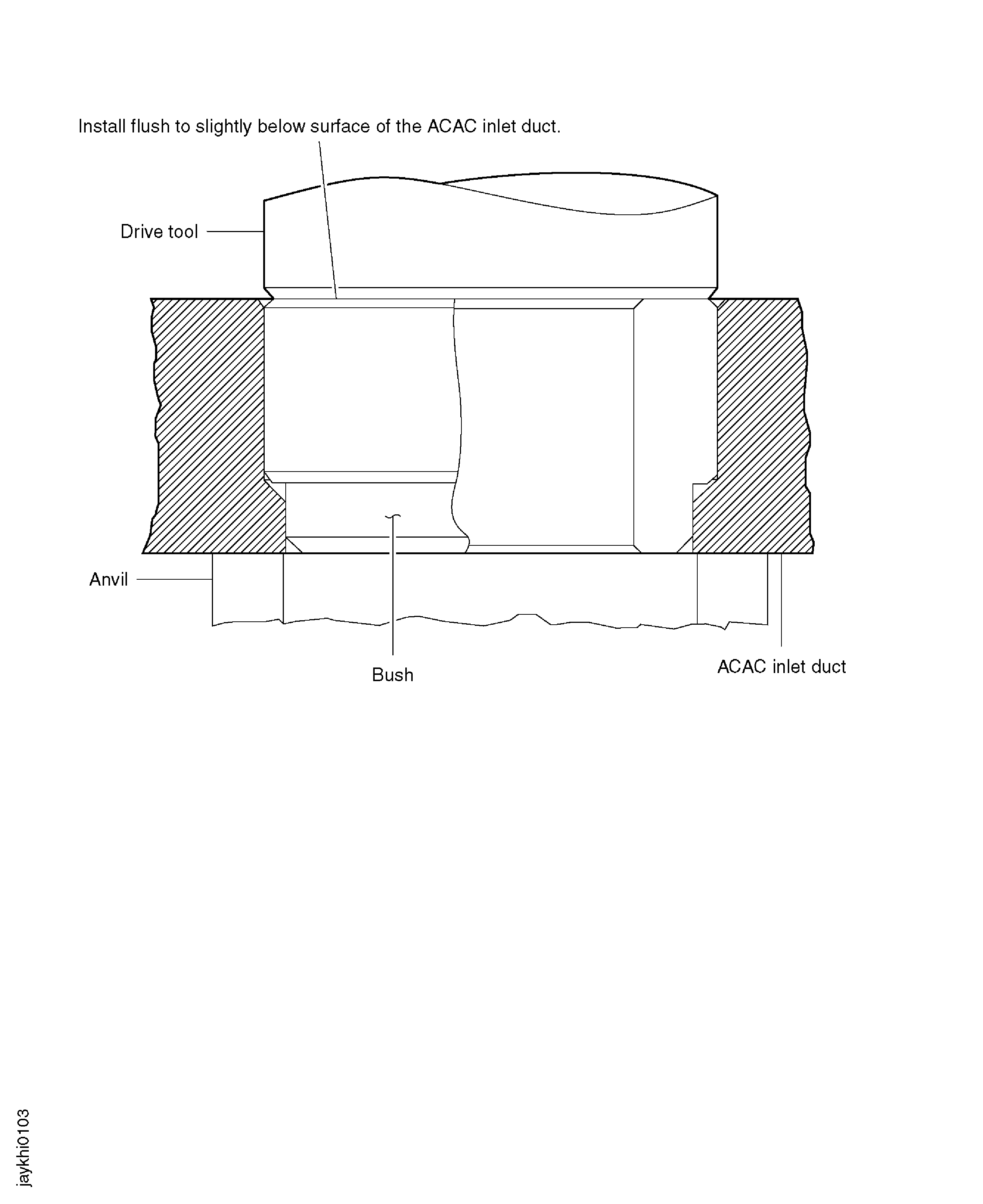

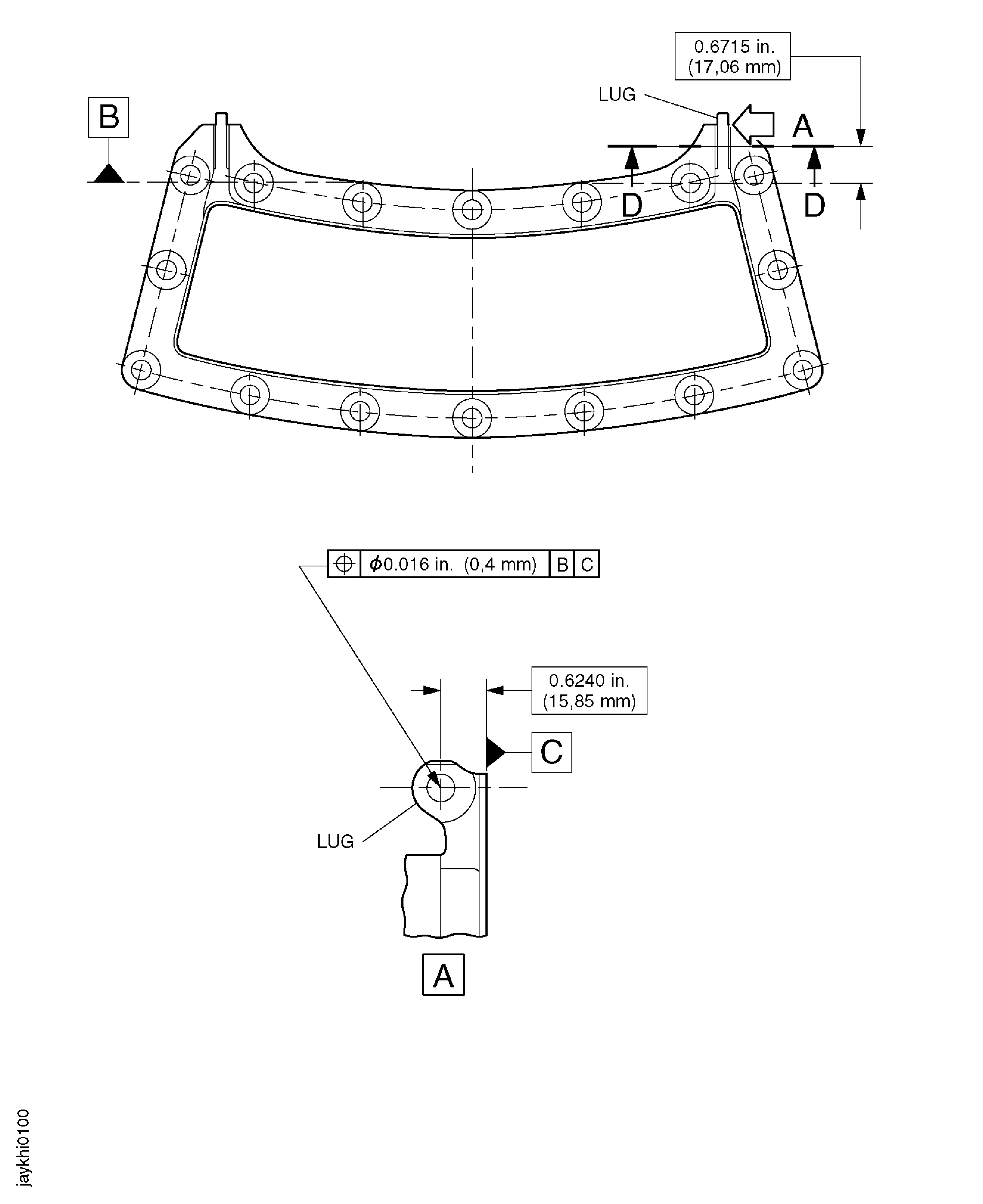

Refer to Figure.

Freeze and install oversize bush in the ACAC inlet duct.

SUBTASK 75-22-41-350-001 Install Standard or Oversize Bush

Make sure the bush is in position and flush to slightly under flush to the lug surface of the ACAC inlet duct.

If necessary, do these procedures again.

Visually examine the bush for location.

SUBTASK 75-22-41-220-003 Examine the Bush for Location

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS1651 TASK 75-22-41-300-007 adjacent to the assembly number.

SUBTASK 75-22-41-350-002 Identify the Repair

Figure: Air Cooled Air Cooler (ACAC) Inlet Duct

Air Cooled Air Cooler (ACAC) Inlet Duct

Figure: Detail of modified hole

Detail of modified hole

Figure: Detail of the Repair part

Detail of the Repair part

Figure: Detail of Installation Hole and Tools

Detail of Installation Hole and Tools