Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-015 LPT ACC Support Assemblies - Weld Repair, Repair-015 (VRS4024)

Effectivity

FIG/ITEM | PART NO. |

02-490 | 3A1749 |

02-720 | 3A1752 |

03-490 | 3A1762 |

03-490 | 3A2320 |

03-720 | 3A1759 |

04-010 | 3A1745 |

04-410 | 3A1755 |

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Gas furnace | LOCAL | Gas furnace | ||

| Hand Held Pneumatic Grinder | LOCAL | Hand Held Pneumatic Grinder |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 |

Spares

NONESafety Requirements

NONEProcedure

SUBTASK 75-24-49-310-051 Prepare the Support Assembly for the Welding Procedure

NOTE

Before trying repair, remove inserts refer to VRS4052 (Repair-017) TASK 75-24-49-300-017 and clip nuts, refer to VRS4025 (Repair-016) TASK 75-24-49-300-016.Before trying a repair to half loop clamp or in a area adjacent to a half loop clamp, remove half loop clamp and clip nuts, refer to VRS4025 (Repair-016) TASK 75-24-49-300-016.After repair, assemble half loop clamp and clip nuts, refer to VRS4025 (Repair-016) TASK 75-24-49-300-016 and put in new inserts where applicable, refer to VRS4052 (Repair-017) TASK 75-24-49-300-017.It is permitted to vee-groove cracks before weld repair.

Vee-groove the cracks.

SUBTASK 75-24-49-322-051 Remove the Cracks

Refer to SPM TASK 70-31-13-310-501.

Clean the areas around the cracks on both sides of the support assembly if possible.

SUBTASK 75-24-49-110-060 Clean the Support Assembly

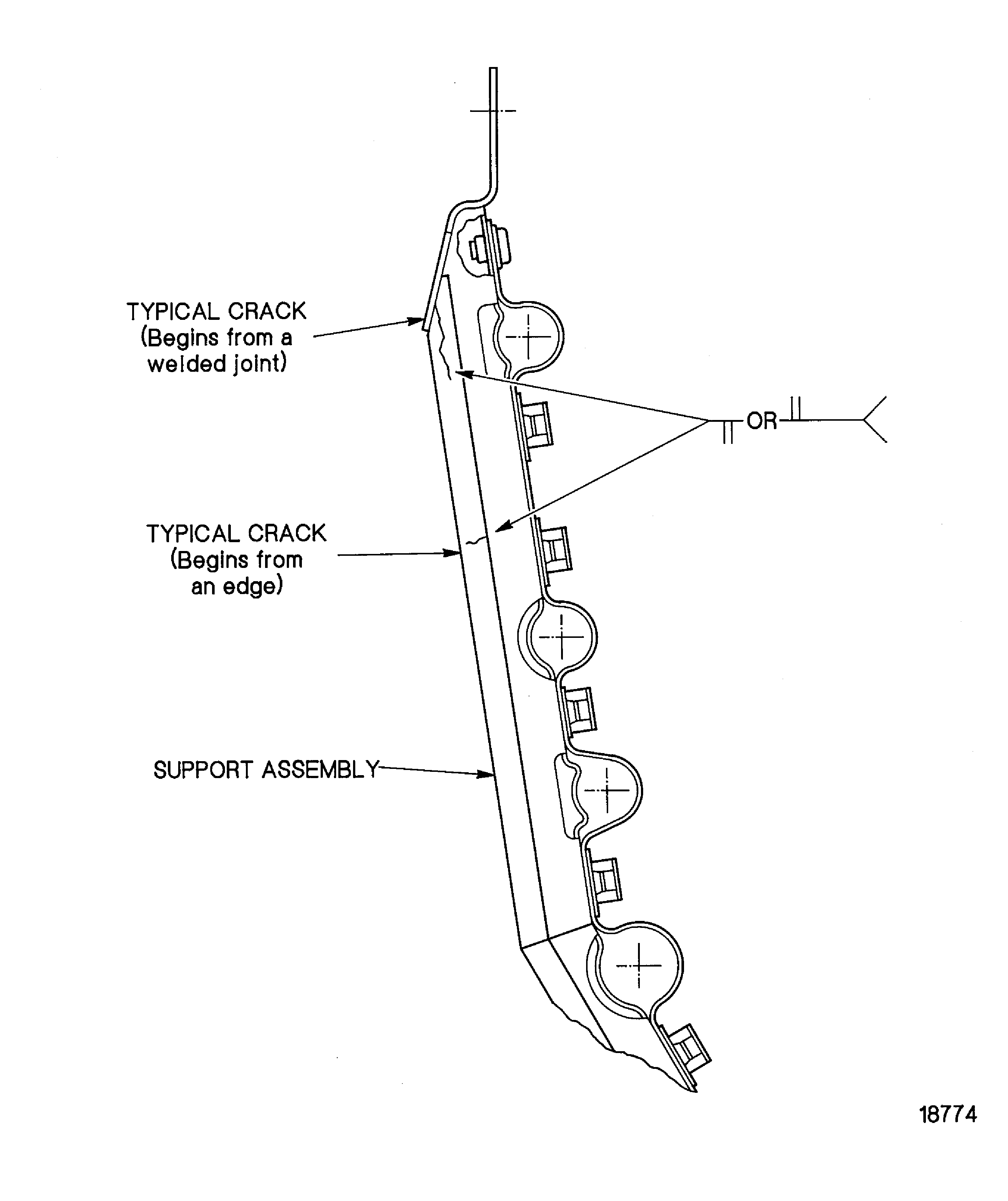

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Tungsten inert gas weld cracks on the two sides.

SUBTASK 75-24-49-310-052 Weld Repair the Support Assembly

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-066 Examine the Welded Areas for Cracks

No raised material is permitted on functional or connecting faces.

If necessary dress the welds on functional or connecting faces until they make a continuous surface with the adjacent areas.

SUBTASK 75-24-49-320-051 Dress the Welded Areas

CAUTION

DO NOT OVERHEAT THE AREAS WHICH ARE TO BE DRESSED.Use Gas furnace for eight hours at 1472 deg F (800 deg C).

Decrease the temperature in the air.

Heat treat the support assemblies and the half loop clamps.

SUBTASK 75-24-49-370-051 Heat Treat after Weld Repair

Refer to SPM TASK 70-23-01-230-501 or to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-067 Do the Post Repair Inspection

Figure: Weld Repair of the Support Assemblies

Weld Repair of the Support Assemblies