Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-22-41-460-401 Oil Scavenge Pump - Related Parts - Assemble The Oil Scavenge Pump, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Refer to the V2500 Illustrated Tool and Equipment Manual (ITEM), Pub.ref. ITE-V2500-1IA, for the illustrations of the special tools given in this procedure.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts. Refer to SPM TASK 70-64-00-640-501.

To identify, lubricate and install sealing rings, refer to SPM TASK 70-64-00-640-501.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

After assembly apply CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM chromate conversion coating to any damaged surfaces protection, joint flanges and attach parts. Refer to SPM TASK 70-38-02-300-503.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10308 Base | 0AM53 | IAE 1F10308 | 1 | |

| IAE 1F10304 Clamping fixture | 0AM53 | IAE 1F10304 | 1 | |

| IAE 1F10306 Support stud (long) | 0AM53 | IAE 1F10306 | 3 | |

| IAE 1F10305 Support stud (short) | 0AM53 | IAE 1F10305 | 3 | |

| IAE 1F10307 Loading fixture | 0AM53 | IAE 1F10307 | 1 | |

| IAE 1F10309 Installation drift | 0AM53 | IAE 1F10309 | 1 | |

| IAE 1F10312 Adapter wrench | 0AM53 | IAE 1F10312 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | LOCAL | CoMat 02-119 | ||

| CoMat 01-275 CHROMATE CONVERSION COATING FOR ALUMINIUM | LOCAL | CoMat 01-275 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

MAKE SURE THAT THE COVERS ARE INSTALLED IN SAME LOCATION FROM WHICH THEY WERE REMOVED.

CAUTION

IF A GEAR REQUIRES REPLACEMENT ALSO, REPLACE ITS MATING GEAR WITH THE SAME CLASS OF PART NUMBER.

CAUTION

CHECK THE CIRCUMFERENTIAL CLEARANCE OF THE GEARS ASSEMBLY. CHECK THAT THE CLEARANCE BETWEEN THE SPACERS AND RELEVANT SEAT IS WITHIN THE LIMITS SPECIFIED IN THE FITS AND CLEARANCES.

CAUTION

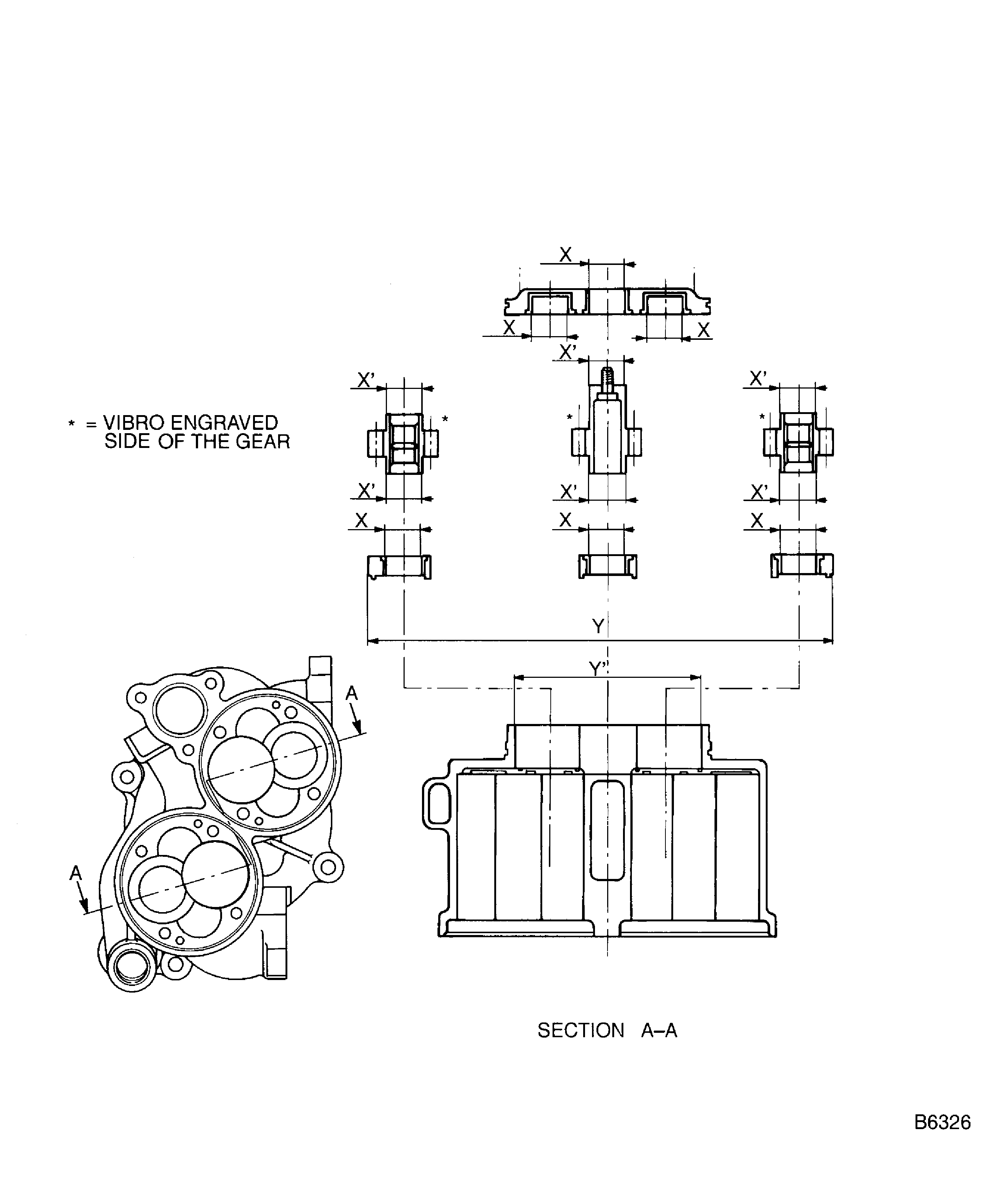

MAKE SURE THAT ALL THE PUMP COMPONENTS HAVE REACHED ROOM TEMPERATURE. IT IS RECOMMENDED TO MEASURE THE COMPONENTS IN A THERMOSTATICALLY CONTROLLED ROOM.Measure dimensions Y' on pump casing and write them.

Select the spacers and the gears following the formulas:

Y' - Y = 0.001 TO 0.0024 in. (0.025 TO 0.06 mm).

X - X' = 0.0012 in. (0.03 mm) minimum.

SUBTASK 79-22-41-470-051 Select the Components of the Oil Scavenge Pump

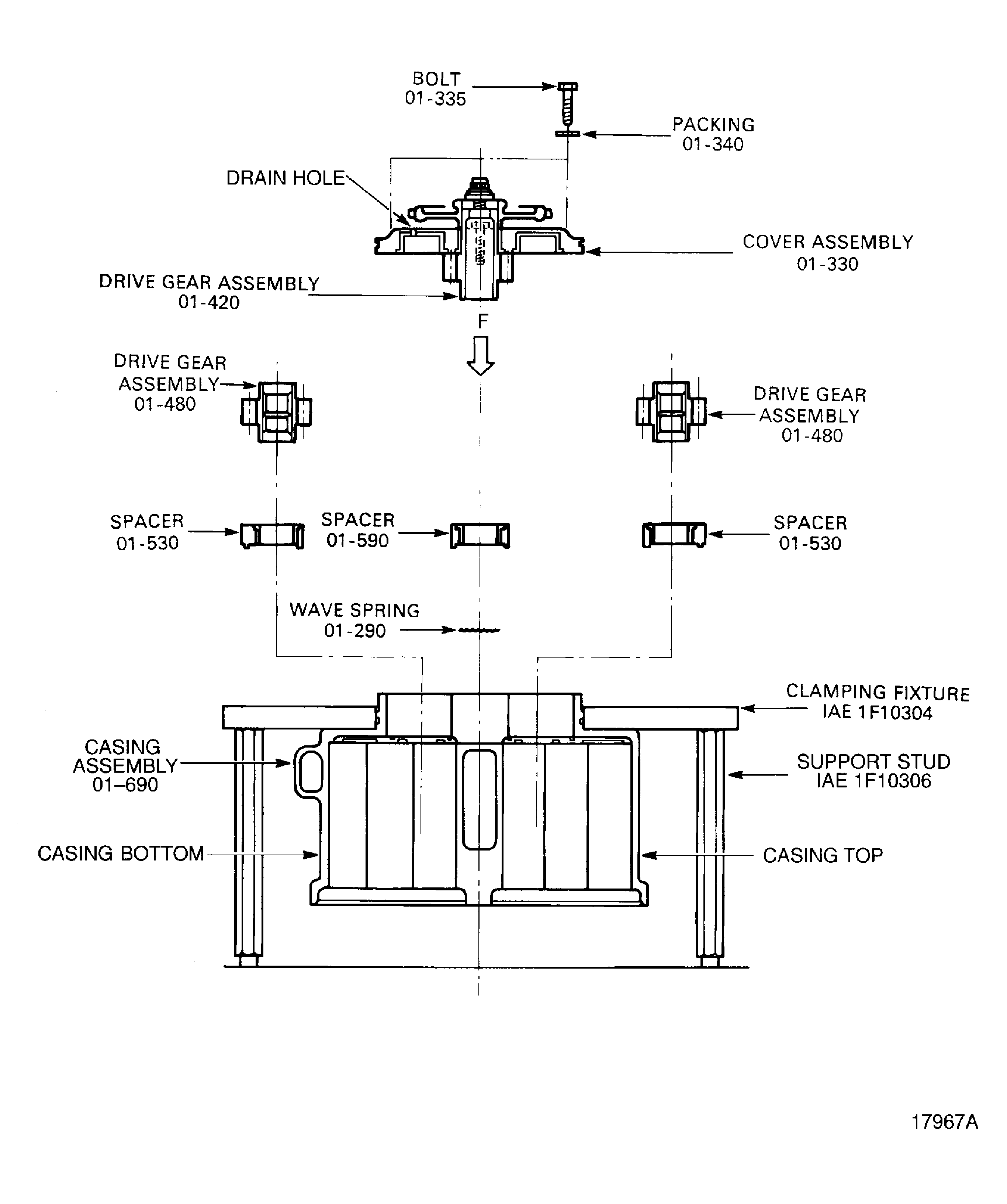

Refer to Figure.

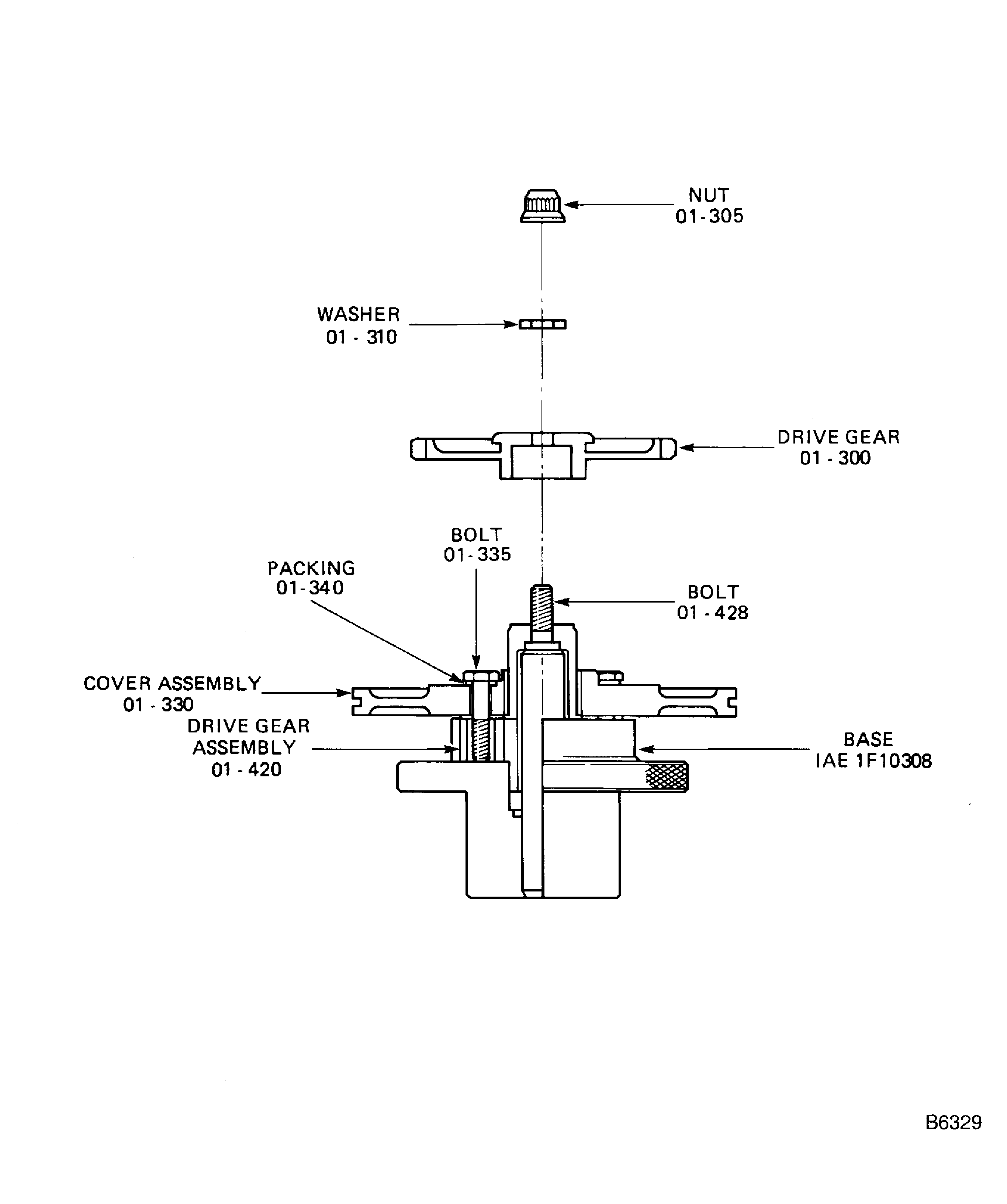

Position the IAE 1F10308 Base on a bench.

If necessary install the bolt (01-428) into the seat of the drive gear. Use a soft drift to facilitate the operation.

Install the drive gear assembly (01-420) on the base, with the long hub to the TOP.

Install the cover assembly (01-330) over the drive gear assembly.

Put the (01-340) packings 2 off and (01-335) bolts 2 off in holes adjacent to the drive gear hole in the cover assembly.

CAUTION

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES. HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED. IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN BURNED. IMMEDIATELY GET THE MEDICAL ATTENTION IF PAIN OR BLISTERING PERSISTS.Heat the oil pump drive gear to 356 deg F (160 to 180 deg C).

Position the collar uppermost, and engage the notch on the drive gear with the key in the front of the drive gear assembly hub.

Install the pump drive gear. Use IAE 1F10309 Installation drift 1 off.

Attach the oil pump drive gear with the (01-310) washer and the (01- 305) nut.

Install the IAE 1F10312 Adapter wrench 1 off on the drive gear.

Hold the drive gear with rotating wrench. Torque the nut to 85 to 95 lbfin (9.604 to 10.734 Nm).

Remove the rotating wrench from the drive gear.

Remove the assembled parts from the base.

Install the drive gear (01-300) to the drive gear assembly hub.

SUBTASK 79-22-41-470-052 Preassembly the Drive Gear Assembly and Cover Assembly

Install IAE 1F10306 Support stud (long) 3 off to IAE 1F10304 Clamping fixture 1 off and position on the bench.

Install the (01-690) casing assembly to the IAE 1F10304 Clamping fixture, put the drive gear side turned to the top.

Put a new (01-290) wave spring in the central seat of the casing. Check for proper position.

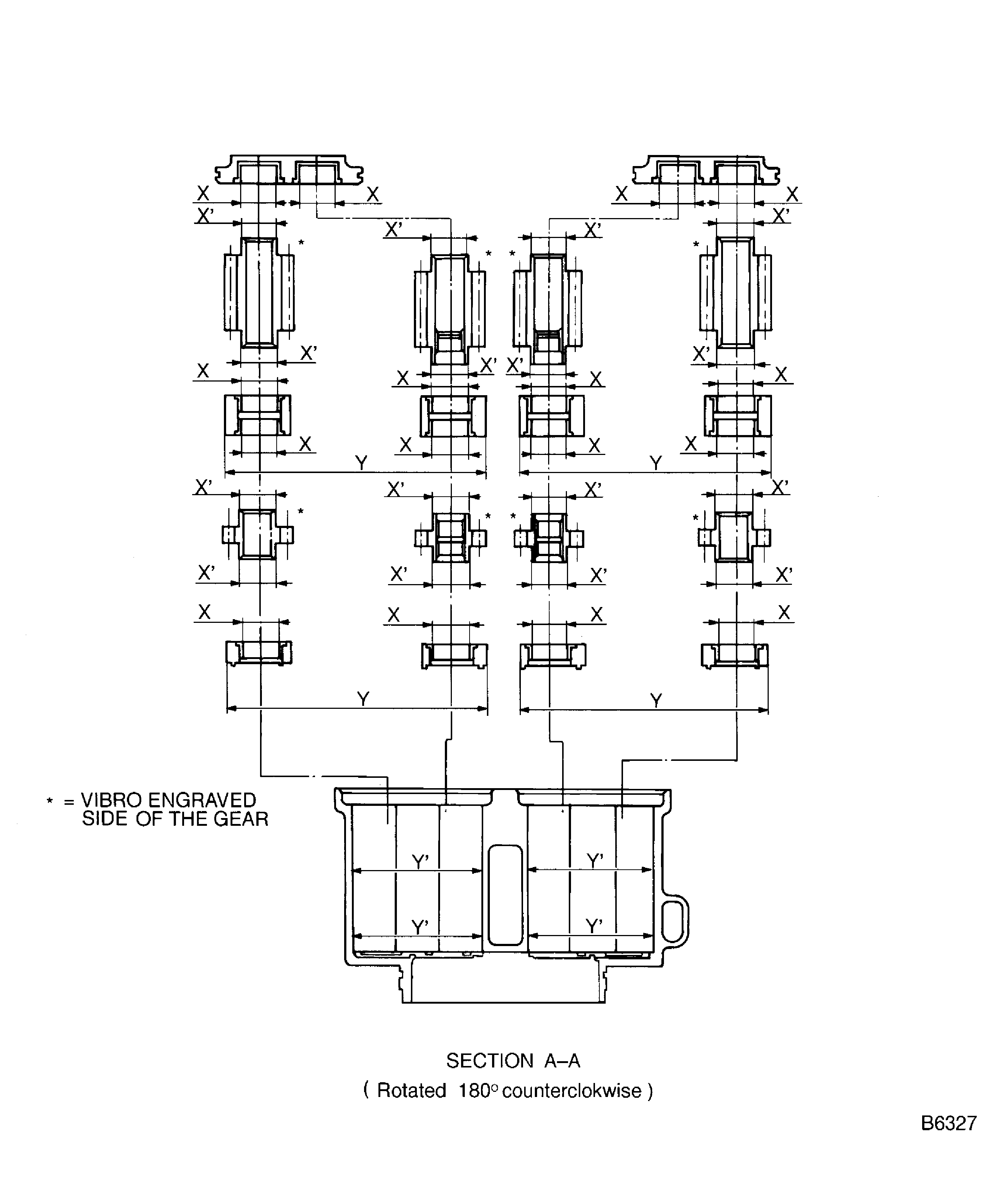

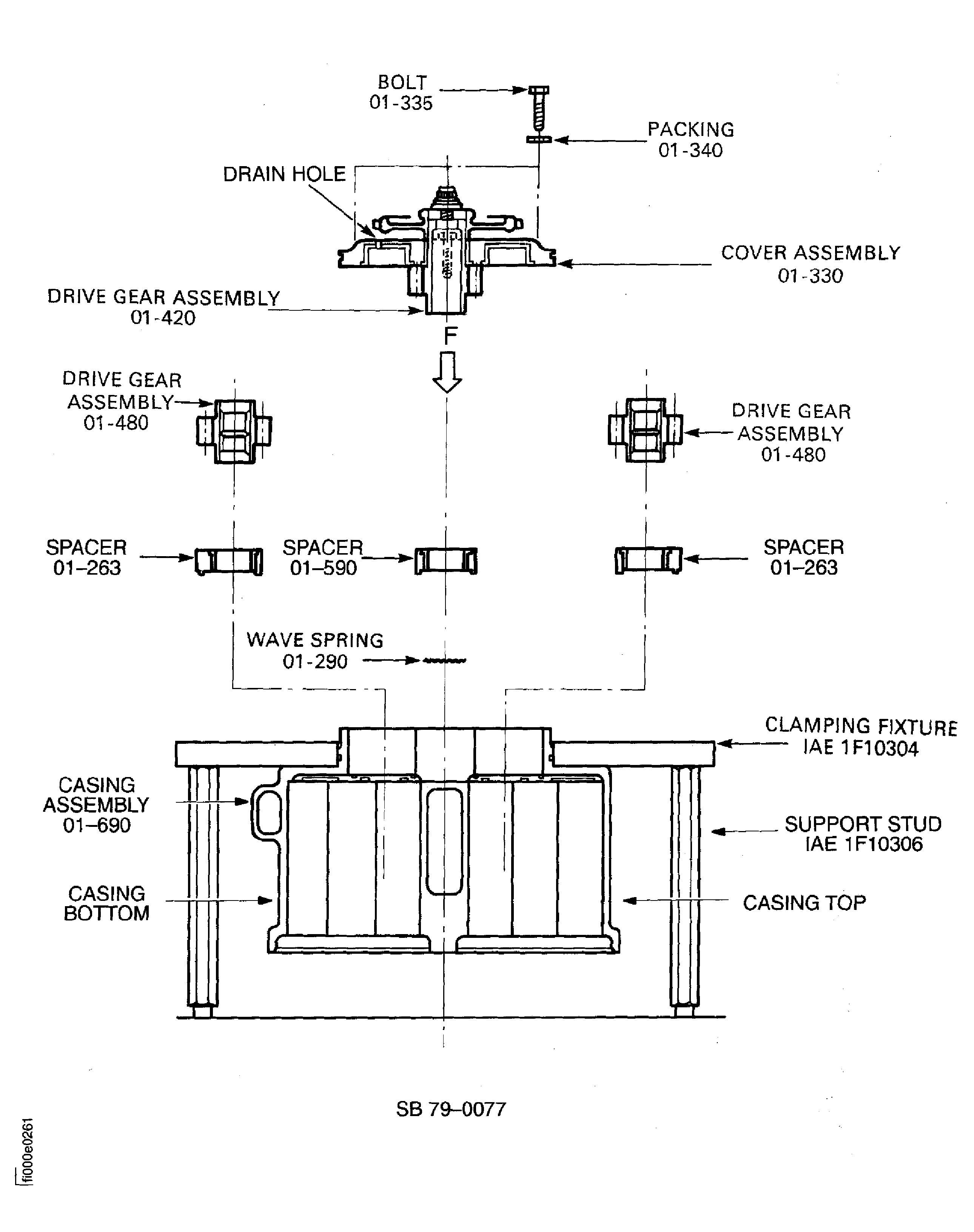

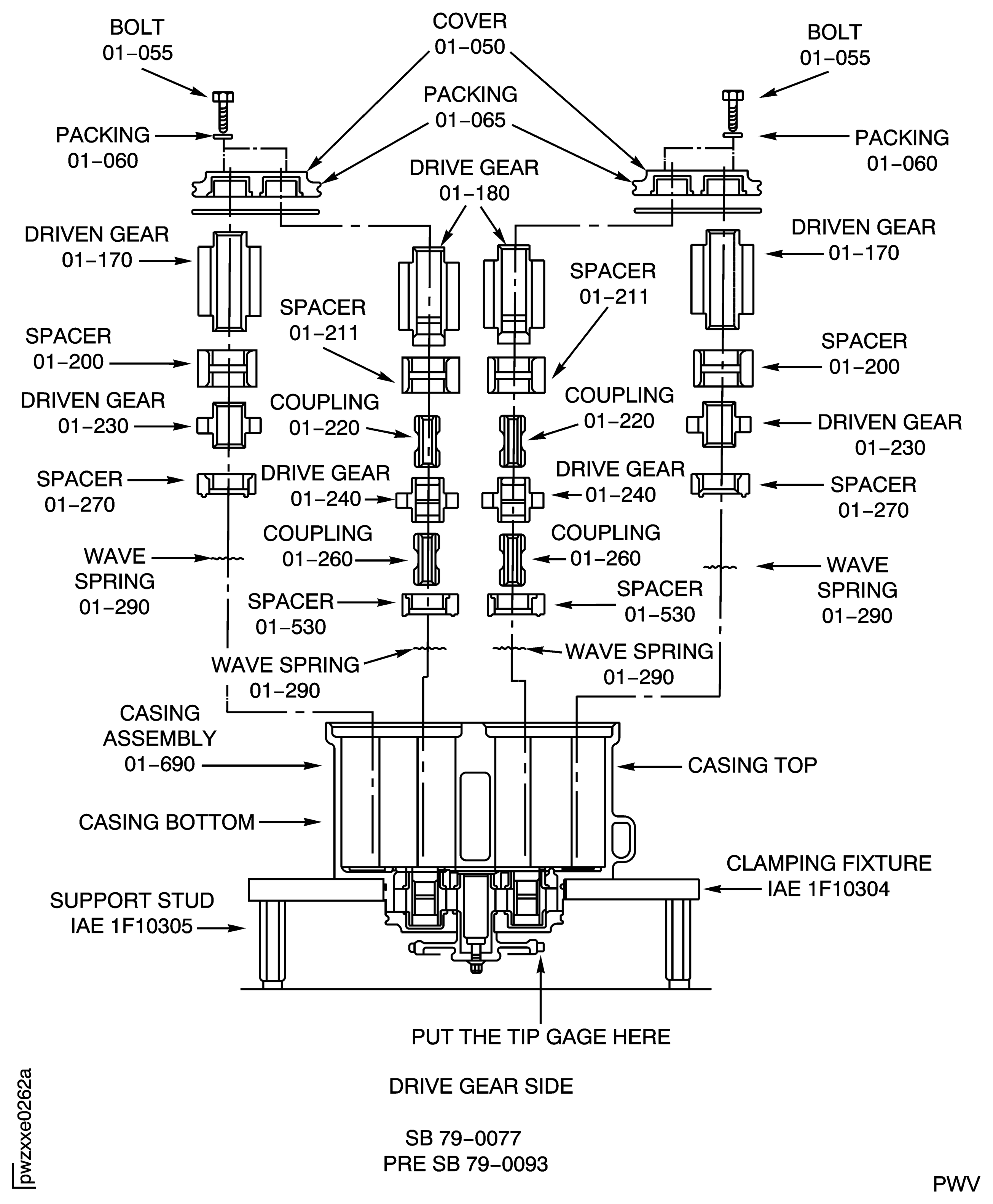

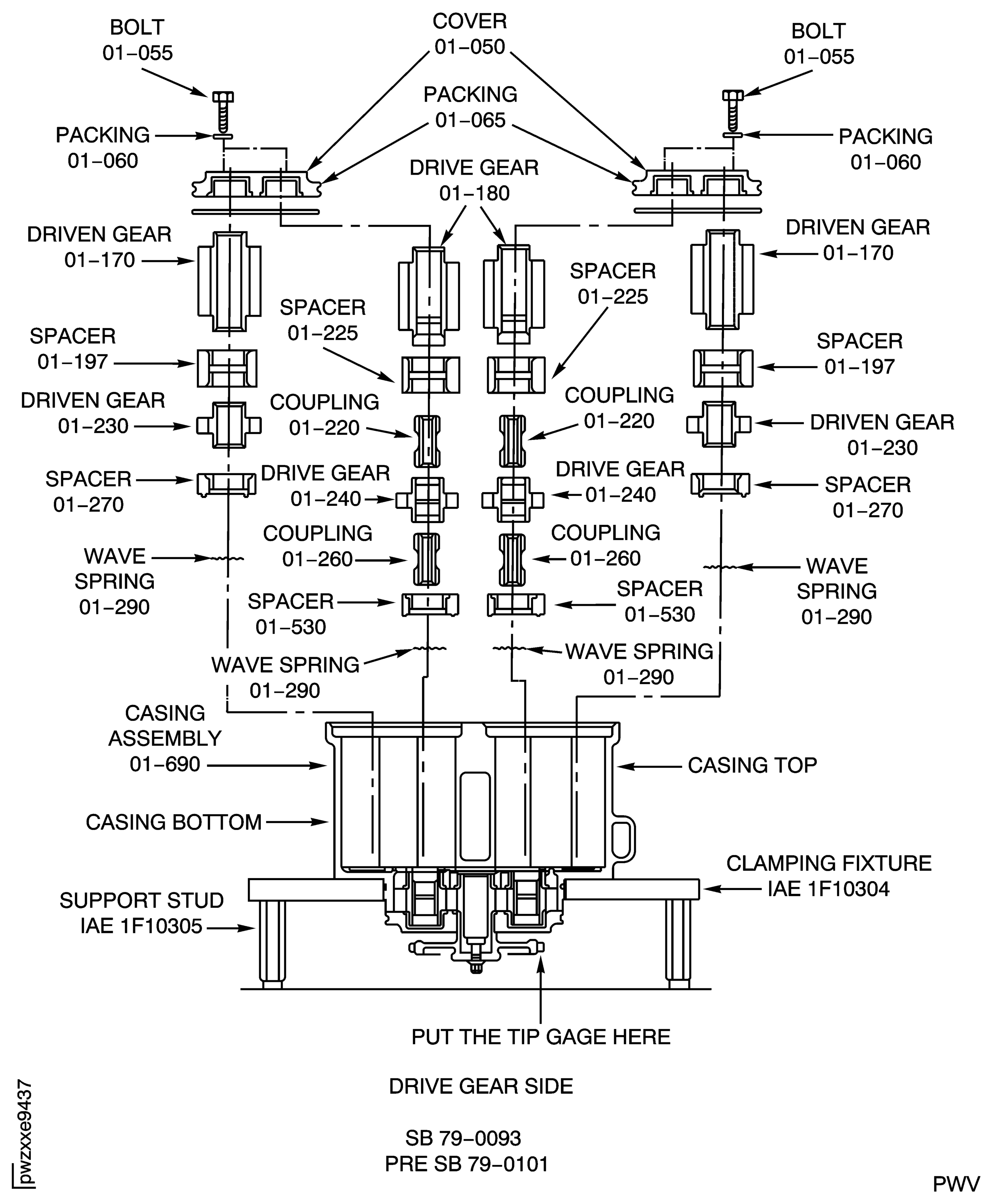

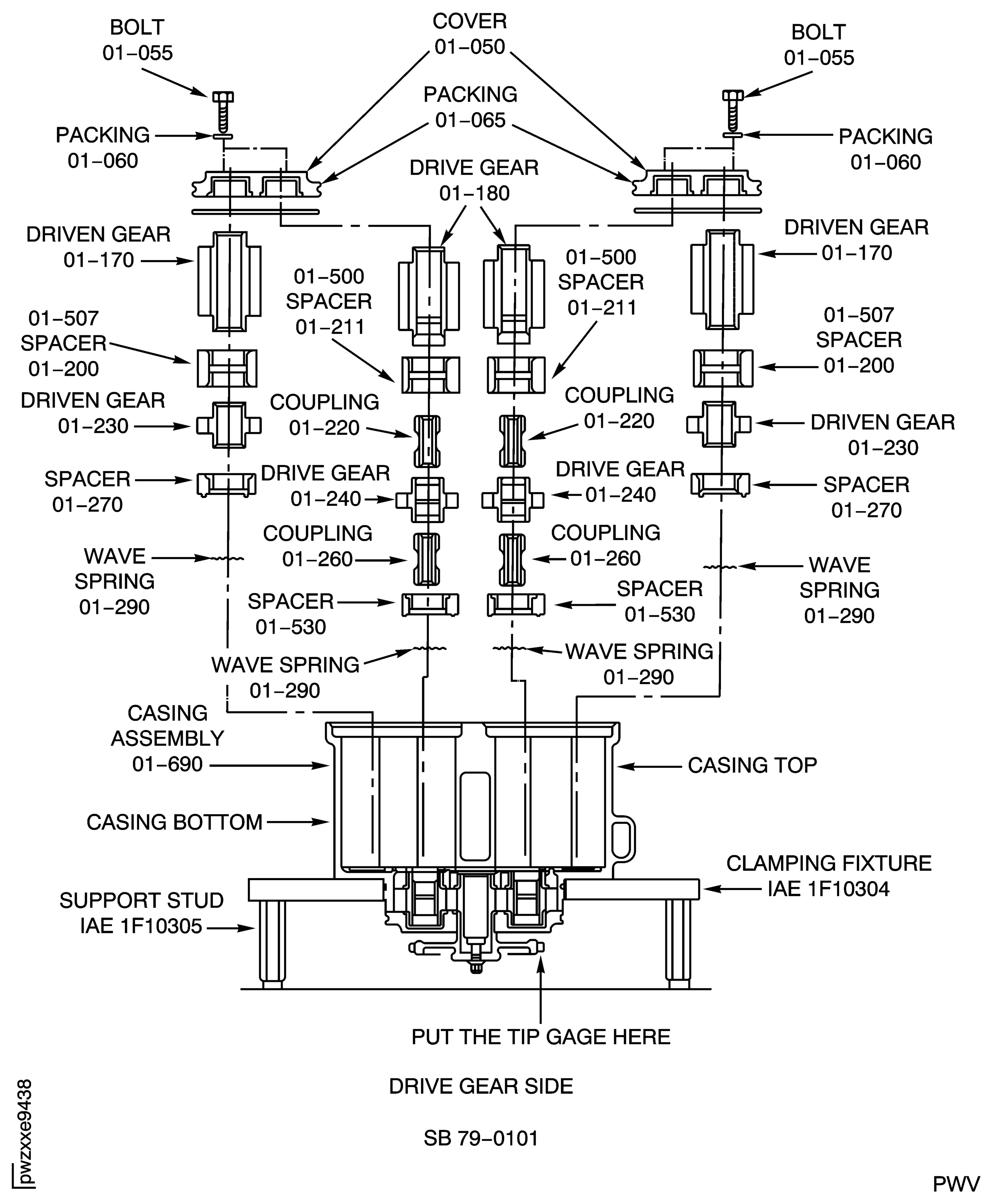

Put the spacers together into their seat. Install the spacers as indicated in Figure.

Check the three spacers for proper position.

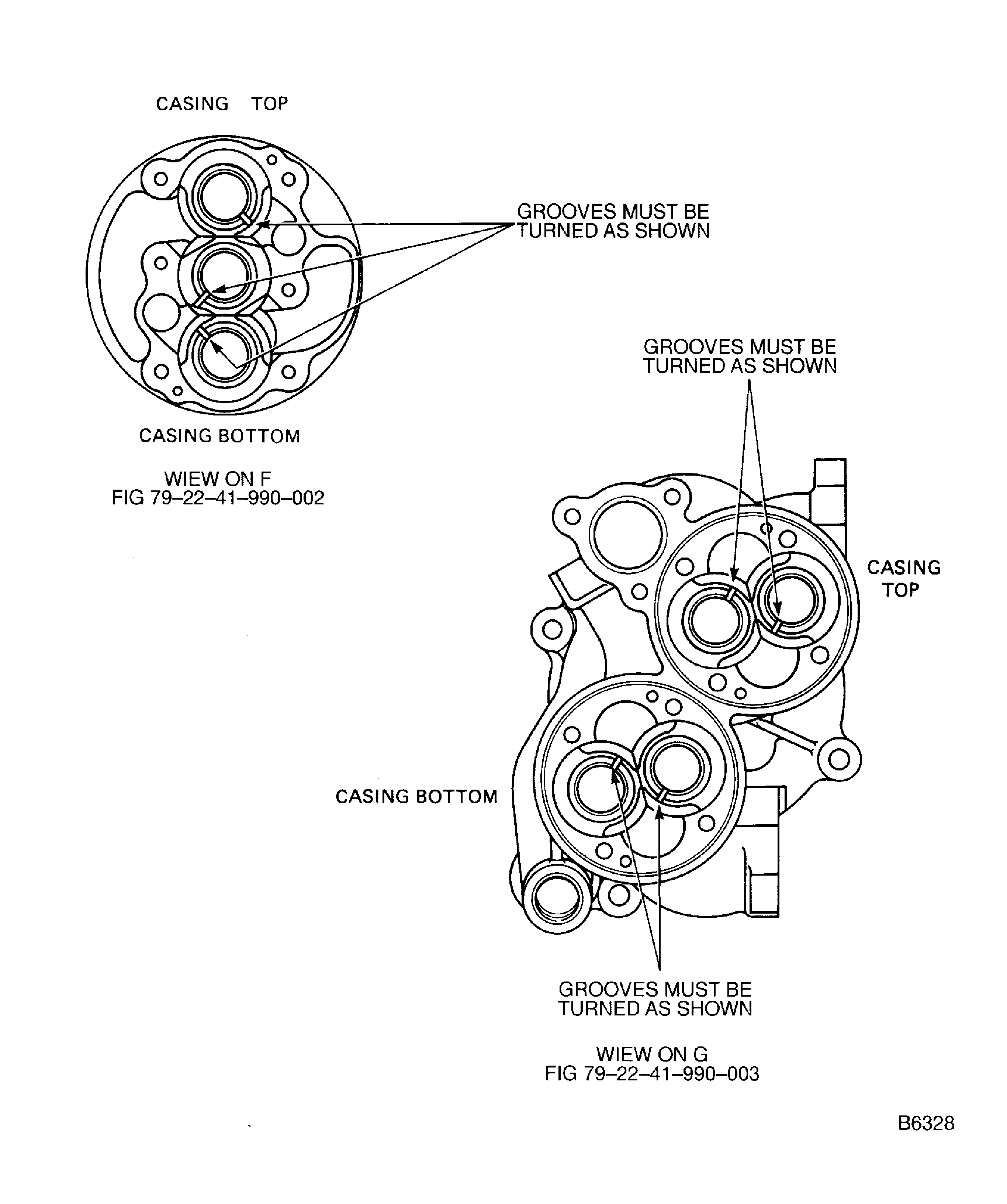

Install the two (01-480) drive gears assembly in the respective seats. Make sure the vibro engraved sides are turned to the top. Refer to Figure.

Align the gear and the preassembled cover with the casing assembly.

Engage correctly the gears and run down the two bolts, and keep the cover holes with the pins on the casing.

Install the (01-340) packings 4 off and (01-335) bolts 4 off on the cover assembly.

Attach the cover assembly to the casing assembly. Torque the six bolts to 85 to 95 lbfin (9.604 to 10.734 Nm).

NOTE

Make sure that the drain hole on the cover points to the bottom of the casing.Install the gear and cover previously assembled.

SUBTASK 79-22-41-470-053 Install the Components on the Side of the Drive Gear

Install IAE 1F10305 Support stud (short) 3 off to the IAE 1F10304 Clamping fixture 1 off.

Turn the clamping fixture with the casing drive gear side down.

Remove the IAE 1F10306 Support stud (long) 3 off from the clamping fixture.

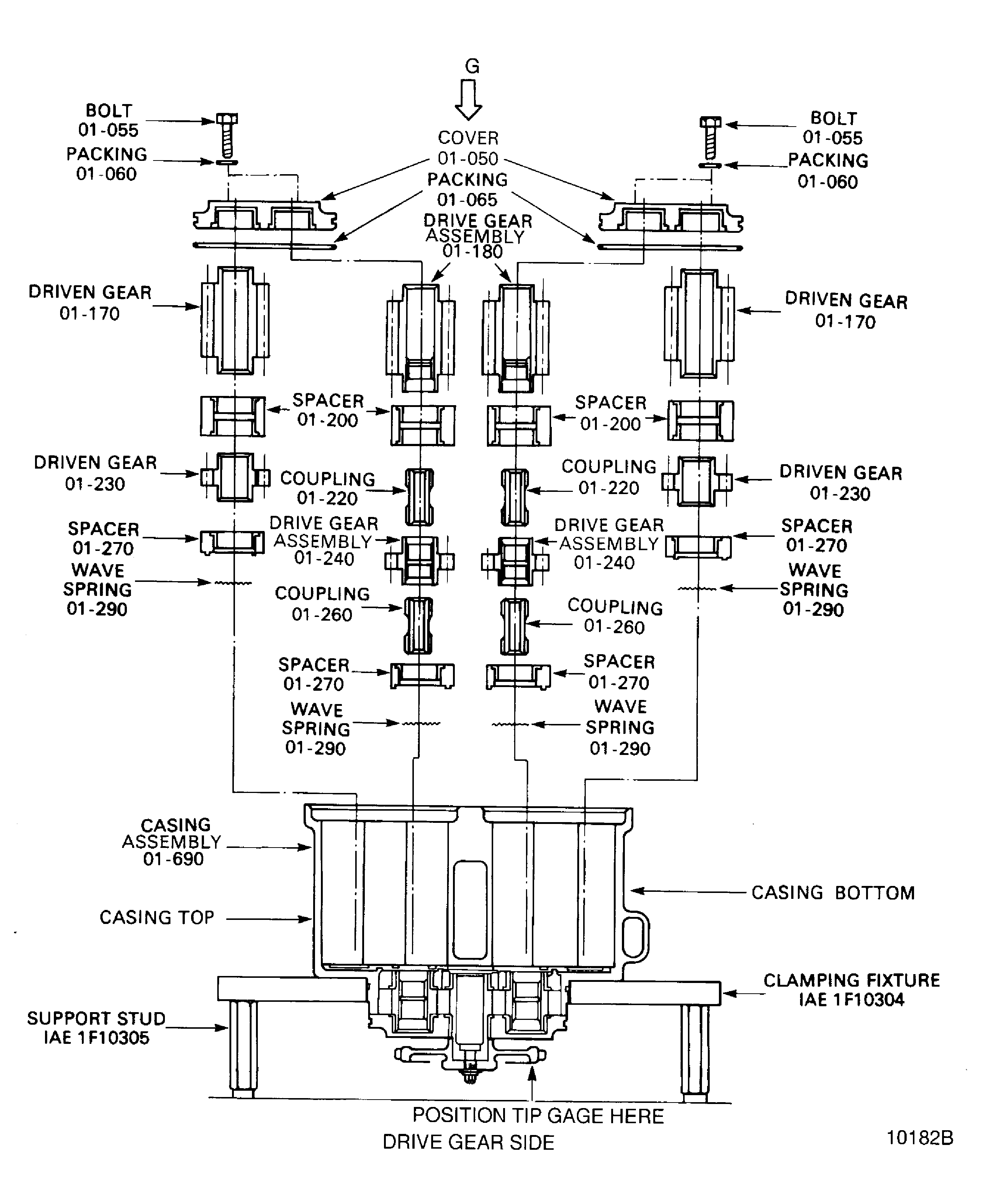

Put the matched spacers over the wave springs in to the casing. Install the spacers as indicated in Figure.

Align the splines and install the coupling (01-260) in to the seat of the drive gear (01-480).

Align the splines and install the drive gear (01-240) on the coupling. Make sure the vibro engraved side is turned to the top.

Install the (01-230) driven gear in to the seat of the outer spacer. Check for proper position. Make sure the vibro engraved side is turned to the top.

Put the matched spacers over the two gears. Install the spacers as indicated in Figure.

Align the splines and install the coupling (01-220) in to the seat of the drive gear.

Align the splines and install the drive gear (01-180) to fully engage the coupling. Check for proper position on the spacer and with the coupling. Make sure the vibro engraved side is turned to the top.

Install the bottom gear train as follows:

SUBTASK 79-22-41-470-054 Install the Gears on the Opposite Side of the Pump Gear Drive

Refer to Figure.

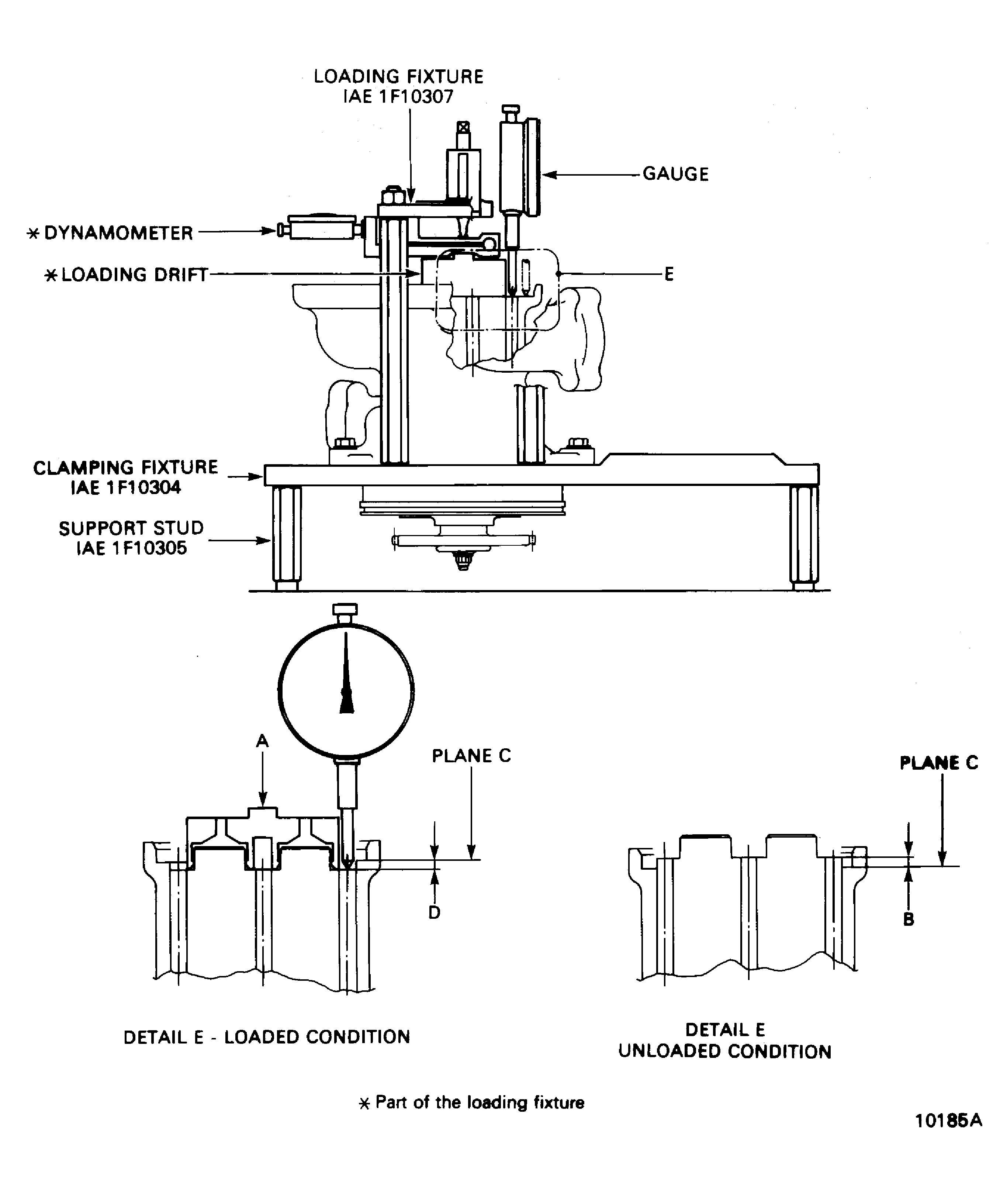

Attach the loading fixture studs 3 off to the IAE 1F10304 Clamping fixture clamping fixture in position A marked on clamping fixture.

Install the loading fixture support 1 off above the casing assembly to the studs.

Install IAE 1F10307 Loading fixture 1 off on the casing.

Insert the loading fixture dynamometer between loading fixture drift and loading fixture support screw.

Put the magnetic support gage on the loading fixture support and position the tip gage on the casing surface cover (Plane C) and set to zero dial indicator.

Turn the magnetic support gage until the tip gage gets the top face of the gear.

Apply gradually the load with the loading fixture screw of 220 lb (100 kg) in direction of arrow A.

Check on the dial indicator Dimension D between Plane C of the casing and the top face of the gear. Its value must be equal to or more than 0.0027 in. (0.07 mm).

Fully release the load gradually and make sure that Dimension B is positive to Plane C.

Remove the magnetic support gage, the loading fixture dynamometer, support and studs and the loading drift.

Reinstall IAE 1F10307 Loading fixture loading fixture with studs 3 off installed on position B.

SUBTASK 79-22-41-470-055 Load Test

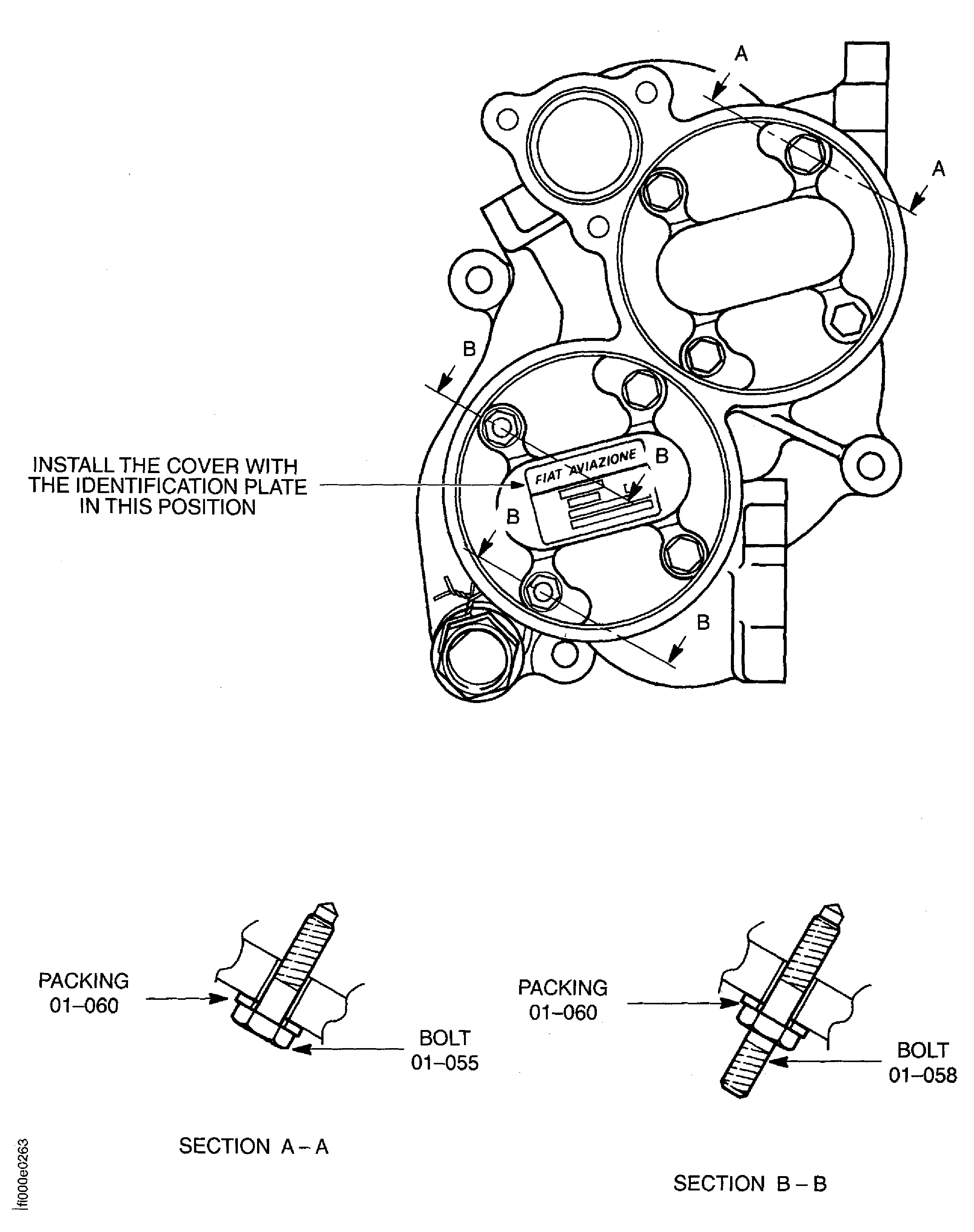

Align the pins on the casing with the holes in the cover and install the cover on the casing.

Install the (01-050) top cover on the casing.

SUBTASK 79-22-41-470-056-A00 V2500-A1: Install the Covers on the Casing

Refer to Figure.

Install (01-065) packing 1 off on the cover groove.

Align the pins on the casing with the holes in the cover, and install the cover on the casing.

Attach the cover to the casing with the four bolts (01-055) . Torque to 85 to 95 lbfin (9.604 to 10.734 Nm).

Install the (01-050) top cover on the casing.

Install (01-065) packing 1 off on the cover groove.

Align the pins on the casing with the holes in the cover, fully install the cover on the casing.

Attach the cover to the casing with the bolts (01-055) and two bolts (01-058). Torque to 85 to 95 lbfin (9.604 to 10.734 Nm).

Install the (01-050) bottom cover with the identification plate on the casing.

SUBTASK 79-22-41-470-056-B00 V2500-A5: Install the Covers on the Casing

Position the pump (attached to IAE 1F10304 Clamping fixture fixture) on a face-plate.

Remove the four bolts which attach the pump to the fixture.

Rotate the pump and check for gear wobble. The maximum permitted wobble is 0.01 in. (0.25 mm).

SUBTASK 79-22-41-470-057 Inspect the Drive Gear Wobble

Install (72-60-03,01-858) packing 1 off on the (72-60-03,01-860) plug.

Install the plug to the casing. Torque to 53 to 71 lbfin (6 to 8 Nm) and safety the plug with CoMat 02-119 LOCKWIRE.

SUBTASK 79-22-41-470-058 Install the Plug to the Casing

Install IAE 1F10306 Support stud (long) 3 off to IAE 1F10304 Clamping fixture 1 off and position on the bench, so the drive gear side of the pump is turned to the top.

Remove the IAE 1F10305 Support stud (short) 3 off.

Install IAE 1F10312 Adapter wrench 1 off on the pump drive gear and measure the static torque. Write the value. The static torque value ranges from 200 to 400 lbfin (22.6 to 45.2 Nm).

Remove the rotating wrench from the pump drive gear.

Remove the assembly from the clamping fixture.

SUBTASK 79-22-41-470-059 Measure the Static Torque

Test the oil scavenge pump. Refer to Testing-001 TASK 79-22-41-700-401.

SUBTASK 79-22-41-470-063 Do a Test on the Oil Scavenge Pump

Figure: Selection of the Components of the Oil Scavenge Pump

Selection of the Components of the Oil Scavenge Pump

Selection of the Components of the Oil Scavenge Pump

Figure: Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Figure: Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Figure: Correct Installation of the Spacers of the Oil Scavenge Pump

Correct Installation of the Spacers of the Oil Scavenge Pump

Figure: Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Assemble the Oil Scavenge Pump

Figure: Load Test on the Oil Scavenge Pump

Load Test on the Oil Scavenge Pump

Figure: V2500-A5: Assemble the Oil Scavenge Pump

V2500-A5: Assemble the Oil Scavenge Pump