Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 71-00-02-400-017-A00 (A1-PPBU) - Install The 400VC to IDG Cable Assembly, Installation-017

General

Fig./Item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig./Item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in this procedure.

For the connection of electrical connectors, refer to the SPM TASK 70-43-01-400-501.

For the installation of open wire harnesses, refer to the SPM TASK 70-43-02-400-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | 0AM53 | CoMat 01-002 | ||

| CoMat 06-086 TIES | 18992 | CoMat 06-086 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Temporarily attach the IDG cable connector to a safe position on the LP compressor/intermediate case with CoMat 06-086 TIES.

WARNING

WHEN YOU USE CoMat 01-002 SOLVENT, DELETED. YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Clean the mating faces of the brackets ELECTRICAL POWER-IDG CABLES (24-21-43,01-950), ELECTRICAL POWER-IDG CABLES (24-21-43,01-952) and the clamp ELECTRICAL POWER-IDG CABLES (24-21-43,01-030) with a clean lint free cloth made moist with CoMat 01-002 SOLVENT, DELETED..

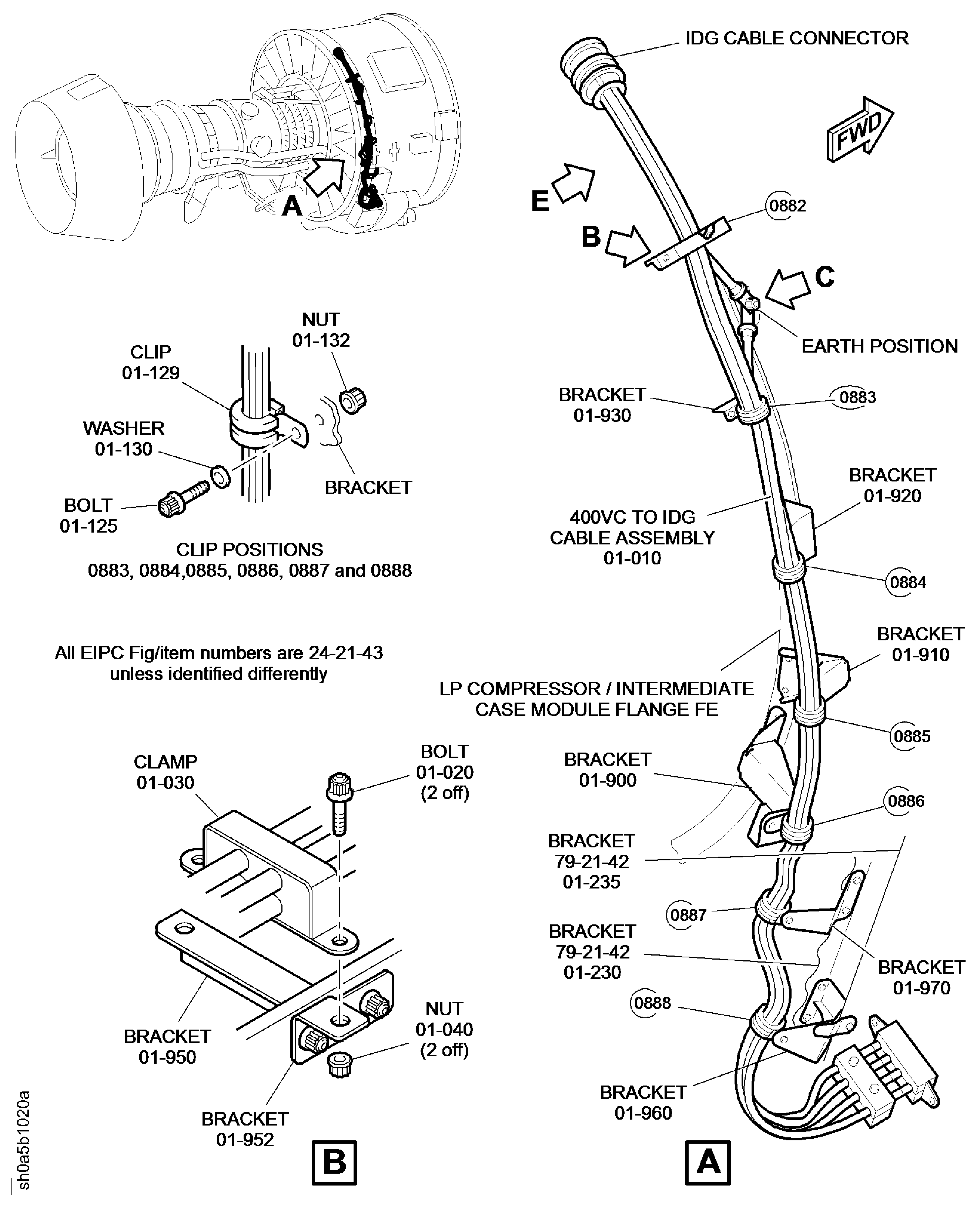

Install the clamp ELECTRICAL POWER-IDG CABLES (24-21-43,01-030) on the cables. Attach the clamp to the brackets ELECTRICAL POWER-IDG CABLES (24-21-43,01-950) and ELECTRICAL POWER-IDG CABLES (24-21-43,01-952) with the two bolts and the two nuts ELECTRICAL POWER-IDG CABLES (24-21-43,01-020) and ELECTRICAL POWER-IDG CABLES (24-21-43,01-040) at the clip position 0882.

Clean the mating faces of the bracket ELECTRICAL POWER-IDG CABLES (24-21-43, 01-940) and the cable terminals at the earth position with a clean lint free cloth made moist with CoMat 01-002 SOLVENT, DELETED..

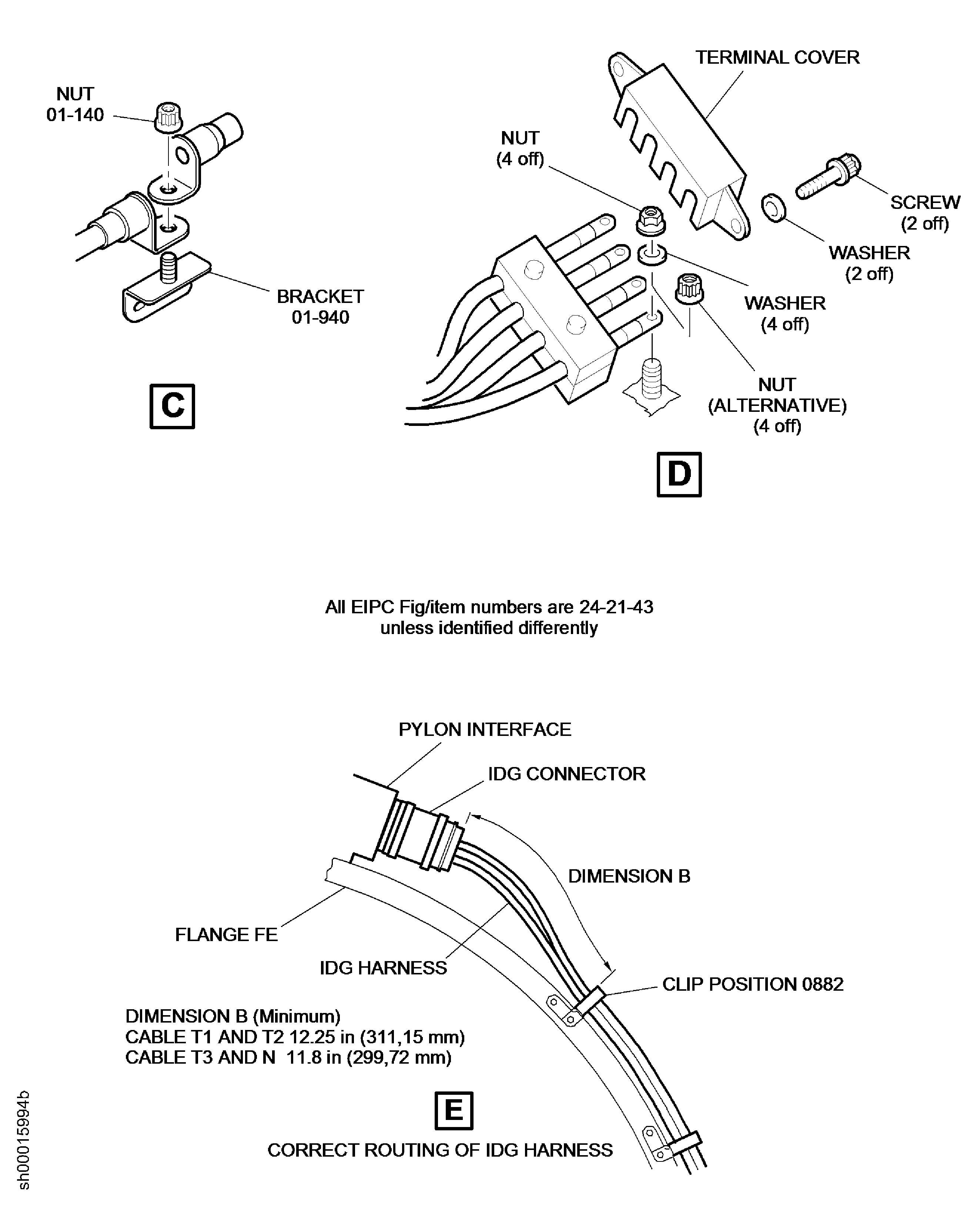

Install the two cable terminals to the earth position on the bracket ELECTRICAL POWER-IDG CABLES (24-21-43,01-940). Install the nut ELECTRICAL POWER-IDG CABLES (24-21-43,01-140) on the bracket. Refer to the view on A.

Remove the CoMat 06-086 TIES which hold the IDG cable connector.

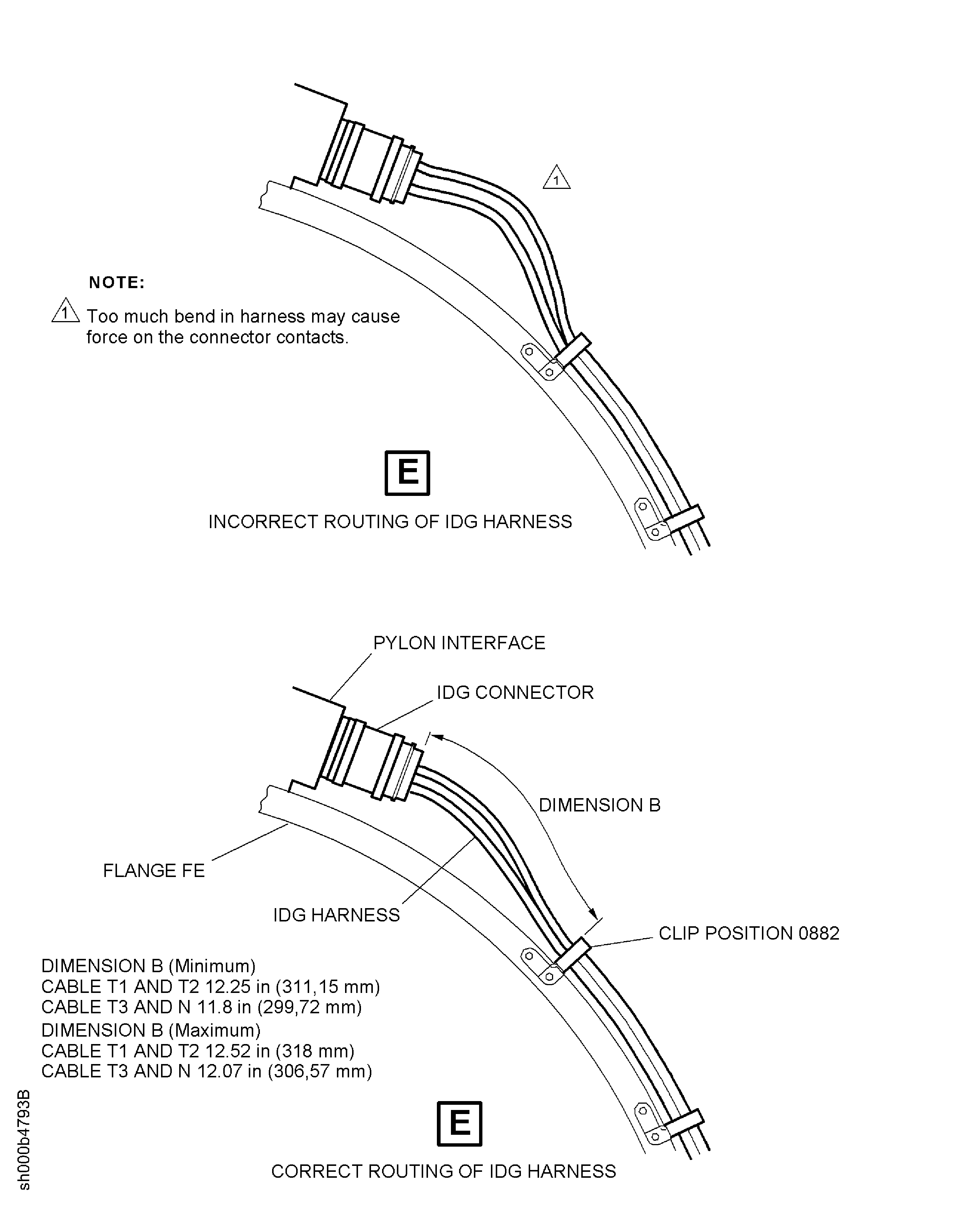

Measure dimension B from the IDG cable connector to the clamp at the clip position 0882. Dimension B must be a minimum of 12.25 in. (311 mm) and a maximum of 12.52 in. (318 mm) for the cables T1 and T2. For the cables T3 and N, the minimum dimension B must be 11.8 in. (300 mm) and the maximum must be 12.07 in. (306 mm). Refer to the view on B.

Loosen the nuts ELECTRICAL POWER-IDG CABLES (24-21-43,01-945).

SBN 24-0020: If there is too much bend on the IDG Harness adjust the IDG Harness routing and the bracket ELECTRICAL POWER-IDG CABLES (24-21-43,01-940) as follows:

Torque the nut ELECTRICAL POWER-IDG CABLES (24-21-43,01-140) at the earth position to 110 lbfin (12.4 Nm).

NOTE

The cable ends and the IDG terminals are identified as T1 (red), T2 (yellow), T3 (blue) and N (white).Torque the nuts to 144 and 168 lbfin (1.62 and 1.89 m.daN) (SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501).

Torque the screws to between 20 and 22 lbfin (0.22 and 0.24 m.daN) (SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501, SPM TASK 70-41-02-400-501).

SUBTASK 71-00-02-420-039 Install the 400VC to IDG Cable Assembly

Figure: Install the 400VC to IDG Cable Assembly

Sheet 1

Figure: Install the 400VC to IDG Cable Assembly

Sheet 2

Figure: Install the 400VC to IDG Cable Assembly

Sheet 3