Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-32-200-001 LPC/Intermediate Case Module - Examine The Rigging Position Of The LPC Bleed Valve Linkage, Special Procedures-001

General

The TASK gives the procedure to examine the wear condition of LPC bleed valve linkage with rigging position check without engine disassembly.

SBE 72-0233: Rod adjustment feature relocation of LPC bleed rigging

Refer to the TASKS that follow for the other related procedures:

TASK 72-00-32-200-002 (SPECIAL PROCEDURES-002) - Adjust the Rigging Position of the LP Compressor Bleed Linkage, SBE 72-0233

TASK 72-32-00-030-008 (72-032-000,DISASSEMBLY-008) - Remove the LP Compressor (LPC) Bleed Duct, the Booster Stage Bleed Valve and Actuating Mechanism, LP Compressor Stage 2.5 Vane and the Right and Left Rod Assemblies

TASK 72-32-00-430-008-A00 (ASSEMBLY-008, CONFIG-001) - Install the LP Compressor Bleed Duct, the Booster Stage Valve and Actuating Mechanism and the Right and Left Rod Assemblies, Pre SBE 72-0233

TASK 72-32-00-430-008-B00 (ASSEMBLY-008, CONFIG-002) - Install the LP Compressor Bleed Duct, the Booster Stage Bleed Valve and Actuating Mechanism and the Right and Left Rod Assemblies, SBE 72-0233

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to TASK 70-41-00-400-501 and TASK 70-41-02-400-501

Lubricate all threads and abutment faces of nuts and bolts with approved engine oils, unless other lubricants are referred to in the procedure. For the approval engine oils and procedures, refer to TASK 70-64-00-640-501

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12444 Setting fixture | 0AM53 | IAE 1J12444 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Make sure that the actuators and the brackets are removed from the fan frame. If they are installed, remove them. Refer to TASK 72-00-40-020-002-A00.

SUBTASK 72-00-32-210-051 Remove the LPC Bleed Valve Actuating Master and Slave Actuators and the Brackets

NOTE

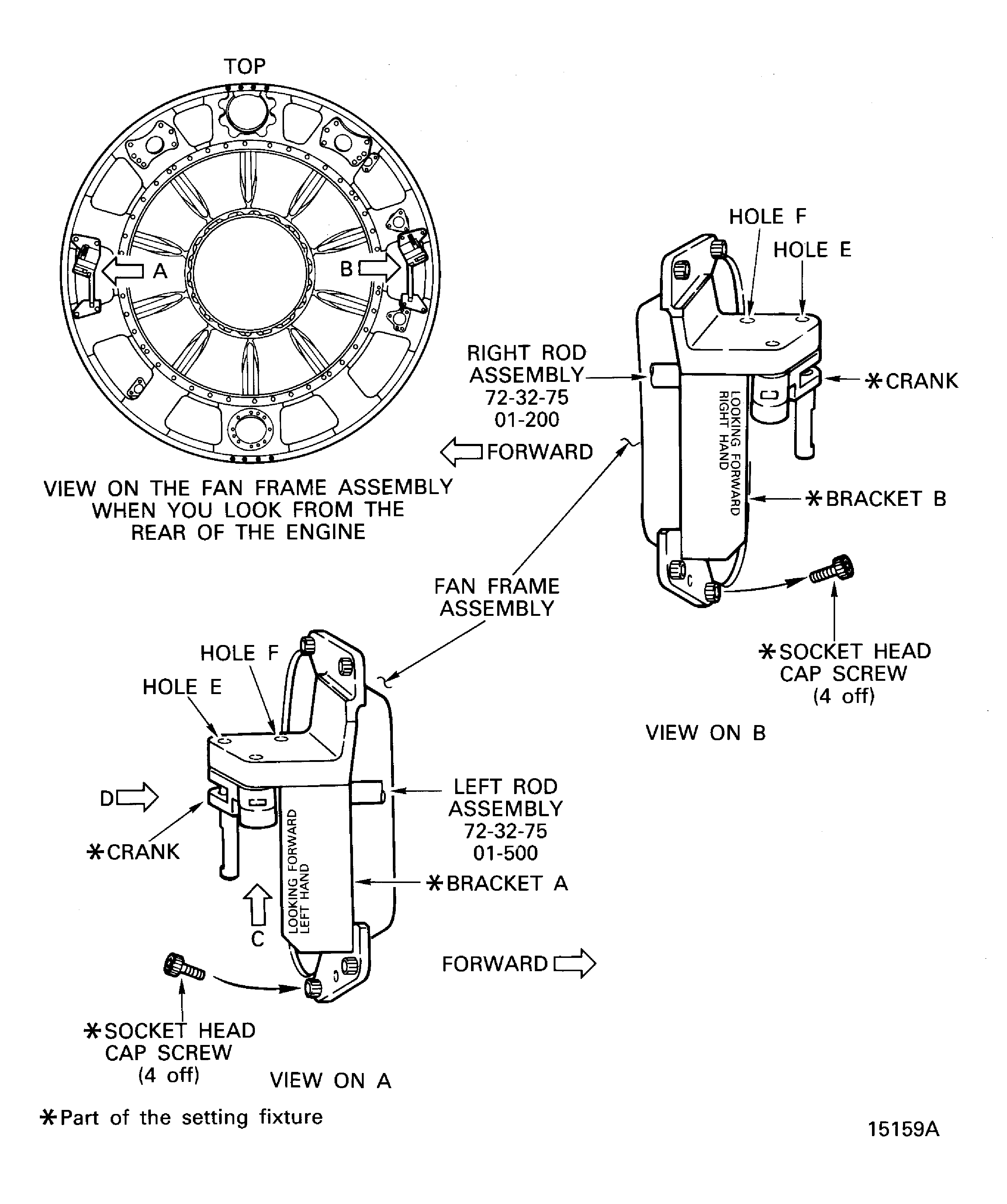

Do not install the magnetic stand, the digital dial gage and the torque wrench in this SUBTASK.Install the brackets A and B (parts of IAE 1J12444 Setting fixture 1 off) onto the fan frame assembly.

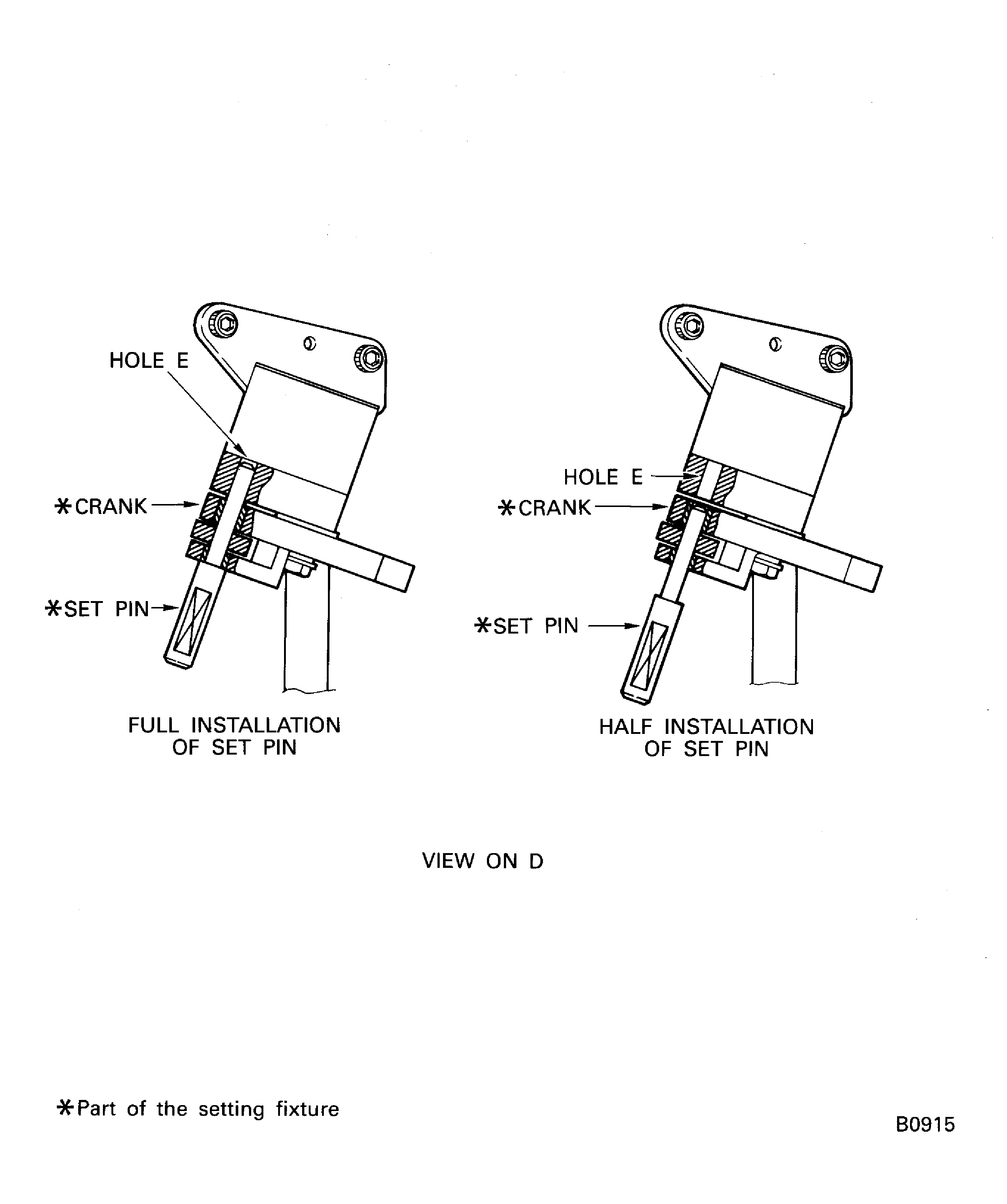

SUBTASK 72-00-32-210-052 Install the Setting Fixture

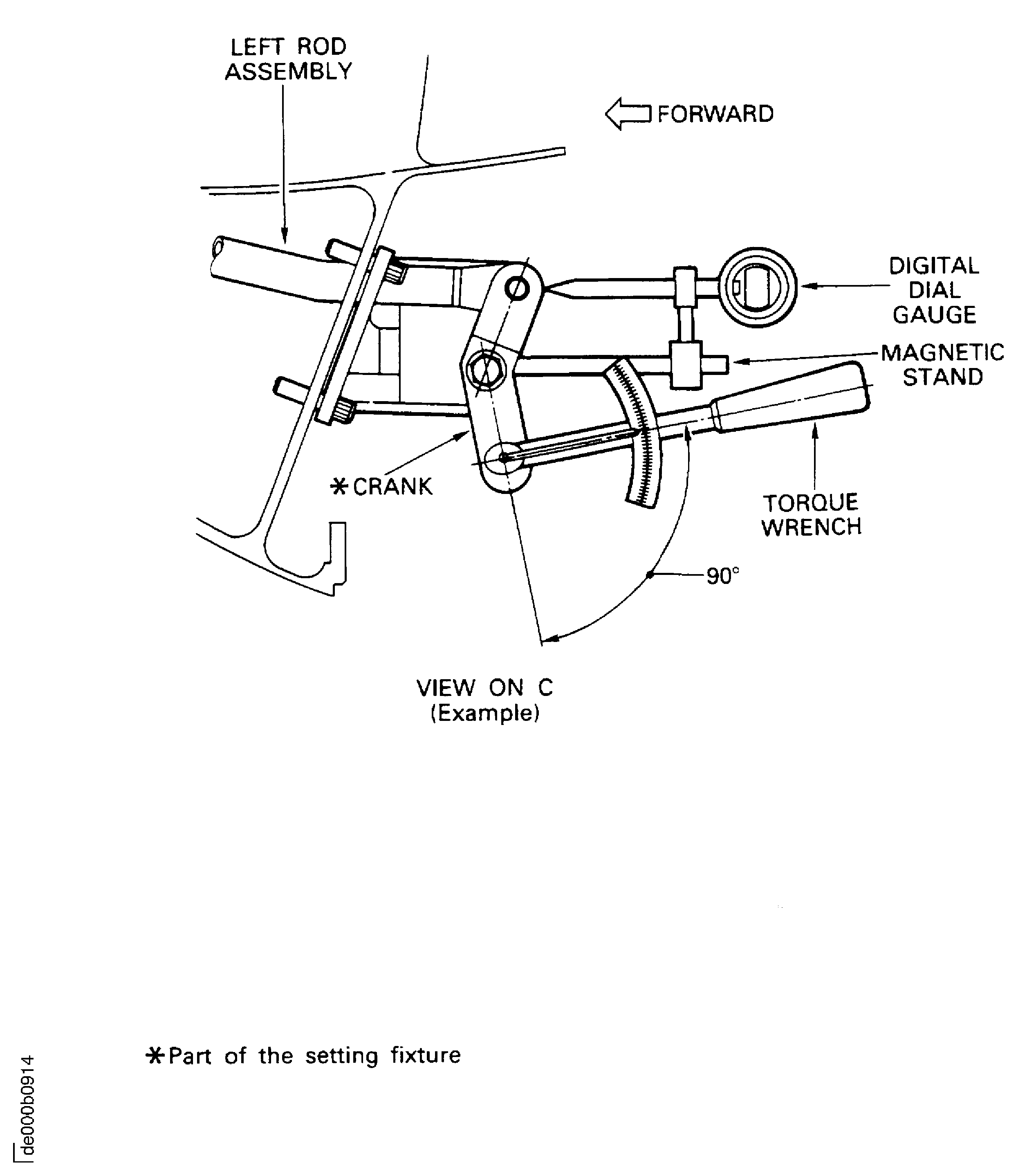

Slowly turn the left and right cranks with the wrenches to push the rod assemblies forward until the bleed valves are at open position. Slowly turn the left and right cranks with the wrenches to pull the rod assemblies rearward until the bleed valves are at closed position. Do this procedure three or four times and make sure that the rod assemblies and the actuating mechanism move lightly.

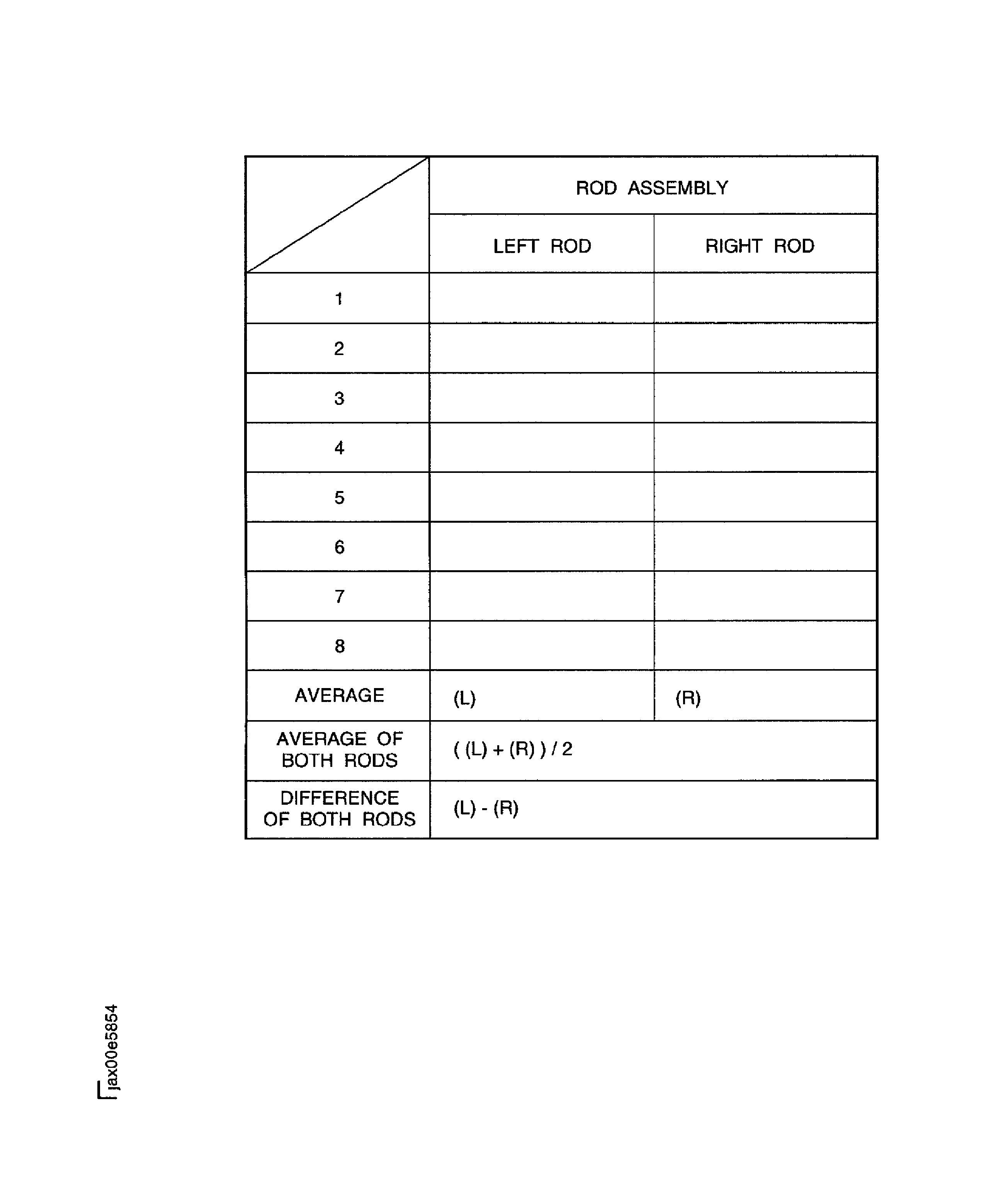

Keep the torque in Step and read indication of the digital dial gages.

Measure the movement of the rod assemblies.

NOTE

Refer to Step for the rejected engine.If the values ML and MR are within the limits, accept the engine. If the values ML and MR are not in the limits, reject the engine.

If the indications are not in the limits, make half installation of the set pins and go to Step.

SUBTASK 72-00-32-210-053-A00 Examine the Rigging Position (Pre SBE 72-0031)

Slowly turn the left and right cranks with the wrenches to push the rod assemblies forward until the bleed valves are at open position. Slowly turn the left and right cranks with the wrenches to pull the rod assemblies rearward until the bleed valves are at closed position. Do this procedure three or four times and make sure that the rod assemblies and the actuating mechanism move lightly.

Keep the torque in Step and read indication of the digital dial gages.

Measure the movement of the rod assemblies.

NOTE

Refer to Step for the rejected engine.If the values ML and MR are within the limits, accept the engine. If the values ML and MR are not in the limits, reject the engine.

If the indications are not in the limits, make half installation of the set pins and go to Step.

SUBTASK 72-00-32-210-053-B00 Examine the Rigging Position (SBE 72-0031)

Pre SBE 72-0233: Disassemble the engine to get access to the rod assemblies and adjust the rigging position. Refer to TASK 72-32-00-030-008 and TASK 72-32-00-430-008-A00 for adjsutment of rigging position of the LP compressor bleed linkage.

SBE 72-0233: Adjust the rigging position. Refer to TASK 72-00-32-200-002 for adjustment of the rigging position of the LP compressor bleed linkage.

SBE 72-0233: Rod adjustment feature relocation of LPC bleed rigging.

SUBTASK 72-00-32-210-100 If the Engine Is Rejected, do the Corrective Procedure

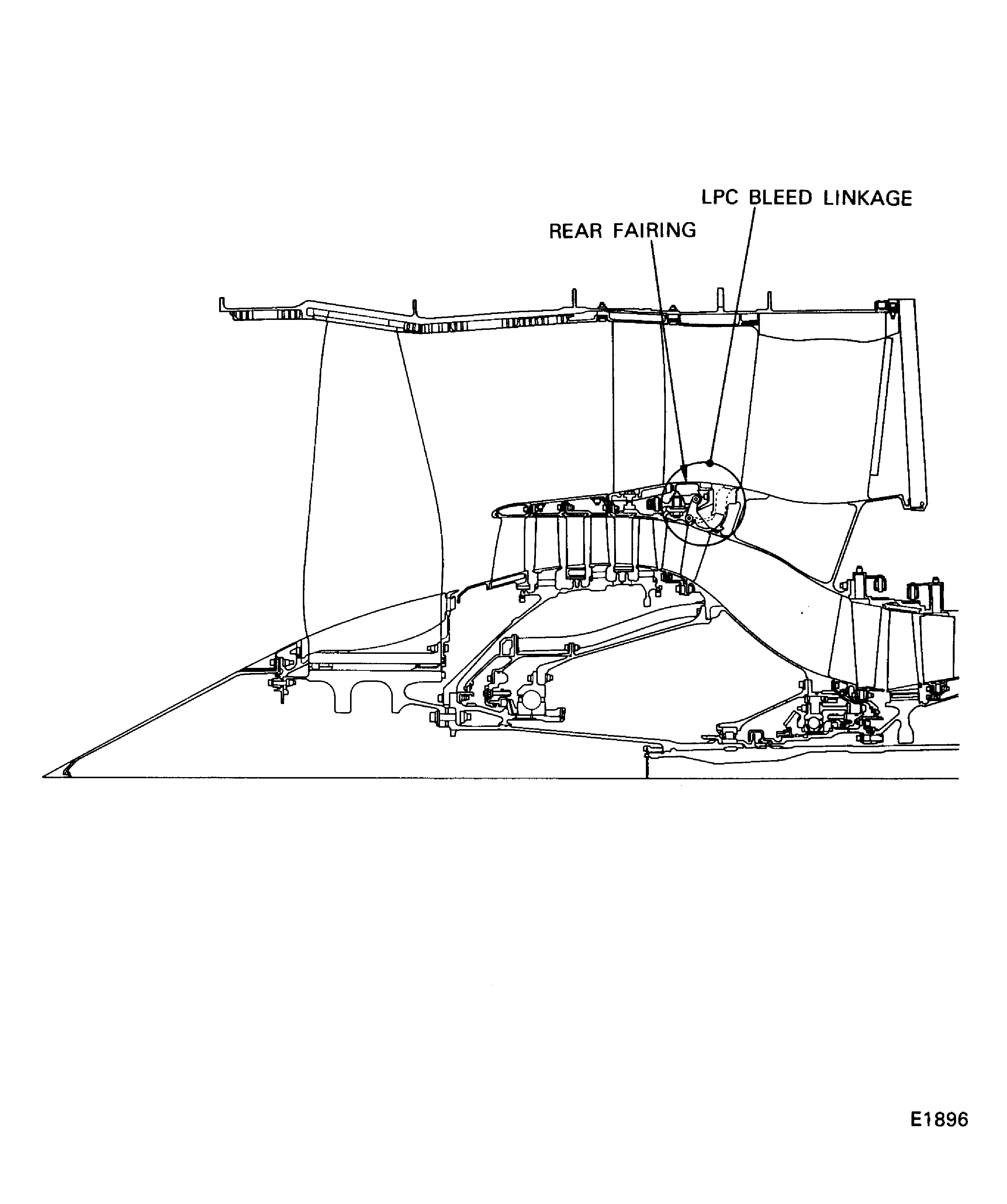

Figure: Sectional View of the Engine

Sectional View of the Engine

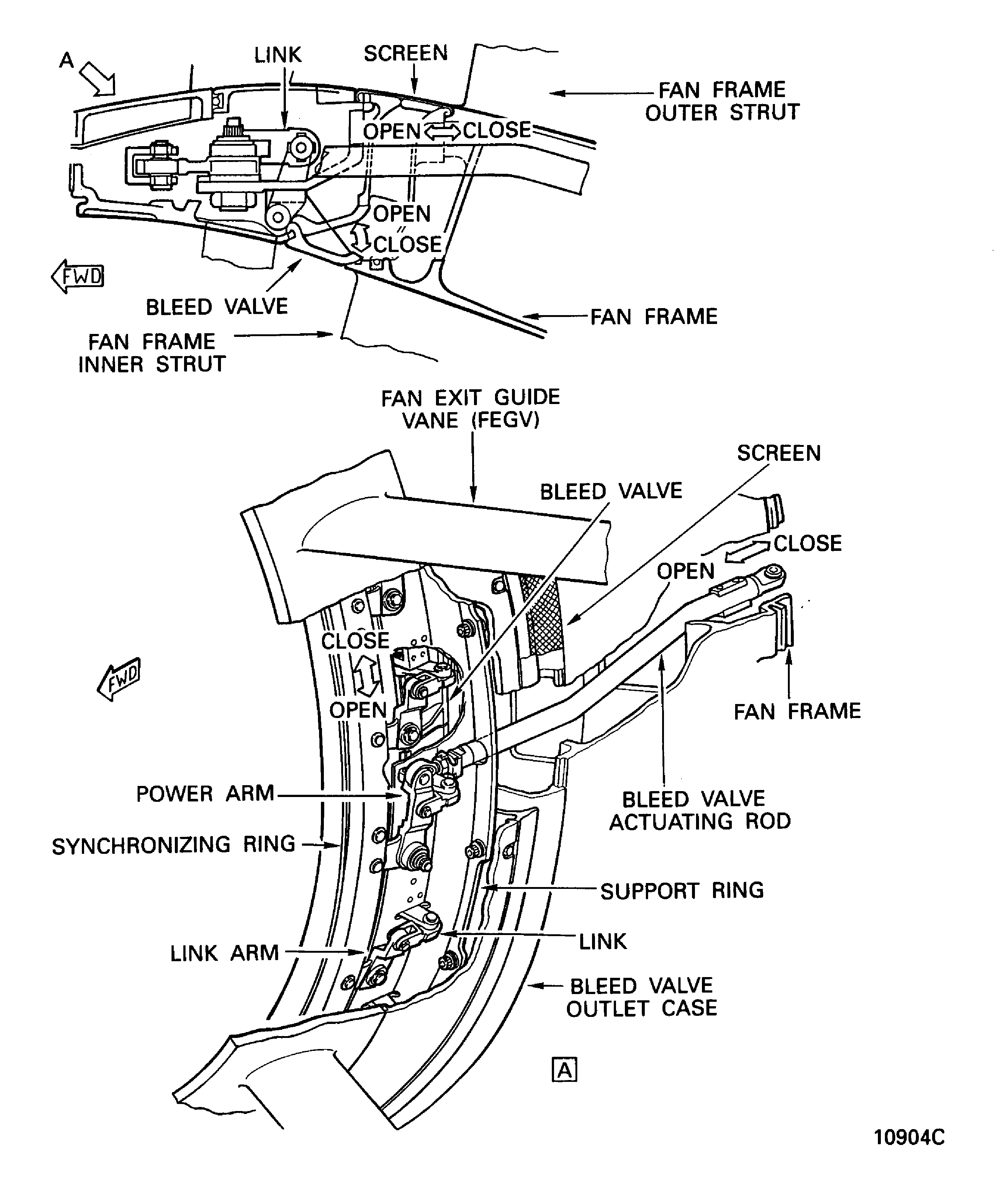

Figure: LPC Bleed Valve Linkage

LPC Bleed Valve Linkage

Figure: Install the Setting Fixture and Connect it to the Rod Assemblies

Sheet 1

Figure: Install the Setting Fixture and Connect it to the Rod Assemblies

Sheet 2

Figure: Install the Setting Fixture and Connect it to the Rod Assemblies

Sheet 3

Figure: Rigging Positions Record Sheet

Rigging Positions Record Sheet

Figure: Identification of the Configuration Standard, Pre and SEB 72-0233

Identification of the Configuration Standard, Pre and SEB 72-0233