Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 and Post SBE 72-0233

Common Information

TASK 72-00-32-200-002 LPC/Intermediate Case Module - Adjust The Rigging Position Of The LPC Bleed Linkage, Special Procedures-002 - SBE 72-0233

General

The TASK gives the procedures to adjust the rigging position of the LP compressor bleed linkage without engine disassembly.

This special procedures must only be done when the instruction to do so is given in TASK 72-00-32-200-001 (SPECIAL PROCEDURES).

SBE 72-0233: Rod adjustment feature relocation of LPC bleed rigging

Refer to the TASKS that follow for the other related procedures:

TASK 72-00-32-200-001 (SPECIAL PROCEDURES-001) - Examine the Rigging Position of the LPC Bleed Valve Linkage

TASK 72-32-00-030-008 (DISASSEMBLY-008) - Remove the LP Compressor (LPC) Bleed Duct, the Booster Stage Bleed Valve and Actuating Mechanism, LP Compressor Stage 2.5 Vane and the Right and Left Rod Assemblies

TASK 72-32-00-430-A00 (ASSEMBLY-008, CONFIG-001) - Install the LP Compressor Bleed Duct, the Booster Stage Bleed Valve and Actuating Mechanism and the Right and Left Rod Assemblies, Pre SBE 72-0233

TASK 72-32-00-430-008-B00 (ASSEMBLY-008, CONFIG-002) - Install the LP Compressor Bleed Duct, the Booster Stage Bleed Valve and Actuating Mechanism and the Right and Left Rod Assemblies, SBE 72-0233

Apply the approved penetrating oil before the removal of the threaded parts. Let the parts soak before removal. For the approved penetrating oil and procedures refer to the SPM TASK 70-64-00-640-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedures.

Discard all tab washers removed in this procedures.

To identify and install tab washers, refer to SPM TASK 70-42-03-400-501.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data is identified with the symbol * after the torque value.

Fig./item numbers in parentheses in the procedures agree with those used in the IPC. Only the primary Fig./item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig./item number.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1J12208 Puller | 0AM53 | IAE 1J12208 | 1 | |

| IAE 1J12209 Installation holder | 0AM53 | IAE 1J12209 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Safety Requirements

NONEProcedure

Make sure that the actuators and the brackets are removed from the fan frame. If they are installed, remove them. Refer to TASK 72-00-40-020-002-A00 (REMOVAL-002, CONFIG-001).

SUBTASK 72-00-32-210-093 Make Sure of the LPC Bleed Valve Actuating Master, Slave Actuators and the Brackets

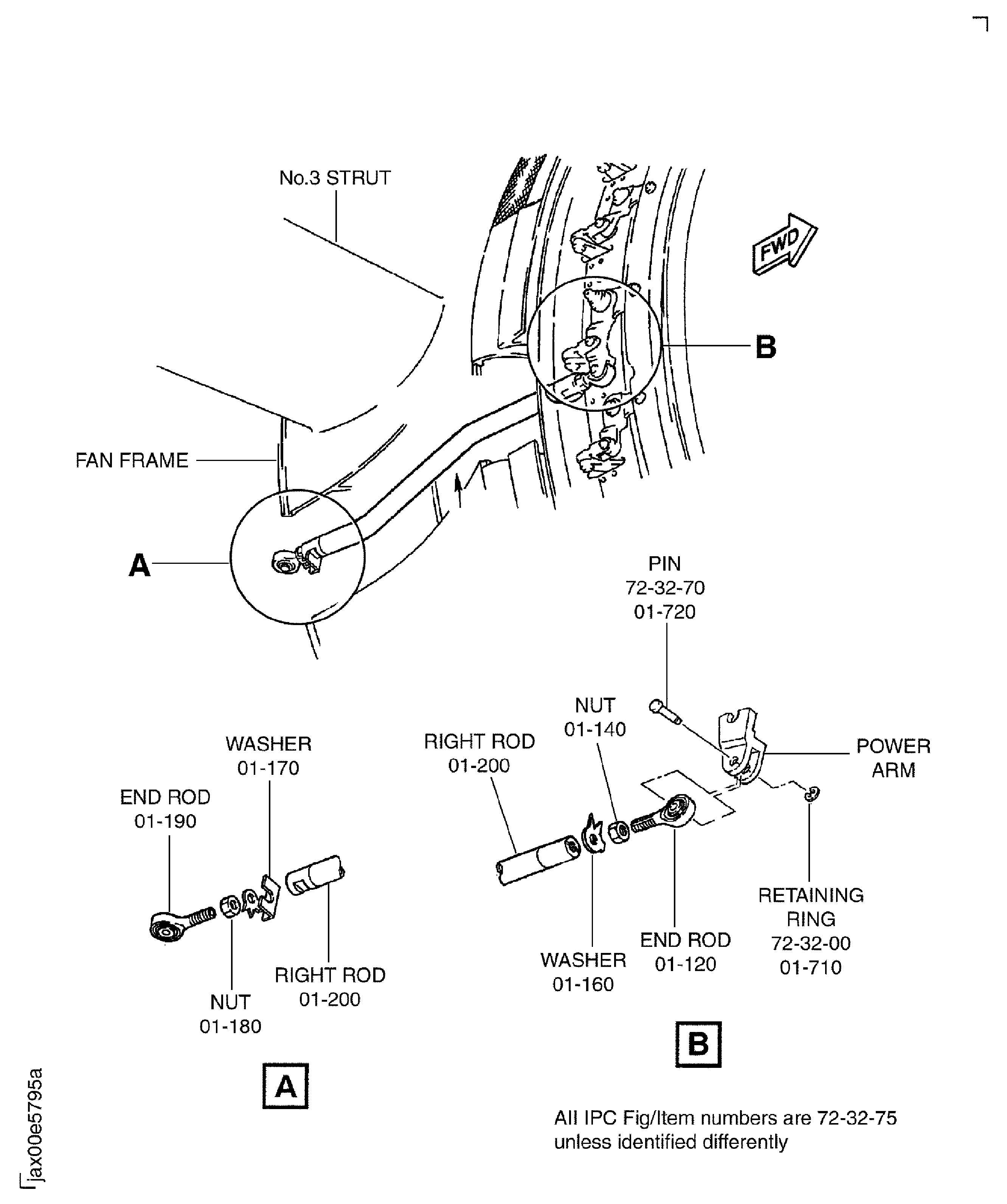

Bend back the tabs on each tab washer to release the jam nut ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-180) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-480).

Remove the rear rod end bearings from the right and left rod assemblies.

Remove the rear tab washers ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-170) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-470) from right and left rod assemblies. Discard the tab washers.

NOTE

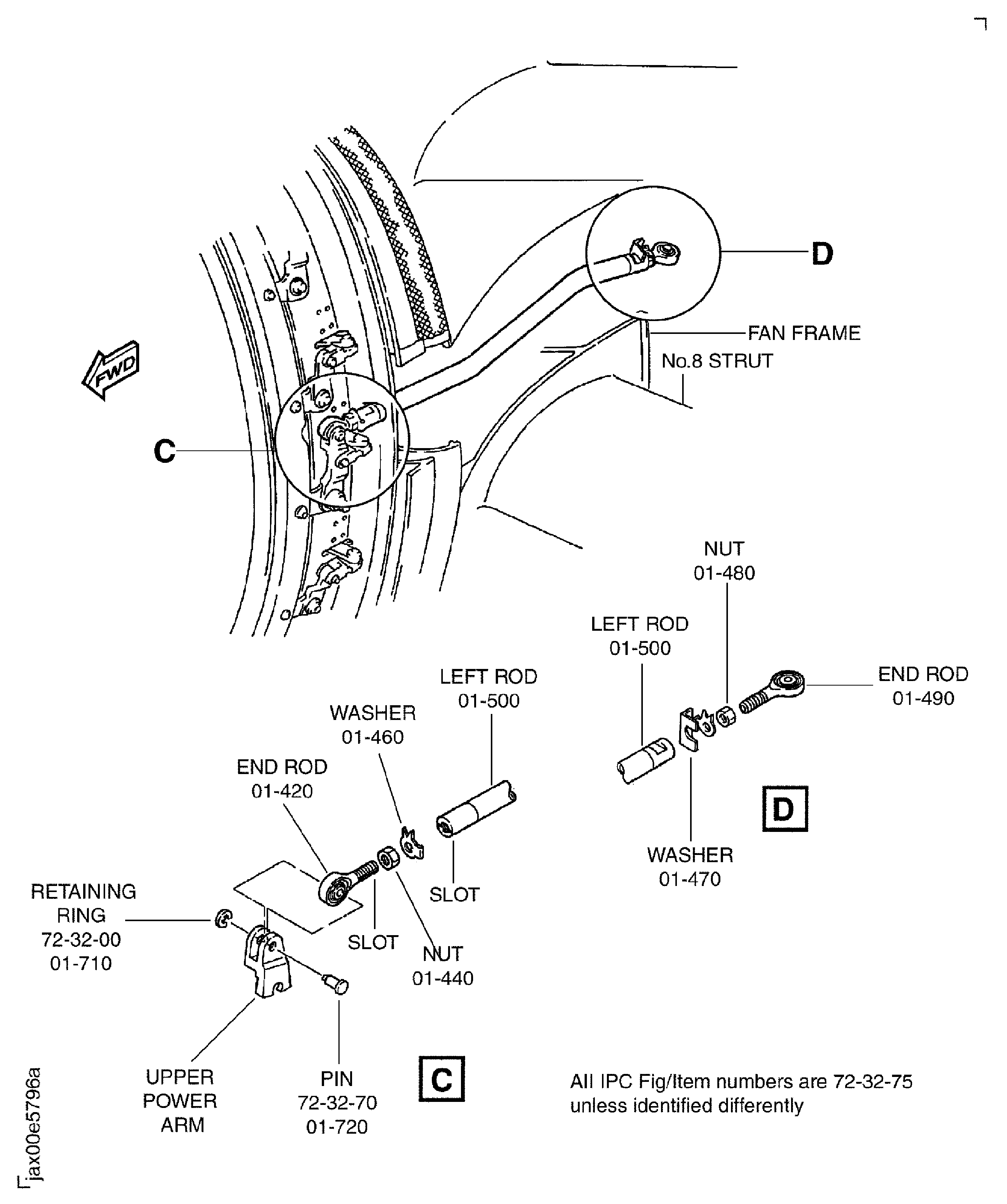

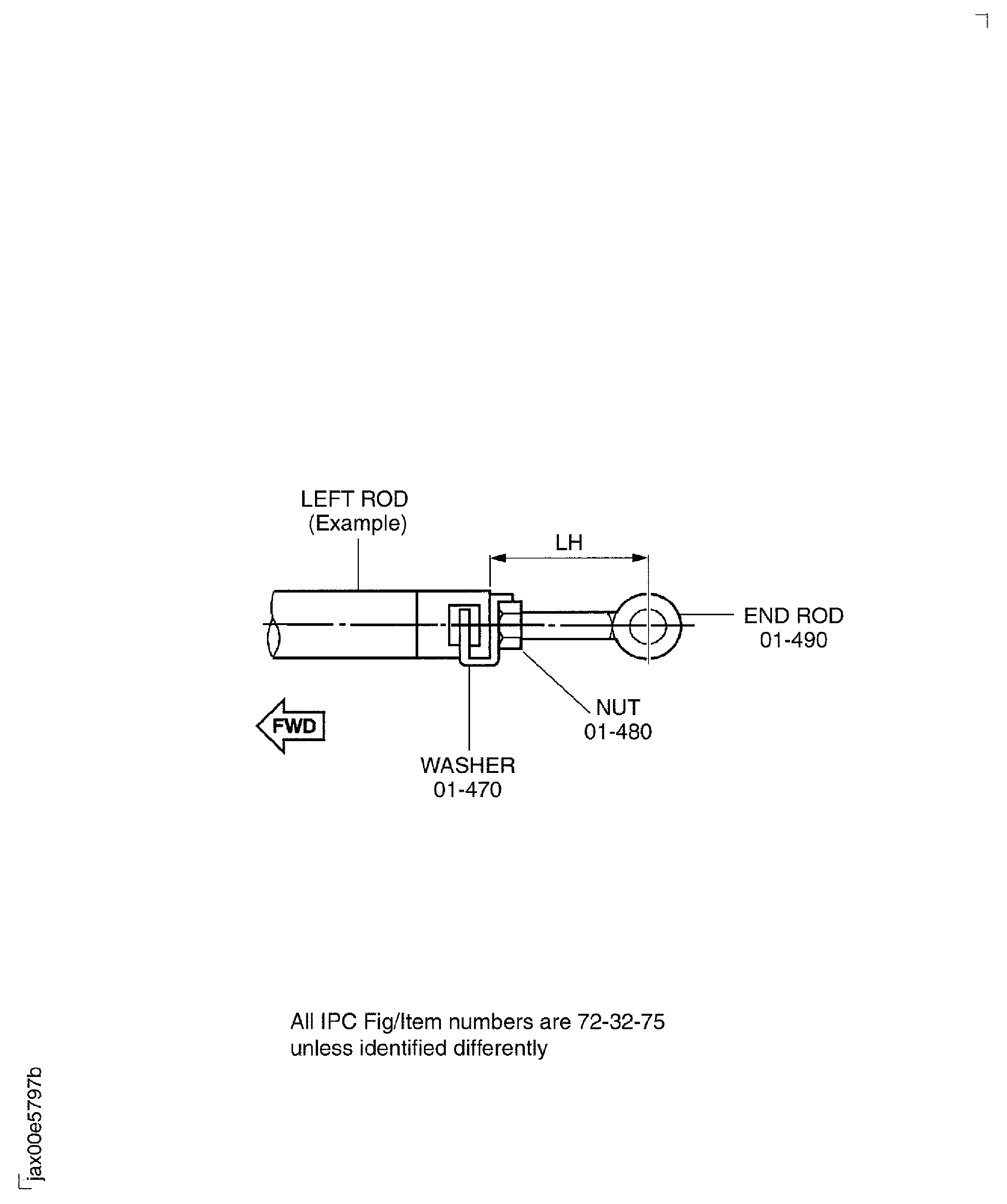

Set the installation length of the rod end bearing approximately 1.00 in. (25.4 mm).Do not bend the tabs of the rear washers.Tighten the nuts lightly.Install the jam nuts ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-180) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-480) and the new rear tab washers ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-170) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-470) to the right and left bearings with the nuts.

Install the rear rod end bearings ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-190) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-490) to the right and left rods ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-200) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-500).

SUBTASK 72-00-32-210-094 Replace the Tab Washers

Install the setting fixture. Refer to TASK 72-00-32-200-001 (Special Procedures).

SUBTASK 72-00-32-210-095 Install the Setting Fixture

Refer to Figure.

Measure the rigging position. Refer to TASK 72-00-32-200-001 (Special Procedures).

If the values ML and MR are within the limits, go to Step.

If the values ML and MR are not in the limits, go to Step.

SUBTASK 72-00-32-210-096 Examine the Rigging Position

Make sure of the measured rigging positions (values ML and MR) with the record sheet which were written in TASK 72-00-32-200-001 (Special Procedures), and identify the lengths to be increased/decreased.

Turn the rear rod end bearings ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-190) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-490) and adjust the lengths of the rod ends.

Adjust the lengths of the rear rod end bearings.

SUBTASK 72-00-32-210-097 Adjust the Lengths of the Rod Assemblies (Right-Hand and Left-hand)

Torque the jam nuts ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-180) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-480) to 119 to 131* lbf.in (13.42 to 14.82* Nm).

Bend the tabs of the tab washers ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-170) and ENGINE-BLEED VALVE ACTUATING ROD ASSEMBLY (72-32-75, 01-470) to safety the jam nuts.

Refer to the SPM TASK 70-42-03-400-501.

SUBTASK 72-00-32-210-098 Safety the Rear Rod End Bearings

Remove the setting fixture. Refer to TASK 72-00-32-200-001 (Special Procedures).

SUBTASK 72-00-32-210-099 Remove the Setting Fixture

Figure: The Right Rod Assembly and the Left Rod Assembly

Sheet 1

Figure: Install the Right and the Left Rod Assemblies

Sheet 2

Figure: Adjust the Rod End Bearing

Sheet 3

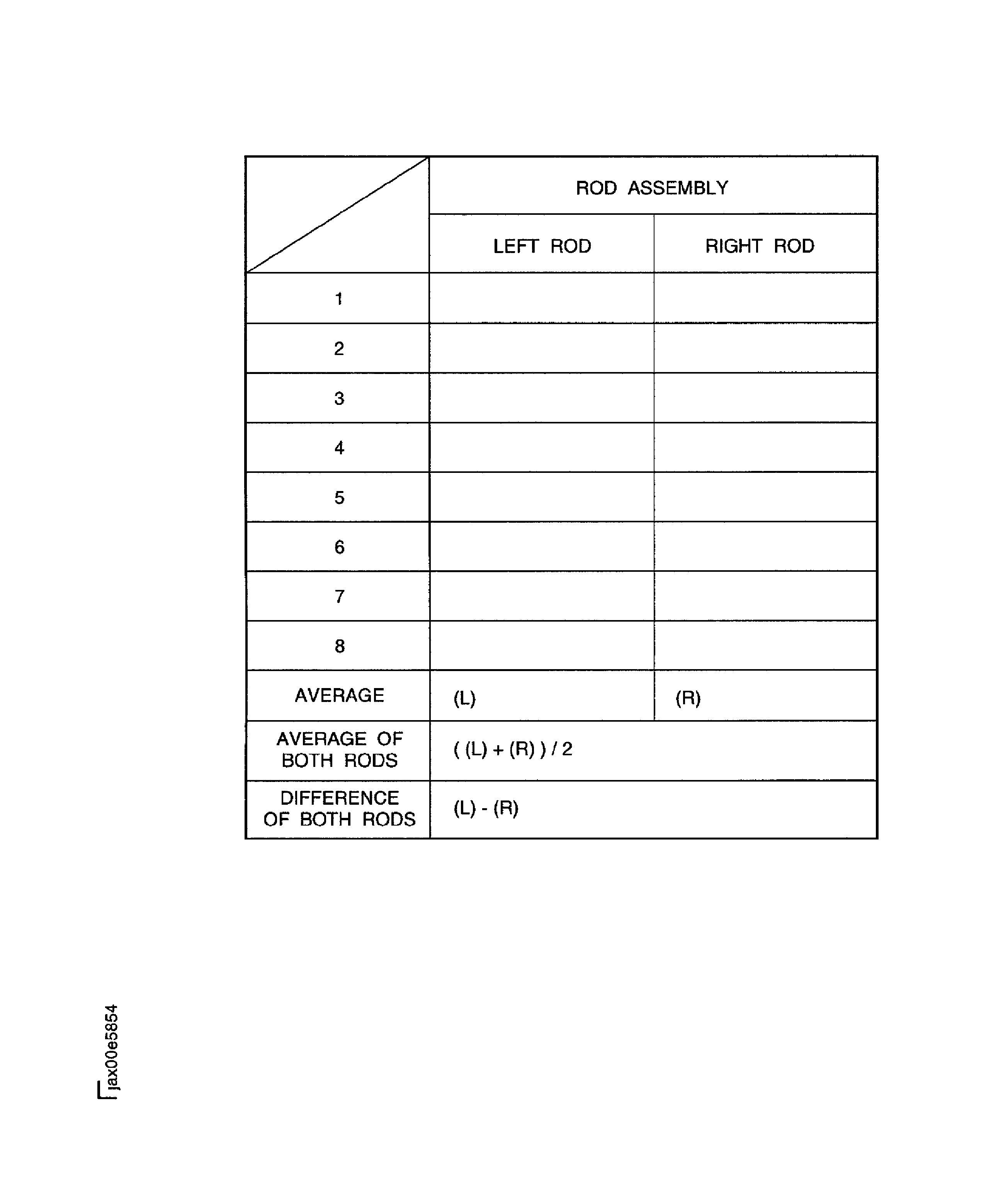

Figure: Rigging Position Record Sheet

Rigging Position Record Sheet