Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-85-300-022 Fan Case - Replace The Attrition Linings, Repair-022 (VRS1538)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-100 | 5W0124 |

01-100 | 5W0168 |

01-100 | 5W0171 |

01-100 | 5W0191 |

01-100 | 5W0192 |

01-100 | 5W0193 |

01-100 | 5W0206 |

01-100 | 5W0207 |

01-100 | 5W0208 |

01-100 | 5W0214 |

01-100 | 5W0215 |

01-100 | 5W0216 |

01-100 | 5W0306 |

General

This TASK gives the procedure for repair by replacement of the attrition linings. Attrition lining panel sections can be replaced individually. Partial replacement of a panel section by cutting is not permitted. If an area of a panel section is damaged beyond limits then the whole section must be replaced.

Throughout this repair cleanliness must be maintained. Dirt or grease on bonding surfaces will result in poor adhesion and unsatisfactory bonds. Clean cotton or polythene gloves must be worn by all personnel handling parts to be bonded. Handling must be kept to a minimum and components must not be handled on prepared surfaces.

Adhesive curing is accomplished at ambient temperature or above using mechanical clamping or a vacuum bag to secure the replacement linings.

To get good bonding, care must be taken on preparing properly abraded surfaces and proper use of adhesive.

Material of components

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Casing | - | Titanium alloy |

Attrition linings | - | Aluminum honeycomb |

Attrition linings | - | Glass reinforced composite |

Attrition linings | - | Filling compound |

Attrition linings | - | Non-metallic honeycomb |

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Air hammers | LOCAL | Air hammer | ||

| Air grinder | LOCAL | Air grinder | ||

| Flux chippers | LOCAL | Flux chippers | ||

| Vacuum bag material and sealant tape | LOCAL | Vacuum bag material and sealant tape | ||

| Hand tools | LOCAL | Tools, hand | ||

| Putty knife | LOCAL | Putty knife | ||

| Vacuum pump | LOCAL | Vacuum pump | ||

| Ultrasonic leak detector | LOCAL | Ultrasonic leak detector | ||

| Vacuum cleaner | LOCAL | Vacuum cleaner | ||

| Vacuum valve | LOCAL | Vacuum valve | ||

| Blasting equipment | LOCAL | Blasting equipment | ||

| IAE 3J13052 Fixture, bonding | 0AM53 | IAE 3J13052 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-097 LINT-FREE GLOVES | LOCAL | CoMat 02-097 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-100 GLOVES, LINT-FREE | LOCAL | CoMat 02-100 | ||

| CoMat 02-166 BREATHER CLOTH | LOCAL | CoMat 02-166 | ||

| CoMat 02-222 BAGGING FILM | LOCAL | CoMat 02-222 | ||

| CoMat 02-223 RELEASE FILM | LOCAL | CoMat 02-223 | ||

| CoMat 02-224 SILICONE ADHESIVE POLYESTERTAPE | LOCAL | CoMat 02-224 | ||

| CoMat 02-225A TAPE, VACUUM BAG SEALANT | 53309 | CoMat 02-225A | ||

| CoMat 02-334 POROUS RELEASE FILM | LOCAL | CoMat 02-334 | ||

| CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE | LOCAL | CoMat 05-003 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-185 POLISHING DISCS | K0993 | CoMat 05-185 | ||

| CoMat 05-186 CONDITIONING DISCS | LOCAL | CoMat 05-186 | ||

| CoMat 08-006 FILLER, TWO PACK | LOCAL | CoMat 08-006 | ||

| CoMat 08-154A SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER | LOCAL | CoMat 08-154A | ||

| CoMat 08-155 ADHESION PROMOTER | LOCAL | CoMat 08-155 | ||

| CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER | LOCAL | CoMat 08-154 | ||

| CoMat 02-225 TAPE, VACUUM BAG SEALANT | 85670 | CoMat 02-225 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Lining, A/O attrition | 5R0182 | AR | ||

| Lining, A/O attrition | 5R0274 | AR | ||

| Lining, A/O attrition | 5R0310 | AR |

Safety Requirements

NONEProcedure

Prepare the bonding surface, refer to Figure.

Refer to Figure.

CAUTION

DO NOT USE POWERED TOOLS WITH STEEL CHISEL OR SIMILAR BITS.

CAUTION

THE FAN CASE IS MADE FROM TITANIUM ALLOY AND IS THIN IN SOME AREAS. IF YOU HIT THE FAN CASE WITH A CHISEL OR SCRAPER YOU CAN MAKE IT UNSERVICEABLE.

CAUTION

YOU MUST USE THE CHISEL, SHARP BLADE OR SCRAPER IN A CIRCUMFERENTIAL DIRECTION TO PREVENT THE EDGES OF THE BLADE SCORING THE FAN CASE.

CAUTION

YOU MUST ALWAYS TRY TO POINT THE CHISEL OR SHARP BLADE PARALLEL WITH THE SURFACE OF THE FAN CASE.

CAUTION

DO NOT OPERATE WITHOUT SAFETY GOGGLES AND OTHER GUARDS EQUIPMENT. FLYING PARTICLES CAN CAUSE INJURY.Remove most of the damaged linings.

Use CoMat 05-185 POLISHING DISCS or CoMat 05-186 CONDITIONING DISCS with air grinder to the case.

Make sure new replacement linings can be placed in the position shown in Figure.

CAUTION

PREVENT TOO MUCH SURFACE ABRASION OF THE FAN CASE MATERIAL. SURFACE FINISH USING ABRASIVE BLASTING IS NECESSARY. THIS WILL GIVE THE BEST BONDING RESULTS.

CAUTION

HAND DRESSING TOOLS ARE NOT TO BE USED AT THE SAME LOCATION, DO NOT DWELL IN ONE AREA OR ANY AREA.Remove the remaining unwanted material and adhesive on the case.

Refer to the SPM TASK 70-11-26-300-503.

Degrease the repair area.

Any nicks, dents, scratches and gouges, repair the damage.

If necessary, do Repair, VRS1554, TASK 72-32-85-300-016 (REPAIR-016).

WARNING

ALWAYS MAKE SURE THAT THERE IS SUFFICIENT VENTILATION IN THE WORK AREA.

WARNING

EYE PROTECTION MUST ALWAYS BE USED.

WARNING

DO NOT LET THE SOLVENT CLEANER OR ITS VAPOR TOUCH THE EYES OR SKIN.

WARNING

PROTECTIVE CLOTHING AND FACE MASKS MUST ALWAYS BE USED.

WARNING

ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLNG, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS IN TO CONSIDERATION.Inspect the repair area.

Mask off all areas except the bonding area with CoMat 02-224 SILICONE ADHESIVE POLYESTERTAPE and/or other applicable procedures.

Make the bonding area.

Use CoMat 05-003 ABRASIVE MEDIUM ALUMINUM OXIDE, 120/220 GRADE with the blasting equipment.

Remove the glossy surface from the repair area of the fan case.

Ensure that a constant matt surface is maintained.

Operate vacuum sand blaster at approximately 70 to 100 psi (480 to 690 kPa).

If you use the pressure blaster to remove the glossy surface from the repair area.

Optimum distance between the nozzle and the repair surface is 5 to 15 in. (127 to 381 mm).

Do the procedure given in the SPM TASK 70-36-02-360-501.

Do not use abrasive paper.

WARNING

A PRESSURIZED AIR STREAM CAN CAUSE INJURY. WEAR SAFETY GOGGLES AND PROTECTIVE CLOTHING.Make the repair area rough.

Refer to the SPM TASK 70-36-02-360-501.

CAUTION

DO NOT USE TAP WATER AND MINERAL WATER. YOU MUST USE DISTILLED OR DEIONIZED WATER DURING THE WATER-BREAK INSPECTION.Water-break inspection of the repair area.

SUBTASK 72-32-85-350-087 Prepare the Bonding Surfaces

Refer to the SPM TASK 70-11-26-300-503.

WARNING

DO NOT GET CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GOGGLES AND A FACE MASK. USE THE FLUID IN A WELL VENTILATED AREA. DO NOT BREATHE THE VAPOR. IF YOU GET THE CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.NOTE

Always pour cleaning fluid on the cloth to avoid contaminating the cleaning fluid supply. Wash one small area at a time.It is important that the surface is dried with a second clean cloth prior to the cleaning fluid evaporating to prevent the redeposition of contaminants on the fan case surface.Remove all grease from the linings and casings.

NOTE

If primed surface contaminated or bonding is not accomplished within eight hours after application of the adhesion promoter, repeat priming procedure.Apply a thin coat of CoMat 08-155 ADHESION PROMOTER to the cleaned surface by brush or clean gauze and allow to dry for approximately 30 minutes at room temperature.

WARNING

YOU MUST FIND AND OBEY THE MANUFACTURER'S HEALTH AND SAFETY DATA FOR THE MATERIAL (MSDS). YOU MUST ALSO REFER TO LOCAL REGULATIONS TO MAKE SURE THAT THE PROCEDURES ARE DONE SAFELY. IF YOU DO NOT DO THIS, AN INJURY OR ENVIRONMENTAL DAMAGE CAN OCCUR.Apply the primer.

Use CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER. Weigh out 100 parts of base compound (white compound) and 18.5 parts of curing compound (black compound). When using SEMKIT form sealant, prepare either by hand, or using a mixing machine as described in the manufacturer's leaflet. Mix the two parts by kneading until the color of compound is constant quality. No streaks permitted.

WARNING

YOU MUST FIND AND OBEY THE MANUFACTURER'S HEALTH AND SAFETY DATA FOR THE MATERIAL (MSDS). YOU MUST ALSO REFER TO LOCAL REGULATIONS TO MAKE SURE THAT THE PROCEDURES ARE DONE SAFELY. IF YOU SO NOT DO THIS, AN INJURY OR ENVIRONMENTAL DAMAGE CAN OCCUR.

CAUTION

DO NOT USE CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER SEALANT (PR2001B-1/2). THIS MATERIAL IS 30 MINUTES APPLICATION LIFE TYPE SEALANT. THIS BONDING STEP IS ESTIMATED TO TAKE MORE THAN 1 HOUR WHEN DONE BY SKILLED MECHANICS FAMILIARIZED WITH THIS APPLICATION PROCEDURE.NOTE

You must use the plastic gloves, during preparation and use of the sealant, to prevent contamination of the skin.Application life is dependent upon ambient environmental conditions. Increases in temperature and low humidity will shorten application time. Conversely, lower temperatures and high humidity will increase application life. For the examples, the life of the mixed sealant is approximately two hours, at 77 deg F (25 deg C) and 50 percent relative humidity.Prepare the sealant.

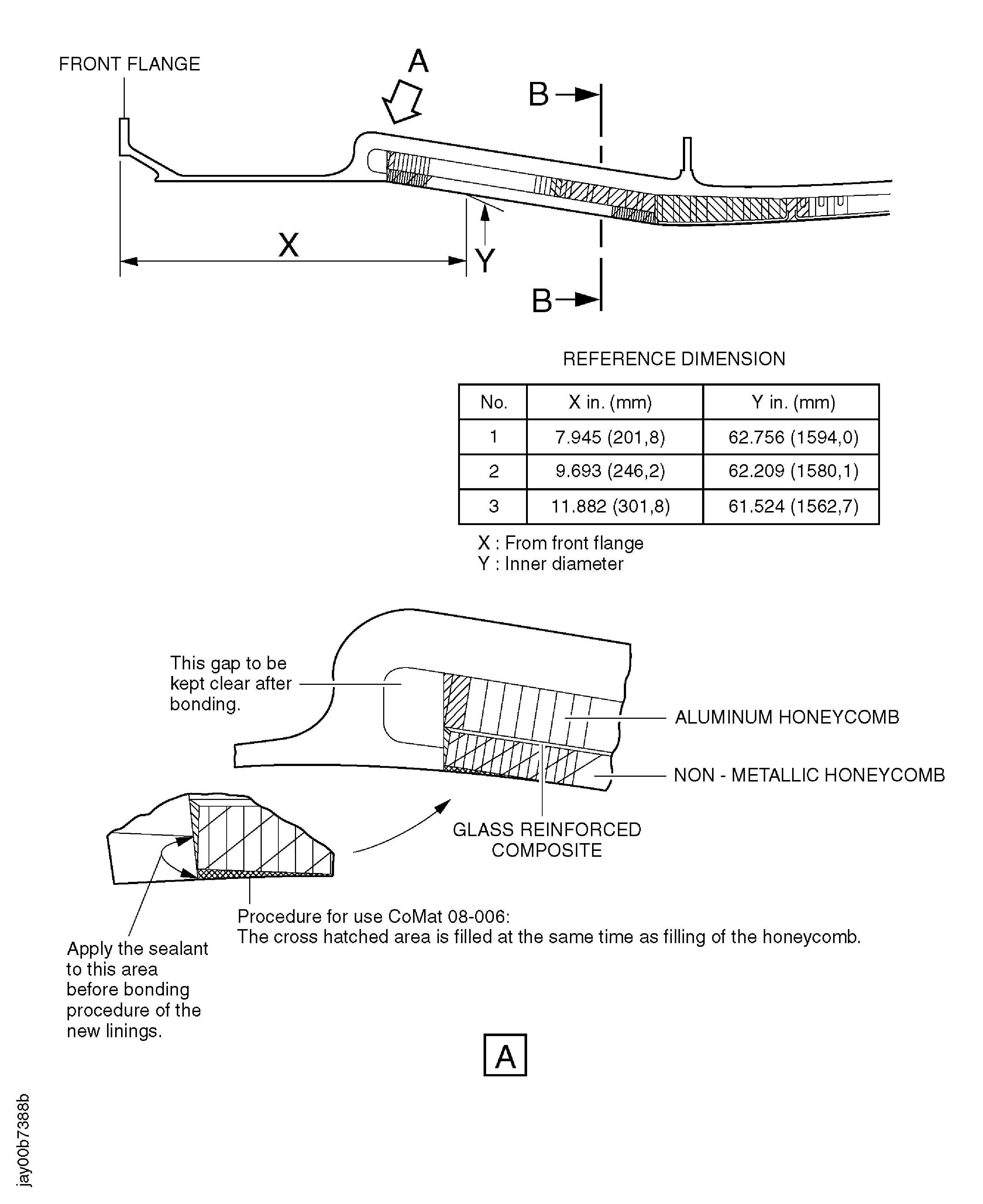

Use a putty knife or airpowered sealant gun to apply the sealant to mating surfaces of both components to a thickness of between 0.079 and 0.118 in. (2.0 and 3.0 mm) and between 0.015 and 0.024 in. (0.38 and 0.61 mm), refer to Figure.

NOTE

In order to ensure that front attrition area of the panel honeycomb has contact with the surface of the sealant it is necessary to apply the sealant to the maximum specified thickness 0.118 in. (3.0 mm). The sealant layer thickness must not fall below the specified minimum 0.079 in. (2.0 mm), refer to Figure.In order to ensure that rear attrition area (filling honeycomb area) of the panel honeycomb has contact with the surface of the sealant it is necessary to apply the sealant to the maximum specified thickness 0.024 in. (0.61 mm). The sealant layer thickness must not fall below the specified minimum 0.015 in. (0.38 mm), refer to Figure.For the best results apply a thin layer of the sealant for rear attrition area but satisfactory results can be achieved with layer as much as 0.02 in. (0.5 mm) thick (for filling honeycomb area only, refer to Figure).Wear (CoMat 02-097 LINT-FREE GLOVES) or (CoMat 02-100 GLOVES, LINT-FREE) when you touch the parts.Apply the sealant to the bonding surfaces.

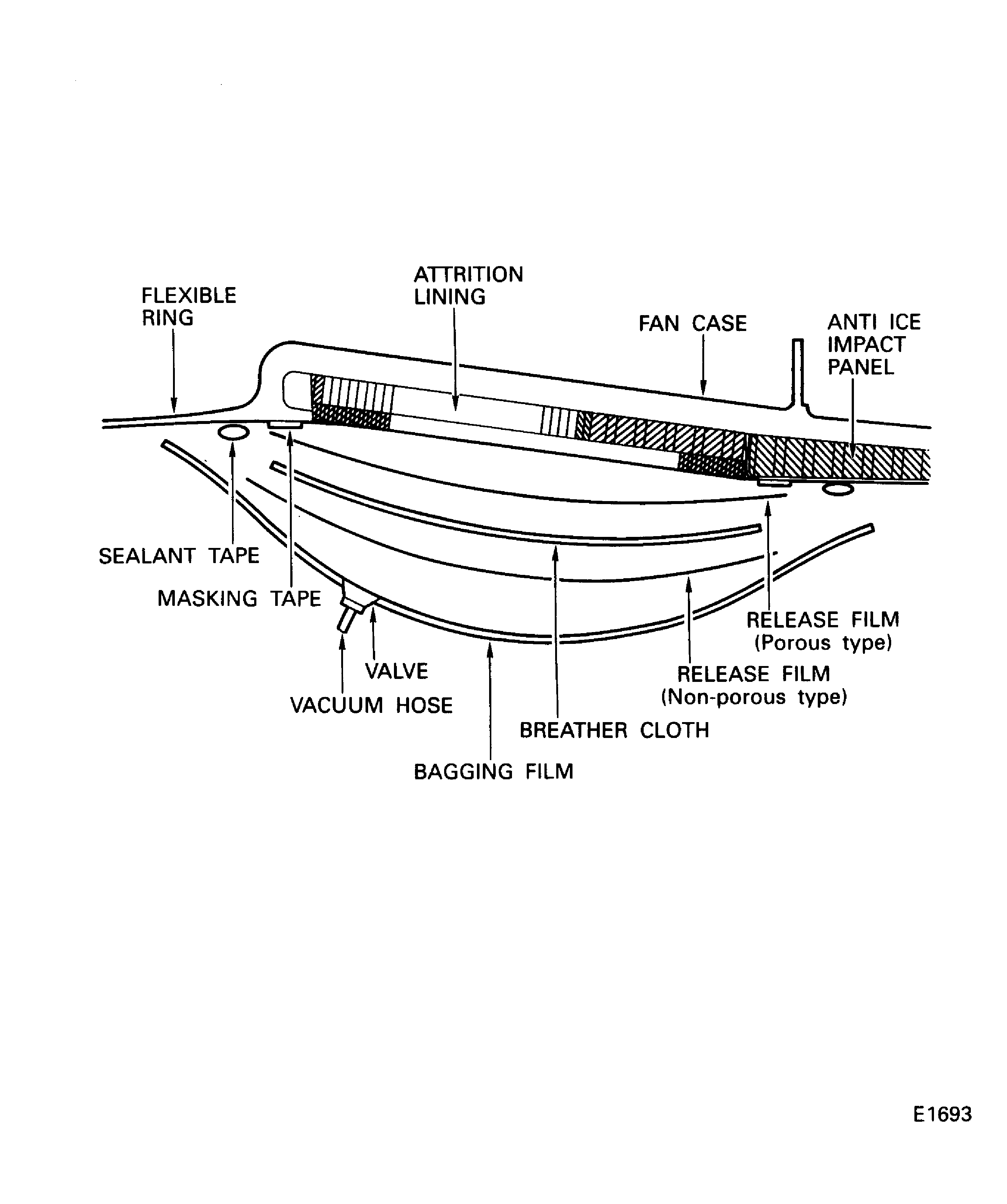

Cover the replacement linings with sheet of CoMat 02-334 POROUS RELEASE FILM that is 3.00in. (76.2 mm) longer than each end of the linings, 3 plies of CoMat 02-166 BREATHER CLOTH and one ply of CoMat 02-223 RELEASE FILM.

Spread over them a sheet of CoMat 02-222 BAGGING FILM between the area of the metal surface of the fan case and the anti-ice impact panels.

Seal the edges of the bagging film to the metal surface of the fan case and the anti-ice impact panels with CoMat 02-225 TAPE, VACUUM BAG SEALANT.

Make-up an annular vacuum bag.

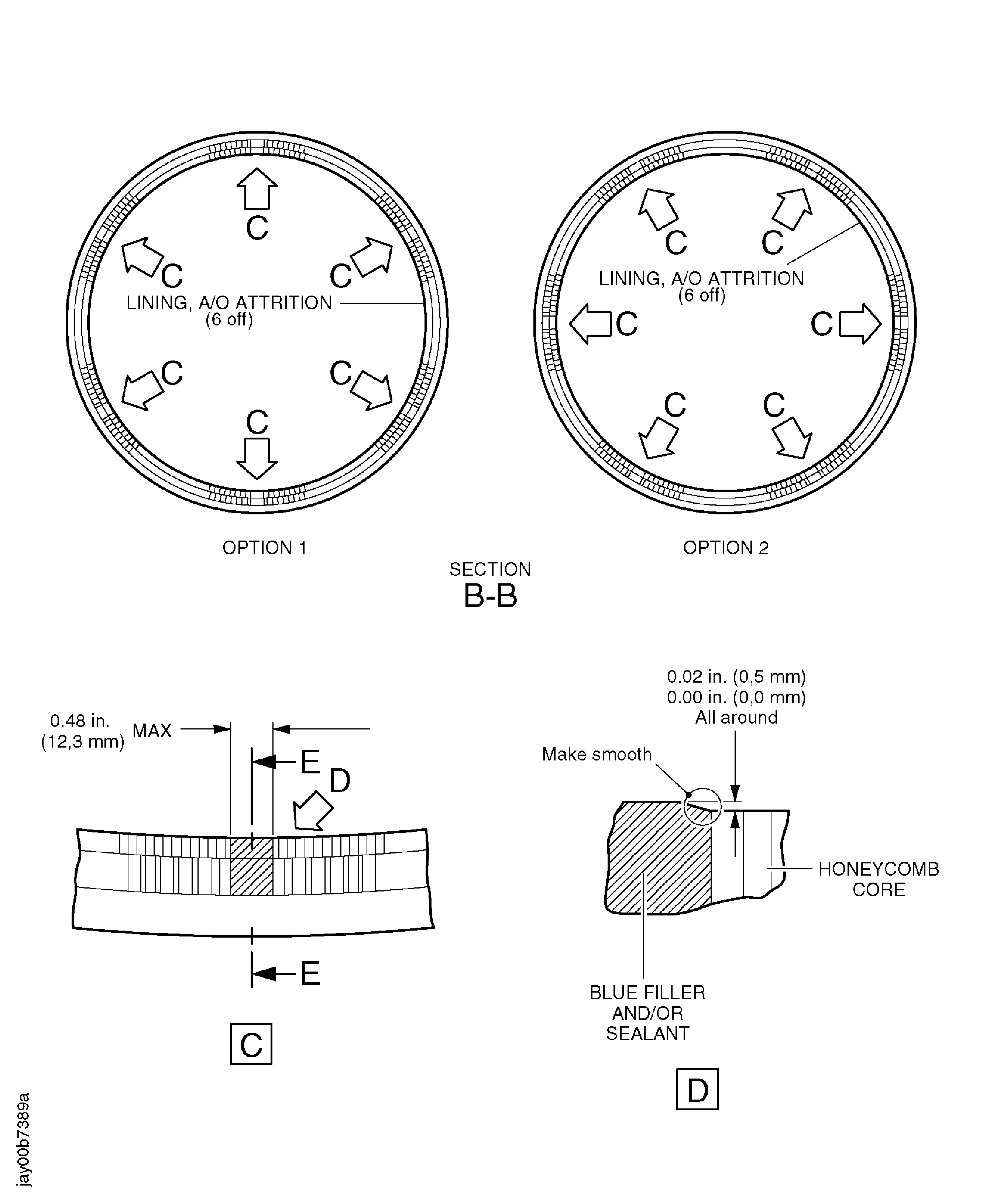

Secure replacement linings, refer to Figure.

Allow the CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER to cure for nine hours at ambient temperature 77 deg F to 95 deg F (25 deg C to 35 deg C).

Cure may be hastened by applying heat. CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER can obtain a serviceable cure hardness after four hours at 113 deg F (45 deg C).

If the remaining sealant material after repair exceeds the limit, dress the sealant material with CoMat 05-020 WATERPROOF SILICON CARBIDE, if necessary, refer to Figure and Figure.

Cure the sealant.

SUBTASK 72-32-85-360-070-001 Bond the Replacement Linings (Vacuum Bag Method)

Refer to the SPM TASK 70-11-26-300-503.

WARNING

DO NOT GET CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GOGGLES AND A FACE MASK. USE THE FLUID IN A WELL VENTILATED AREA. DO NOT BREATHE THE VAPOR. IF YOU GET THE CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.NOTE

Always pour cleaning fluid on the cloth to avoid contaminating the cleaning fluid supply. Wash one small area at a time.It is important that the surface is dried with a second clean cloth prior to the cleaning fluid evaporating to prevent the redeposition of contaminants on the fan case surface.Remove all grease from the linings and casing.

Apply a thin coat of CoMat 08-155 ADHESION PROMOTER to the cleaned surface by brush or clean gauze and allow to dry for approximately 30 minutes at room temperature.

WARNING

YOU MUST FIND AND OBEY THE MANUFACTURER'S HEALTH AND SAFETY DATA FOR THE MATERIAL (MSDS). YOU MUST ALSO REFER TO LOCAL REGULATIONS TO MAKE SURE THAT THE PROCEDURES ARE DONE SAFELY. IF YOU DO NOT DO THIS, AN INJURY OR ENVIRONMENTAL DAMAGE CAN OCCUR.NOTE

If primed surface contaminated or bonding is not accomplished within eight hours after application of the adhesion promoter, repeat priming procedure.Apply the primer.

Use CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER. Weigh out 100 parts of base compound (white compound) and 18.5 parts of curing compound (black compound). When using SEMKIT form sealant, prepare either by hand, or using a mixing machine as described in the manufacturer's leaflet. Mix the two parts by kneading until the color of compound is constant quality. No streaks permitted.

WARNING

YOU MUST FIND AND OBEY THE MANUFACTURER'S HEALTH AND SAFETY DATA FOR THE MATERIAL (MSDS). YOU MUST ALSO REFER TO LOCAL REGULATIONS TO MAKE SURE THAT THE PROCEDURES ARE DONE SAFELY. IF YOU DO NOT DO THIS, AN INJURY OR ENVIRONMENTAL DAMAGE CAN OCCUR.

CAUTION

DO NOT USE CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER SEALANT (PR2001B-1/2). THIS MATERIAL IS 30 MINUTES APPLICATION LIFE TYPE SEALANT. THIS BONDING STEP IS ESTIMATED TO TAKE MORE THAN 1 HOUR WHEN DONE BY SKILLED MECHANICS FAMILIARIZED WITH THIS APPLICATION PROCEDURE.NOTE

You must use the plastic gloves, during preparation and use of the sealant, to prevent contamination of the skin.Application life is dependent upon ambient environmental conditions. Increases in temperature and low humidity will shorten application time. Conversely, lower temperatures and high humidity will increase application life. For the examples, the life of the mixed sealant is approximately two hours, at 77 deg F (25 deg C) and 50 percent relative humidity.Prepare the sealant.

Use a putty knife or airpowered sealant gun to apply the sealant to mating surfaces of both components to a thickness of between 0.079 and 0.118 in. (2.0 and 3.0 mm) and between 0.015 and 0.024 in. (0.38 and 0.61 mm), refer to Figure.

NOTE

In order to ensure that front attrition area of the panel honeycomb has contact with the surface of the sealant it is necessary to apply the sealant to the maximum specified thickness 0.118 in. (3.0 mm). The sealant layer thickness must not fall below the specified minimum 0.079 in. (2.0 mm), refer to Figure.In order to ensure that rear attrition area (filling honeycomb area) of the panel honeycomb has contact with the surface of the sealant it is necessary to apply the sealant to the maximum specified thickness 0.024 in. (0.61 mm). The sealant layer thickness must not fall below the specified minimum 0.015 in. (0.38 mm), refer to Figure.For the best results apply a thin layer of the sealant for rear attrition area but satisfactory results can be achieved with layers as much as 0.02 in. (0.5 mm) thick (for filling honeycomb area only, refer to Figure.Wear (CoMat 02-097 LINT-FREE GLOVES) or (CoMat 02-100 GLOVES, LINT-FREE) when you touch the parts.Apply the sealant to the bonding surfaces.

Use IAE 3J13052 Fixture, bonding 1 off.

Secure the replacement linings.

Cure may be hastened by applying heat. CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER can obtain a serviceable cure hardness after four hours at 113 deg F (45 deg C).

If the remaining sealant material around the repair exceeds the dimensional limits, dress the sealant material with CoMat 05-020 WATERPROOF SILICON CARBIDE, if necessary. Refer to Figure and Figure.

Allow the CoMat 08-154 SEALANT, TWO PART, EPOXY-CURED POLYTHIOETHER to cure for nine hours at ambient temperature 77 deg F to 95 deg F (25 deg C to 35 deg C).

NOTE

Make sure that you monitor the ambient temperature of the sealant and work area with suitable instruments, across all of the lining.Make sure the full cure time is used and correct temperature maintained.If the curing process is applied for 48 hours at 50 deg F (10 deg C) or more the necessary strength has been secured, regardless of the level of humidity.Cure the sealant.

SUBTASK 72-32-85-360-070-002 Bond the Replacement Linings

Refer to the SPM TASK 70-36-02-360-501.

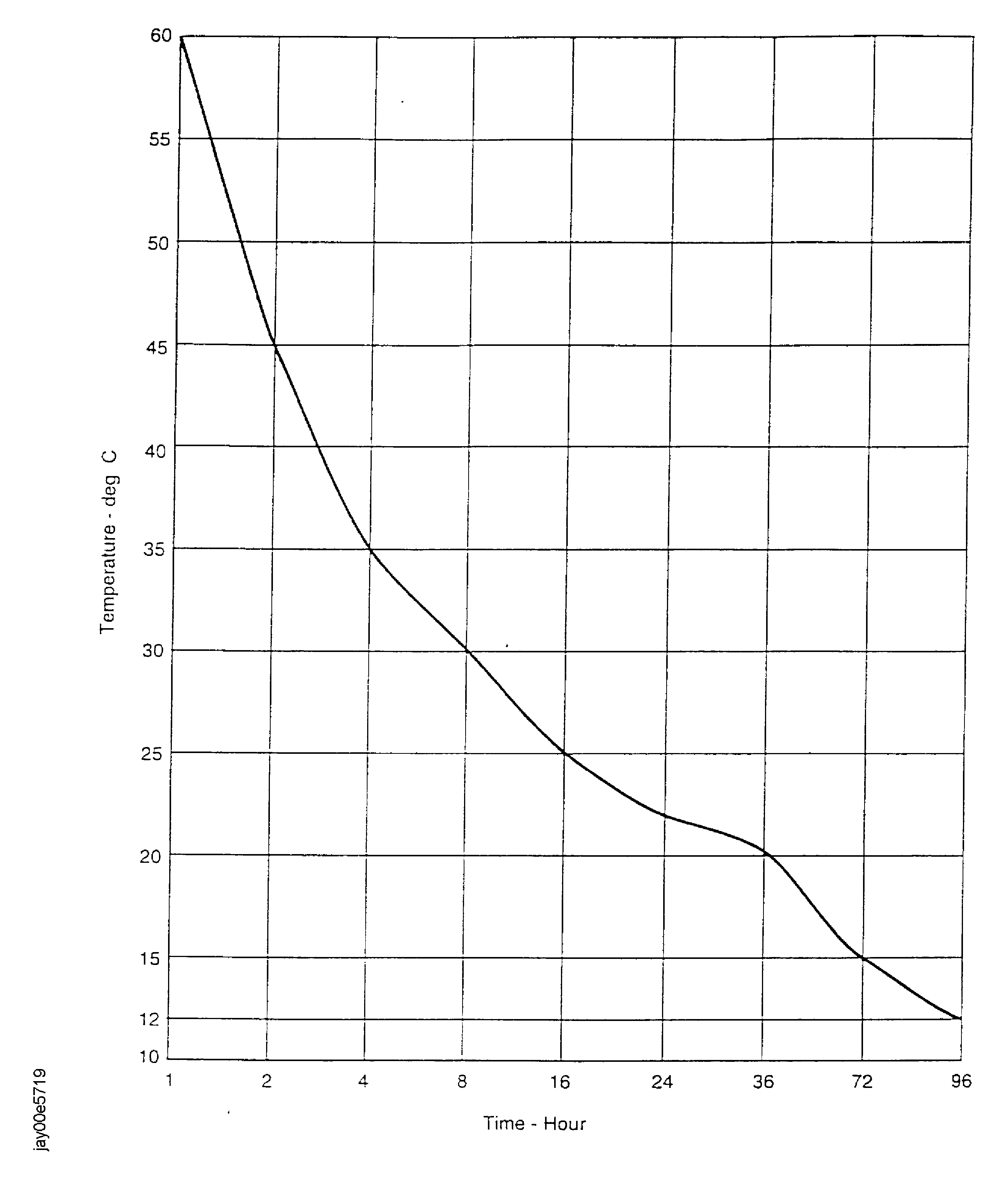

The cure time given in Figure, you can find the cure time and temperature.

Cure the filler.

SUBTASK 72-32-85-360-071 Fill the Lining Honeycomb and Gap around the Replacement Linings

Refer to Figure.

Ensure aerodynamic smoothing is produced.

WARNING

DO NOT INHALE THE DUST. USE A BREATHING PROTECTION MASK DURING THIS OPERATION.

CAUTION

THE MAXIMUM TEMPERATURE WHICH CAN BE USED TO CURE THE FILLER IS 140 DEG F (60 DEG C).

CAUTION

THE MINIMUM CURE TIME IS ONE HOUR. DO NOT CURE AT A TEMPERATURE LESS THAN 54 DEG F (12 DEG C).NOTE

Make sure the full cure time is used and correct temperature maintained.Abrade the lining to produce the required profile, refer to Figure.

SUBTASK 72-32-85-350-130 Dress the Lining

Make a permanent mark by the procedures in the SPM TASK 70-09-00-400-501.

Mark VRS1538 adjacent to the part number.

SUBTASK 72-32-85-350-153 Identify the Repair

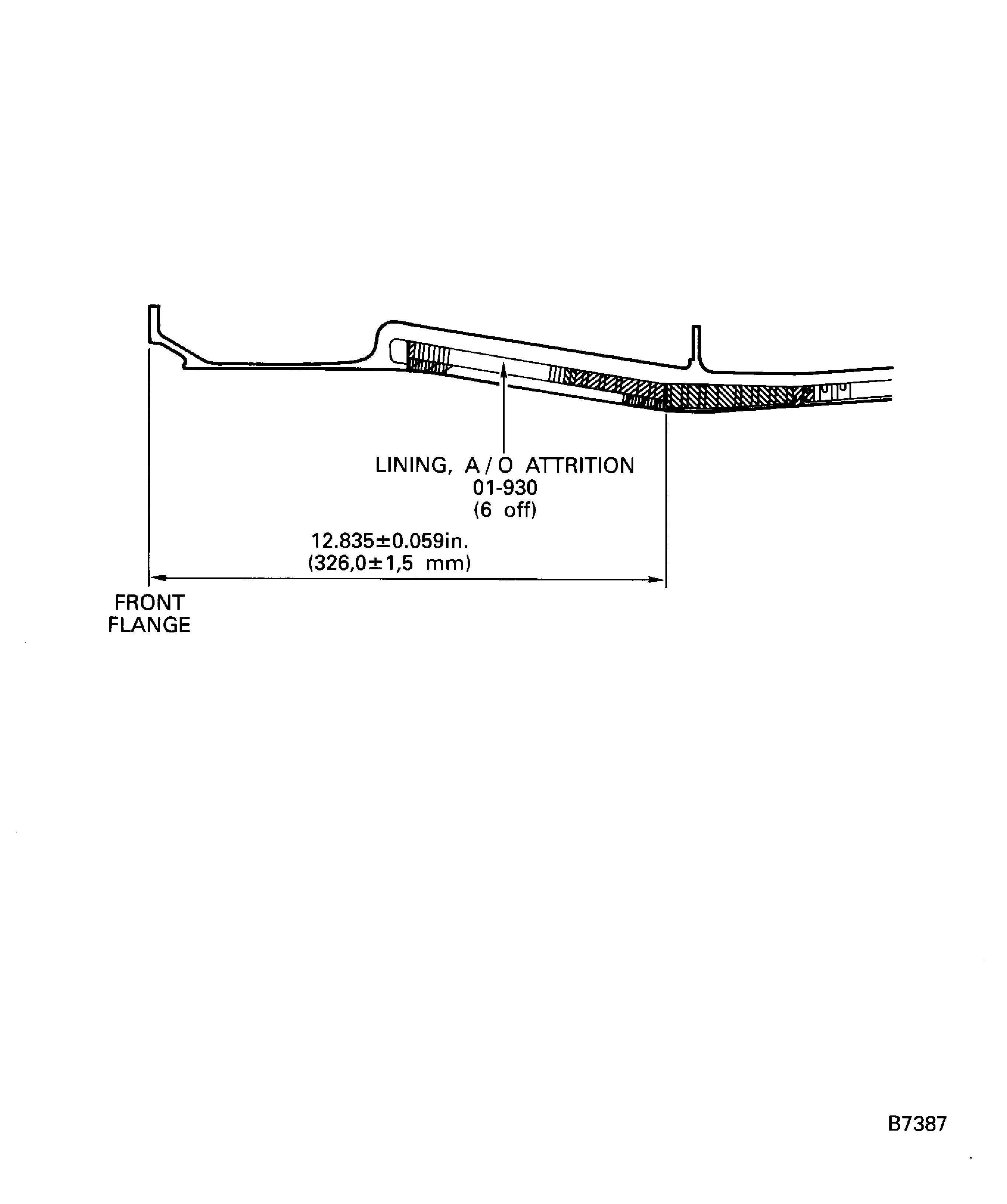

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimension

Repair Details and Dimension

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions