Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-45-10-220-001-A00 HPT Stage 1 Rotor Assembly - Examine, Inspection-001

General

The word "reject" is used after an interface inspection statement to show that a higher level inspection and possible repair to the damaged part is necessary.

Do the higher level inspection procedure as found in the applicable Chapter/Section/Subject of this manual on the damaged part(s). It is not necessary to do the higher level inspection on parts that are serviceable to the interface inspection standard.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

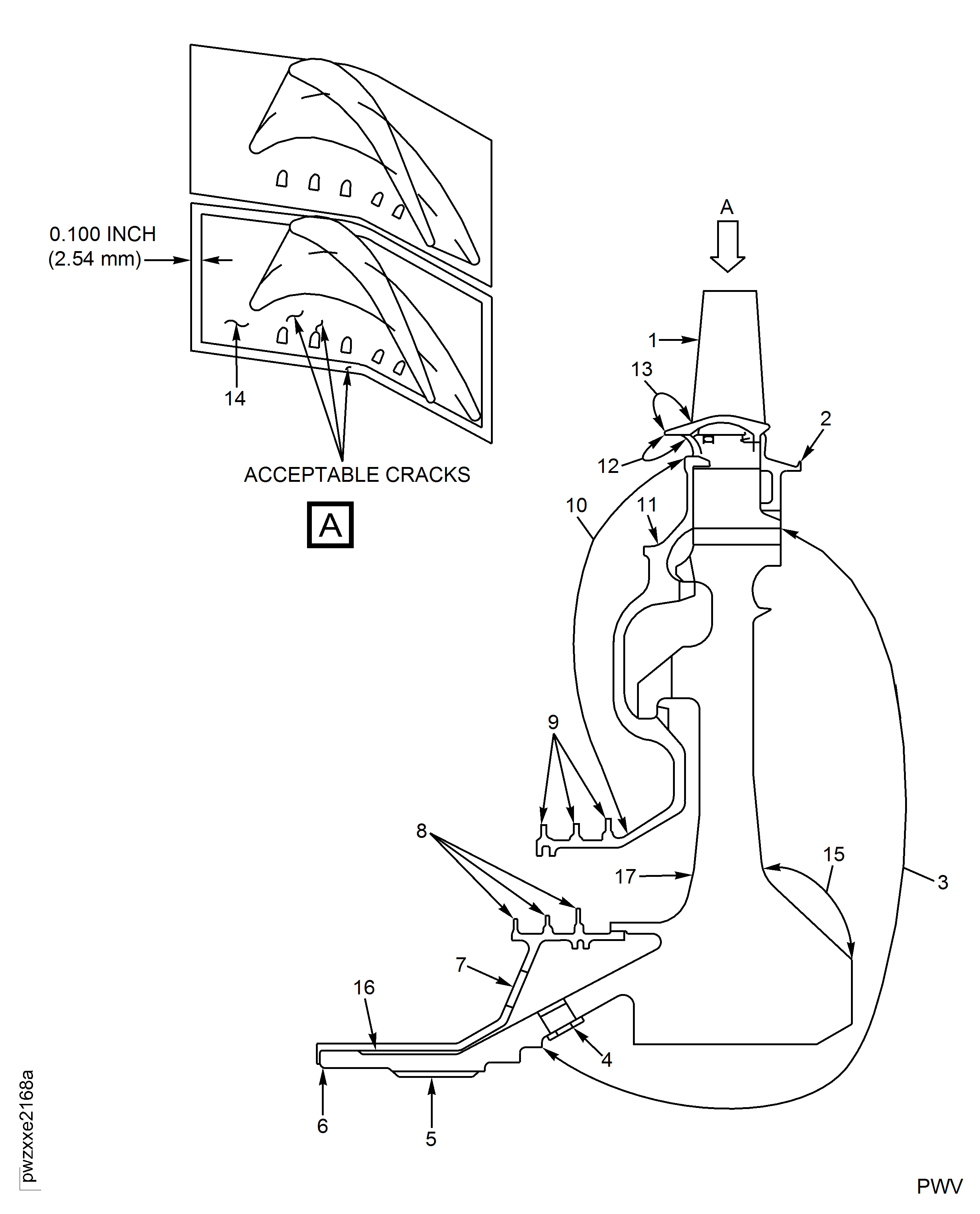

Refer to Figure.

Do inspection of HPT for possible oil ignition event. Refer to TASK 72-45-00-200-801. Report all findings to IAE Technical Services.

Soot or oil.

Examine the rotor assembly at Locations 3, 4, 7, 10, 16 and 17 for soot and oil.

SUBTASK 72-45-10-220-099 Examine the Stage 1 HPT Rotor Assembly for Soot and Oil

CAUTION

MAKE SURE THAT YOU DO THIS INSPECTION BEFORE YOU CLEAN THE PART OR CLEANING PROCEDURE WILL REMOVE THE INDICATION OF SOOT AND OIL.Reject

NOTE

The tip of the trailing edge may have a blend no more than 0.060 in. (0.24 mm) deep, extending from the tip to the middle of the third trailing edge window. Reference Repair, VRS3685, TASK 72-45-14-300-021. This condition is acceptable.

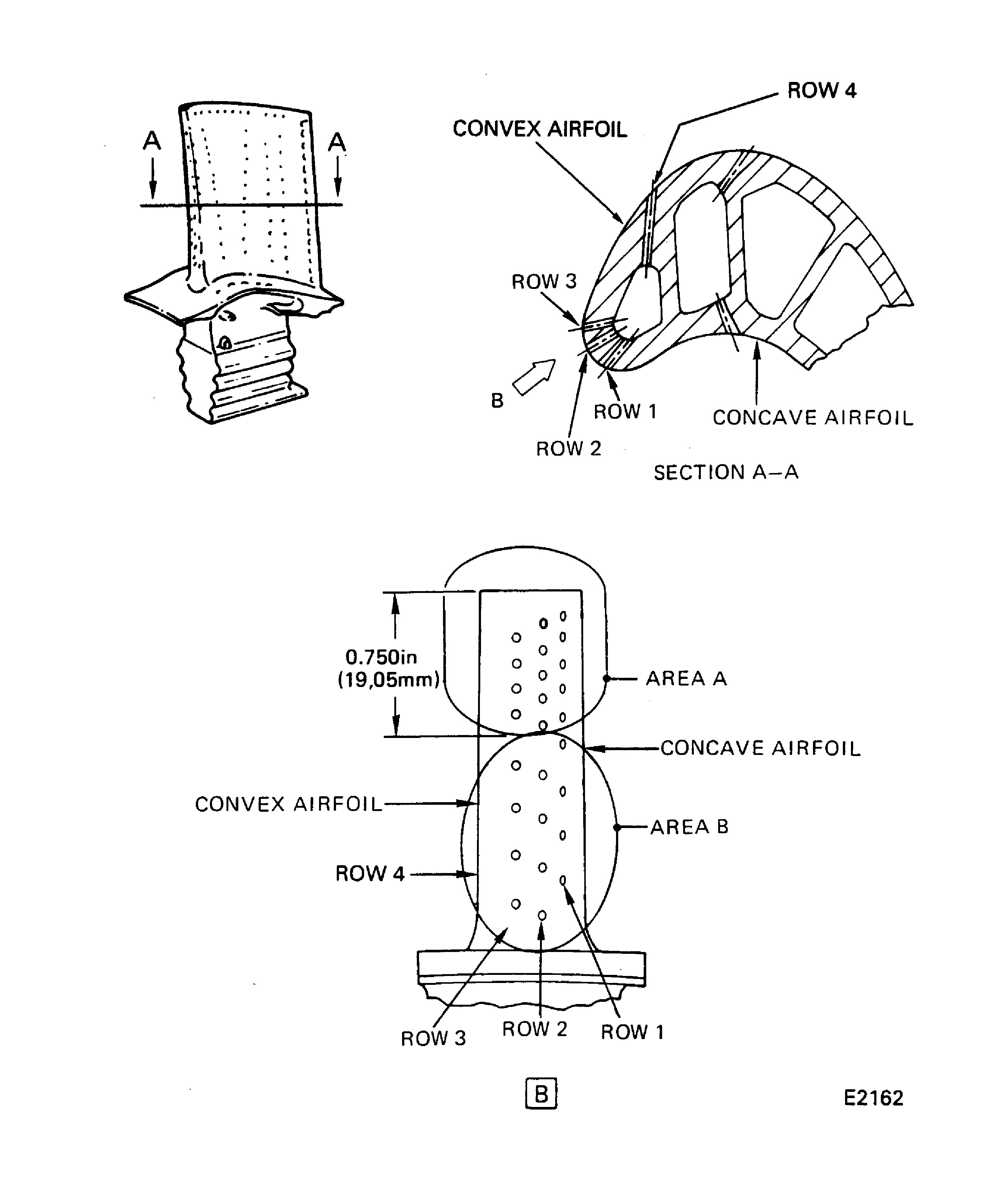

There are nicks or chips in the coating on the platform at location 14 or the airfoil fillet radius that show the base metal.

Examine the blade airfoil and platform coating for nicks and chips.

CAUTION

FAILURE TO REPLACE AN ADEQUATE NUMBER OF BLADE TIPS MAY REDUCE ENGINE PERFORMANCE AND/OR REDUCE BLADE AND OUTER AIRSEAL REPAIRABILITY.NOTE

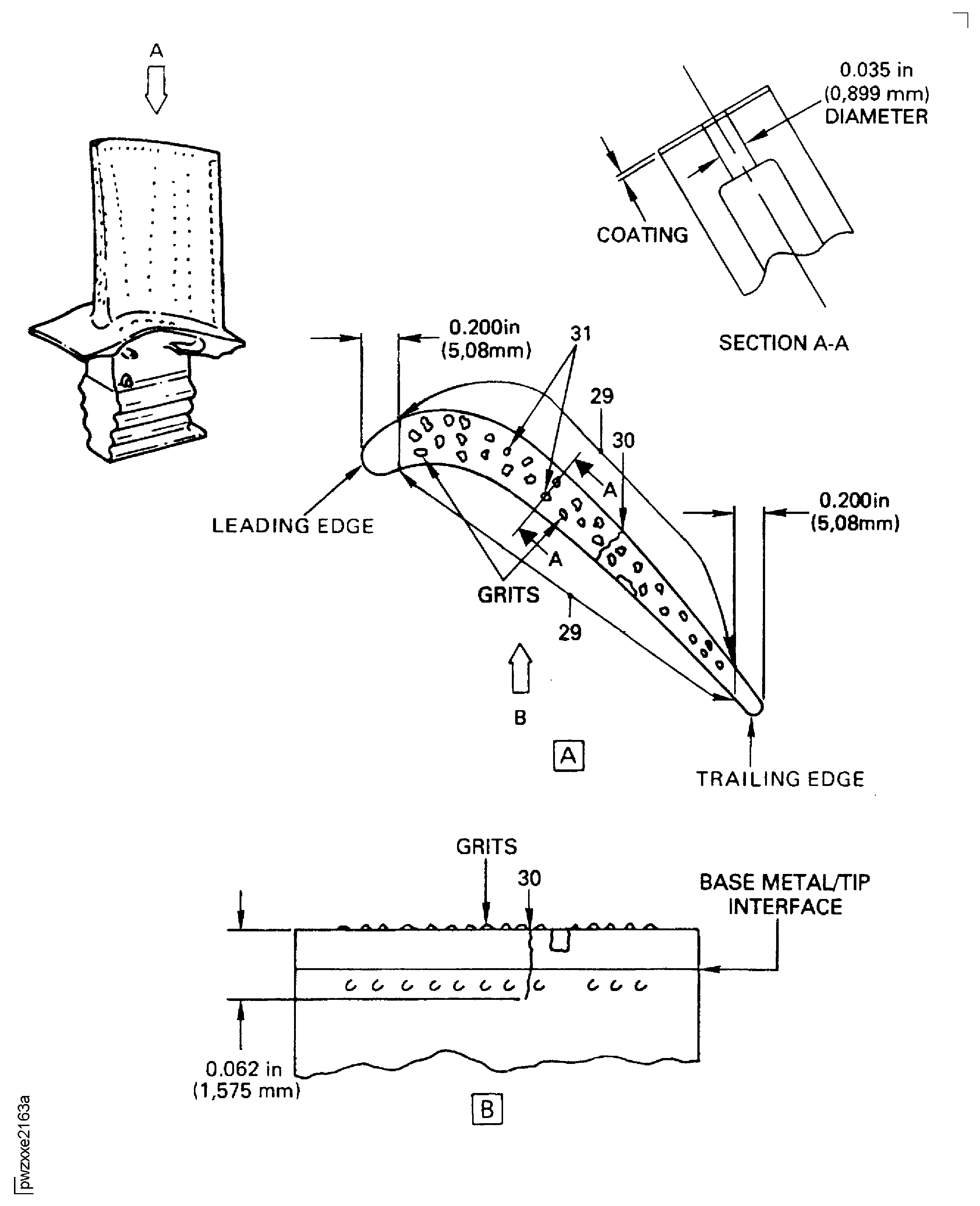

If new or fully repaired Stage 1 HPT Duct Segments (BOAS) are to be installed, two thirds of Stage 1 HPT blades must have fully repaired tips. One third of the blades can have complete, partial, or no tip coating.There is base metal that shows on the base metal/tip interface at location 29

Examine the stage 1 HPT blade abrasive tip.

SUBTASK 72-45-10-220-070 Visually Examine the Stage 1 Turbine Blade at Location 1

Refer to Figure.

SUBTASK 72-45-10-220-071 Visually Examine the Outer Surface of the Outer Seal at Location 11

Refer to Figure.

SUBTASK 72-45-10-220-072 Visually Examine the Outer Seal Surfaces at Location 10

Refer to Figure.

SUBTASK 72-45-10-220-073 Visually Examine the Knife-Edges of the Outer Seal at Location 9

Refer to Figure.

SUBTASK 72-45-10-220-074 Measure the Inner Seal Knife-Edge Diameters at Location 8

Refer to Figure.

SUBTASK 72-45-10-220-075 Visually Examine the Knife-Edges of the Inner Seal at Location 8

Refer to Figure

SUBTASK 72-45-10-220-076 Visually Examine the Disk Surface at Location 3

Refer to Figure

Reject. Inspect the No.4 bearing rear carbon seal. Refer to TASK 72-43-20-200-002. Report all findings to IAE Technical Services

The metering plugs are missing, damaged, and/or have missing or cracked tangs

SUBTASK 72-45-10-220-077 Visually Examine the Stage 1 Disk Metering Plug at Location 4

Refer to Figure

SUBTASK 72-45-10-220-078 Visually Examine the Stage 1 Disk Splines at Location 5

Refer to Figure

Repair, VRS3184 TASK 72-45-11-300-001 (REPAIR-001)

Scored or high metal

SUBTASK 72-45-10-220-079 Visually Examine the Stage 1 Disk at Location 6

Refer to Figure

SUBTASK 72-45-10-220-080 Visually Examine the Cooling Air Holes of the Inner Seal at Location 7

Refer to Figure

SUBTASK 72-45-10-220-081 Visually Examine the Stage 1 HPT Air Seal at Location 2

Refer to Figure.

Accept.

No wear.

Do inspection of HPT for possible oil ignition event. Refer to TASK 72-45-00-200-801. Report all findings to IAE Technical Services.

Wear marks.

Examine the bore for wear at Location 15.

SUBTASK 72-45-10-220-107 Visually Examine the Disk Surface at Location 15

Figure: Stage 1 Turbine Rotor Assembly Inspection

Sheet 1

Figure: Stage 1 Turbine Rotor Assembly Inspection

Sheet 2

Figure: Stage 1 Turbine Rotor Assembly Inspection

Sheet 3