Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 and POST SBE 72-0063

Common Information

TASK 72-50-00-030-001-B00 LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit - Disassemble The TEC From The LPT Module, Disassembly-001 - SBE 72-0063

General

Refer to TASK 72-50-10-030-001 (DISASSEMBLY-001) before you do this TASK.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Discard all rubber seal rings, cotter pins and key washers removed in this procedure.

Refer to TASK 72-50-00-990-501 (DESCRIPTION AND OPERATION) for a sectional view of the LP turbine module.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10016 Mechanical wrench | 0AM53 | IAE 1F10016 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10035 Hydraulic Removal puller | 0AM53 | IAE 1F10035 | 1 | |

| IAE 1F10037 Wrench support | 0AM53 | IAE 1F10037 | 1 | |

| IAE 1F10038 Torque wrench | 0AM53 | IAE 1F10038 | 1 | |

| IAE 1F10039 Anti-torque adapter | 0AM53 | IAE 1F10039 | 1 | |

| IAE 1F10040 Anchor wrench plate | 0AM53 | IAE 1F10040 | 1 | |

| IAE 1F10073 remove/installation fixture | 0AM53 | IAE 1F10073 | 1 | |

| IAE 1F10074 Guide pogo stick | 0AM53 | IAE 1F10074 | 1 | |

| IAE 1F10178 Storage and Turnover adapter | 0AM53 | IAE 1F10178 | 1 | |

| IAE 1P16374 Wrench support | 0AM53 | IAE 1P16374 | 1 | |

| IAE 1P16624 Slide Puller | 0AM53 | IAE 1P16624 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Attach the IAE 1P16374 Wrench support 1 off to the inner rear flange of the turbine exhaust case.

Install the IAE 1F10038 Torque wrench 1 off through the wrench support. Engage the torque wrench with the rear lock nut of the LP turbine shaft.

Install the IAE 1F10039 Anti-torque adapter 1 off through the torque wrench. Lock the anti-torque adapter to the LP turbine shaft.

Install the IAE 1F10016 Mechanical wrench 1 off to the torque wrench. Safety the anti-torque adapter to the mechanical wrench with the IAE 1F10040 Anchor wrench plate 1 off.

SUBTASK 72-50-00-030-076 Remove the Rear Lock Nut

NOTE

If the removal of the No. 5 bearing inner race and the carbon seal is necessary continue with this SUBTASK. If the removal of these two parts is not necessary, continue with Step.Refer to Figure.

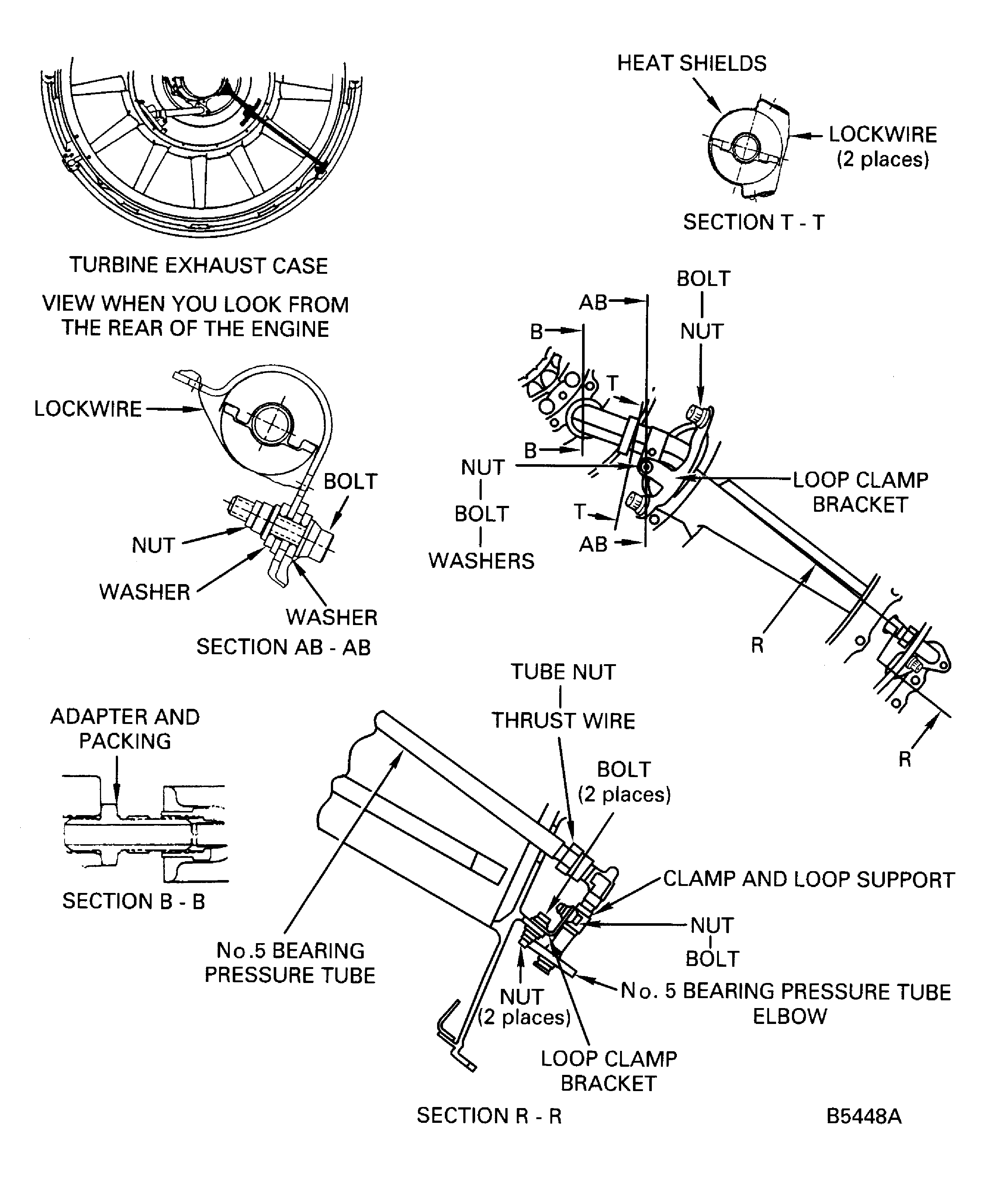

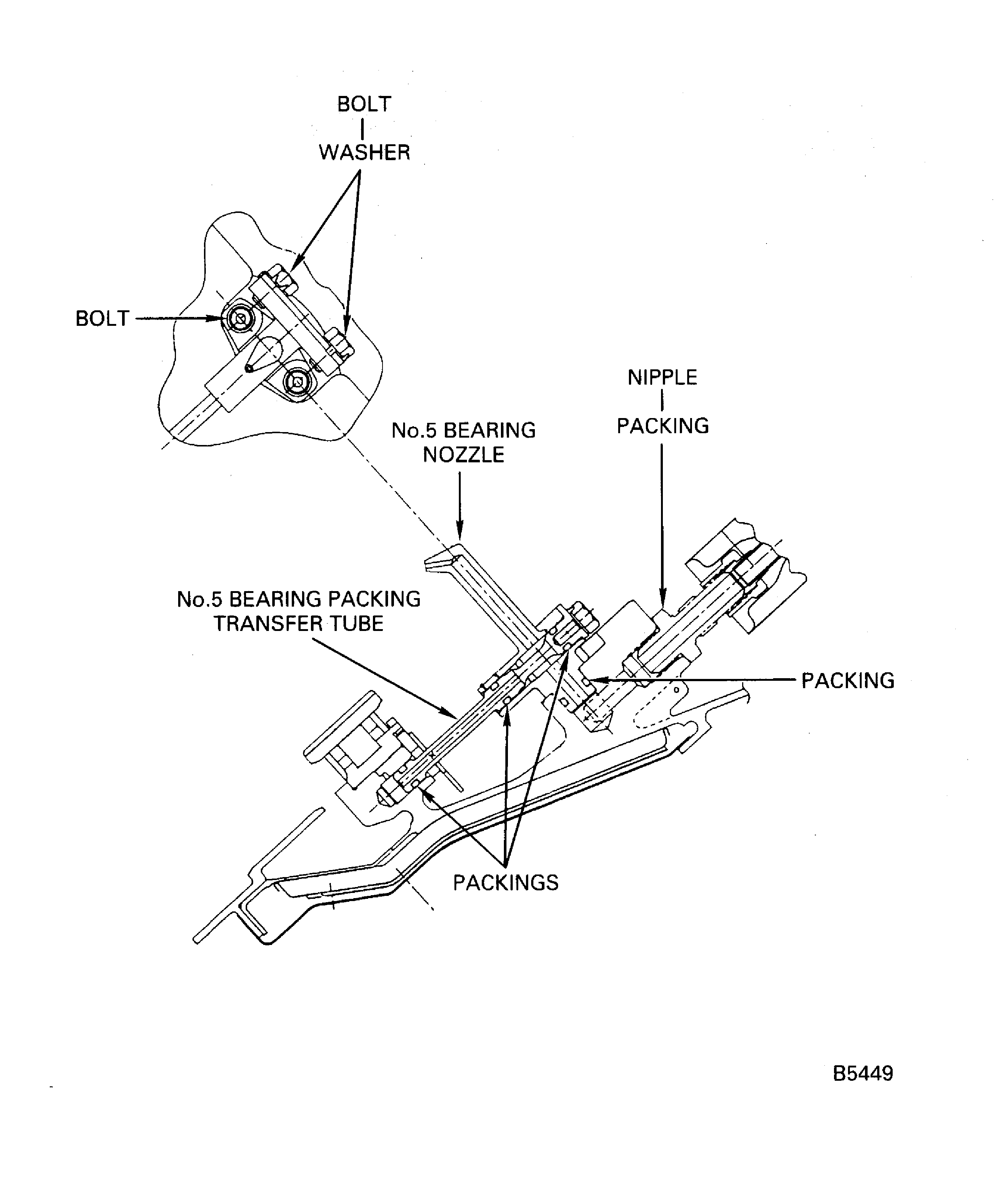

SUBTASK 72-50-00-030-077 Disconnect the No. 5 Bearing Pressure Tube Assembly

Refer to Figure.

Install the IAE 1P16624 Slide Puller 1 off into No. 5 Bearing Packing Transfer Tube.

Move the knocker puller rearwards quickly and hit the handle to remove the No. 5 Bearing Packing Transfer Tube from the No. 5 Bearing Nozzle.

SUBTASK 72-50-00-030-078 Remove the No. 5 Bearing Nozzle

Refer to Figure.

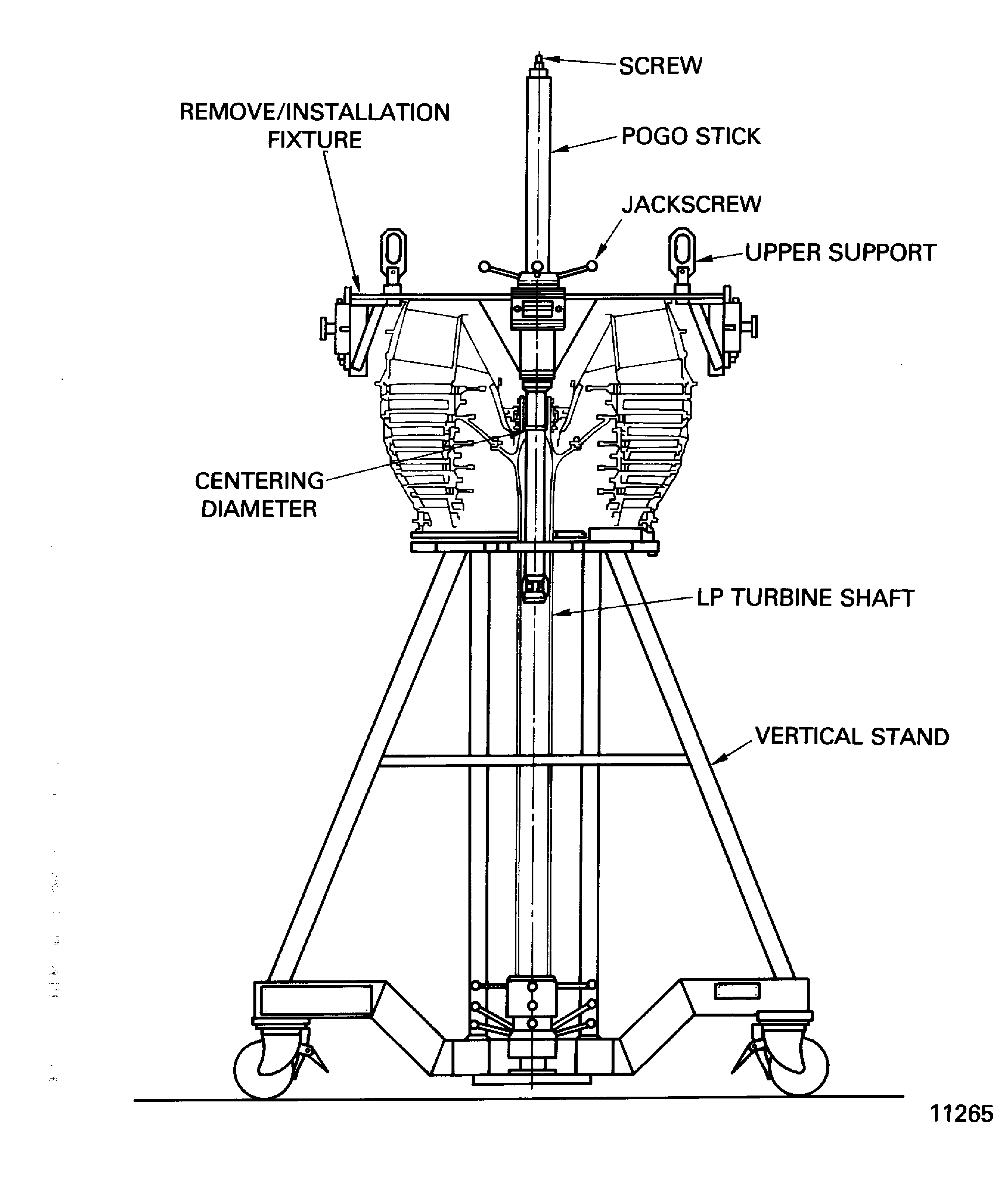

Install the IAE 1F10074 Guide pogo stick 1 off through the inner diameter of the LP turbine shaft. Use an applicable webbing sling.

SUBTASK 72-50-00-030-079 Install the Guide Pogo Stick to the LP Turbine Shaft

Refer to: Figure

Attach a hoist equipment to the upper supports of the IAE 1F10073 remove/installation fixture 1 off.

SUBTASK 72-50-00-030-080 Install the Remove/Installation Fixture to the Turbine Exhaust Case

Turn the jack-screw (part of IAE 1F10073 remove/installation fixture) clockwise to release the turbine exhaust case from the LP turbine case.

Remove the turbine exhaust case from the guide pogo stick and install it to the IAE 1F10178 Storage and Turnover adapter 1 off.

SUBTASK 72-50-00-030-081 Remove the Turbine Exhaust Case from the LP Turbine Case

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU LOOSEN AND REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE LP TURBINE CASE/TURBINE EXHAUST CASE FLANGE AND/OR THE BOLTS CAN BE DAMAGED.Refer to Figure.

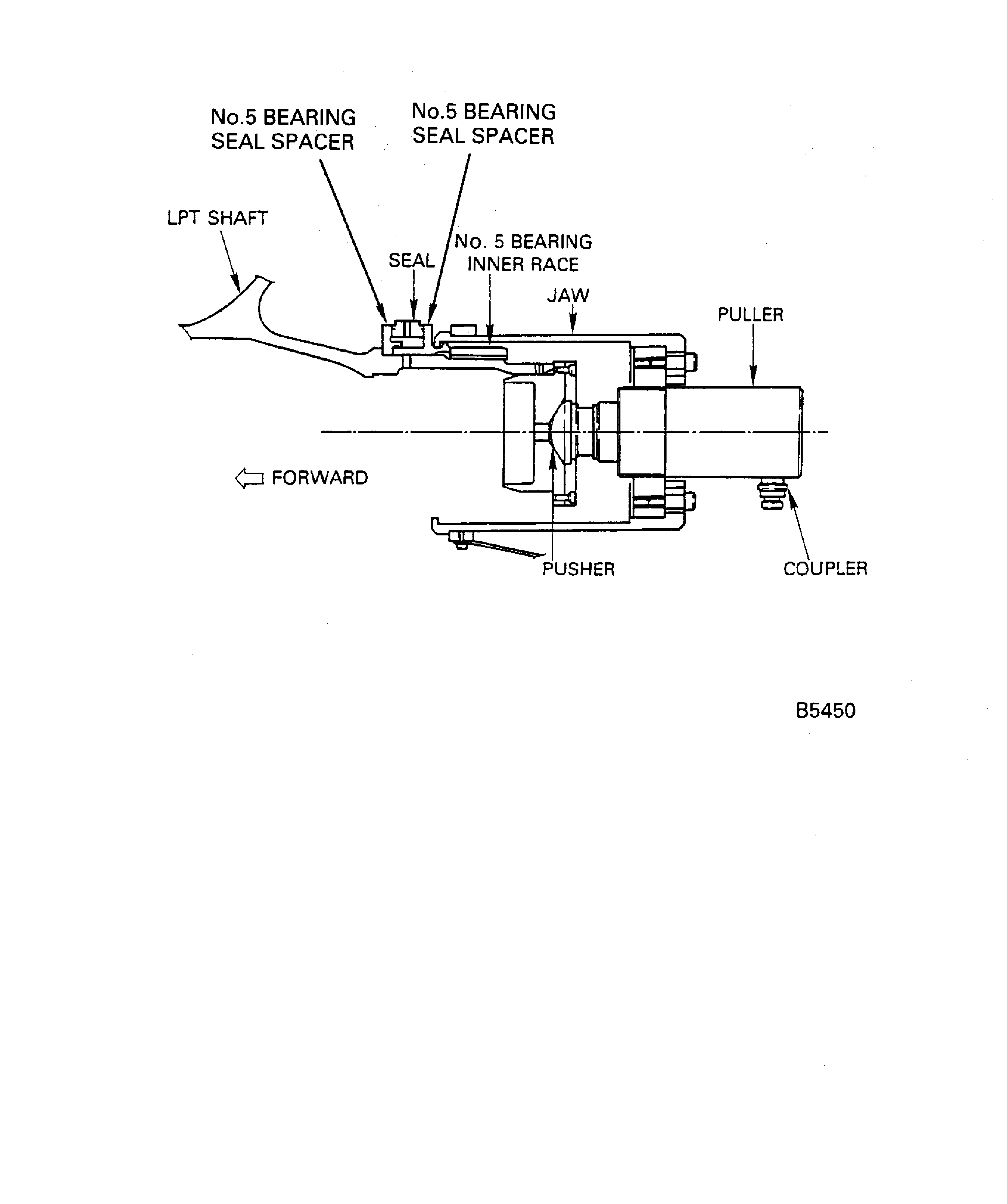

Make sure that the rear lock nut is removed. Install the IAE 1F10035 Hydraulic Removal puller 1 off to the rear face of the LP turbine shaft. Engage the jaws of the puller with the grooves of the rear No. 5 bearing seal spacer.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the puller.

SUBTASK 72-50-00-030-082-A00 Remove the No. 5 Bearing and the No. 5 Bearing Seal and Spacers (Pre SBE 72-0165)

Refer to: Figure

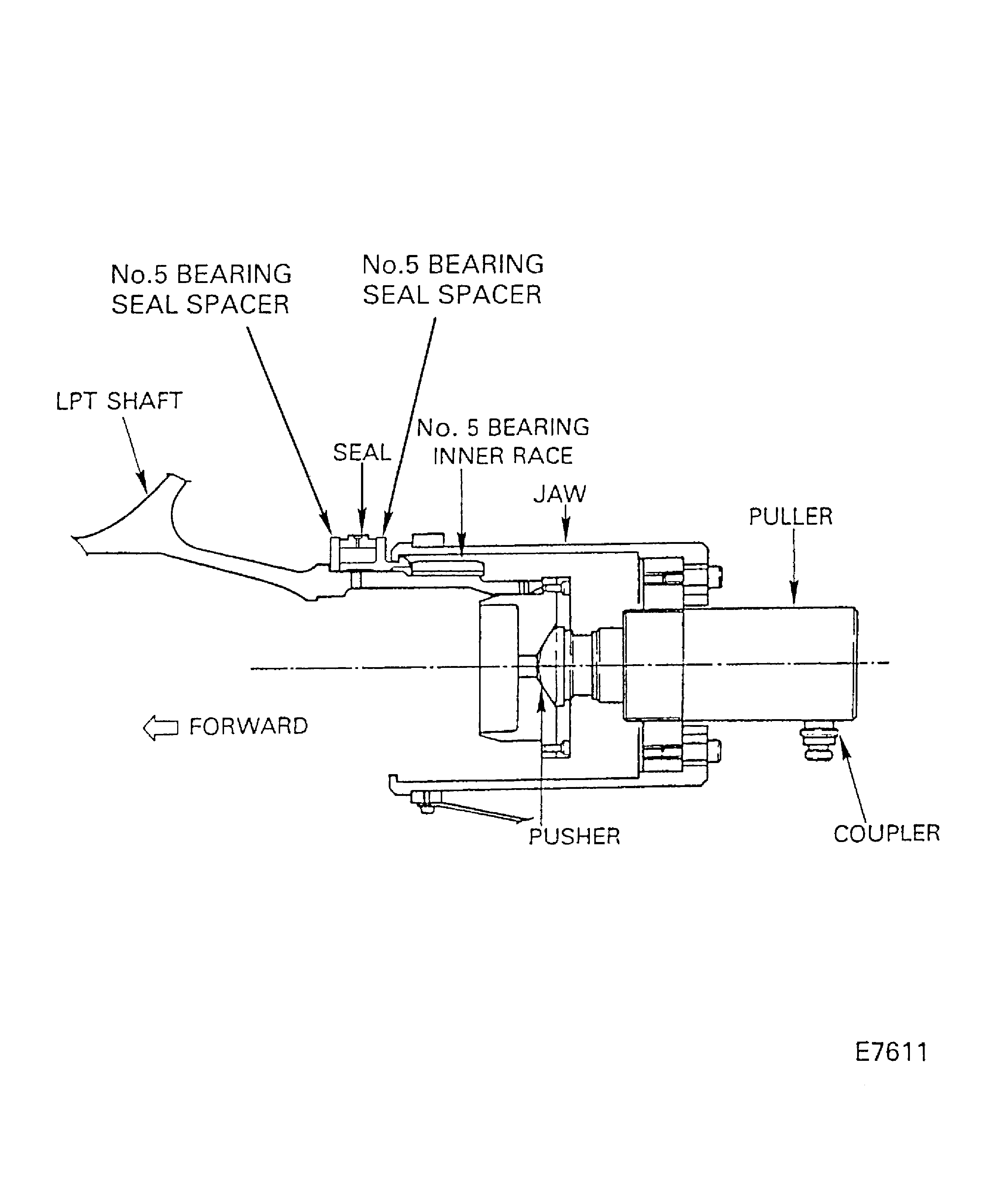

SBE 72-0165: Replace the No. 5 bearing seal spacer with a spacer incorporating fool-proof installation features

Make sure that the rear lock nut is removed. Install the IAE 1F10035 Hydraulic Removal puller 1 off to the rear face of the LP turbine shaft. Engage the jaws of the puller with the grooves of the rear No. 5 bearing seal spacer.

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the puller.

SUBTASK 72-50-00-030-082-B00 Remove the No. 5 Bearing and the No. 5 Bearing Seal and Spacers (SBE 72-0165)

Figure: Remove the Turbine Shaft Rear Lock Nut

Remove the Turbine Shaft Rear Lock Nut

Figure: Pre SBE 72-0165: Remove the No. 5 Bearing Inner Race Carbon Seal and the No. 5 Bearing Seal Spacers

Pre SBE 72-0165: Remove the No. 5 Bearing Inner Race Carbon Seal and the No. 5 Bearing Seal Spacers

Figure: SBE 72-0165: Remove the No. 5 Bearing Inner Race Carbon Seal and the No. 5 Bearing Seal Spacers

Sheet 2

Figure: Pressure Tube of No. 5 Bearing

Pressure Tube of No. 5 Bearing

Figure: Remove the No. 5 Bearing Nozzle

Remove the No. 5 Bearing Nozzle

Figure: Install the guide pogo stick

Install the guide pogo stick