Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-50-32-200-009-A00 LPT Stage 6 Blade - Examine For Overtemperature, Inspection-009

General

This TASK gives the procedure for the inspection of the stage 6 turbine blades.

Fig/Item numbers in parentheses in the procedure agree with those used in the EIPC.

The policy that is necessary for inspection is given in the SPM TASK 70-20-00-200-501.

All parts must be cleaned before any part is examined. Refer to TASK 72-50-32-100-000,(CLEANING-000).

All parts must be visually examined for damage, corrosion and wear. Any defects that are not identified in the procedure must be referred to IAE.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

References

Refer to the SPM for data on these items:

Definition of Damage, SPM TASK 70-02-02-350-501.

Inspection of Parts, SPM TASK 70-20-00-200-501.

Some data on these items are contained in this TASK. For more data on these items refer to the SPM.

Chemical Processes

Surface Protection

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Do this inspection if the stage 5 LP turbine blades are rejected for an overtemperature condition.

Before examination of the blade do the hardness test of the stage 6 turbine disk. Refer to TASK 72-50-31-200-002-A00 (INSPECTION/CHECK-002).

Blades that were at temperatures more than the limit of 2000 deg F (1093 deg C) for a short time will cause a change in the alloy microstructure of the blade.

Overtemperature condition, also for a short time, changes the structure of the gamma particles, together with a decrease of size and volume percentage. Signs of overtemperature are decrease in volume percentage of the gamma phase and compare the microstructure against a referenced standard.

Examine one blade for overtemperature by metallurgical analysis. Use the blade with the strongest discoloration.

NOTE

Do this inspection only if the hardness test of the stage 6 turbine disk shows no decrease of hardness. Refer to TASK 72-50-31-200-002-A00 (INSPECTION/CHECK-002).

SUBTASK 72-50-32-220-249 Examine the Stage 6 Turbine Blades for Overtemperature

NOTE

Refer to Figure.

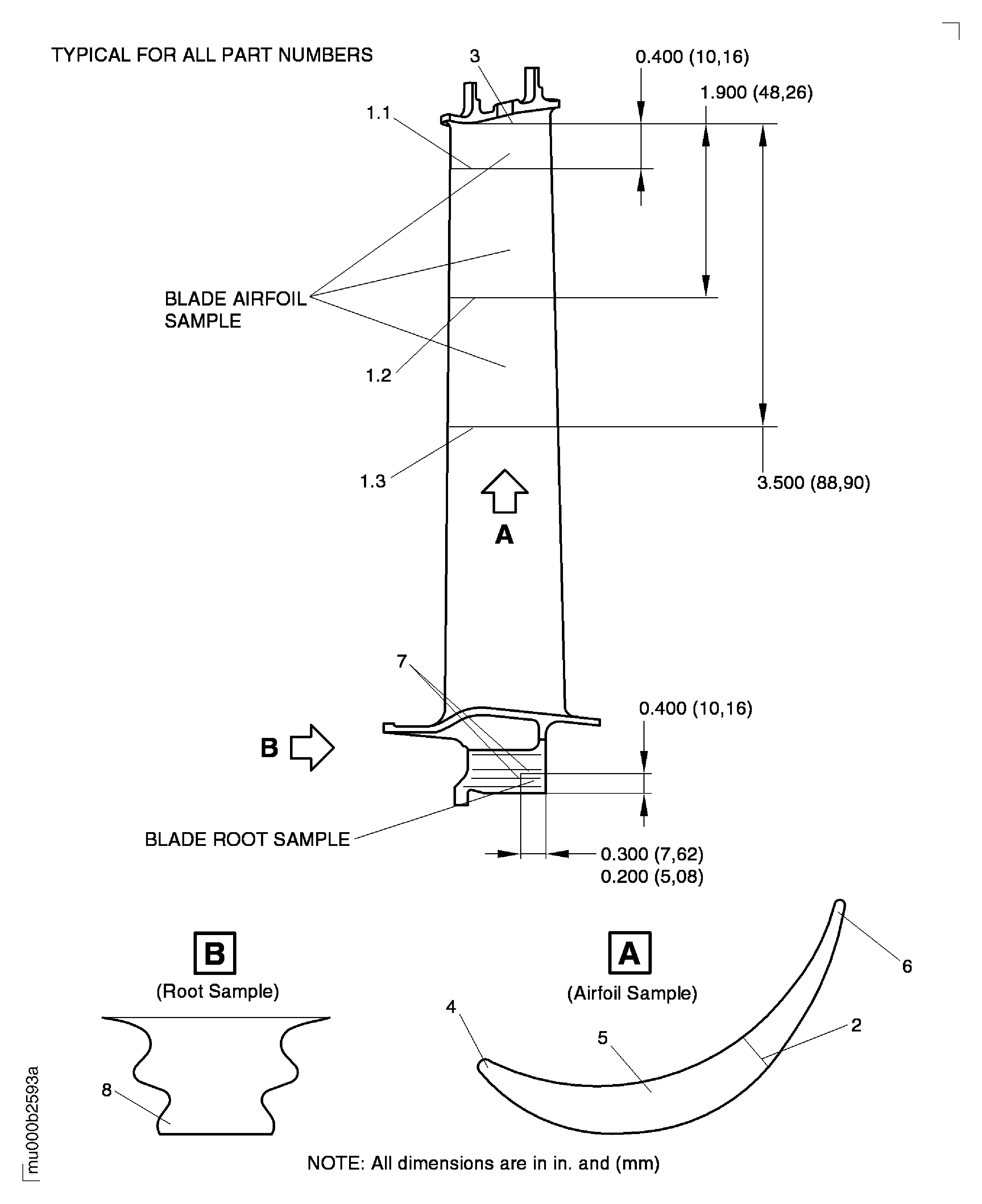

Cut the blade at locations 1.1, 1.2 and 1.3 to get the blade airfoil samples to be analyzed. Refer to the SPM TASK 70-02-03-220-501.

NOTE

When a discoloration on the airfoil indicates a position of max. overtemperature deviating from the specified locations, make an additional cut at the position where the max. overtemperature is expected.Attach and polish the blade samples as follows, refer to the SPM TASK 70-02-03-220-501:

SUBTASK 72-50-32-320-072 Prepare the Stage 6 Turbine Blade for Metallurgical Analysis

Examine the microstructure of the blade samples. Refer to the SPM TASK 70-02-09-220-501.

SUBTASK 72-50-32-220-250 Metallurgical Analysis of the Stage 6 Turbine Blade

If the stage 6 turbine blades were rejected because of overtemperature, examine the stage 7 turbine blades, refer to TASK 72-50-32-200-010-A00 (INSPECTION/CHECK-010).

SUBTASK 72-50-32-220-253 Examine the Stage 7 Turbine Blades for Overtemperature

Figure: LP Stage 6 Turbine Blade - Inspection Locations

LP Stage 6 Turbine Blade - Inspection Locations