Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-60-820-001 External Gearbox Components - Convert The Woodward FMU SBE 73-0172 And SBE 73-0223 - Rework-001

General

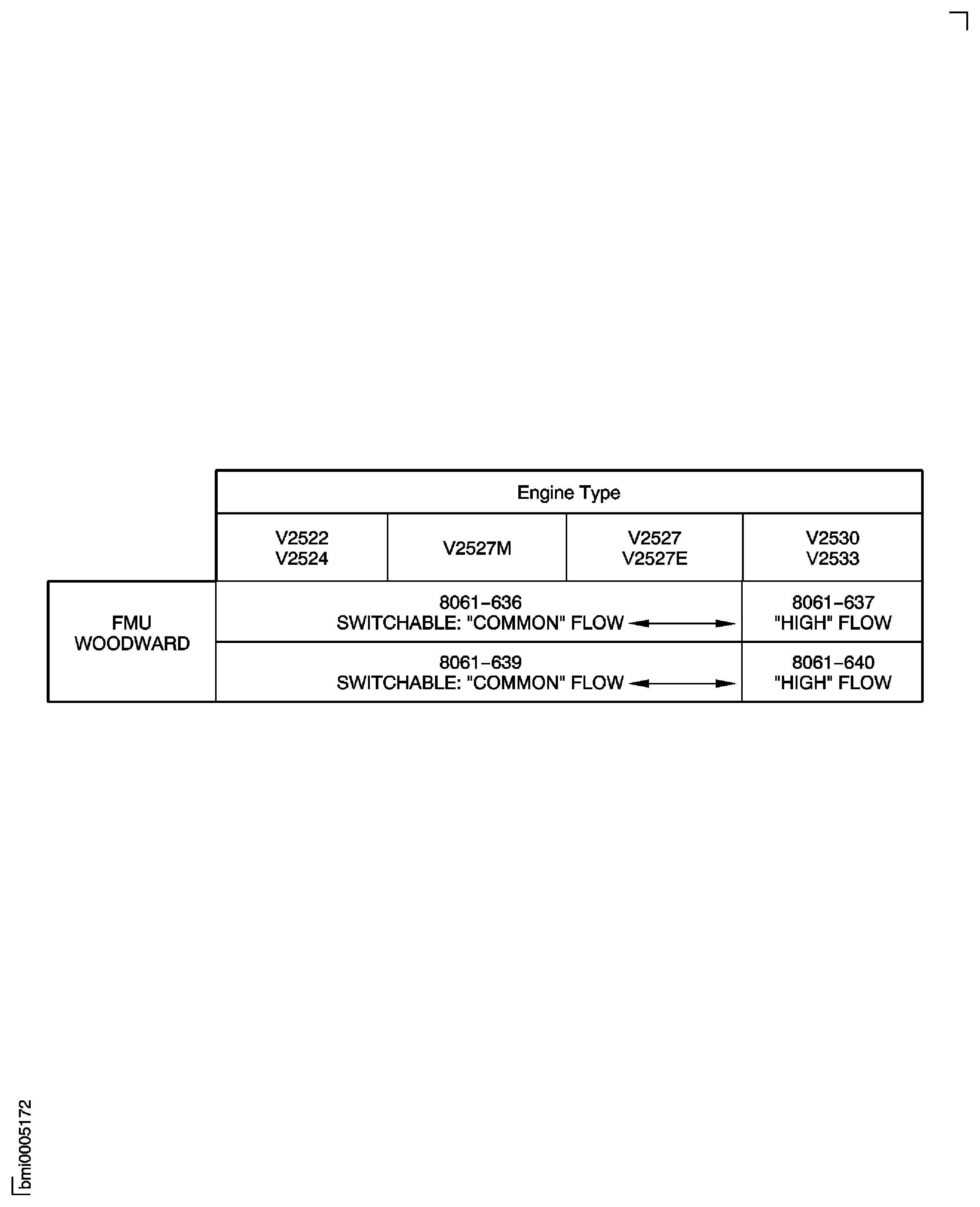

This TASK gives the re-setting procedure to convert the Woodward FMU part number 8061-636 or 8061-639 to part number 8061-637 or 8061-640 and part number 8061-637 or 8061-640 to part number 8061-636 or 8061-639.

The practices and processes referred to in the procedure by TASK/SUBTASK number are in SPM.

Refer to the Service Bulletin SBE 73-0172 and/or SBE 73-0223 for specific application requirements.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Special torque data is identified with the symbol * after the torque value.

For standard torque data and procedures, refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

For lockwire data refer to SPM TASK 70-42-05-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of air drying enamel. Refer to SPM TASK 70-38-21-380-501.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop tools | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-127 LOCKWIRE | LOCAL | CoMat 02-127 | ||

| CoMat 02-138 LOCKWIRE | LOCAL | CoMat 02-138 | ||

| CoMat 07-038 AIR DRYING ENAMEL | k3504 | CoMat 07-038 |

Spares

NONESafety Requirements

CAUTION

Procedure

WARNING

YOU MUST MAKE SURE THAT THE FMU FUEL SYSTEM IS DE-PRESSURIZED BEFORE YOU DO THIS CONVERSION PROCEDURE. THIS IS TO AVOID POTENTIAL HARZARDS FROM FIRE AND INJURY TO PERSONS FROM PRESSURIZED FUEL.

WARNING

YOU MUST BE CAREFUL WHEN YOU REMOVE LOCKWIRE. IF YOU PULL LOCKWIRE WITH FORCE FROM A COMPONENT IT CAN CAUSE YOU INJURY.

CAUTION

LOCKWIRE FRAGMENTS WILL BE LIBERATED DURING THE REWORK PROCEDURE. ALL SUCH FRAGMENTS MUST BE RECOVERED.

CAUTION

YOU MUST NOT APPLY TORQUE MORE THAN THE RECOMMENDED TORQUE VALUES. OVER TORQUING CAN RESULT IN DAMAGE TO THE FUEL METERING UNIT (FMU) WHICH CAN NECESSITATE REPLACEMENT OF THE FMU.

CAUTION

YOU MUST NOT APPLY TORQUE MORE THAN 50 LBFIN. (5.65 NM) DURING THIS PROCEDURE.Disconnect the two lower electrical connectors from the FMU to provide sufficient working space during this procedure. Refer to TASK 72-00-60-050-002-B00 (REMOVAL-006).

Re-setting procedure.

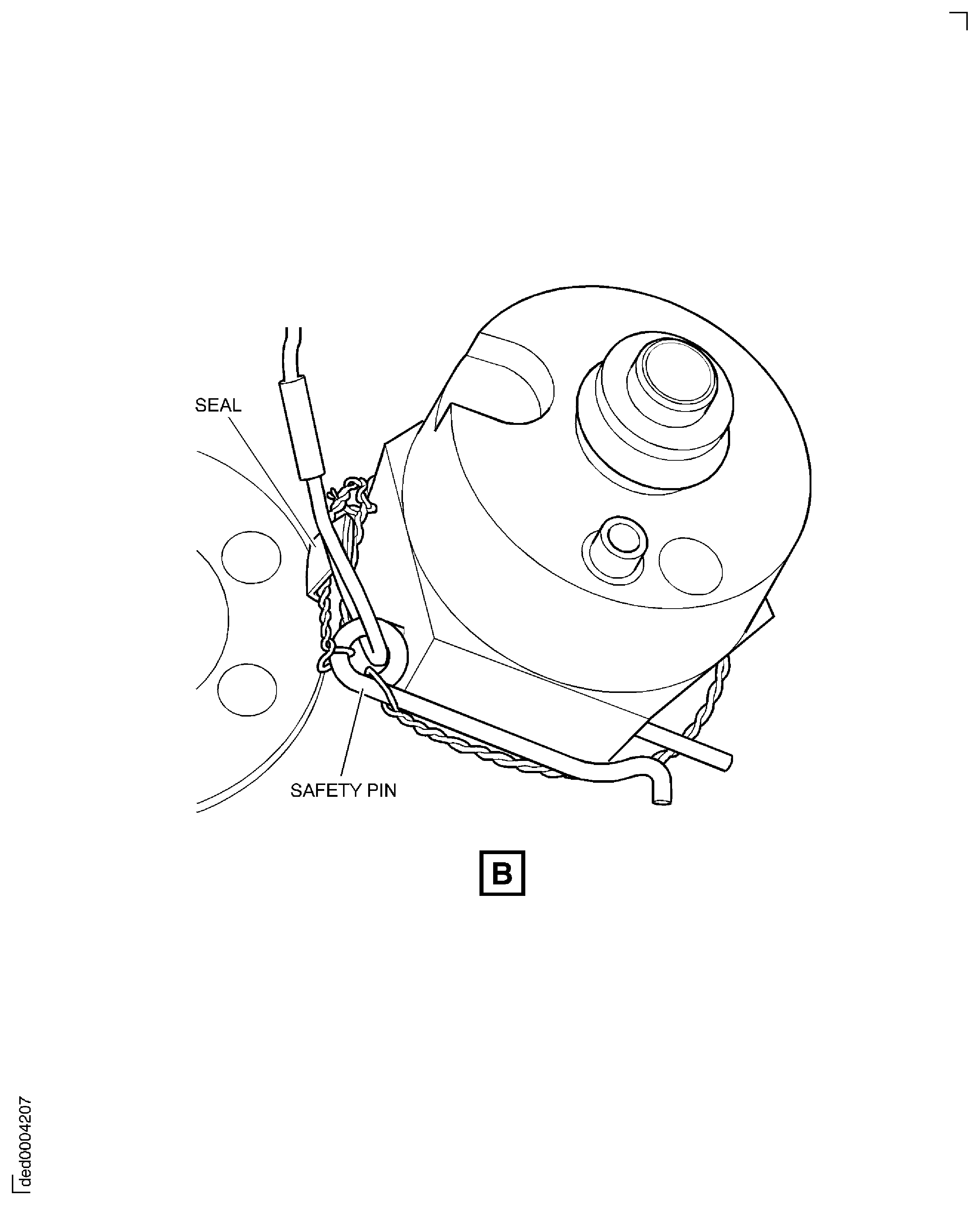

Safety the pin eyelet with CoMat 02-127 LOCKWIRE and bend the wire back on itself.

NOTE

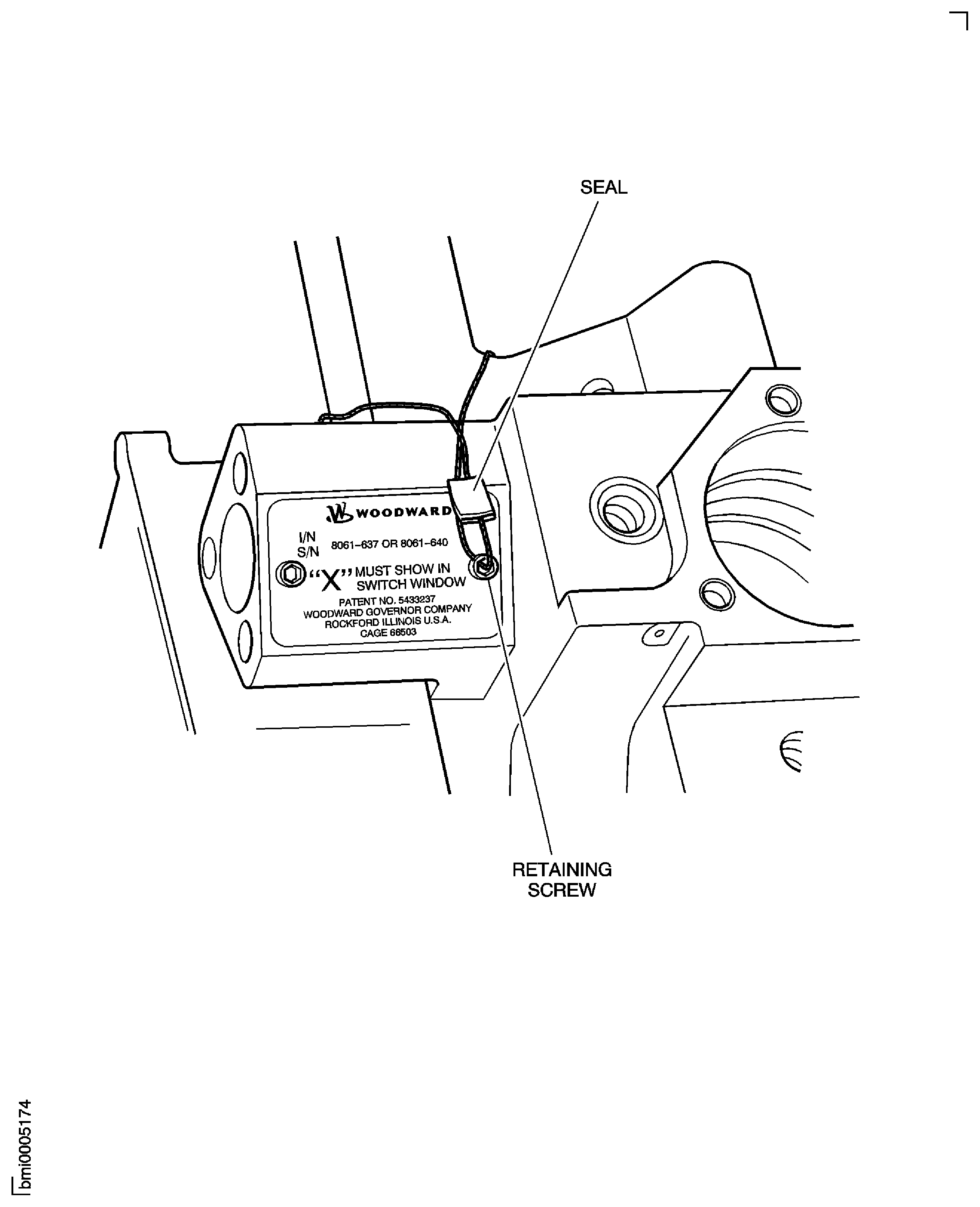

The inclusion of the seal (SAE AS567) is optional. The seal is available from the Woodward Governor Company. Refer to Service Bulletin 83724-73-0004.Attach one seal (SAE AS567) and apply end twists. Use WT-140418 assembly tool to crimp the seal. Tie down the pigtail of the lockwire to the lockwire underneath.

NOTE

Install of seal is optional.Safety the screw with CoMat 02-138 LOCKWIRE.

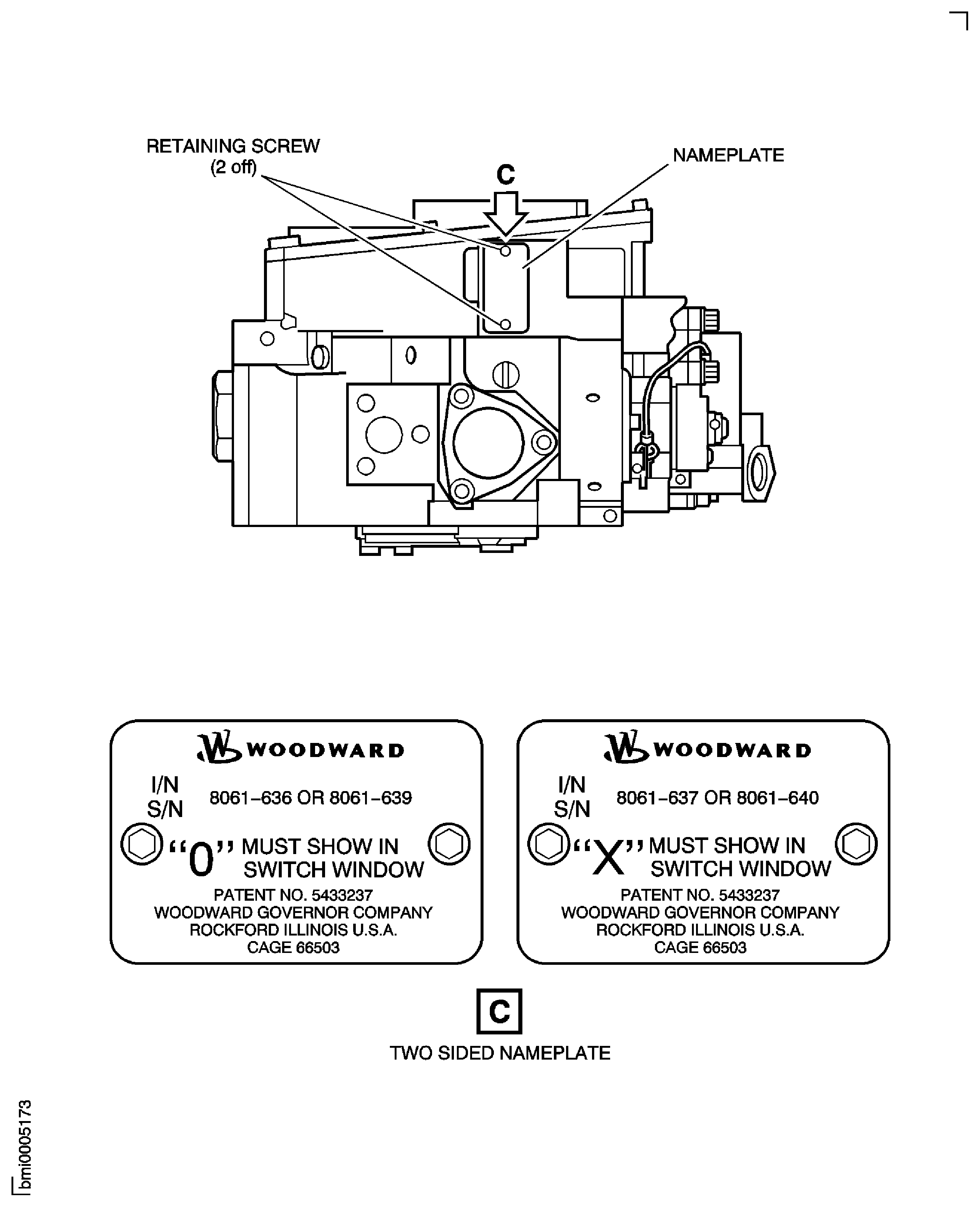

Identify the FMU with the correct nameplate.

SUBTASK 72-00-60-820-001 Convert the Woodward FMU Part Number 8061-636 or 8061-639 to Part Number 8061-637 or 8061-640

WARNING

YOU MUST MAKE SURE THAT THE FMU FUEL SYSTEM IS DE-PRESSURIZED BEFORE YOU DO THIS CONVERSION PROCEDURE. THIS IS TO AVOID POTENTIAL HARZARDS FROM FIRE AND INJURY TO PERSONS FROM PRESSURIZED FUEL.

WARNING

YOU MUST BE CAREFUL WHEN YOU REMOVE LOCKWIRE. IF YOU PULL LOCKWIRE WITH FORCE FROM A COMPONENT IT CAN CAUSE YOU INJURY.

CAUTION

LOCKWIRE FRAGMENTS WILL BE LIBERATED DURING THE REWORK PROCEDURE. ALL SUCH FRAGMENTS MUST BE RECOVERED.

CAUTION

YOU MUST NOT APPLY TORQUE MORE THAN THE RECOMMENDED TORQUE VALUES. OVER TORQUING CAN RESULT IN DAMAGE TO THE FUEL METERING UNIT (FMU) WHICH CAN NECESSITATE REPLACEMENT OF THE FMU.

CAUTION

DO NOT APPLY TORQUE MORE THAN 50 LBFIN. (5.65 NM) DURING THIS PROCEDURE.Disconnect the two lower electrical connectors from the FMU to provide sufficient working space during this procedure. Refer to TASK 72-00-60-050-002-B00 (REMOVAL-006).

Re-setting procedure.

Safety the pin eyelet with CoMat 02-127 LOCKWIRE and bend the wire back on itself.

NOTE

The inclusion of the seal (SAE AS567) is optional. The seal is available from the Woodward Governor Company. Refer to Service Bulletin 83724-73-0004.Attach one seal (SAE AS567) and apply end twists. Use WT-140418 assembly tool to crimp the seal. Tie down the pigtail of the lockwire to the lockwire underneath.

NOTE

Install of seal is optional.Safety the screw with CoMat 02-138 LOCKWIRE.

Identify the FMU with the correct nameplate.

SUBTASK 72-00-60-820-002 Convert the Woodward FMU Part Number 8061-637 or 8061-640 to Part Number 8061-636 or 8061-639

Connect the two lower electrical connectors to the FMU. Refer to TASK 72-00-60-450-002-B00 (INSTALLATION-006).

SUBTASK 72-00-60-420-209 Reconnect Electrical Harness

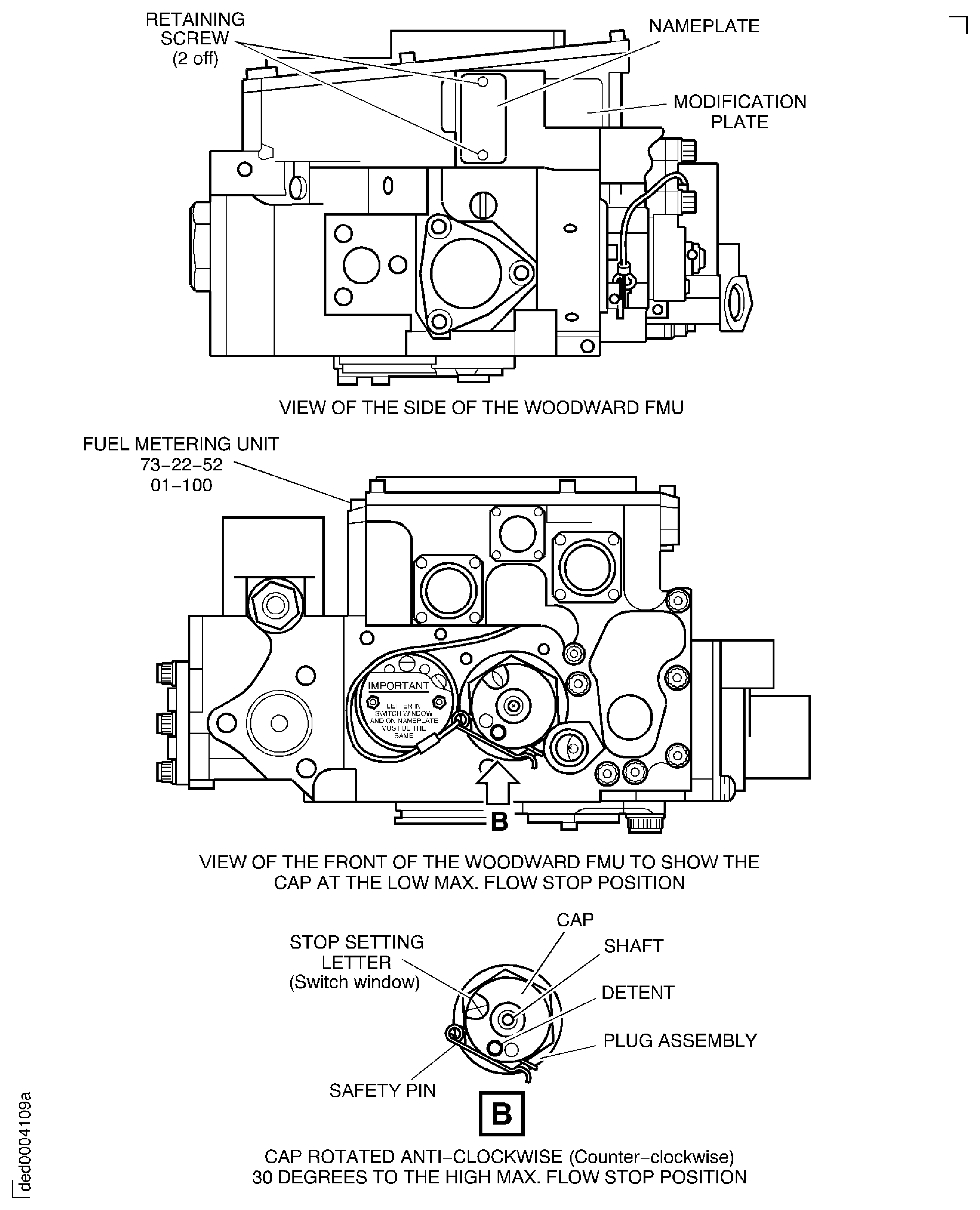

Figure: Woodward FMU - Adjust the Max. Fuel Flow Stop

Sheet 1

Figure: Woodward FMU - Adjust the Max. Fuel Flow Stop

Sheet 2

Figure: Woodward FMU - Adjust the Max. Fuel Flow Stop

Sheet 3

Figure: Woodward FMU - Adjust the Max. Fuel Flow Stop

Sheet 4

Figure: Woodward FMU - Adjust the Max. Fuel Flow Stop

Sheet 5