Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-00-430-012-C00 LPC/Intermediate Case Module - Install The Panel Rubber Seals, Rear Liner Panels, And Middle Liner Panels, Assembly-012

General

This TASK gives the procedure to install the panel rubber seals, the rear liner panels and the middle liner panel.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501.

Lubricate all threads and abutment faces of nuts and bolts with the approved engine oils, unless other lubricants are referred to in the procedure. For the approved engine oils and procedures, refer to the SPM TASK 70-64-00-640-501.

Special torque data is identified with the symbol * after the torque value.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No.1 strut, which is the top position strut of the fan frame, is identified by the five pressure tubes on the No.1 strut leading edge.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Sealant dispenser | LOCAL | Sealant dispenser |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-045 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-045 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-32-00-430-214 Turn the Fan Frame and Fan Case Assembly to the Horizontal Position

Procedure transferred to TASK 72-32-00-430-014-B00 (ASSEMBLY-014, CONFIG-002).

SUBTASK 72-32-00-430-215-A00 Install the Rear Fairing on to the LP Compressor Bleed Duct

Procedure transferred to TASK 72-32-00-430-014-B00 (ASSEMBLY-014, CONFIG-002).

SUBTASK 72-32-00-430-215-B00 Install the Rear Fairing on to the LP Compressor Bleed Duct

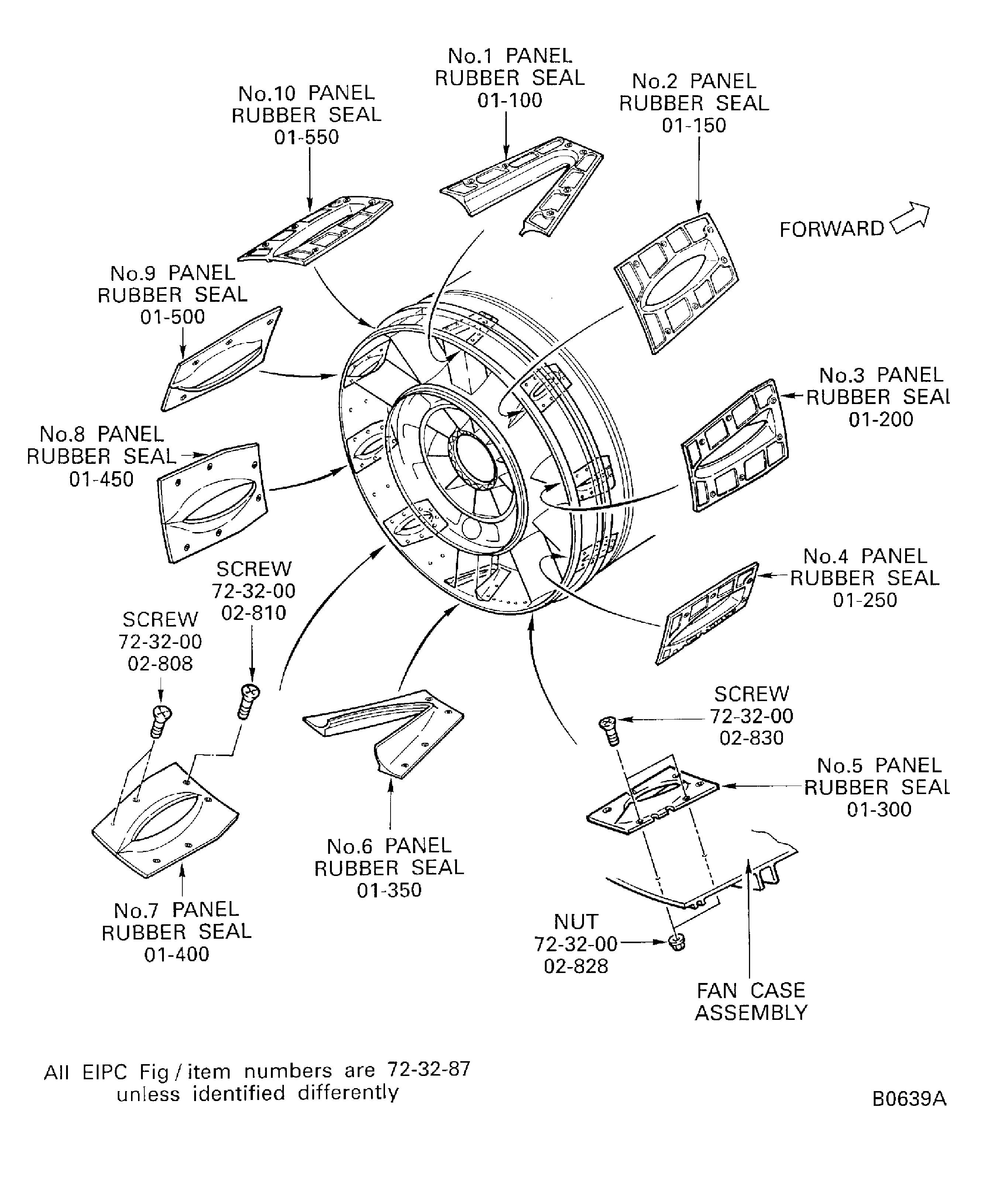

Install the 10 panel rubber seals Fan Case Liner Panels And Related Parts (72-32-87, 01-100), Fan Case Liner Panels And Related Parts (72-32-87, 01-150), Fan Case Liner Panels And Related Parts (72-32-87, 01-200), Fan Case Liner Panels And Related Parts (72-32-87, 01-250,Fan Case Liner Panels And Related Parts (72-32-87, 01-300, Fan Case Liner Panels And Related Parts (72-32-87, 01-350), Fan Case Liner Panels And Related Parts (72-32-87, 01-400), Fan Case Liner Panels And Related Parts (72-32-87, 01-450), Fan Case Liner Panels And Related Parts (72-32-87, 01-500) and Fan Case Liner Panels And Related Parts (72-32-87, 01-550).

SUBTASK 72-32-00-430-314 Install the Panel Rubber Seals on to the Fan Case

Refer to Figure.

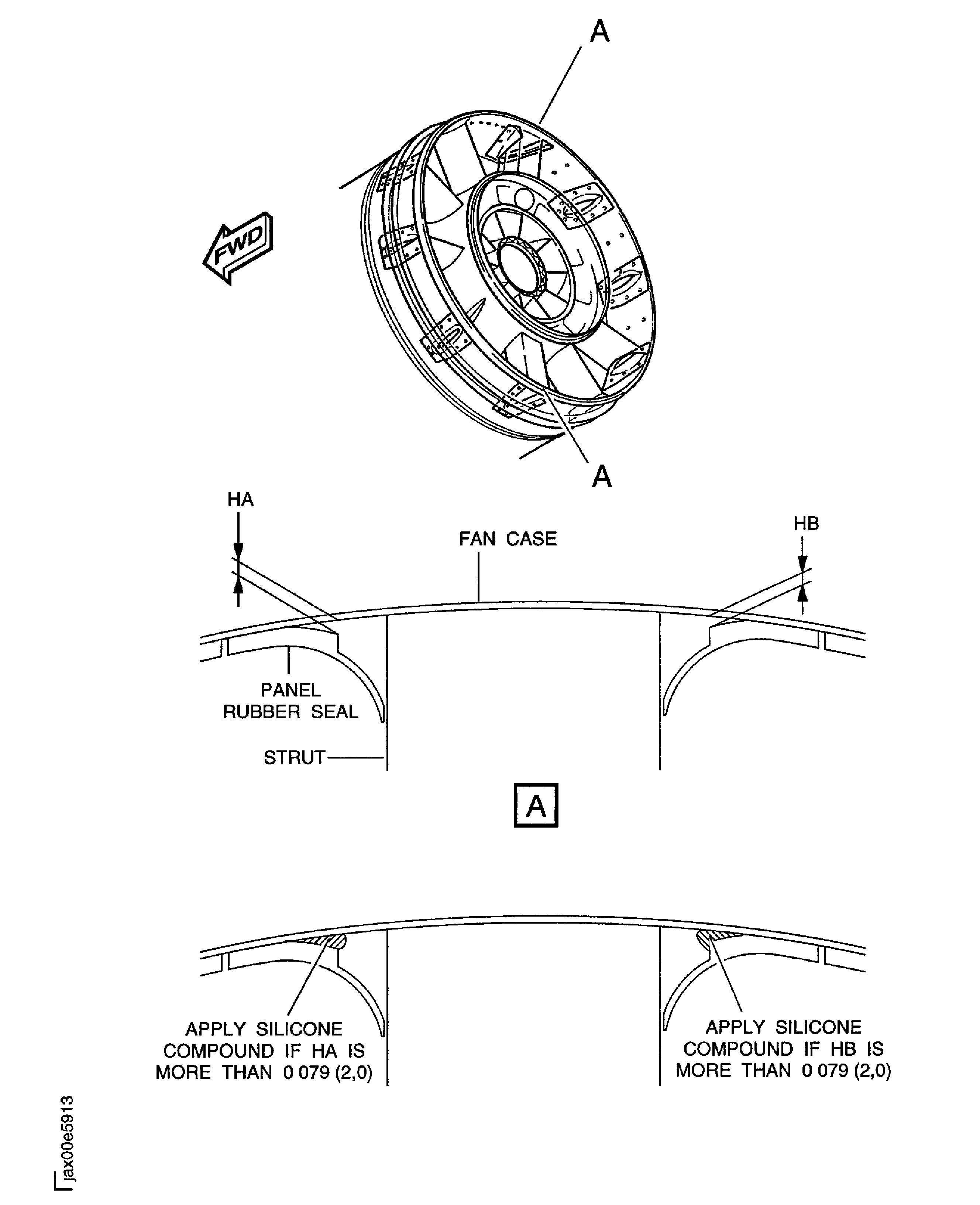

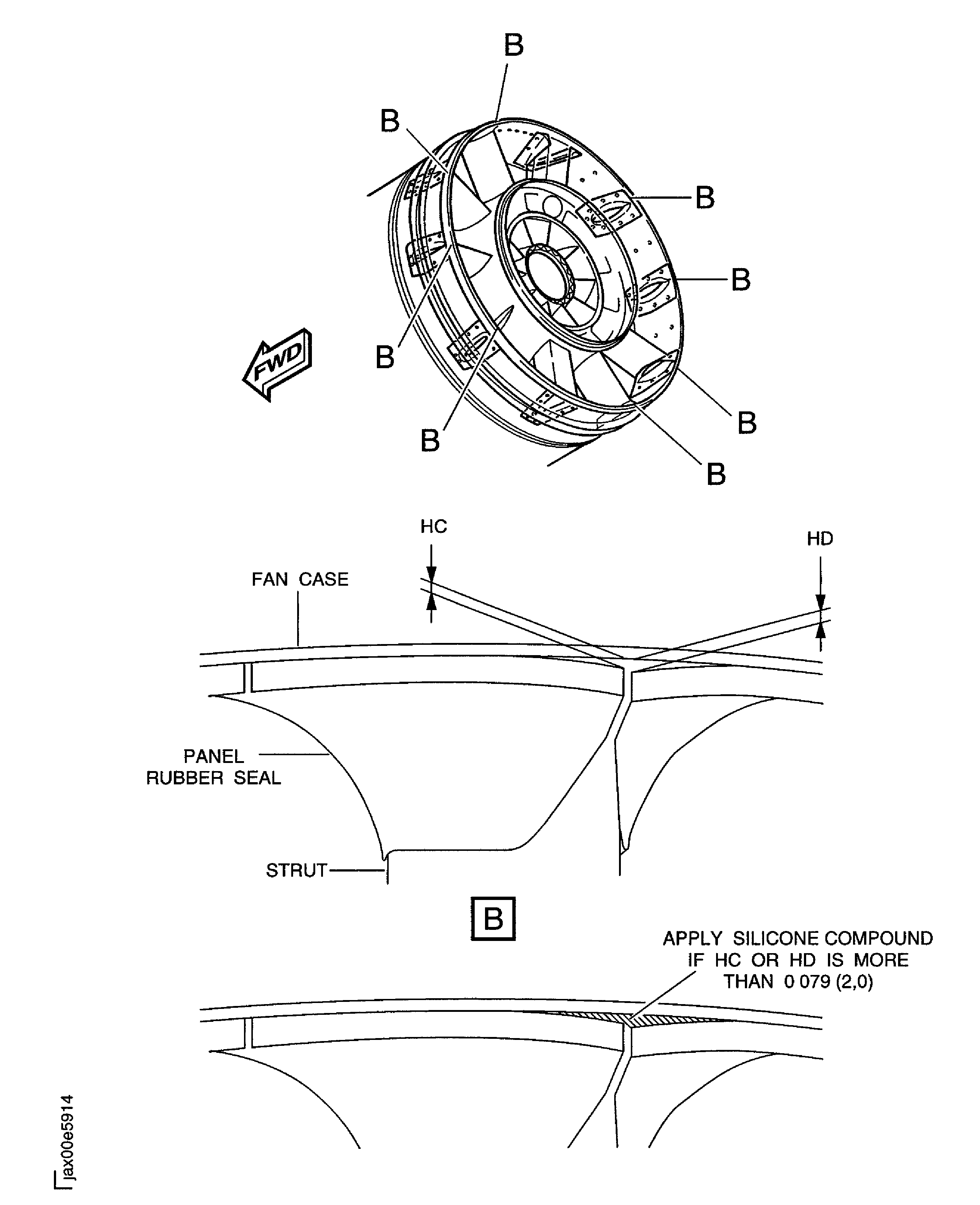

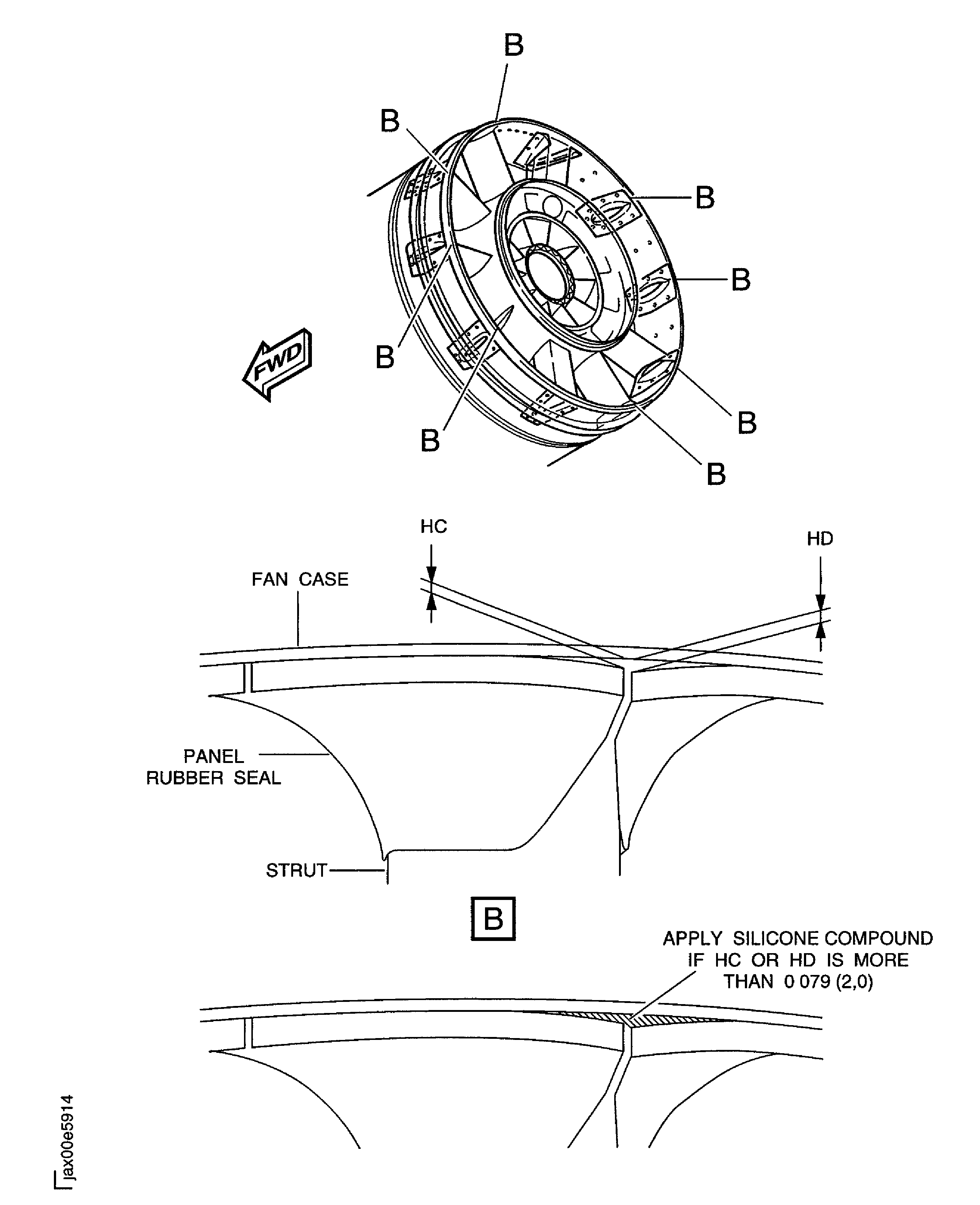

Clean the faces of the corner with a clean cloth or a soft brush moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-124 ISOPROPYL ALCOHOL.

NOTE

Apply the primer in less than eight hours after the faces are cleaned.Apply a thin layer of CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT with a soft brush to the faces. Air dry for 30 minutes minimum.

Put CoMat 08-045 SILICONE RUBBER COMPOUND in to the corner.

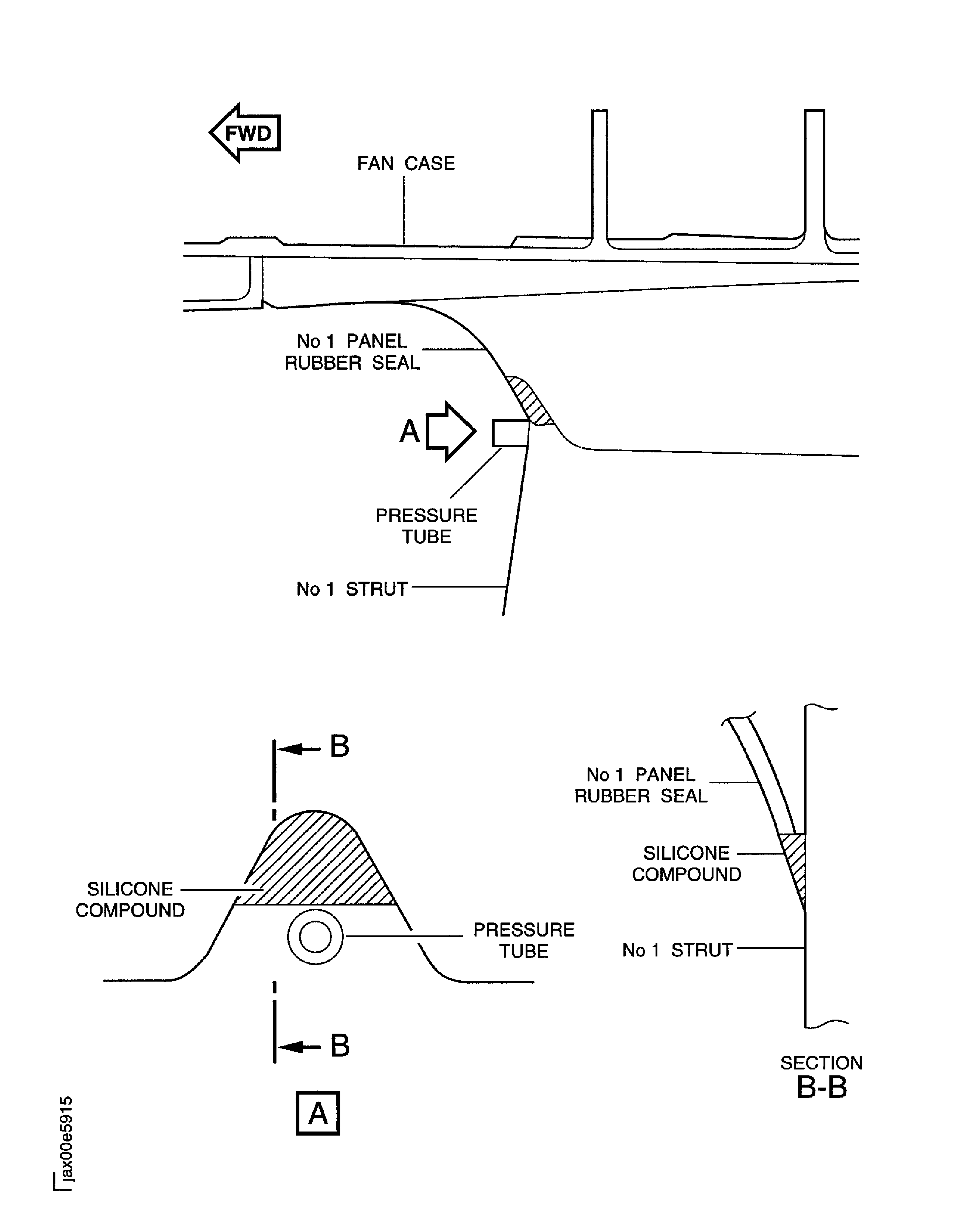

SUBTASK 72-32-00-430-315 Fill Silicone Compound in to the Corner between the No.1 Panel Rubber Seal and the Fan Frame No.1 Strut (SBE 72-0156)

SBE 72-0156: Replace the fan case No. 1 rubber seal

Clean the faces of the clearances with a clean cloth or a soft brush moist with CoMat 01-031 ACETONE (CH3)2CO or CoMat 01-124 ISOPROPYL ALCOHOL.

NOTE

Apply the primer in less than eight hours after the faces are cleaned.Apply a thin layer of CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT with a soft brush to the faces. Air dry for 30 minutes minimum.

Put CoMat 08-045 SILICONE RUBBER COMPOUND in to the clearances with the sealant dispenser.

Fill silicone compound in to the clearances identified by step A.

SUBTASK 72-32-00-430-316 Fill Silicone Compound in to Clearance between the Panel Rubber Seals and the Fan Case

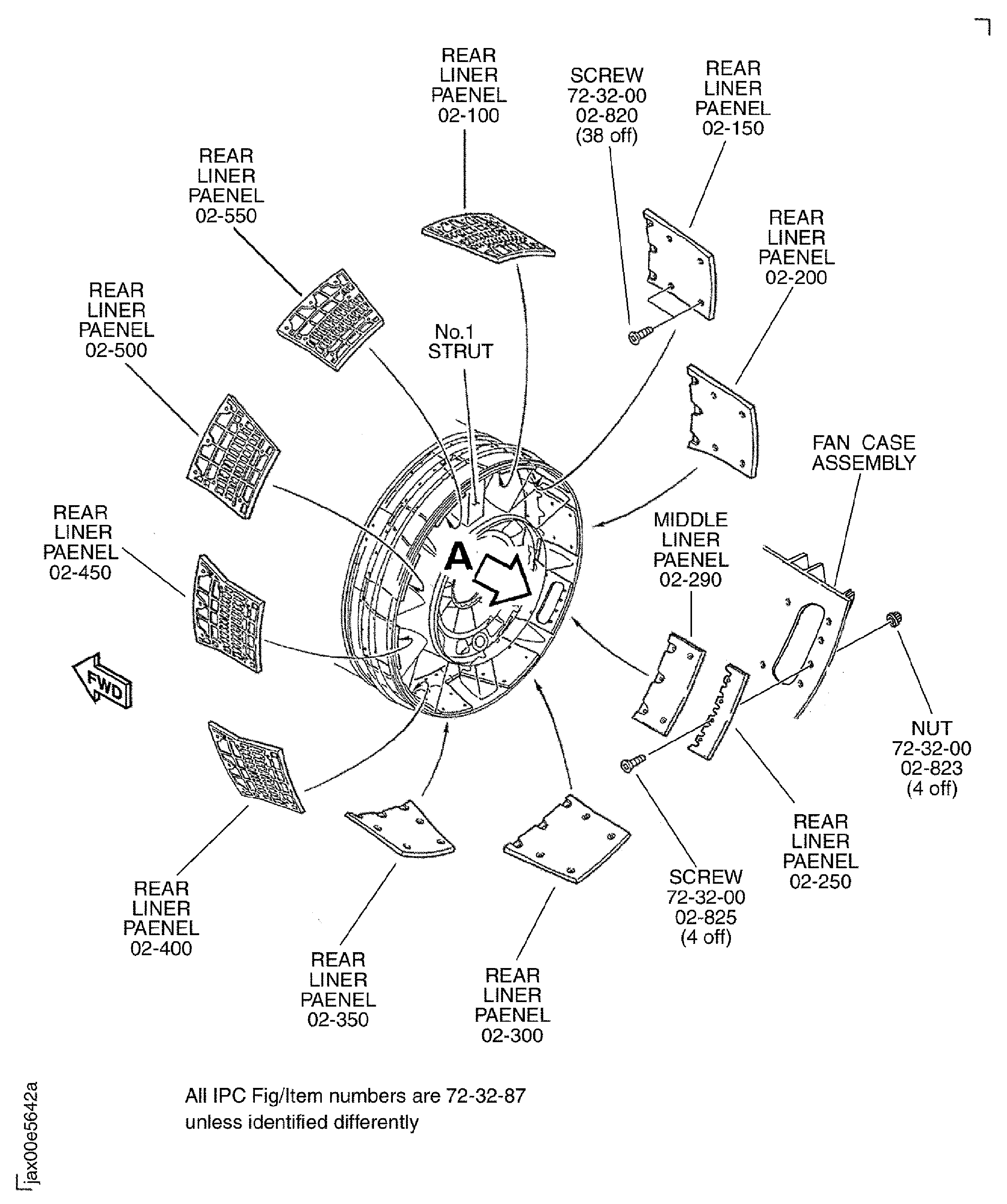

Install the 10 rear liner panels Fan Case Liner Panels And Related Parts (72-32-87, 02-100), Fan Case Liner Panels And Related Parts (72-32-87, 02-150), Fan Case Liner Panels And Related Parts (72-32-87, 02-200), Fan Case Liner Panels And Related Parts (72-32-87, 02-250), Fan Case Liner Panels And Related Parts (72-32-87, 02-300), Fan Case Liner Panels And Related Parts (72-32-87, 02-350), Fan Case Liner Panels And Related Parts (72-32-87, 02-400), Fan Case Liner Panels And Related Parts (72-32-87, 02-450), Fan Case Liner Panels And Related Parts (72-32-87, 02-500) and Fan Case Liner Panels And Related Parts (72-32-87, 02-550) on to the fan case.

Install the middle liner panel Fan Case Liner Panels And Related Parts (72-32-87, 02-290) on to the fan case.

SUBTASK 72-32-00-430-217 Install the Rear Liner Panels and the Middle Liner Panel on to the Fan Case

Procedure transferred to TASK 72-32-00-430-014-B00 (ASSEMBLY-014, CONFIG-002).

SUBTASK 72-32-00-430-216-A00 Install the 20 FEGVs and the 10 Front Liner Panels to the Fan Case

Procedure transferred to TASK 72-32-00-430-014-B00 (ASSEMBLY-014, CONFIG-002).

SUBTASK 72-32-00-430-216-B00 Install the 20 FEGVs and the Front Liner Panels to the Fan Case

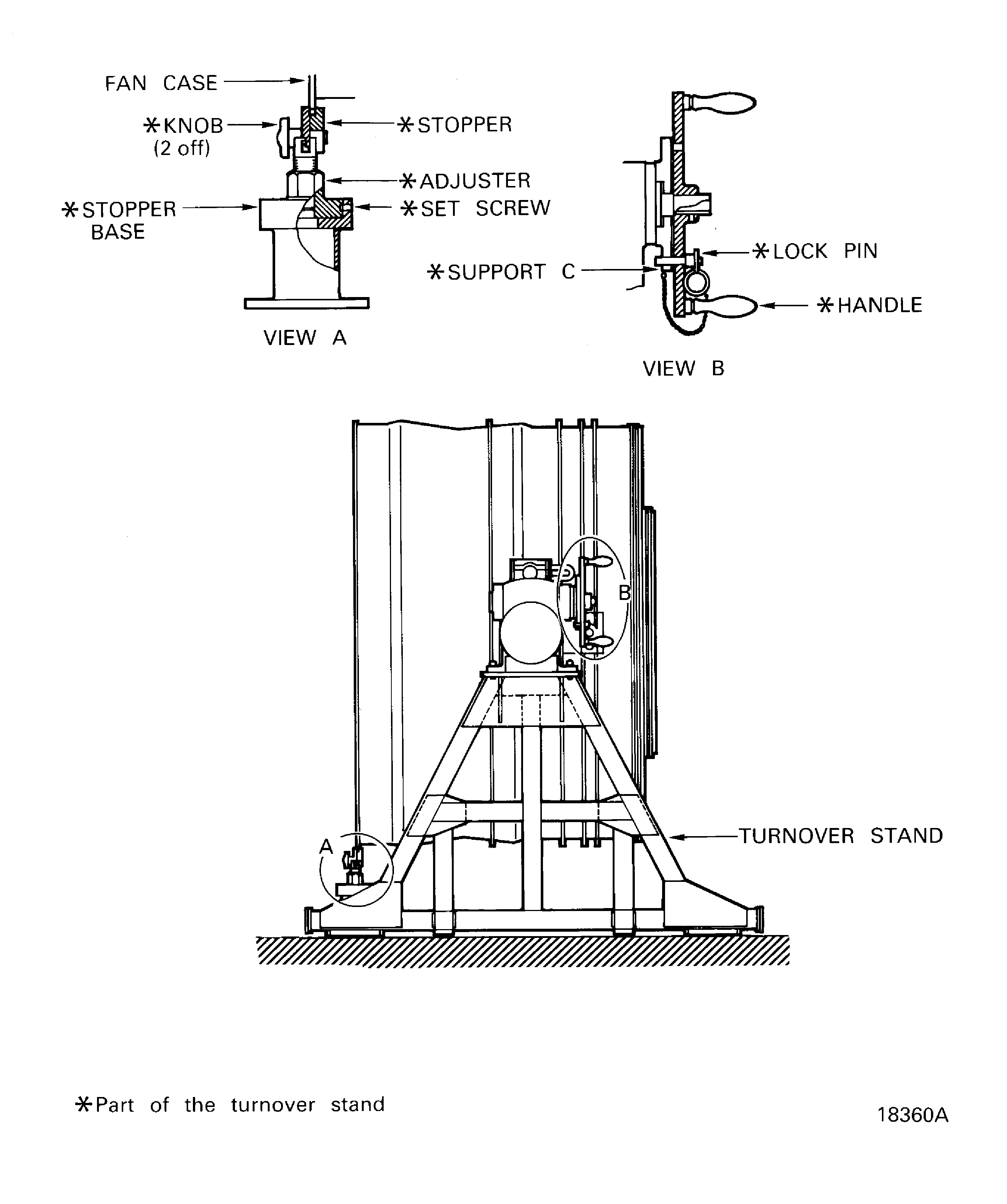

Figure: Install the lock pin in to position to lock the handle and hold the fan case front flange with the stopper

Install the lock pin in to position to lock the handle and hold the fan case front flange with the stopper

Figure: Pre SBE 72-0155: Install the rear fairing on the LP compressor bleed duct

Sheet 1

Figure: Pre SB 72-0155: Install the rear fairing on the LP compressor bleed duct

Sheet 2

Figure: SBE 72-0155: Install the rear fairing on the LP compressor bleed duct

SBE 72-0155: Install the rear fairing on the LP compressor bleed duct

Figure: Install the FEGVs on the fan case

Install the FEGVs on the fan case

Figure: SBE 70-377: Install the FEGVs on the fan case

SBE 70-377: Install the FEGVs on the fan case

Figure: Install the panel rubber seals on the fan case

Install the panel rubber seals on the fan case

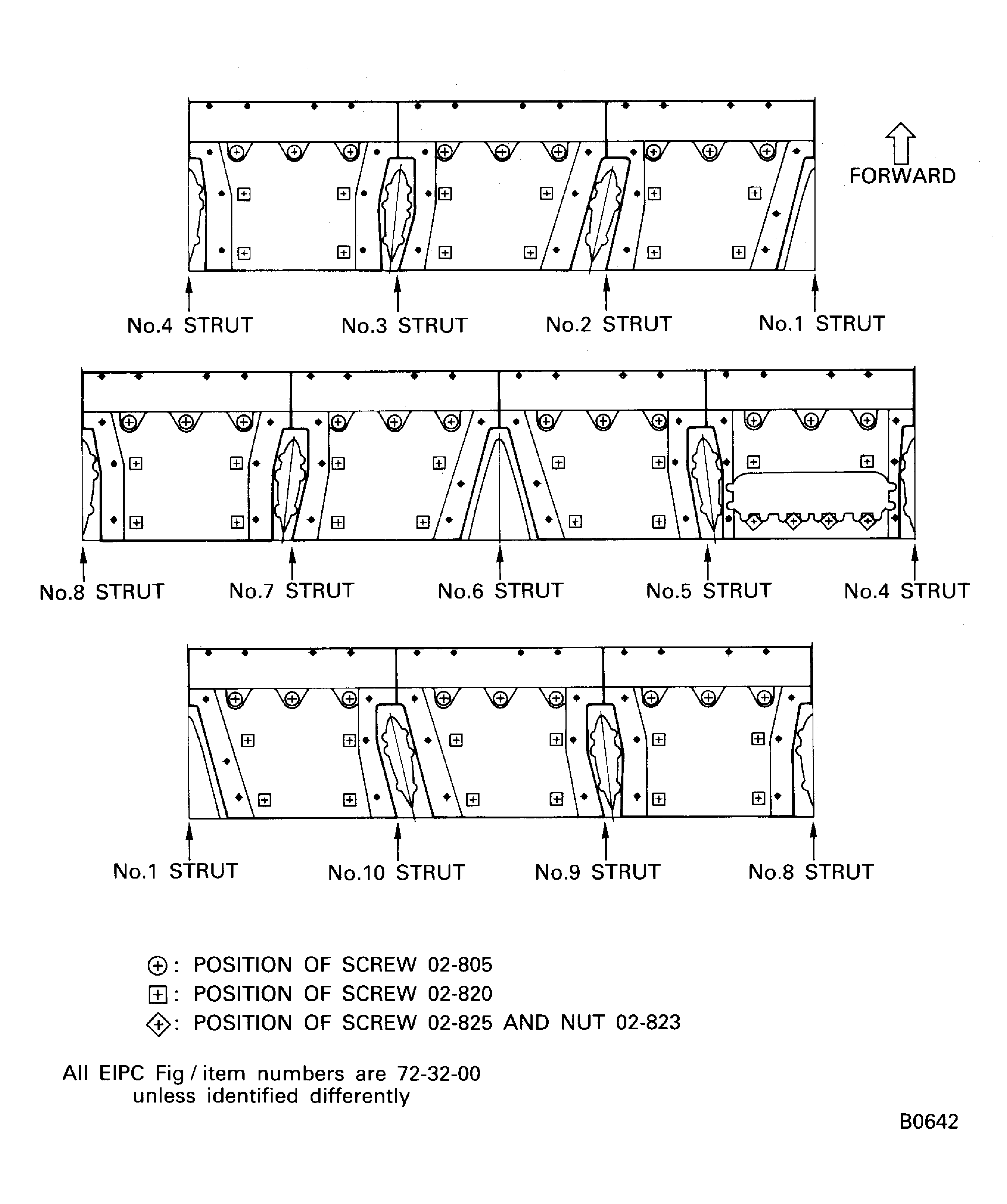

Figure: Position of the screws and the nuts which attach the panel rubber seals to the fan case

Position of the screws and the nuts which attach the panel rubber seals to the fan case

Figure: SBE 72-0156: Fill silicone compound in to the corner between the No.1 panel rubber seal and the fan frame No.1 strut

SBE 72-0156: Fill silicone compound in to the corner between the No.1 panel rubber seal and the fan frame No.1 strut

Figure: Fill silicone compound in to the clearances between the panel rubber seals and the fan case

Sheet 1

Figure: Fill silicone compound in to the clearances between the panel rubber seal and the fan case

Sheet 2

Figure: Fill silicone compound in to the clearances between the panel rubber seal and the fan case

Sheet 3

Figure: Install the rear liner panels and the middle liner panel on the fan case

Sheet 1

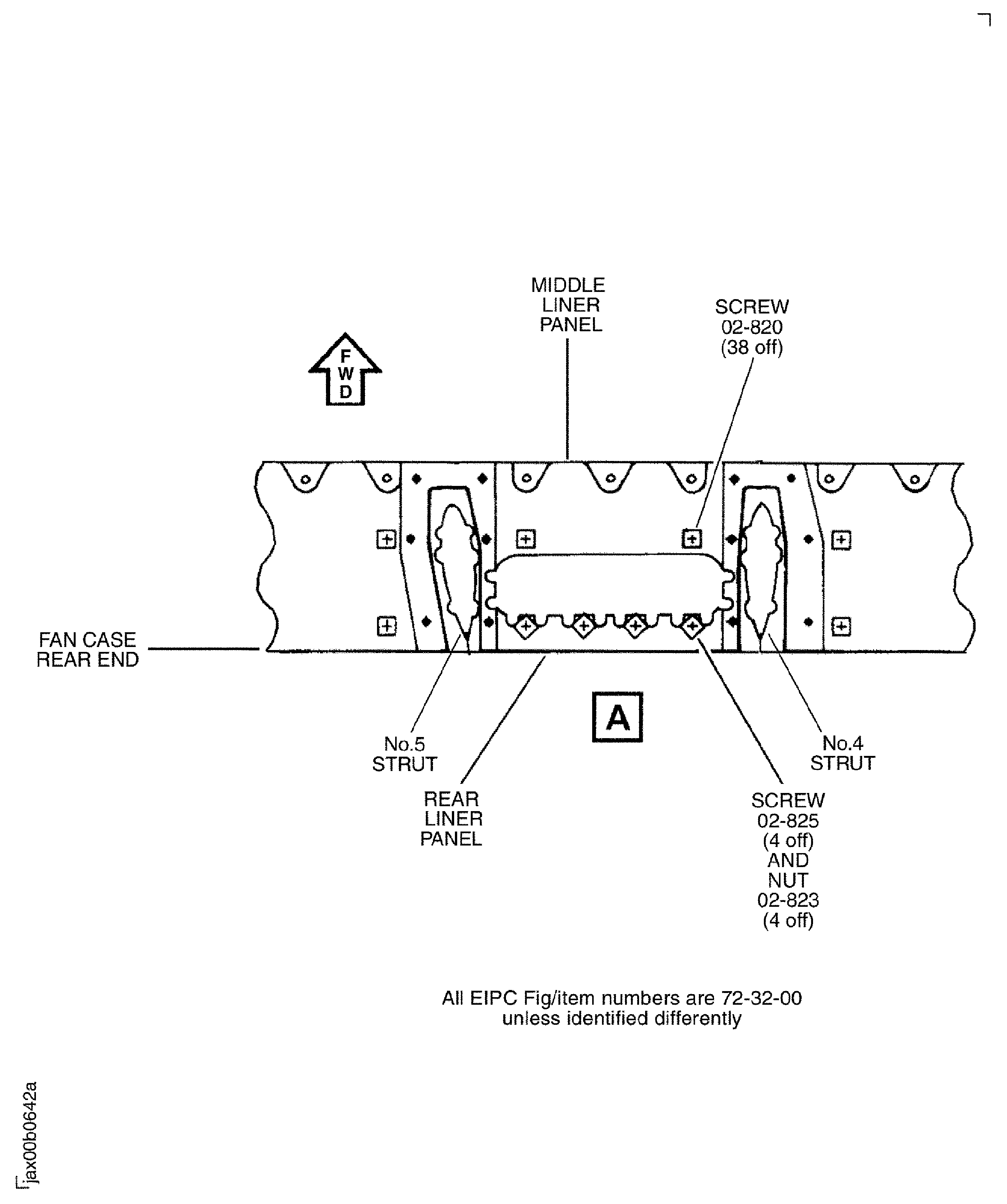

Figure: Install the rear liner panels and the middle liner panel on the fan case

Sheet 2

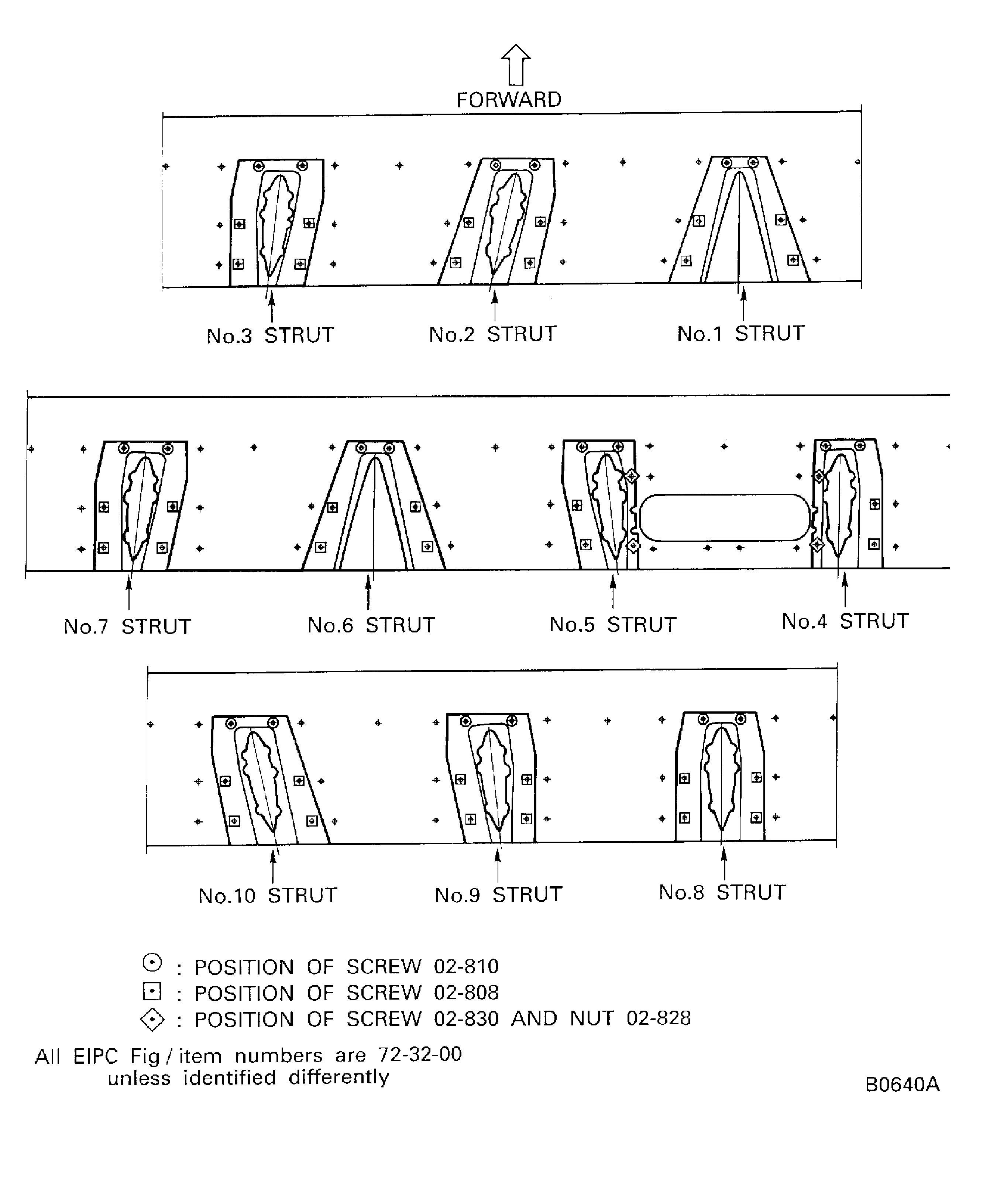

Figure: Position of the screws and the nuts which attach the rear liner panels, the middle liner panel and the front liner panels to the fan case

Position of the screws and the nuts which attach the rear liner panels, the middle liner panel and the front liner panels to the fan case