DMC:V2500-A5-72-32-6001-00A-933A-CIssue No:001.00Issue Date:2013-11-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

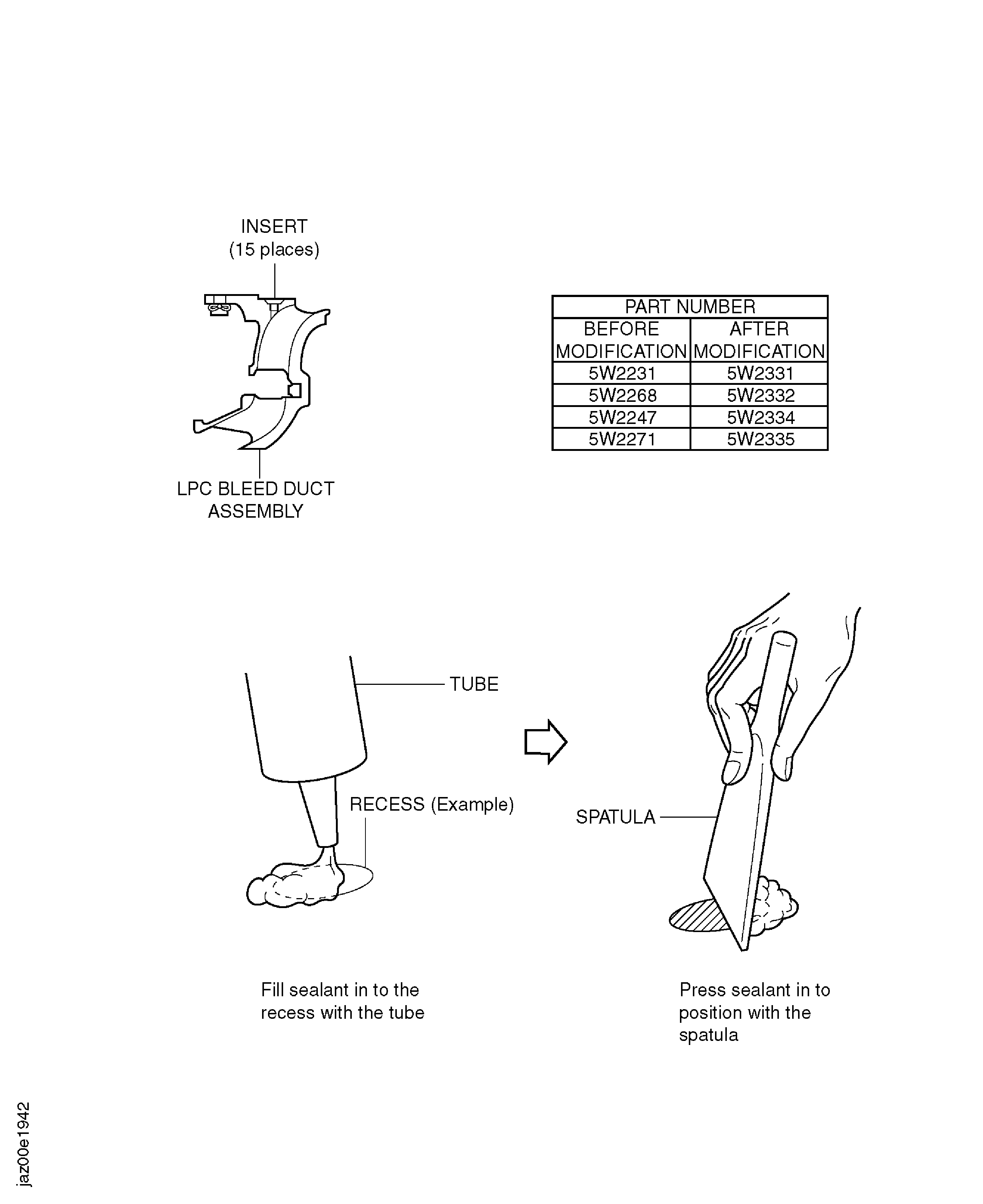

TASK 72-32-60-840-001 LPC Bleed Duct - Rework The Inset Holes, Rework-001 - SBE 72-0485

General

The practices and procedures referred to in the procedure by the TASK numbers are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

NOTE

To identify the consumable materials, refer to the PCI.

Other consumable materials are given in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-028 CHROMATE CONVERSION COATING FOR ALUMINUM | LOCAL | CoMat 07-028 | ||

| CoMat 07-070 ZINC CHROMATE PRIMER | IAE59 | CoMat 07-070 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 | ||

| CoMat 08-074 SEALANT, RTV SILICONE | 01139 | CoMat 08-074 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-35-08-300-501.

Remove the Helicoil inserts from LPC bleed duct assembly.

SUBTASK 72-32-60-350-114 Remove the Inserts

NEW NUMBER - 5W2331.

Case 2. NUMBER BEFORE - 5W2268.

NEW NUMBER - 5W2332.

Refer to the SPM TASK 70-09-00-400-501.

Vibro engrave the new part number near to the existing part number.

SUBTASK 72-32-60-350-118 Vibro Engrave the New Part Number

Refer to the SPM TASK 70-11-26-300-503.

De-grease the blended surface with a cloth.

SUBTASK 72-32-60-350-119 Surface Treat the Vibro Area

Figure: Rework and re-identification of LPC Bleed Duct Assembly

Rework and re-identification of LPC Bleed Duct Assembly

Figure: Family Tree - LPC Bleed Duct Assembky for V2500-A5

Family Tree - LPC Bleed Duct Assembky for V2500-A5