Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-32-86-300-009 Intermediate Structure Rear Fairing - Replace Damaged Pads, Repair-009 (VRS1983)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Rear fairing assembly | Resin impregnated carbon fiber fabric |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard equipment | LOCAL | Standard equipment | none | |

| IAE 3J12143 Machining fixture | 0AM53 | IAE 3J12143 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-050 SILICON CARBIDE GRIT | 1E1X8 | CoMat 05-050 | ||

| CoMat 05-082 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-082 | ||

| CoMat 05-083 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-083 | ||

| CoMat 06-073 INK, METAL MARKING | 88303 | CoMat 06-073 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Block | 5A1925 | AR | (Pad) |

Safety Requirements

NONEProcedure

Refer to Figure.

SUBTASK 72-32-86-350-067 Remove the Dimple Washers and Damaged Pads from the Rear Fairing Assembly

Refer to Figure.

Use CoMat 05-082 WATERPROOF SILICON CARBIDE and CoMat 05-083 WATERPROOF SILICON CARBIDE and/or fine file.

Remove burrs.

SUBTASK 72-32-86-350-068 Prepare the New Pads for Replacement

Refer to Figure.

Use CoMat 01-124 ISOPROPYL ALCOHOL. Refer to the SPM TASK 70-11-26-300-503.

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.Remove the grease from the mating surfaces of the rear fairing assembly and pads.

Use CoMat 05-050 SILICON CARBIDE GRIT at 75.8 to 81.4 psi (523.1 to 561.6 KPa) pressure and 45 degree impingement angle.

Dry abrasive blast the pads surface.

Use CoMat 01-124 ISOPROPYL ALCOHOL. Refer to the SPM TASK 70-11-26-300-503.

Do Step again.

SUBTASK 72-32-86-360-056 Prepare the Mating Surface for the Cold Curing Silicon Compound

Refer to the SPM TASK 70-36-02-360-501.

CAUTION

DO NOT EAT OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.NOTE

The primer must be applied immediately after the mating surfaces are prepared. Cure at room temperature.Apply a thin layer of primer only to the prepared mating surface of rear fairing assembly.

Use a spatula and CoMat 08-013 COLD CURING SILICONE COMPOUND.

Apply the cold curing silicon rubber compound to each of the mating surfaces as soon as the primer is dry.

Use a clamp.

Make sure that the compound can be seen around the pads edges.

Make smooth the fillet radius using the protruded silicone rubber compound around three edges.

The rear edge of the pad may be filled with silicon rubber compound.

Do not damage the assembled component.

Keep the required position and apply sufficient pressure to ensure good adhesion.

Install the pads to the inside of the rear fairing assembly aligning the dimple washer holes, in not more than ten minutes after the compound is applied.

SUBTASK 72-32-86-360-057 Apply and Cure the Cold Curing Silicone Compound

Refer to Figure.

Use CoMat 05-082 WATERPROOF SILICON CARBIDE, CoMat 05-083 WATERPROOF SILICON CARBIDE and/or fine file.

Material of the pad must be removed smoothly to keep the countersunk hole contour of the rear fairing.

Dress any steps found in the countersunk hole.

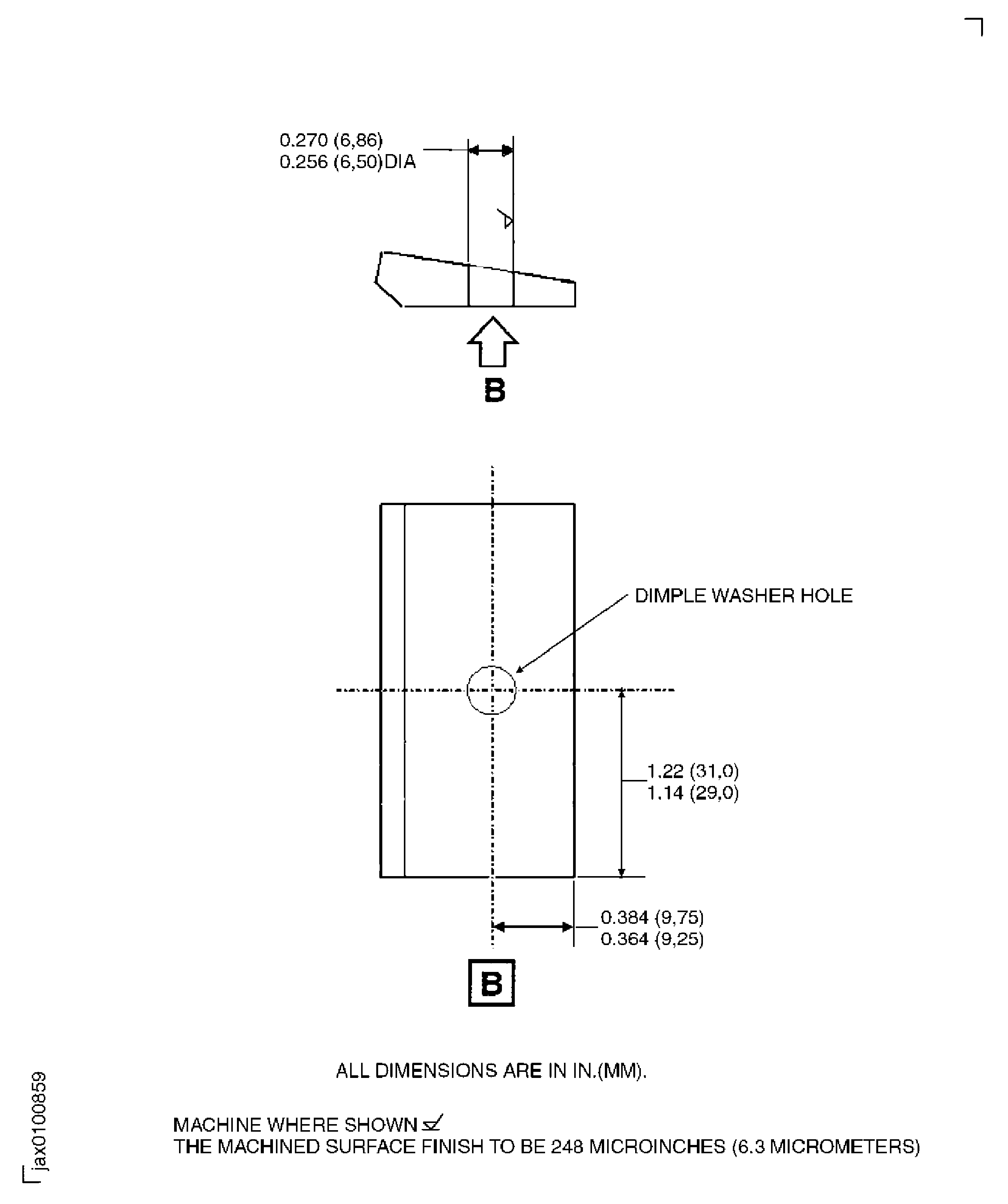

SUBTASK 72-32-86-322-001 Machine the Bonded Pads of the Rear Fairing Assembly

Refer to Figure.

SUBTASK 72-32-86-220-100 Examine the Machined Pads of the Rear Fairing Assembly

Refer to Repair, VRS1784 TASK 72-32-86-300-003 (REPAIR-003).

Install the dimple washers to the rear fairing assembly.

SUBTASK 72-32-86-360-058 Install the Dimple Washer

Refer to the SPM TASK 70-09-00-400-501.

Use the ink method.

Mark VRS1983, adjacent to the part number.

SUBTASK 72-32-86-350-069Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions