Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 70-11-49-110-501 Stock Loss Determination Of Cleaning Solutions

Equipment and Material | |

Testing of Cleaning Solutions | |

Prepare the Standard Test Panels for Cleaning Solution Stock Loss Test | |

Apply a Layer to Test Panels for the Stock Loss Test | |

Cleaning Solution Stock Loss Test | |

Procedure for Correction | |

Criteria to Use Panels Again for Subsequent Stock Loss Tests | |

Solution Testing Schedule | |

Material or Coating Densities | |

Cleaning and Preservation Consumables |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-393 ACETONE | LOCAL | CoMat 01-393 | ||

| CoMat 01-410 ISOPROPYL ALCOHOL, REAGENT GRADE | 0AL61 | CoMat 01-410 | ||

| CoMat 10-061 STODDARD SOLVENT | LOCAL | CoMat 10-061 | ||

| CoMat 12-027A CORROSION PREVENTIVE COMPOUND | 0AM53 | CoMat 12-027A |

Spares

NONESafety Requirements

WARNING

WARNING

WARNING

WARNING

Procedure

This document specifies controls and tests for cleaning and preservation consumables that you use in a tank.

NOTE

Service-related corrosion is usually on local areas of the part. When cleaning solutions cause corrosive attack, the attack is on all surfaces of the part.NOTE

The chemical properties of cleaning solutions can change if the solution temperature becomes higher than the specified operating temperature, and this can cause stock loss rates to increase on some metals. Thermostat malfunction or operator error can cause the solution temperature to become too high.

General.

SUBTASK 70-11-49-860-010 Testing of Cleaning Solutions

Refer to Step for the panel materials and coatings that are necessary for the cleaning solution.

Cut panels from the applicable sheet stock materials to: 5 inches plus or minus 0.0625 (127.00 plus or minus 1.588 mm) long x 2 plus or minus 0.0625 inches (50.8 plus or minus 1.588 mm) x approximately 0.040 inch (1.016 mm) or 0.060 inch (1.524 mm) thick.

To make the standard test panels, do the steps in the subsequent procedure:

Refer to Step for the panel materials and coatings that are necessary for the cleaning solution.

The subsequent list gives the part numbers for the standard test panels made of each sheet stock material:

Material

Test Panel Part Number

AMS 5504 Stainless Steel

PWA 37606

AMS 5508 Stainless steel

PWA 37623

AMS 5536 Nickel Alloy

PWA 37611

AMS 4911 Titanium Alloy

PWA 37604

These test panels are available from:

It is permitted to purchase the standard test panels.

As an alternative, it is permitted to use a plain uncoated test panel from a completed stock loss test again for a subsequent stock loss test if the test panel agrees with the requirements in Step (Criteria To Use Test Panels Again). It is necessary to do the abrasive blast step below to prepare the panel before you do the subsequent stock loss test.

Make or purchase the standard test panels.

SUBTASK 70-11-49-180-002 Prepare the Standard Test Panels For Cleaning Solution Stock Loss Test

Use AMS 5504 steel panels plated with nickel 0.0018 in. to 0.0022 in. (0.046 mm to 0.056 mm) thick. Refer to SPM TASK 70-33-06-300-503.

SUBTASK 70-11-49-300-001 Apply a Layer to the Test Panels for Stock Loss Test

Use stainless steel wire to hang the test panel in the cleaning solution.

NOTE

Electrical connection between the test panel and the tank or other grounding source will cause a galvanic effect, which will cause the test result to not be accurate.NOTE

If the test panel touches or is very near to the heater coils, the test result will not be accurate.Keep the test panel in the solution for the time specified in Step.

Hang the test panel in the cleaning solution 2.0 inches (50.8 mm) minimum below the surface of the cleaning solution.

SUBTASK 70-11-49-180-003 Cleaning Solution Stock Loss Test

SUBTASK 70-11-49-180-005 Procedure for Correction

CAUTION

CHEMICALS USED WITH THE CLEANING PROCEDURES WHICH REFER TO CONCENTRATIONS, CYCLE TIMES, AND OPERATION TEMPERATURES HAVE BEEN APPROVED AS SATISFACTORY TO BE APPLIED TO THE JET ENGINE PARTS SPECIFIED. IT IS THE RESPONSIBILITY OF THE OPERATOR TO MAKE SURE THAT THESE SPECIFICATIONS ARE FOLLOWED.Do Step before you use the test panel for a subsequent stock loss test.

If a plain uncoated panel shows no etching or pits after the stock loss test, it is permitted to use the again for subsequent stock loss tests.

Plain Uncoated Panels.

SUBTASK 70-11-49-180-004 Criteria to Use Panels Again for Subsequent Stock Loss Tests

SUBTASK 70-11-49-180-006 Solution Testing Parameters

NOTE

Refer to the SPM TASK 70-11-48-110-501 for the solution make-up instructions.Solution Name (Specification)

Panel Material or Coating Layer

Applicable Cleaning Procedure (Note)

Time in Solution

(In Minutes)

Acidic Scale Conditioner Solution

(Solution Code 91, 96, 119, 160)

AMS 5504

AMS 5508

AMS 5536

(1)

(1)

(1)

60

60

60

Alkaline Permanganate Solution

(Solution Code 100, 140, 161, 162, 168)

AMS 5504

AMS 5508

AMS 5536

(1)

(1)

(1)

60

60

60

Alkaline Rust Remover Solution

(Solution Code 20, 23, 24, 25, 97)

AMS 2416

AMS 5504

AMS 5508

AMS 5536

AMS 4911

AMS 4911

(2)

(1) (2)

(1) (2)

(1) (2)

(3)

(4)

60

60

60

60

10

60

Alkaline Rust Remover Solution

(Solution Code 175)

AMS 2416

AMS 5504

AMS 5508

AMS 5536

(2)

(1) (2)

(1) (2)

(1) (2)

60

60

60

60

Alkaline Rust Remover Solution

(Solution Code 106, 108, 109, 111)

AMS 4911

(4)

60

Caustic-Potassium Permanganate Descaling Solution

(Solution Code 1)

AMS 5504

AMS 5508

AMS 5536

(1)

(1)

(1)

60

60

60

Inhibited Phosphoric Acid

(Solution Code 14)

AMS 2424

AMS 5504

AMS 5508

AMS 5536

(1)

(1)

(1)

(1)

60

60

60

60

Sodium Hydroxide Solution

(11 percent)

(Solution Code 51)

Refer to TASK 70-11-47-110-501, SUBTASK 70-11-47-180-035 for the Test Method.

NOTE

(1) SPM TASK 70-11-54-300-503.(2) SPM TASK 70-11-13-300-503.(3) SPM TASK 70-11-06-300-503, SUBTASK 70-11-06-300-002-A01.(4) SPM TASK 70-11-06-300-503, SUBTASK 70-11-06-300-002-A02.Controls and tests for cleaning and preservation consumables that you can use in a tank:

CoMat Number and Name

Frequency

Test and Requirements

Deleted

Deleted

Deleted

Each 2 months

Specific Gravity: 0.775 to 0.805. Copper corrosion: ASTM B5 corrosion standard 1b maximum and no pitting.

Each 1 month

Copper corrosion: ASTM B5 corrosion standard 1b maximum and no pitting. Volatile content: 60 to 94 percent.

SUBTASK 70-11-49-180-008 Cleaning and Preservation Consumables

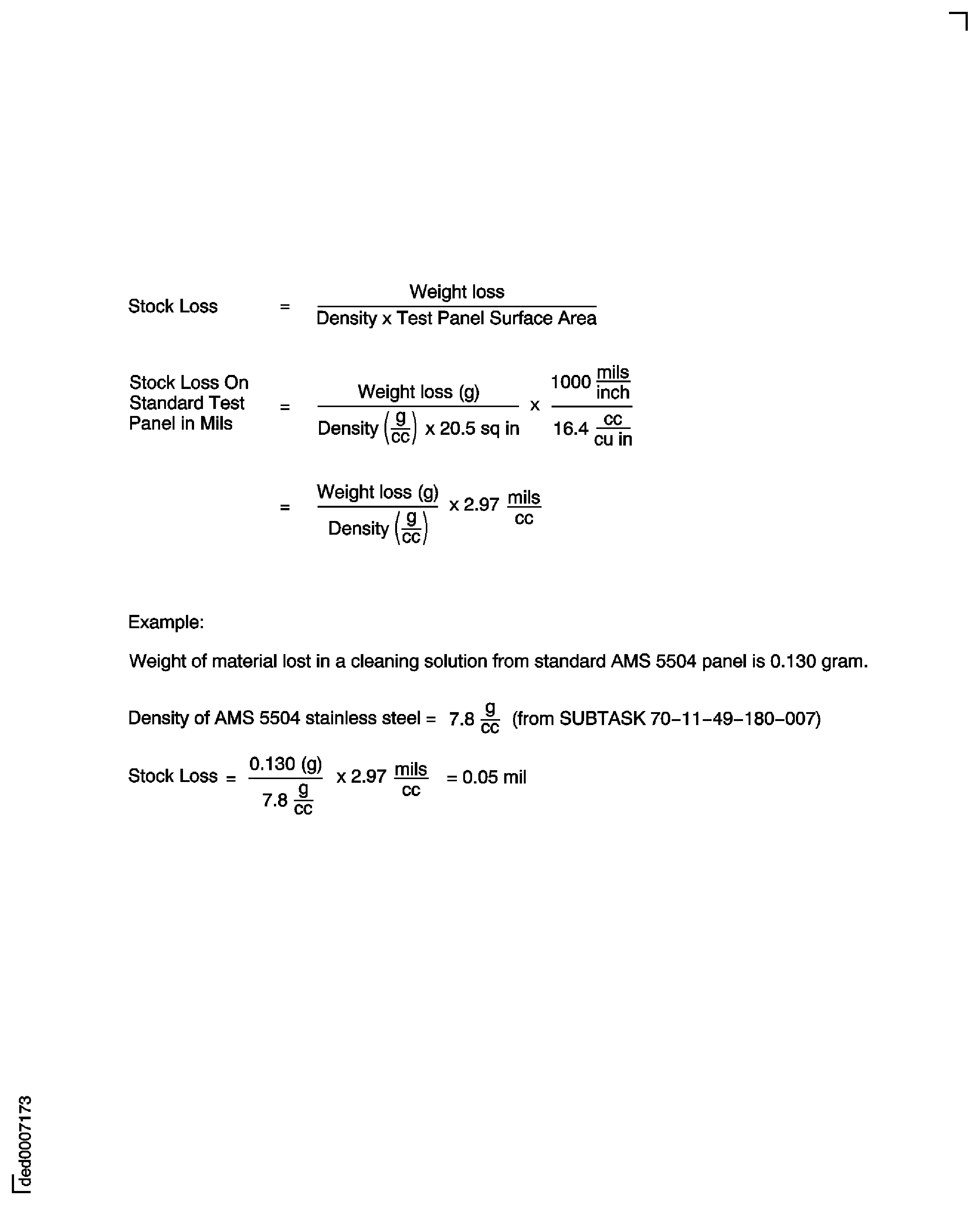

Figure: Calculate the material loss in the cleaning solution

Calculate the material loss in the cleaning solution