Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-32-450-016 LPC/Intermediate Case Module Components - Install The Low Pressure Oil Switch, Installation-023

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha-variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the item number.

For standard torque date and procedures, refer to the SPM.TASK 70-41-00-400-501 and SPM TASK 70-41-02-400-501

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-039 ENGINE OIL, unless other lubricants are referred to in te procedure.

For lockwire data and procedures refer to SPM TASK 70-42-05-400-501.

For the data on electrical connectors refer to the SPM TASK 70-43-00-400-501 and SPM TASK 70-43-01-400-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Torque wrench, range 0 to 250 lbfin (0 to 20 Nm) | LOCAL | Torque Wrench 0-250 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | 0AM53 | CoMat 01-002 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-126 LOCKWIRE | LOCAL | CoMat 02-126 | ||

| CoMat 10-039 ENGINE OIL | LOCAL | CoMat 10-039 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

WARNING

DO NOT LET ENGINE OIL STAY ON YOUR SKIN FOR A LONG TIME. FLUSH THE OIL FROM YOUR SKIN WITH WATER. THE OIL IS POISONOUS AND CAN GO THROUGH YOUR SKIN AND IN TO YOUR BODY.DO NOT GET THE CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. USE THE FLUID IN A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET THE FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL HELP IF YOUR SKIN OR EYES BECOME IRRITATED.

CAUTION

DO NOT LET ENGINE OIL FALL ON THE ENGINE. UNWANTED OIL MUST BE REMOVED IMMEDIATELY WITH A CLEAN CLOTH. THE OIL CAN CAUSE DAMAGE TO THE SURFACE PROTECTION AND TO SOME PARTS.NOTE

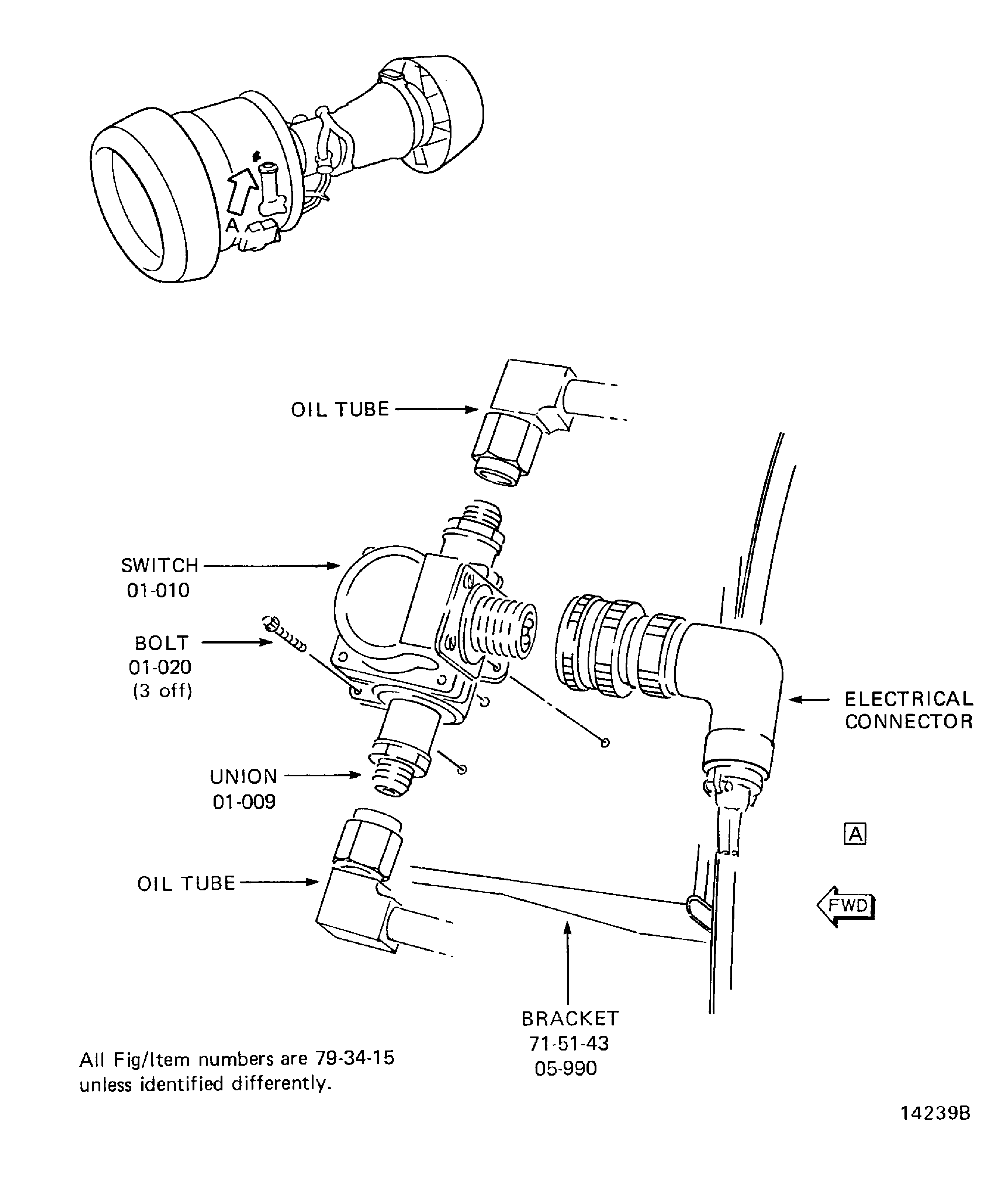

Wipe the components with a clean piece of lint free cloth before the fluid dries.Use CoMat 02-099 LINT-FREE CLOTH and CoMat 01-002 SOLVENT, DELETED. to clean the interfaces of these components: bracket General Services Harness (71-51-43, 05-990), low pressure oil (LPO) switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010), bolts LOW OIL PRESSURE SWITCH (79-34-15, 01-020), electrical connectors and oil tubes.

SUBTASK 72-00-32-110-051 Clean the Parts

Refer to Figure.

Hold the LPO switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010) on the bracket General Services Harness (71-51-43, 05-990), in the position noted on removal. Attach the switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010) to the bracket General Services Harness (71-51-43, 05-990) with the bolts LOW OIL PRESSURE SWITCH (79-34-15, 01-020). Torque the bolts LOW OIL PRESSURE SWITCH (79-34-15, 01-020) to 100 lbf.in (11.3 Nm).

Connect the oil tubes to the LPO switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010). Hold the unions LOW OIL PRESSURE SWITCH (79-34-15, 01-009) with an applicable wrench and torque the tube nuts to between 135 and 145 lbf.in (15.3 and 16.4 Nm).

Connect the electrical connector to the LPO switch LOW OIL PRESSURE SWITCH (79-34-15, 01-010).

SUBTASK 72-00-32-440-063 Install the LPO Switch

Refer to Figure.

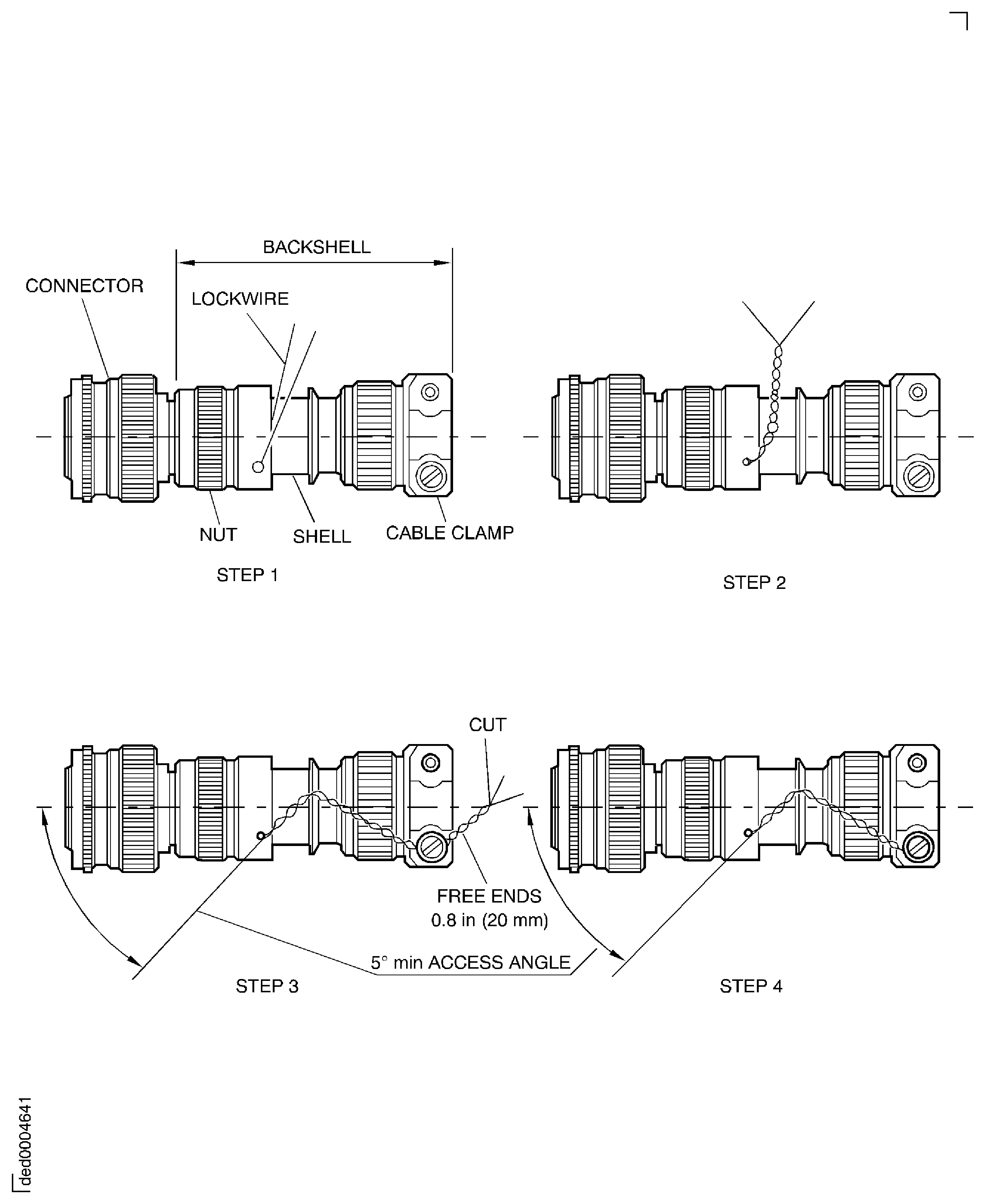

Make sure that all the applicable backshells and cable clamps are safetied with CoMat 02-126 LOCKWIRE. Refer to the SPM TASK 70-42-05-400-501.

SUBTASK 72-00-32-210-071 Visually Inspect the Electrical Backshells and Cable Clamps

Figure: Low pressure oil switch

Low pressure oil switch

Figure: Visually inspect the backshells and cable clamps

Visually inspect the backshells and cable clamps