Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-00-60-020-003-001 External Gearbox Module - Remove The External Gearbox Module - Method 1, Removal-003

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of the threaded parts and parts with an interference fit. Let the parts soak before removal.

Remove and discard the lockwire before parts are disconnected or removed.

Discard all rubber seal rings, cotter pins and seal washers removed in this procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10011 Handling fixture | 0AM53 | IAE 1F10011 | 2 | |

| IAE 1F10021 Storage stand | 0AM53 | IAE 1F10021 | 1 | |

| IAE 1F10022 Hydraulic jack | 0AM53 | IAE 1F10022 | 1 | |

| IAE 1F10023 Gearbox adapter | 0AM53 | IAE 1F10023 | 1 | |

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10292 Puller | 0AM53 | IAE 1F10292 | 1 | |

| IAE 1F10293 Puller | 0AM53 | IAE 1F10293 | 1 | |

| IAE 1F10294 Puller | 0AM53 | IAE 1F10294 | 1 | |

| IAE 1F10412 Puller | 0AM53 | IAE 1F10412 | 1 | |

| IAE 1J12082 Holding Cap | LOCAL | IAE 1J12082 | 1 | |

| Container - Minimum capacity of about 10 USgal (38 l) | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-147 LOCKWIRE | LOCAL | CoMat 02-147 | ||

| CoMat 10-058 PENETRATING OIL | LOCAL | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Release and remove the drain oil plug ENGINE-MAIN GEARBOX CASE AND FITTINGS (72-60-21, 01-120) from the front flange of the main gearbox casing, below the oil pressure pump. Discard the packing from the plug.

WARNING

DO NOT GET ENGINE OIL ON YOUR SKIN FOR LONG PERIODS. THE OIL IS POISONOUS AND CAN GO THROUGH YOUR SKIN AND IN TO YOUR BODY.TO LET THE TANK PRESSURE BLEED OFF, DO NOT REMOVE THE OIL TANK CAP FOR FIVE MINUTES AFTER THE ENGINE STOPS. THE HOT OIL IS DANGEROUS.

CAUTION

DO NOT LET THE ENGINE MOTOR WHEN THE OIL IS DRAINED.Drain the oil tank.

Remove the Left-Hand Gearbox magnetic chip detector (MCD). Refer to TASK 72-00-00-050-001 (REMOVAL-001).

Remove the MCD housing OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-120).

Unscrew and remove the MCD housing. Discard the lockwire. Let the oil drain into a container.

Remove and discard the seal ring OIL-MAGNETIC CHIP DETECTOR (79-22-45, 01-140) from the MCD housing.

Drain the external gearbox.

SUBTASK 72-00-60-020-051 Drain the Engine Oil System

Remove the gearbox dressings, refer to TASK 72-00-60-020-001.

SUBTASK 72-00-60-020-052 Remove the Gearbox Dressings

Refer to Figure.

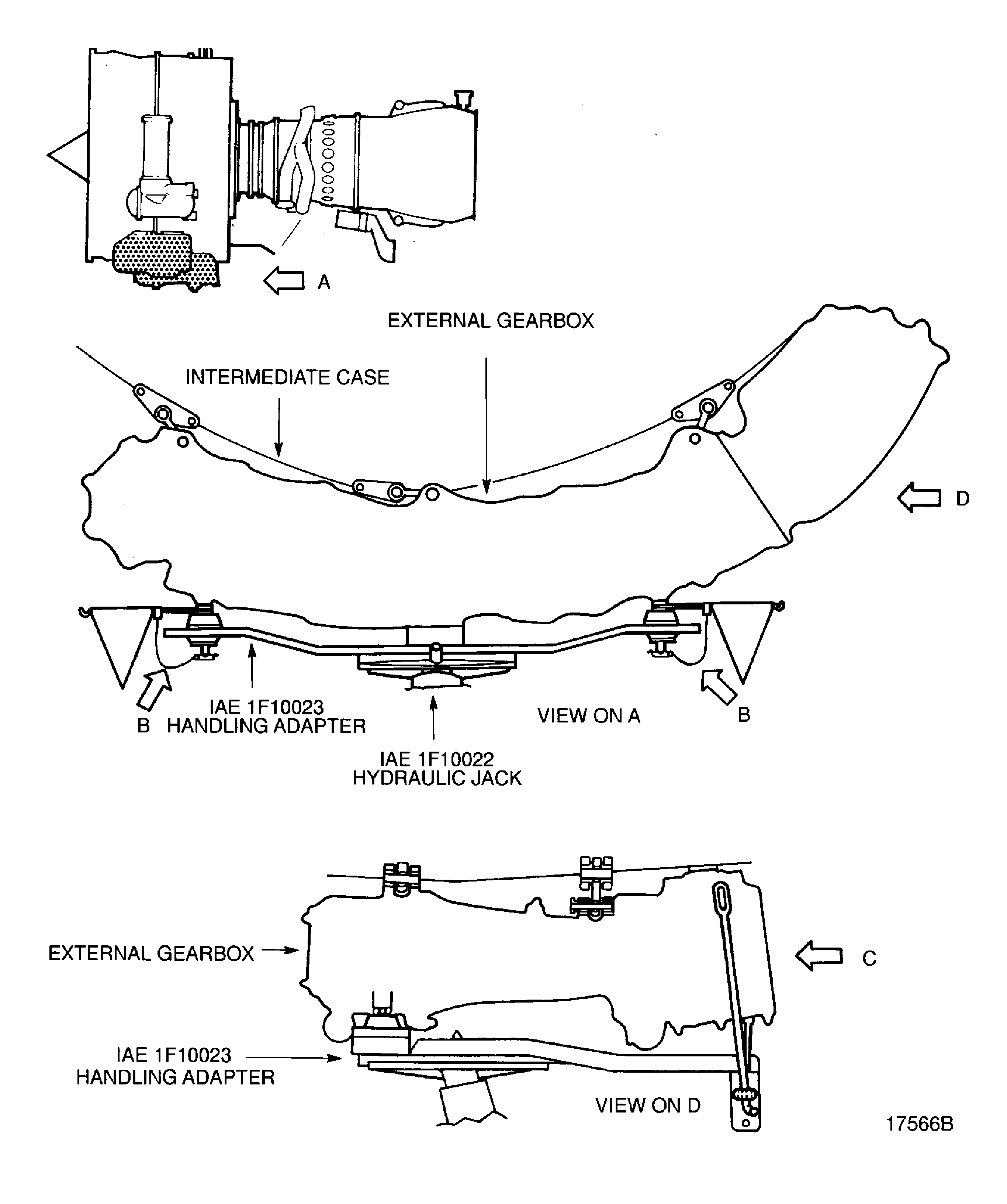

Install the IAE 1F10011 Handling fixture 2 off on the ground handling bosses on the bottom of the external gearbox.

If necessary, install the IAE 1F10026 Hydraulic hand pump 1 off on the IAE 1F10022 Hydraulic jack 1 off and connect the hose.

Install IAE 1F10023 Gearbox adapter 1 off on the plate of the hydraulic jack. Make sure the adjustable support of the hydraulic jack is in lowered position.

SUBTASK 72-00-60-020-053 Install the External Gearbox Support Tooling

Refer to Figure.

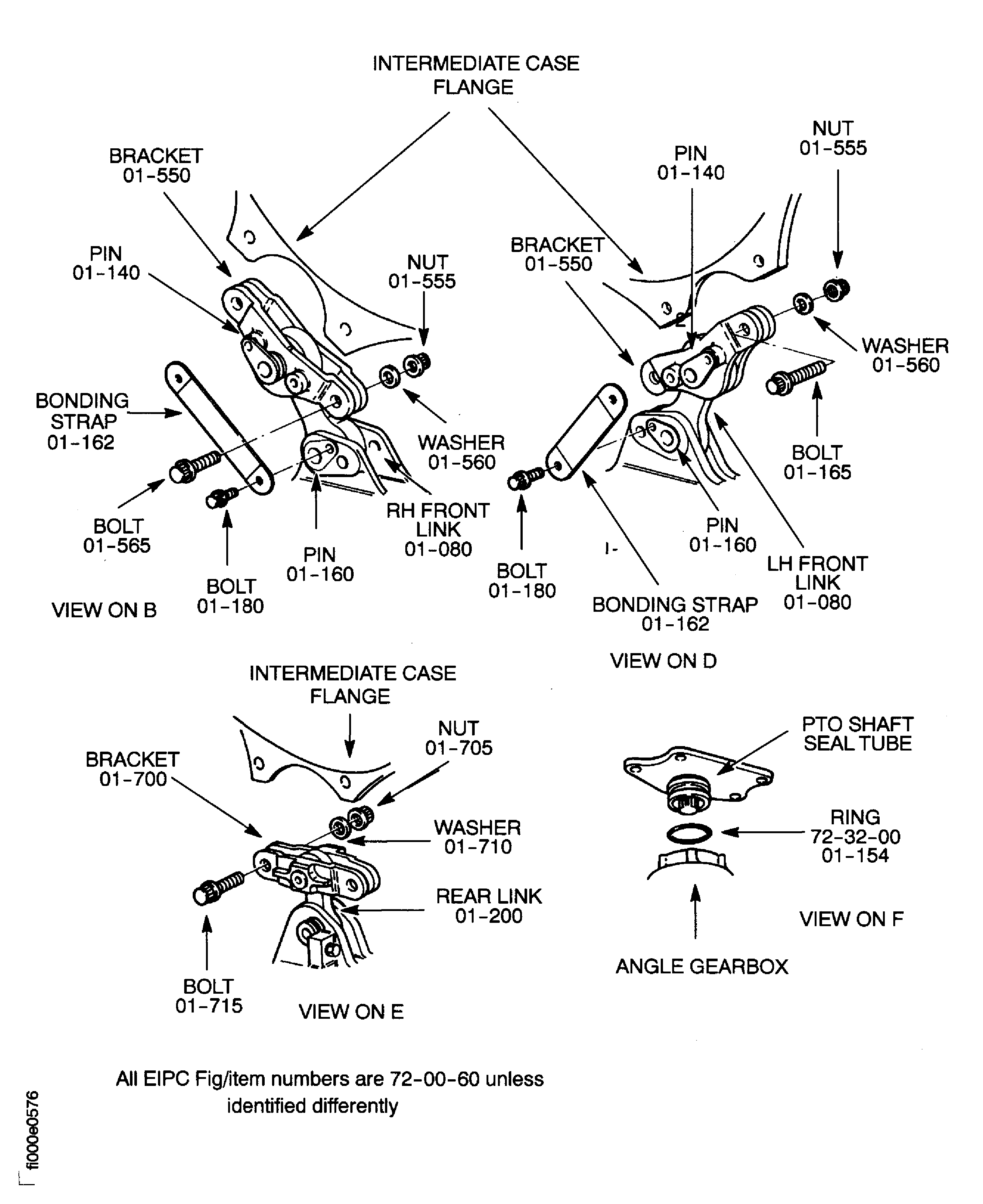

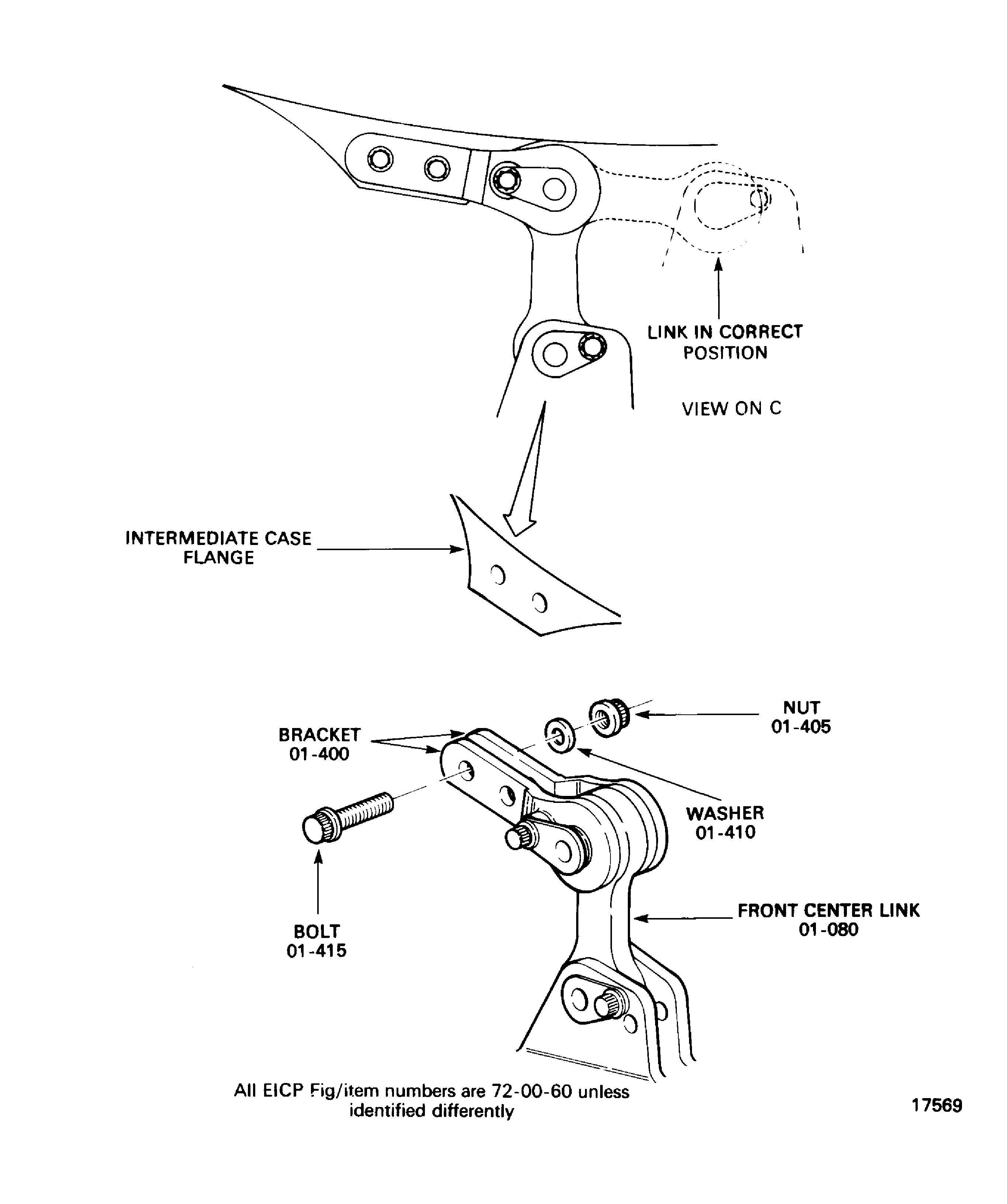

SUBTASK 72-00-60-020-054 Disconnect the External Gearbox from the Intermediate Case

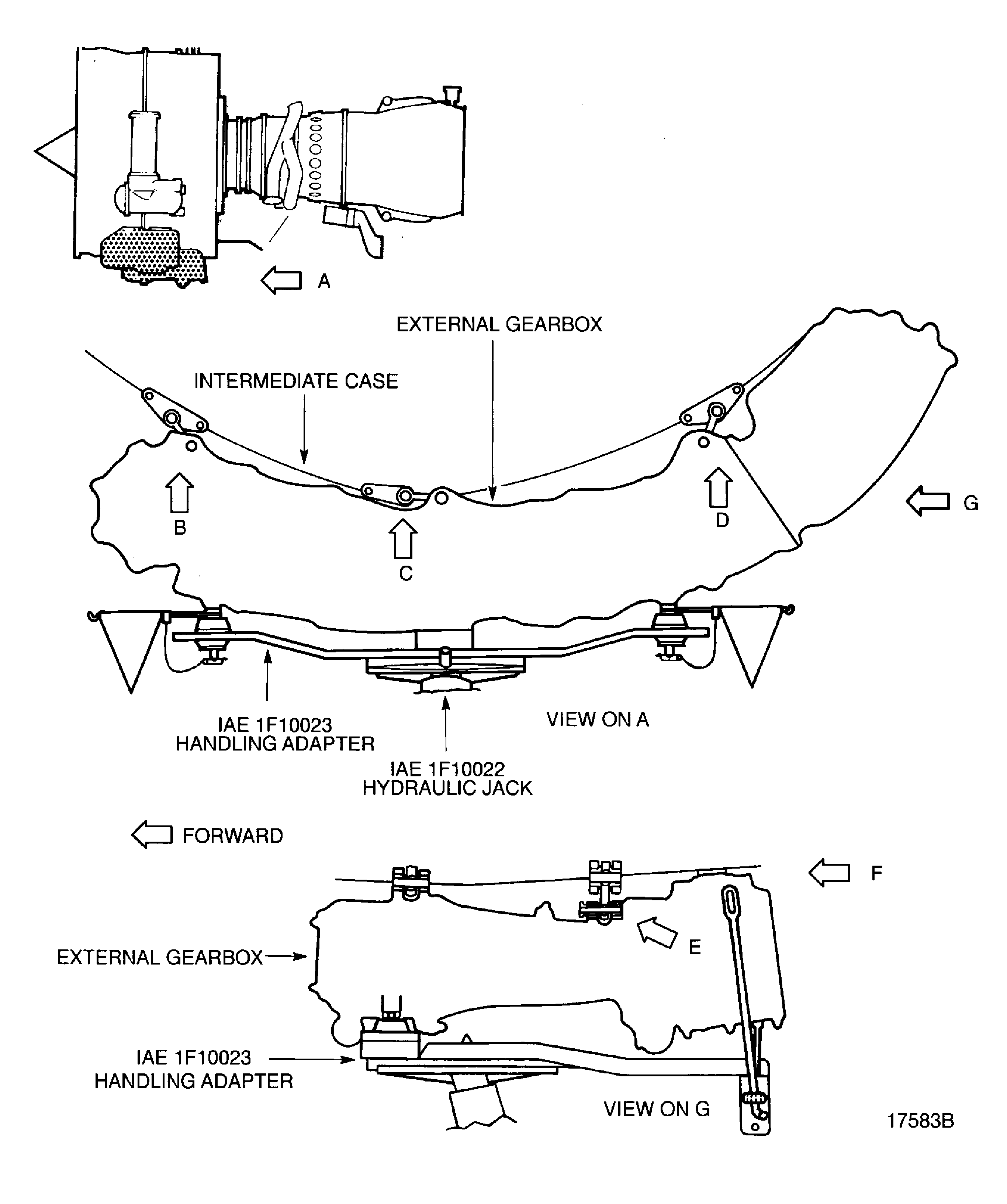

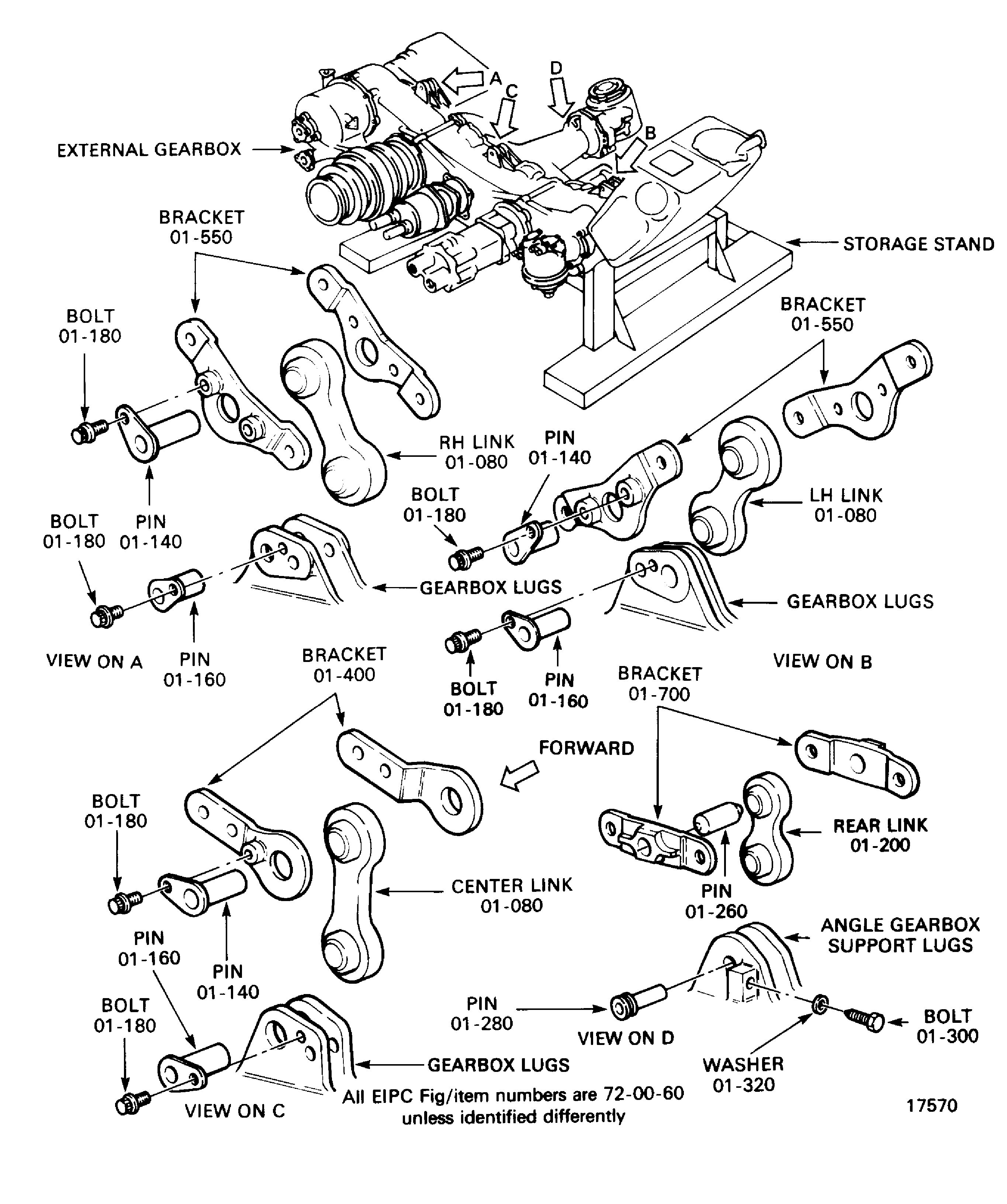

Put the assemblies adapter gearbox/external gearbox on the IAE 1F10021 Storage stand 1 off.

SUBTASK 72-00-60-020-055 Remove the External Gearbox from the Intermediate Case

Refer to Figure.

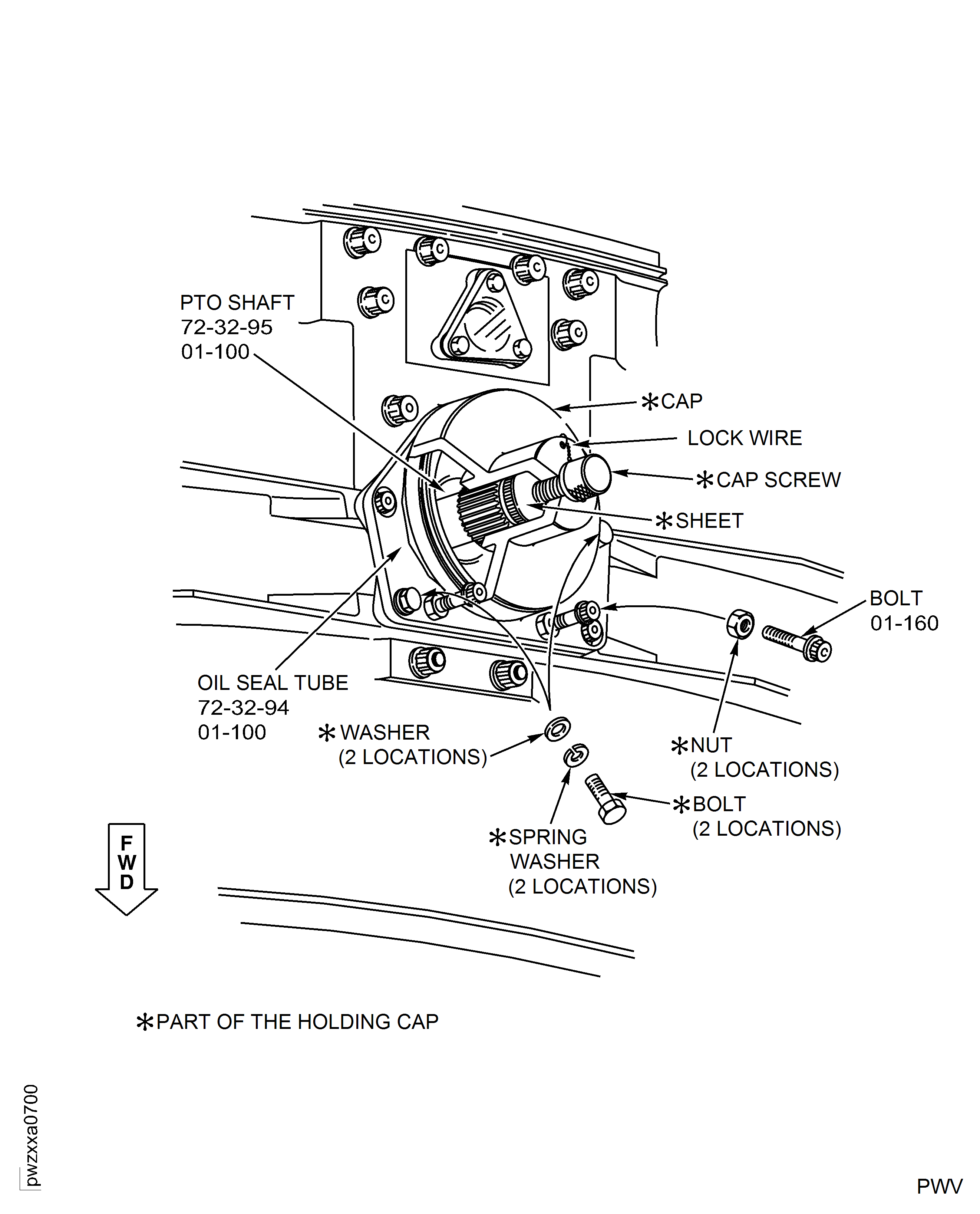

Remove two of the four bolts (01-160) to replace them with the two bolts of the holding cap. Refer to Figure for the positions of the bolts to be replaced.

Turn the cap screw (part of IAE 1J12082 Holding Cap 1 off) counterclockwise fully to move it out of the cap.

Align the four boltholes in the cap (part of the holding cap) with the two bolts and the two holes in the oil seal tube.

Attach the cap to the oil seal tube and safety with the two washers, spring washers and bolts (part of the holding cap). Tighten the bolts.

Turn the cap screw clockwise until the sheet touches the PTO shaft.

Safety the cap screw with CoMat 02-147 LOCKWIRE. Refer to SPM TASK 70-42-05-400-501.

Install the two nuts (part of the holding cap) on to the two bolts (01-160) that were removed before. Install the bolts in to the threaded holes in the cap and tighten the nuts.

NOTE

The holding cap is removed from the oil seal. The two bolts (01-160) are moved from the cap to the oil seal tube in TASKS which install the external gearbox to the fan case.

SUBTASK 72-00-60-020-138 Install Holding Cap on to the Oil Seal Tube to Hold the PTO Shaft

Refer to Figure.

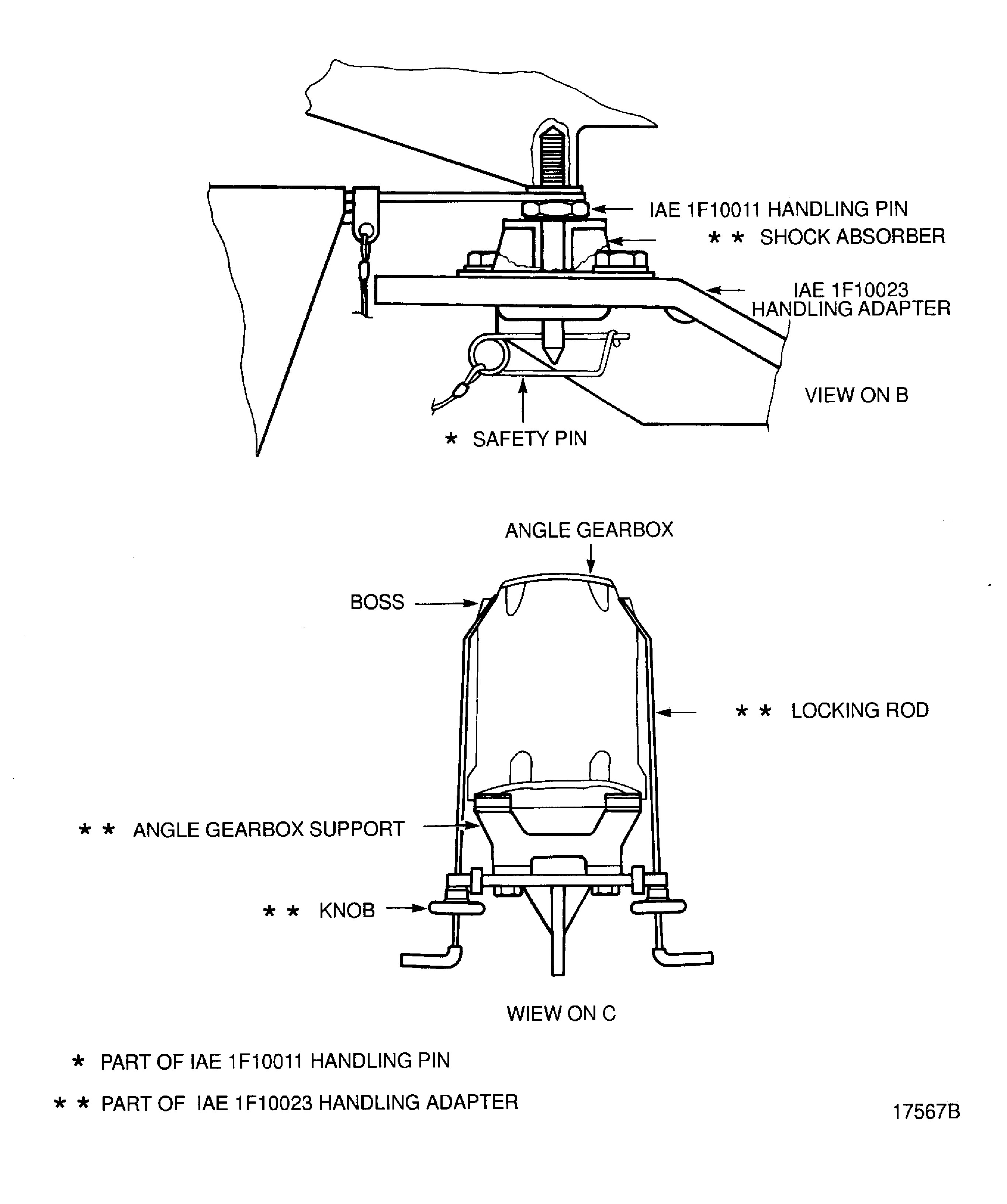

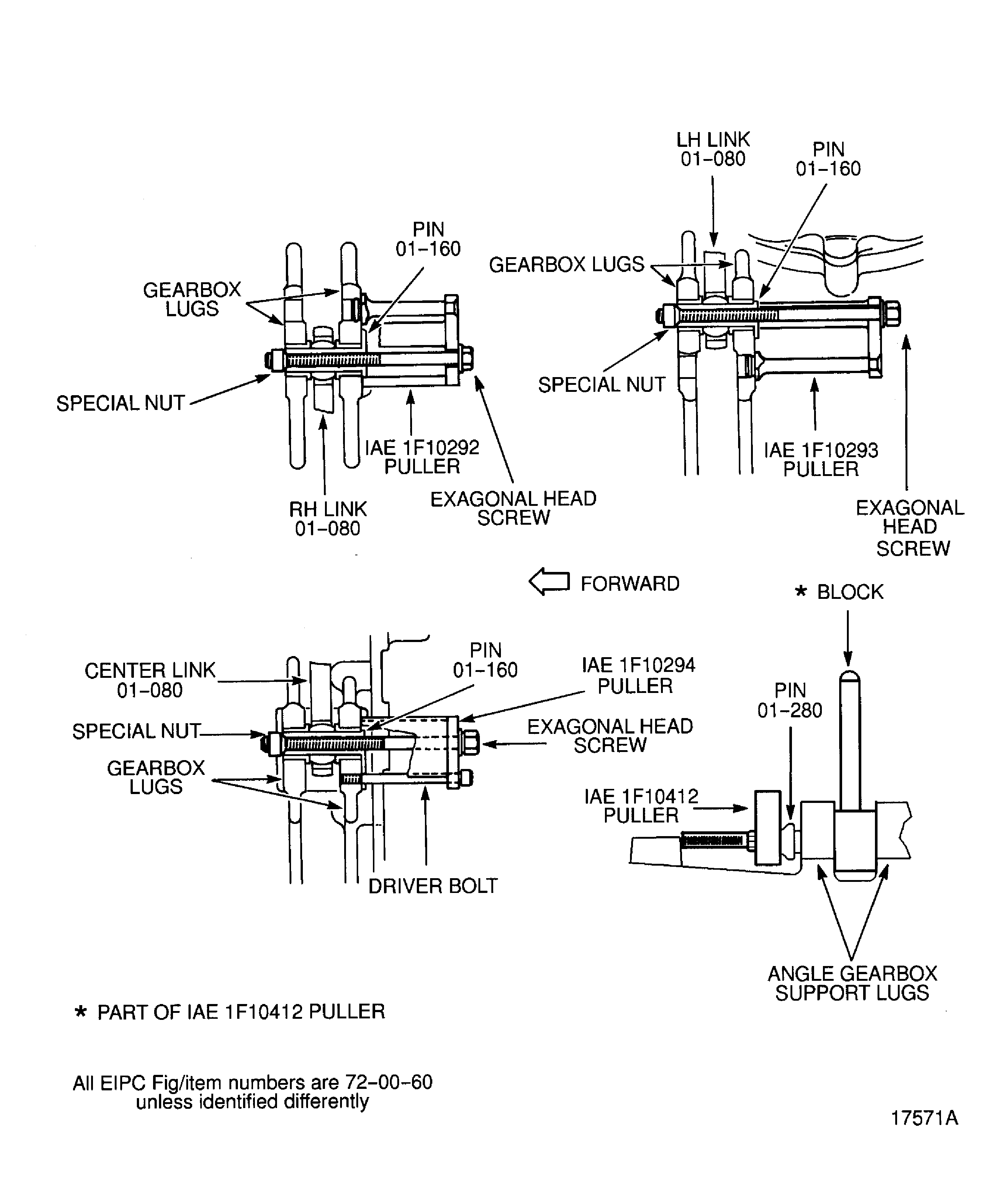

Remove the right hand link with IAE 1F10292 Puller 1 off.

Remove the left hand link with IAE 1F10293 Puller 1 off. Do the Step thru Step.

Remove the center link with IAE 1F10294 Puller 1 off.

Remove the bolt from the puller.

Prepare the IAE 1F10412 Puller 1 off. Refer to Figure.

Put the two blocks of IAE 1F10412 Puller 1 off equally spaced between the two lugs of the Angle Gearbox Support.

Install the bolt through the puller into the threaded bolthole in the pin.

Rotate the two screws at the same time until the pin is free.

Remove the pin.

Remove the puller from the lugs.

Remove the rear link from the angle gearbox support.

SUBTASK 72-00-60-020-056 Remove the Support Link Assemblies from the External Gearbox

Figure: External gearbox support tooling

External gearbox support tooling

Figure: External gearbox support tooling

External gearbox support tooling

Figure: Removal of the external gearbox from the intermediate case

Removal of the external gearbox from the intermediate case

Figure: Removal of the external gearbox from the intermediate case

Removal of the external gearbox from the intermediate case

Figure: Removal of the external gearbox from the intermediate case

Removal of the external gearbox from the intermediate case

Figure: Removal of the support link assembly from the external gearbox

Removal of the support link assembly from the external gearbox

Figure: Removal of the support link assembly from the external gearbox

Removal of the support link assembly from the external gearbox

Figure: Install The Holding Cap On To The PTO Shaft To Hold The PTO Shaft

Install The Holding Cap On To The PTO Shaft To Hold The PTO Shaft