Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-31-11-300-028 Annulus Filler - Repair The Surface Damage, Repair 028(VRS1014)

Effectivity

FIG/ITEM | PART NO. | |

01-100 | 5A1459 | Assembly A |

01-100 | 5A1611 | Assembly A |

01-100 | 5A1710 | Assembly B |

01-100 | 5A1750 | Assembly A |

01-100 | 5A1752 | Assembly A |

01-100 | 5A1753 | Assembly B |

General

This repair can be done only one time on both front and aft trunnion fillet R (Locations 10 and 11). Refer to Figure. When this repair is applied to front trunnion fillet R, a code letter F is put following the repair identification mark, or R for aft trunnion fillet R, or FR for both front and aft trunnion fillet R.

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Magnifying glass, 10x | LOCAL | Magnifying glass, 10x | ||

| Weighing equipment | LOCAL | Weighing equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-35-03-300-501. The diameter of the repaired area is to be a minimum of five times the depth.

Remove nicks, scratches, dents, galls, corrosion pits and/or damage.

SUBTASK 72-31-11-350-088 Remove the Damage from the Annulus Filler Assembly, Except Front/Aft Trunnion Fillet R at Locations 10 and 11

Find the repair identification mark. If the mark with "VRS1014 F" is found, Step must not be applied to the front trunnion fillet R.

If the mark with "VRS1014 R" is found, Step must not be applied to the aft trunnion fillet R.

If the mark with "VRS1014 FR" is found, Step must not be applied to neither front nor aft trunnion fillet R.

Visually examine the part to make sure that repair at front or aft trunnion fillet R has not been done before.

Refer to the SPM TASK 70-35-03-300-501. The repaired area must be smoothly continous to the adjacent area.

Remove corrosion pits and/or damage.

The surface finish of the repaired area must be the same as the adjacent area. Use CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE.

Make smooth and hand polish the repaired area.

SUBTASK 72-31-11-350-133 Remove the Damage from Front/Aft Trunnion Fillet R at Locations 10 and 11

If the weight is not more than 16.57 oz (469.5 g), reject it.

FIG/ITEM

PART NO.

PART IDENT

QTY

01-130

5A0906

Suction side seal

1

01-140

5A1711 or

5A1462

Pressure side seal

Pressure side seal (for Assembly A)

1

01-150

5A1114

Pad bumper

1

01-180

5A1116

Locating pin

1

01-190

AGS3758

Thread insert

1

NOTE

The following parts must be included in the weight per one annulus filler assembly. If any parts are not installed, weigh together with the repaired annulus filler and new spare of the attaching parts.

For Assembly B.

SUBTASK 72-31-11-350-127 Weigh the Repaired Annulus Filler Assembly

Refer to the SPM TASK 70-38-02-300-503.

Apply the chromate conversion coating to the repaired area with a brush.

SUBTASK 72-31-11-380-072 Apply the Surface Protection to the Annulus Filler Assembly

Refer to Repair VRS1009, TASK 72-31-11-300-002 (REPAIR-002) or.

Repair VRS1016, TASK 72-31-11-300-027 (REPAIR-027).

Apply the heat resisting E.S. coating.

SUBTASK 72-31-11-380-073 Apply the Heat Resisting Epoxy Silicone (E.S.) Coating to the Annulus Filler Assembly

Use a vibro-peen.

Refer to the SPM TASK 70-09-00-400-501.

If front trunnion fillet R is repaired in Step, put a code letter F following the mark VRS1014.

If aft trunnion fillet R is repaired in Step, put a code letter R following the mark VRS1014.

If both front and aft trunnion fillet R are repaired in Step, put a code letter FR following the mark VRS1014.

Make a mark VRS1014 adjacent to the part number.

Refer to the SPM TASK 70-38-02-300-503, SUBTASK 70-38-02-300-002.

Apply chromate conversion coating to the marking letters.

SUBTASK 72-31-11-350-128 Identify the Repair

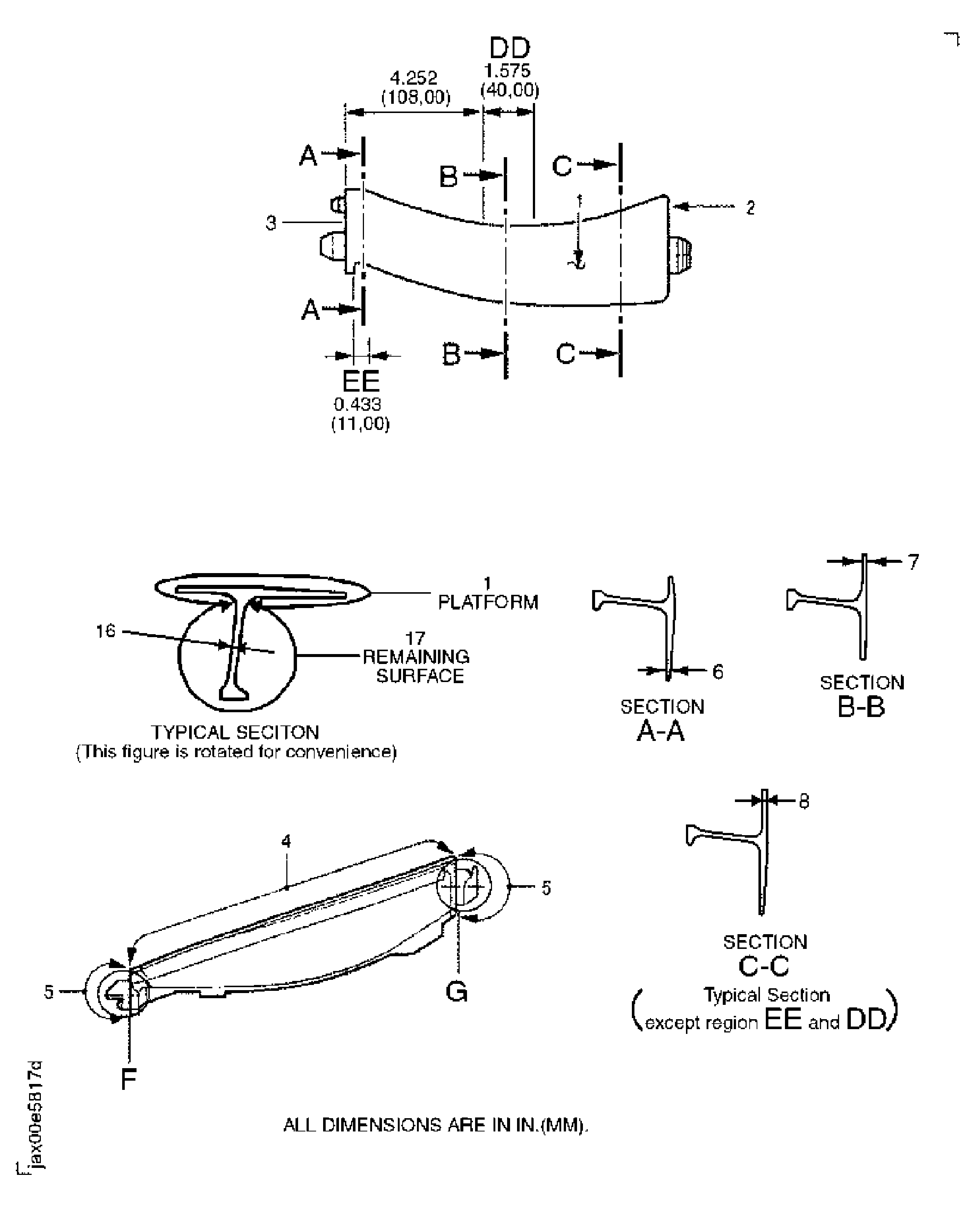

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4