Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-00-430-004 LPC/Intermediate Case Module - Install The No. 2 Bearing Oil Feed Tube, No. 3 Bearing Oil Feed Tube, NF Electrical Harness, Rear Seal Drain Tube, And P2.5 CM Tube, Assembly-004

General

This TASK gives the procedure to install the No. 2 and No. 3 bearing oil feed tubes, the NF electrical harness and the P2.5CM tube.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the Applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-00-400-501 and SPM TASK 70-41-02-410-501 .

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in procedure.

The No.1 strut, which is the top position strut of the fan frame, is identified by the five pressure tubes on the No. 1 strut leading edge.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Ohm meter | LOCAL | Ohm meter | or equivalent |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-019 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-019 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Ring | 1 | (V2500-A1/Pre SBE 72-0150) | ||

| Ring | 1 | |||

| Ring | 1 | |||

| Sealing ring | 1 | |||

| Ring | 1 | |||

| Ring | 1 | |||

| Ring | 1 | |||

| Ring | 2 | |||

| Ring | 1 | |||

| Ring | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

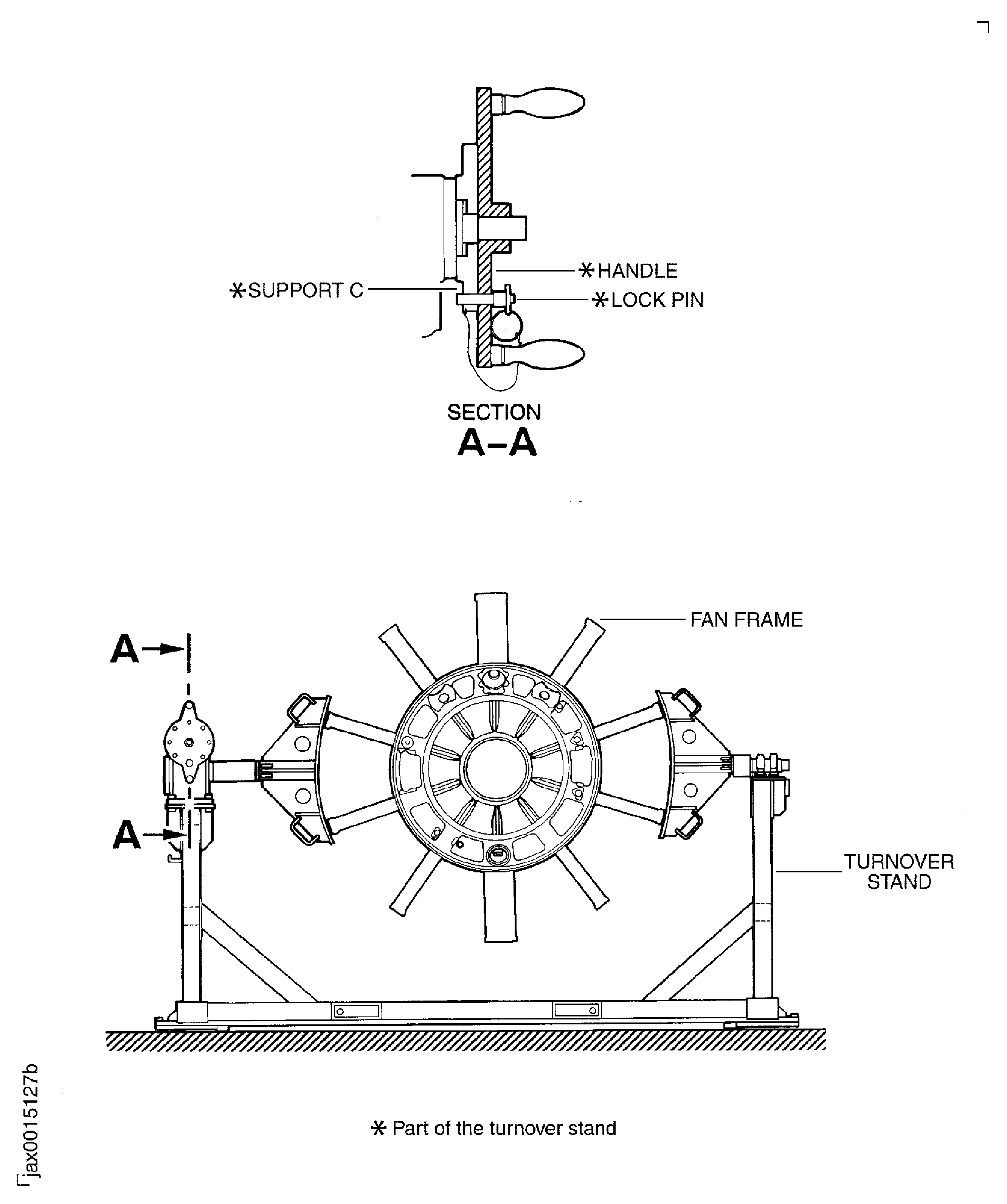

Make sure that the fan frame is installed, vertically with the front end up, on the turnover stand. Refer to TASK 72-32-00-430-003 (ASSEMBLY-003).

SUBTASK 72-32-00-430-099 Turn the Fan Frame to the Horizontal Position

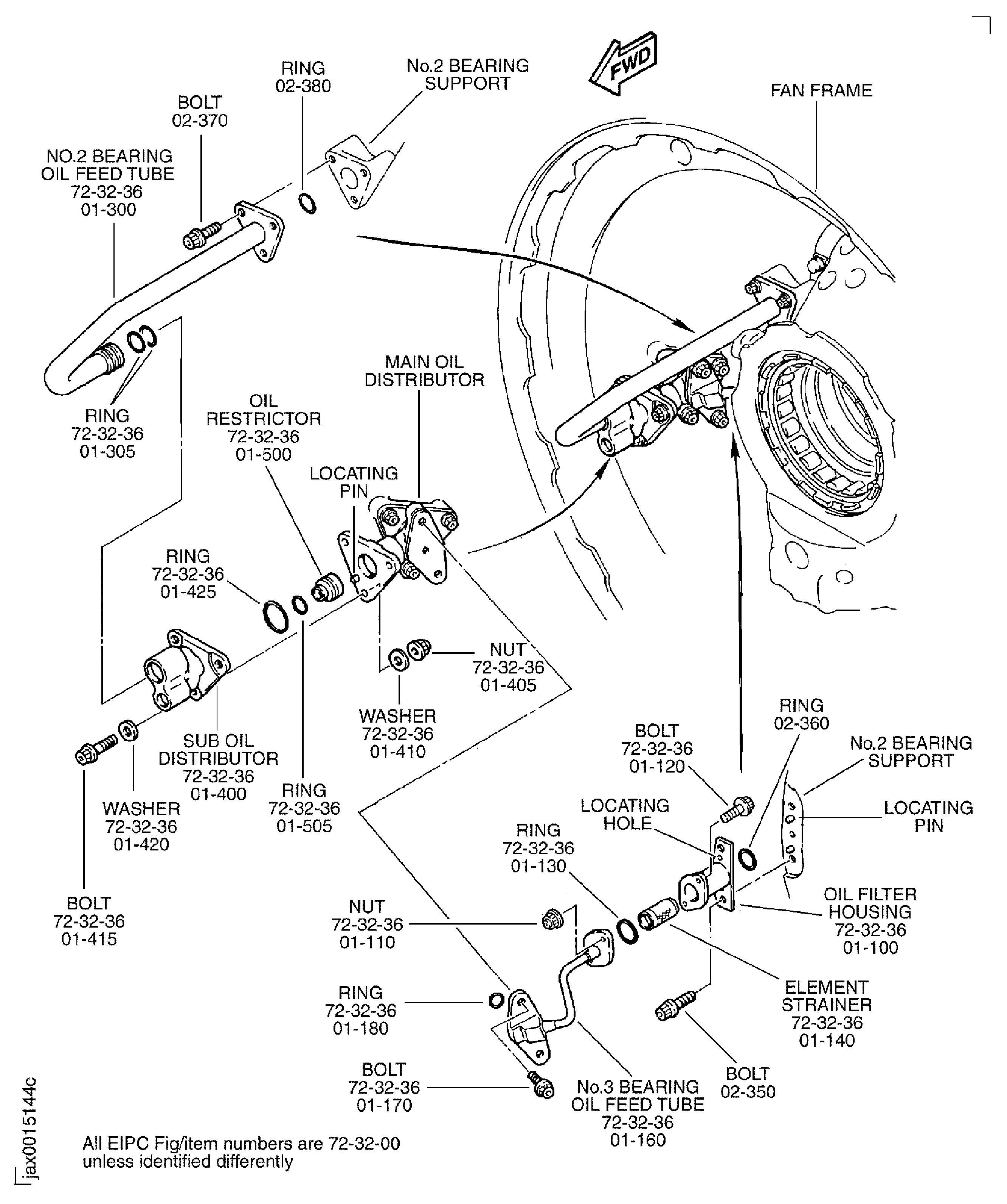

Lubricate the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-360) ring 1 off with CoMat 10-077 APPROVED ENGINE OILS.

Attach the oil filter housing to the No.2 bearing support rear flange with the two bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-350).

Install the oil filter housing No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-100) to the No. 2 bearing support.

Install the strainer element No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-140) into the hole in the oil filter housing.

Lubricate the new No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-130) ring 1 off with the approved engine oils.

Attach the ring and the No.3 bearing oil feed tube to the oil filter housing with the two bolts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-120) and two nuts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-110).

Lubricate the new No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-180) ring 1 off with the approved engine oils.

Attach the ring and the No.3 bearing oil feed tube to the main oil distributor with the two bolts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-170).

Torque the two nuts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-110) to 36 to 45 lbfin (4.00 to 5.00 Nm).

Torque the two bolts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-170) to 85 to 105 lbfin (10.00 to 12.00 Nm).

Install the No. 3 bearing oil feed tube No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-160).

Lubricate the new No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-505) ring 1 off with the approved engine oils.

Install the oil restrictor No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-500) into the main oil distributor.

Lubricate the new No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-425) ring 1 off with the approved engine oils.

Attach the sub oil distributor to the main distributor with the three bolts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-415), washers No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-410) washers No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-420) and nuts No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-405).

Install the sub oil distributor No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-400) onto the main oil distributor.

Lubricate the new No. 2 And No. 3 Bearing Oil Distributor And Tubes (72-32-36, 01-305) rings 2 off and the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-380) ring 1 off with the approved engine oils.

Install the oil feed tube in the sub oil distributor and into the connection of the No.2 bearing support with the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-370).

Attach the No.2 bearing oil feed tube No. 2 And No. 3 Bearing Oil Distributor And Tubes(72-32-36,01-300) to the sub oil distributor and the No. 2 bearing support.

SUBTASK 72-32-00-430-100 Install the No. 2 and No. 3 Bearing Oil Feed Tubes

SBE 71-0303: Introduction of voltage divider harness assembly between the trim balance and engine harness.

SBE 72-0553: Introduction of a new trim balance probe and deletion of related powerplant voltage divider harness assembly.

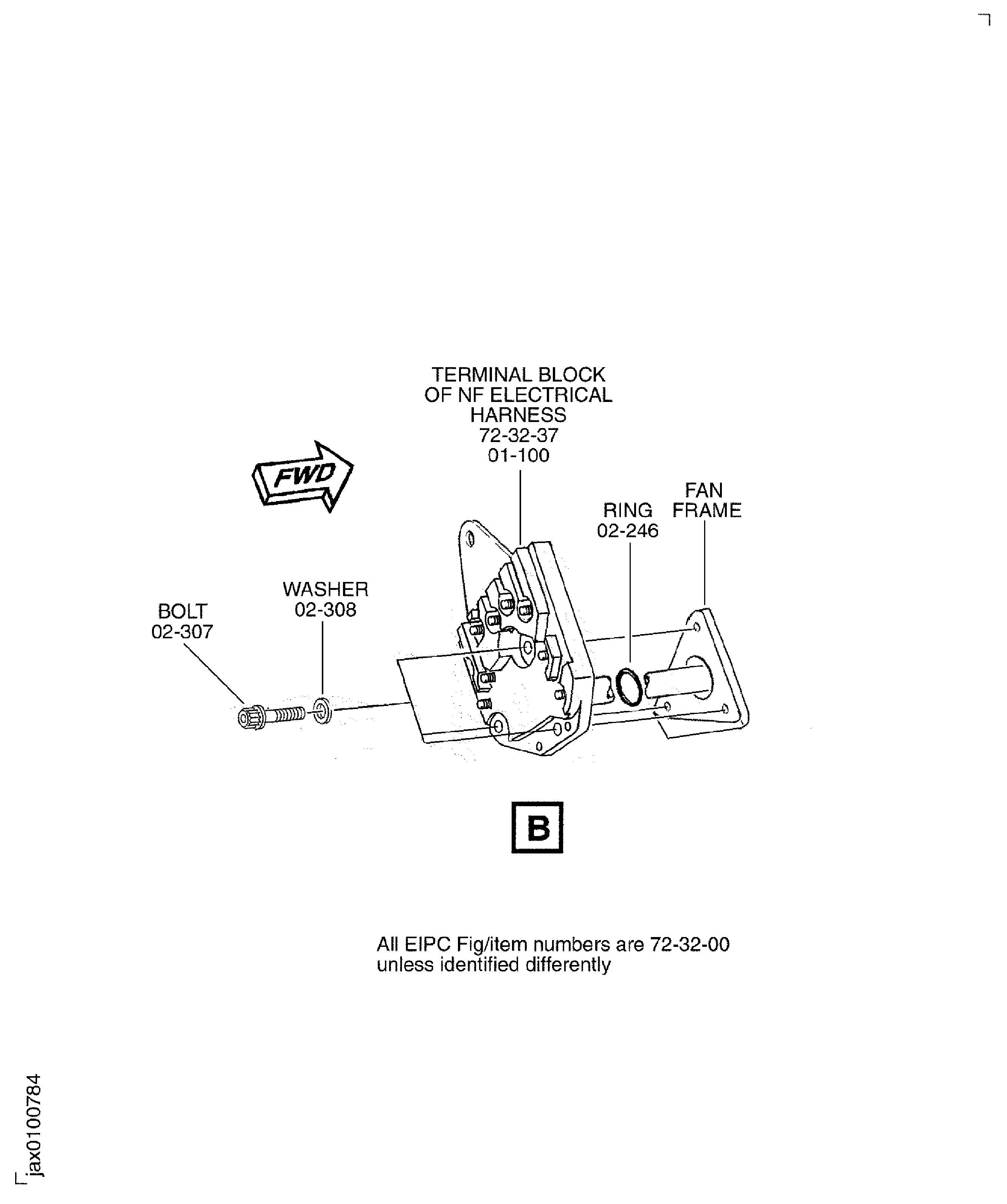

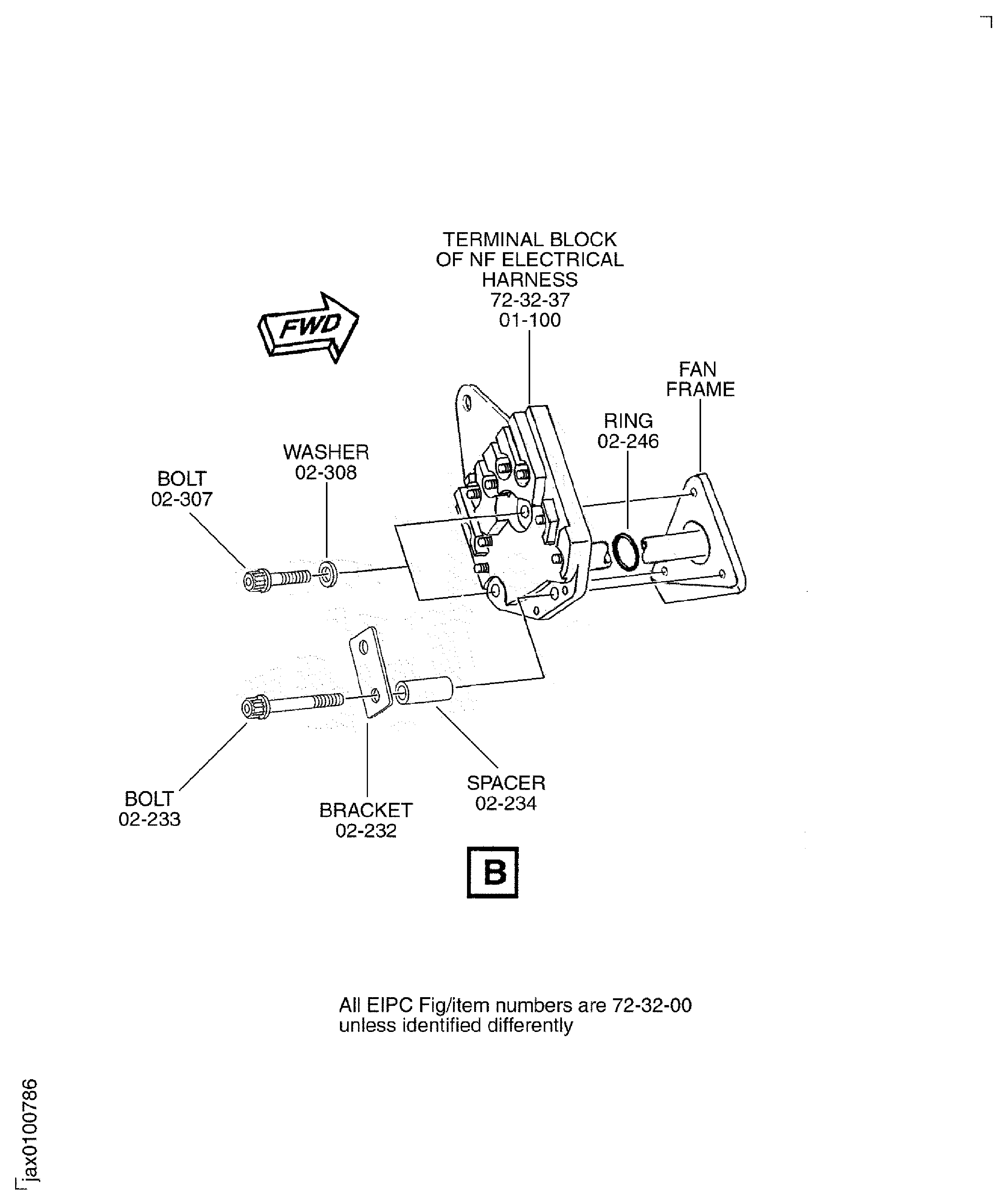

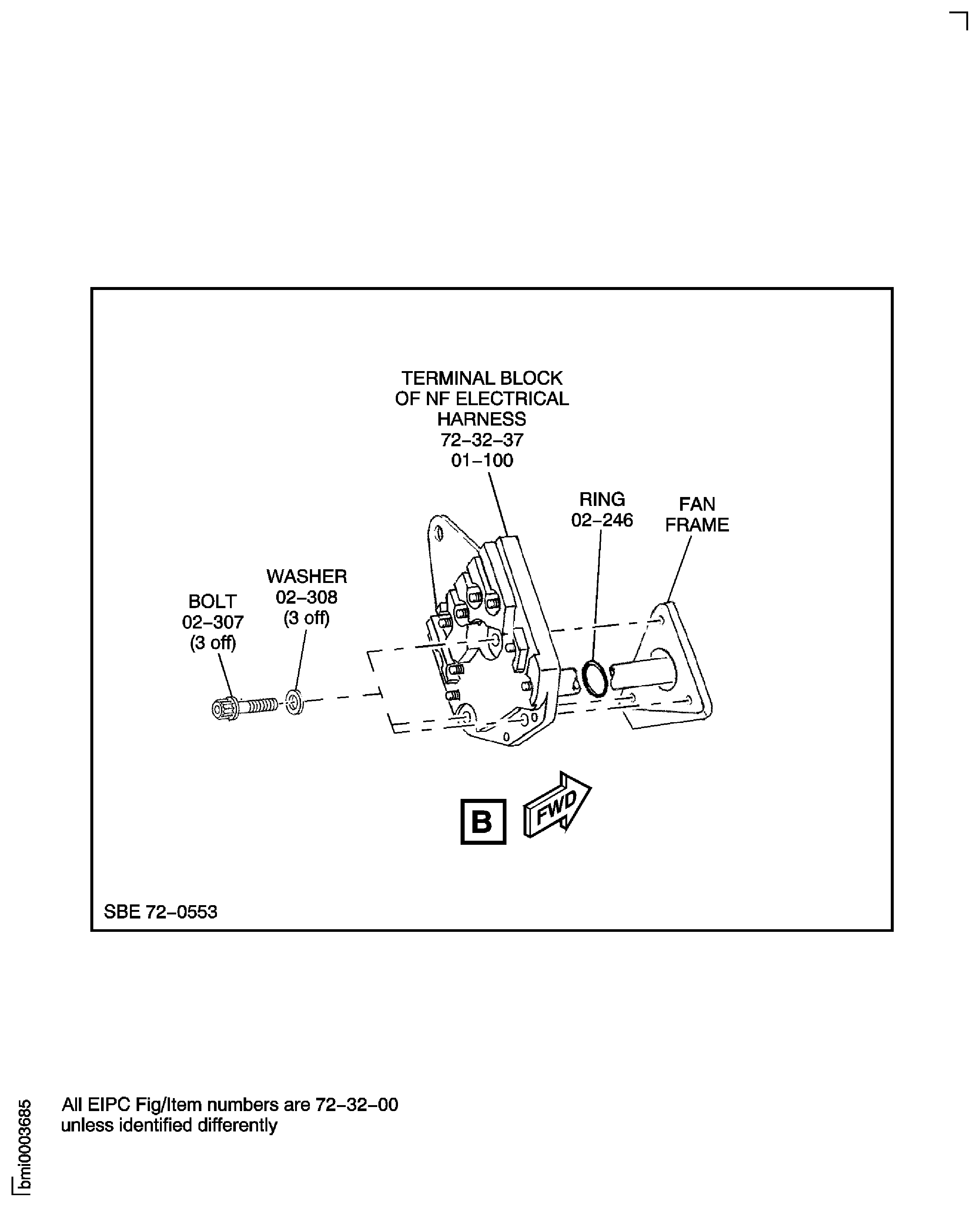

Lubricate the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-246) ring 1 off with the approved engine oils.

Pre SBE 71-0303: Attach the terminal block of the harness to the boss on the fan frame with the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-307) and washers LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-308).

SBE 71-0303 and Pre SBE 72-0553: Attach the terminal block of the harness to the boss on the fan frame with the two bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-307), the two washers LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-308) the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-233), the bracket LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-232) and the spacer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-234).

SBE 72-0553: Attach the terminal block of the harness to the boss on the fan frame with the three bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-307) and three washers LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-308).

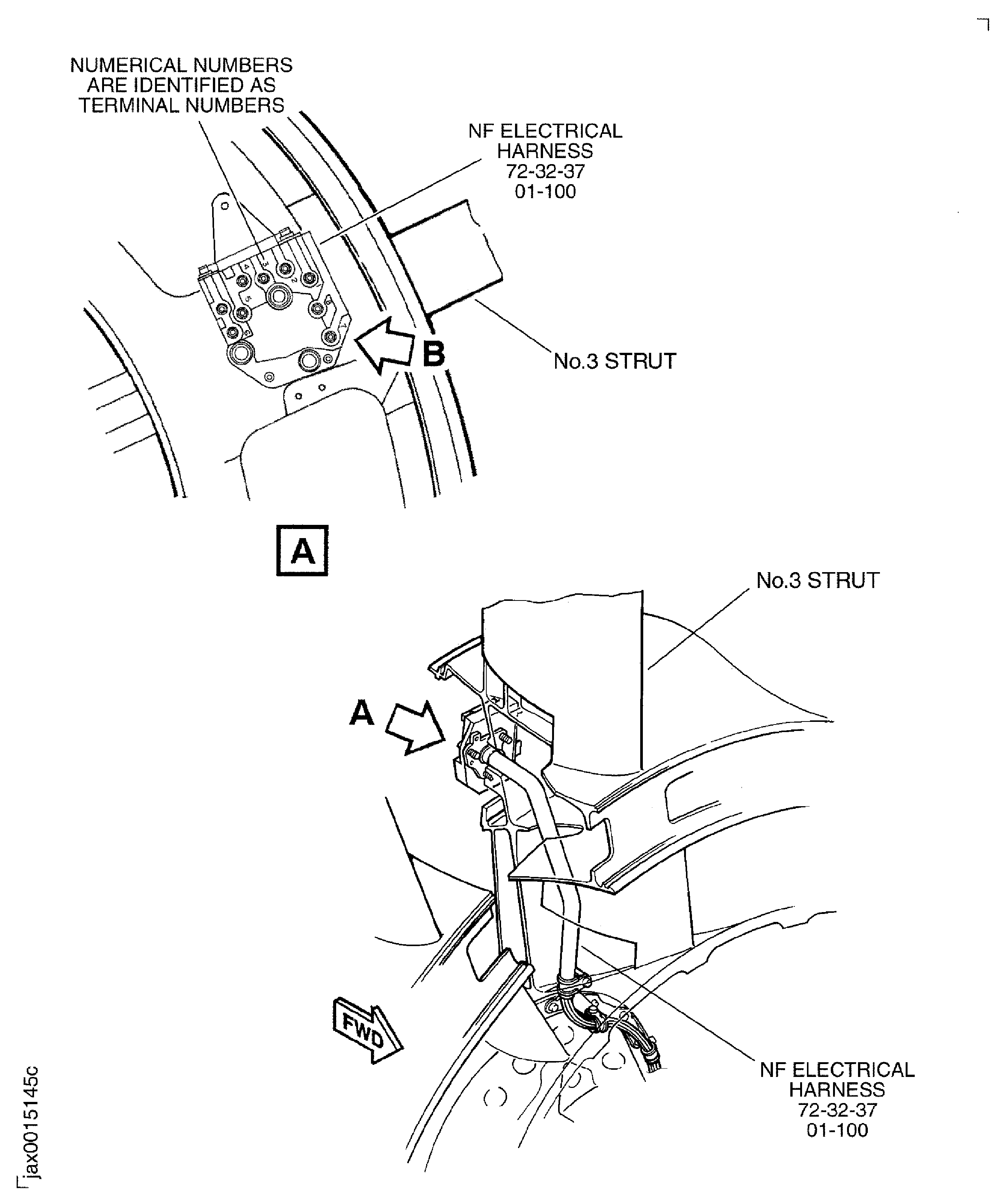

Install the NF electrical harness Fan Speed/Trim Balance Probes Electrical Harness (72-32-37, 01-100) into the No. 3 strut of the fan frame.

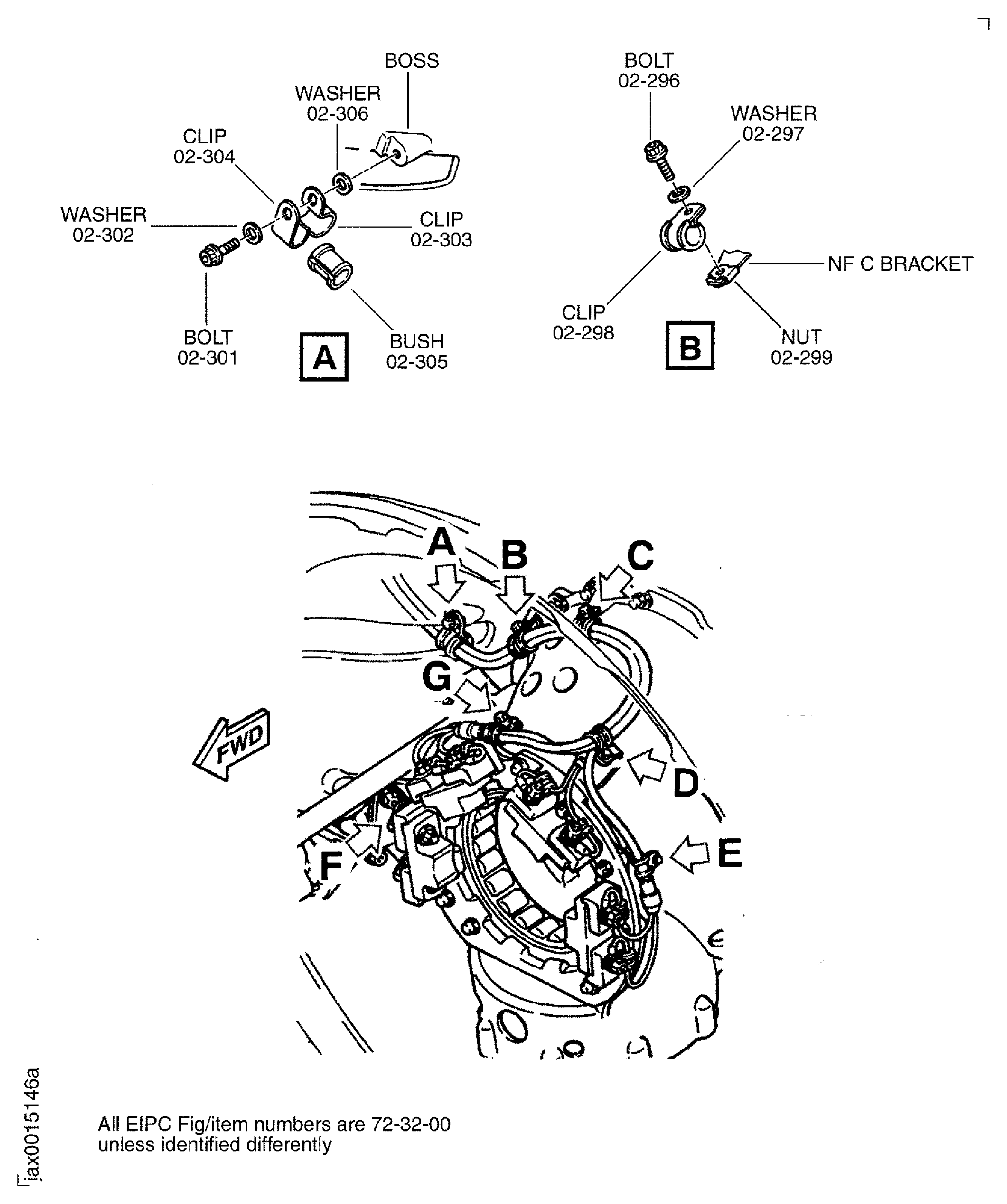

Attach the bush LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-305) around the harness adjacent to the boss.

Install the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-304) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-303) on to the bush with the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-301) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-306) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-302).

Attach the harness to the boss on the fan frame.

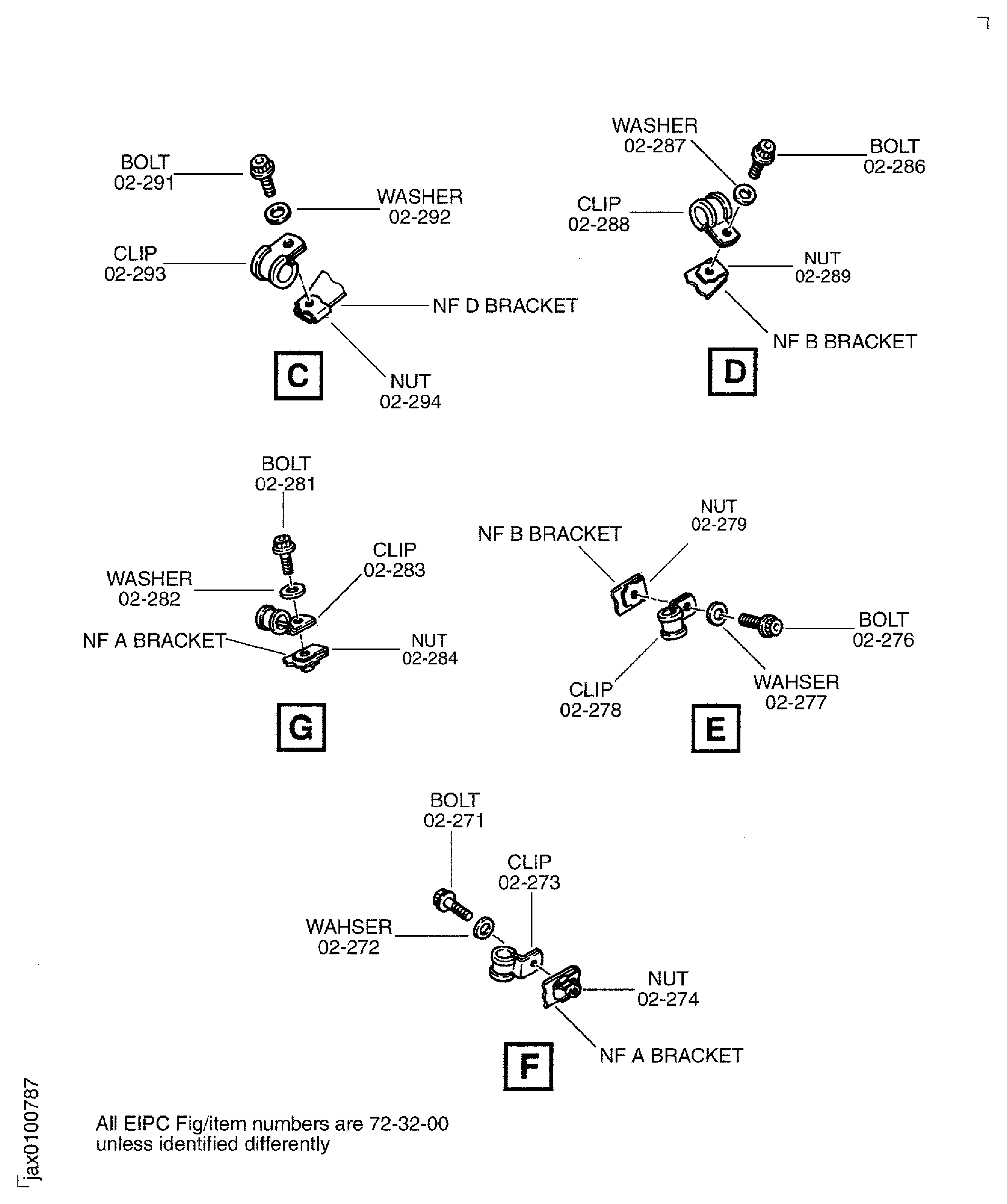

Install the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-274) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-284) on to the bracket.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-273) and clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-283) around the harness adjacent to the bracket.

Attach each clip to the bracket with the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-271), the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-281), the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-272) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-282).

Attach the harness to the NF A bracket.

Install the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-279) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-289) on to the bracket.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-278) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-288) around the harness adjacent to the bracket.

Attach each clip to the bracket with the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-276), the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-286), the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-277) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-287).

Attach the harness to the NF B bracket.

Install the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-299) on to the bracket.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-298) around the harness adjacent to the bracket.

Attach each clip to the bracket with the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-296) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-297).

Attach the harness to the NF C bracket.

Install the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-294) on to the bracket.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-293) around the harness adjacent to the bracket.

Attach the clip to the bracket with the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-291) and the washer LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-292).

Attach the harness to the NF D bracket.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-248) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-251) around the harness lead.

Attach each clip and the harness with the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-247) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-250).

Connect the two harness terminals to the two mounting pins on the fan speed probes.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-254) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-257) around the harness lead.

Attach each clip and the harness with the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-253) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-256).

Connect the two harness terminals to the two mounting pins on the fan speed probes.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-260) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-263) around the harness lead.

Attach each clip and the harness with the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-259) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-262).

Connect the two harness terminals to the two mounting pins on the fan speed probes.

Attach the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-266) and the clip LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-269) around the harness lead.

Attach each clip and the harness with the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-265) and the nut LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-268).

Connect the two harness terminals to the two mounting pins on the trim balance probes.

SUBTASK 72-32-00-430-101 Install the NF Electrical Harness (Pre SBE 71-0303, SBE 71-0303, Pre SBE 72-0553 and SBE 72-0553)

Use CoMat 05-019 WATERPROOF SILICON CARBIDE and remove oxide on surfaces of the terminals.

Measure electrical resistances between terminals on the terminal block.

NOTE

The electrical resistances are affected by temperature. The limits for loop electrical resistance are defined in 68 deg F (20 deg C) condition. It is necessary to convert the measured electrical resistance to the electrical resistance in 68 deg F (20 deg C) condition.Calculate the corrected electrical resistances (R20) at 68 deg F (20 deg C) and make a record of the results in the Table 1.

NOTE

For electrical resistance of the probes, refer to the Shinko Electric Co. Component Maintenance Manual (72-32-18). For electrical resistance of the harness, refer to the Component Maintenance Manual (CMM-EHC-V2500-1IA).Make sure that the corrected electrical resistances (R20) are in the limits given in the Table 1. If they are not in the limits, investigate the cause.

SUBTASK 72-32-00-430-333 Do an Electrical Resistance Check for Loops of the Harness and the Probes

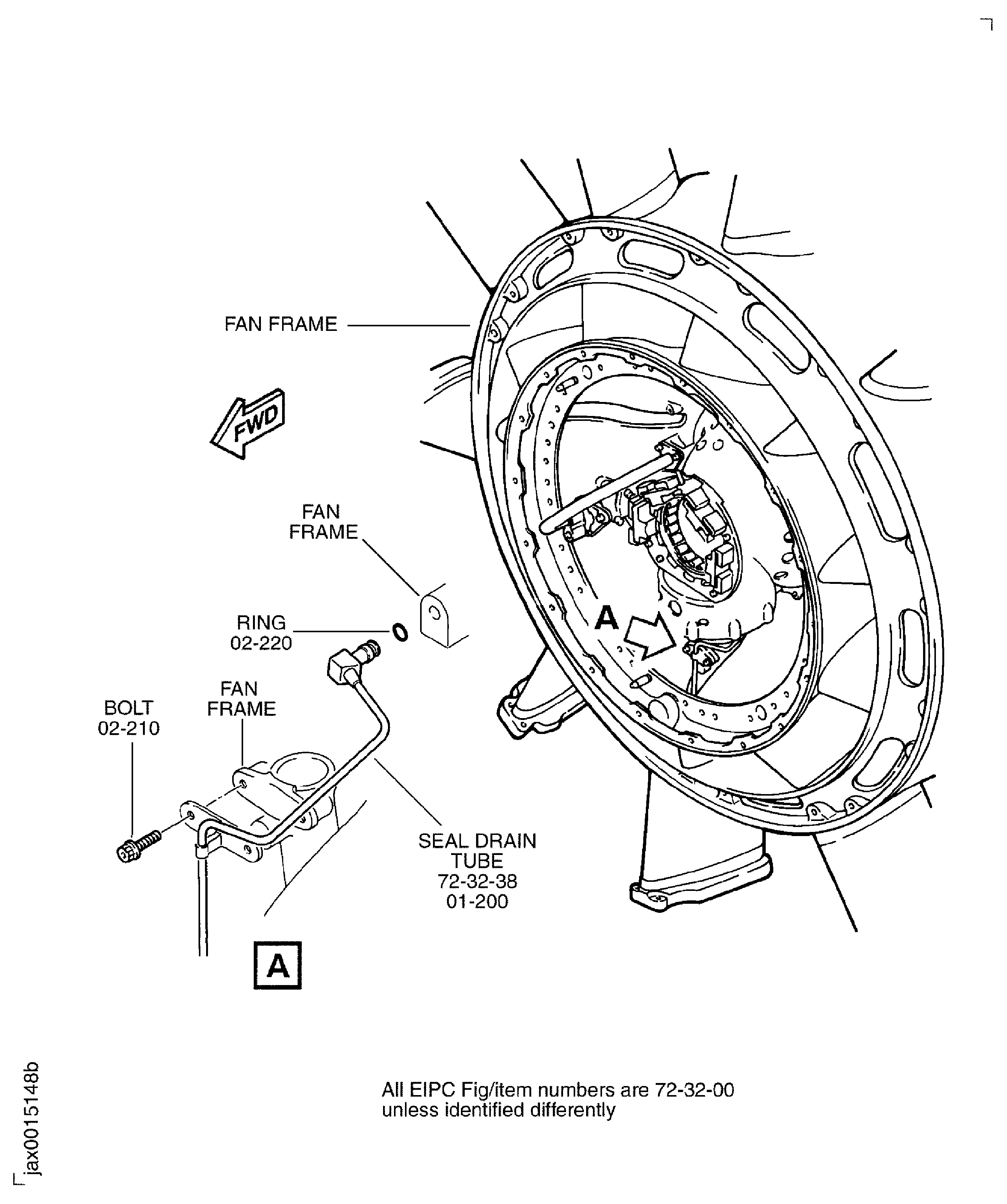

Refer to Figure.

Lubricate the new LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-220) ring 1 off with the approved engine oils. Install the ring into the groove in the seal drain tube (72-32-38, 01-200).

Install the seal drain tube into the connection of the fan frame with the two bolts LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 02-210).

SUBTASK 72-32-00-430-102-A00 V2500-A1: Install the Rear Seal Drain Tube (Pre SBE 72-0150)

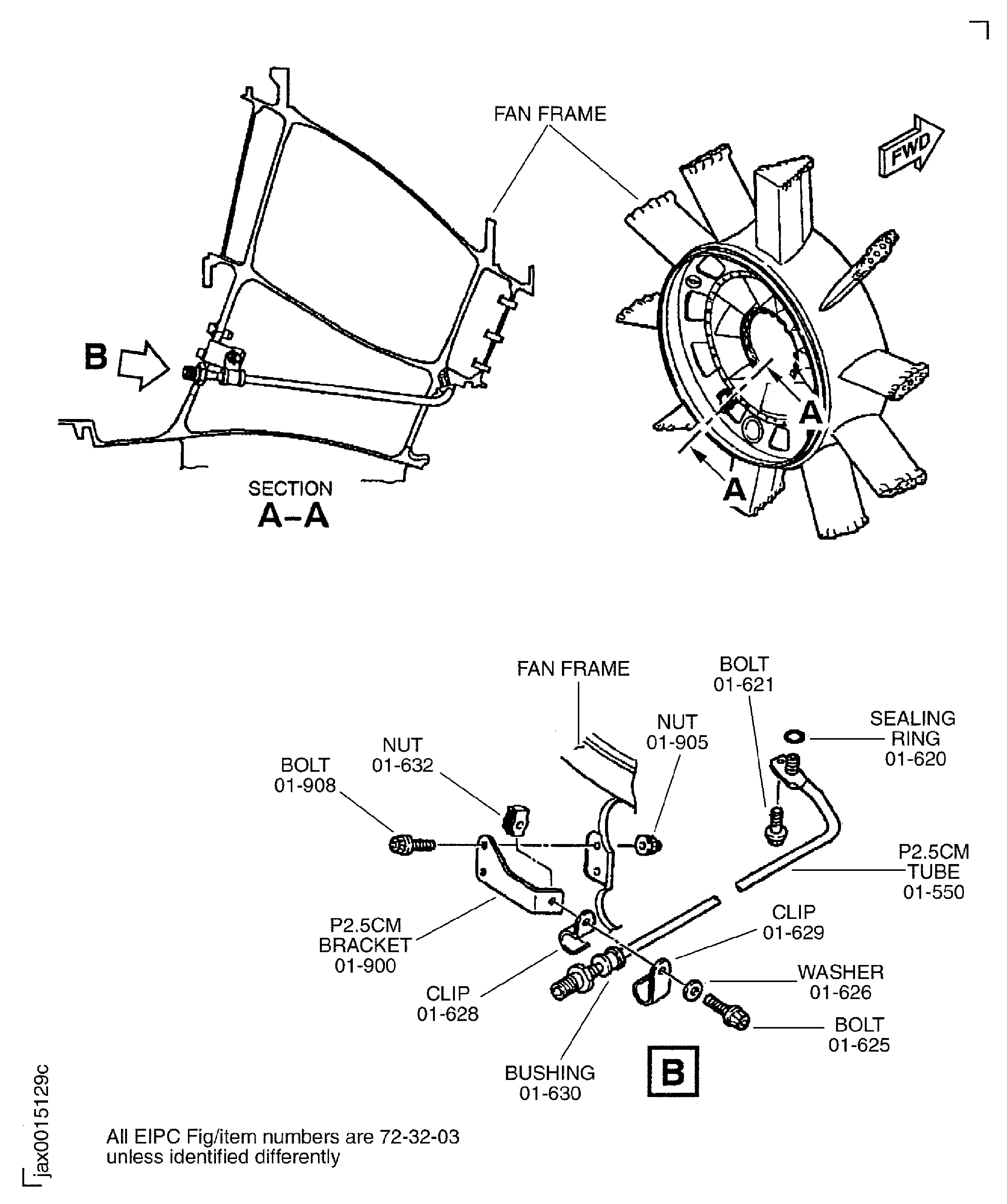

Refer to Figure.

Attach the P2.5CM bracket Fan Frame Assembly And Related Parts (72-32-03, 01-900) to the fan frame with the two bolts Fan Frame Assembly And Related Parts (72-32-03, 01-908) and the two nuts Fan Frame Assembly And Related Parts (72-32-03, 01-905).

Install the nut Fan Frame Assembly And Related Parts (72-32-03, 01-632) on the P2.5CM bracket.

Lubricate the new Fan Frame Assembly And Related Parts (72-32-03, 01-620) sealing ring 1 off with the CoMat 10-077 APPROVED ENGINE OILS.

Install the sealing ring into the groove in the P2.5CM tube Fan Frame Assembly And Related Parts (72-32-03, 01-550).

Install the P2.5CM tube into the hole in the fan frame with the bolt Fan Frame Assembly And Related Parts (72-32-03, 01-621).

Attach the bushing Fan Frame Assembly And Related Parts (72-32-03, 01-630) around the P2.5CM tube adjacent to the P2.5CM bracket.

Install the inner clip Fan Frame Assembly And Related Parts (72-32-03, 01-629) and the outer clip Fan Frame Assembly And Related Parts (72-32-03, 01-628) on the bushing with the bolt Fan Frame Assembly And Related Parts (72-32-03, 01-625) and the washer Fan Frame Assembly And Related Parts (72-32-03, 01-626).

Torque the bolt Fan Frame Assembly And Related Parts (72-32-03, 01-621) and the bolt LP Compressor (LPC) - Intermediate Structure Module (72-32-00, 01-625) to 36 to 45 lbfin (4.00 to 5.00 Nm).

SUBTASK 72-32-00-430-293 Install the P2.5CM Bracket and the P2.5CM Tube

Figure: Turn the Fan Frame to the Horizontal Position

Turn the Fan Frame to the Horizontal Position

Figure: Install the No.2 Bearing Oil Feed Tube and No.3 Bearing Oil Feed Tube

Install the No.2 Bearing Oil Feed Tube and No.3 Bearing Oil Feed Tube

Figure: Install the NF Electrical Harness

Sheet 1

Figure: Pre SBE 71-0303: Install the NF Electrical Harness

Sheet 2

Figure: SBE 71-0303 and Pre SBE 72-0553: Install the NF Electrical Harness

Sheet 3

Figure: SBE 72-0553: Install the NF Electrical Harness

Sheet 4

Figure: Install the NF Electrical Harness

Sheet 1

Figure: Install the NF Electrical Harness

Sheet 2

Figure: Install the NF Electrical Harness

Sheet 3

Figure: Do an Electrical Resistance Check for Loops of the Harness and the Probes

Do an Electrical Resistance Check for Loops of the Harness and the Probes

Figure: V2500-A1/Pre SBE 72-0150 Install the Seal Drain Tube

V2500-A1/Pre SBE 72-0150 Install the Seal Drain Tube

Figure: Install the No.2 and No.3 Bearing Oil Feed Tubes

Install the No.2 and No.3 Bearing Oil Feed Tubes

Figure: Install the P2.5CM Tube

Install the P2.5CM Tube