Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-23-300-010 Rotor Center Ring Seal Carrier Assembly - Repair The Location Diameter By Metal Spray, Repair-010 (VRS6114)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-720 | 6A2238 | Assembly A |

01-720 | 6A3890 | Assembly A |

01-720 | 6A3902 | Assembly A |

01-720 | 6A3916 | Assembly B |

01-720 | 6A4469 | Assembly C |

General

This Repair must only be done when the instruction to do so is given in TASK 72-32-23-200-000 (INSPECTION-000).

If removal of the surface protection is not necessary do Step.

If the surface protection is to be replaced do Step.

Make sure the protective coating is not damaged during this repair.

Make sure the coating on the outside diameter is not damaged during this repair.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in SPM.

NOTE

NOTE

Price and availability.

Refer to International Aero Engines.

Related repairs.

HP Compressor Seal Ring Carrier Assembly - Replace the Seal Ring, refer to Repair, VRS6113 TASK 72-32-23-300-009 (REPAIR-009).

HP Compressor Seal Ring Carrier Assembly - Replace the Surface Protection, refer to Repair, VRS6119 TASK 72-32-23-300-012 (REPAIR-012).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive Blast Equipment | LOCAL | |||

| Chemical cleaning equipment | LOCAL | Chemical Cleaning Equipment | ||

| Dial Test Indicators | LOCAL | Dial Test Indicators | ||

| Grinding Machine | LOCAL | Grinding Machine | ||

| Metal spray equipment | LOCAL | Metal spray equipment | ||

| Penetrant Crack Test Equipment | LOCAL | |||

| Standard workshop equipment | LOCAL | |||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| IAE 3R18725 Turn/Grind Fixture | 0AM53 | IAE 3R18725 | 1 | |

| IAE 3R18729 Clamp plate | 0AM53 | IAE 3R18729 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-005 SOLVENT CLEANER | 72190 | CoMat 01-005 | ||

| CoMat 02-001 ADHESIVE TAPE (MASKING) | LOCAL | CoMat 02-001 | ||

| CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL | K0993 | CoMat 02-006 | ||

| CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY) | LOCAL | CoMat 02-198 | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 06-073 INK, METAL MARKING | LOCAL | CoMat 06-073 | ||

| CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR | LOCAL | CoMat 07-024 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-11-03-300-503.

Use chemical cleaning equipment.

Chemically clean.

SUBTASK 72-32-23-110-061 Clean the Assembly

Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Use standard workshop equipment.

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-053-A00 Machine the Location Diameter, Assembly A

Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-053-B00 Machine the Location Diameter, Assembly B

Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-053-C00 Machine the Location Diameter, Assembly C

Refer to Figure.

SUBTASK 72-32-23-220-078-A00 Examine the Machined Surface, Assembly A

Refer to Figure.

SUBTASK 72-32-23-220-078-B00 Examine the Machined Surface, Assembly B

Refer to Figure.

SUBTASK 72-32-23-220-078-C00 Examine the Machined Surface, Assembly C

Refer to SPM TASK 70-23-05-230-501.

Use penetrant crack test equipment.

Cracks are not permitted.

Do a penetrant crack test on the machined surface.

SUBTASK 72-32-23-230-065 Do a Crack Test

Refer to SPM TASK 70-11-03-300-503.

Chemically clean the seal ring carrier assembly.

SUBTASK 72-32-23-110-059 Chemically Clean

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-062-A00 Mask the Area not to be Repaired, Assembly A

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-062-B00 Mask the Area not to be Repaired, Assembly B

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-062-C00 Mask the Area not to be Repaired, Assembly C

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface for repair.

SUBTASK 72-32-23-120-054-A00 Abrasive Blast the Surface for Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface for repair.

SUBTASK 72-32-23-120-054-B00 Abrasive Blast the Surface for Repair, Assembly B

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface for repair.

SUBTASK 72-32-23-120-054-C00 Abrasive Blast the Surface for Repair, Assembly C

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimensions.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-053-A00 Metal Spray the Surface for Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimensions.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-053-B00 Metal Spray the Surface for Repair, Assembly B

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimensions.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-053-C00 Metal Spray the Surface for Repair, Assembly C

Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with Grinding Machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-056-A00 Machine the Metal Sprayed Surface, Assembly A

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-056-B00 Machine the Metal Sprayed Surface, Assembly B

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier assembly onto the fixture.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-056-C00 Machine the Metal Sprayed Surface, Assembly C

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Refer to Figure

SUBTASK 72-32-23-220-088-A00 Examine the Machined Surface, Assembly A

Refer to Figure

SUBTASK 72-32-23-220-088-B00 Examine the Machined Surface, Assembly B

Refer to Figure

SUBTASK 72-32-23-220-088-C00 Examine the Machined Surface, Assembly C

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

Make sure parent material is vibro-engraved.

Make a mark VRS6114/1 adjacent to the part number.

SUBTASK 72-32-23-350-065-A00 Identify the Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

Make sure parent material is vibro-engraved.

Make a mark VRS6114/1 adjacent to the part number.

SUBTASK 72-32-23-350-065-B00 Identify the Repair, Assembly B

Refer to Figure

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

NOTE

Make sure parent material is vibro-engraved.

Make a mark VRS6114/1 adjacent to the part number.

SUBTASK 72-32-23-350-065-C00 Identify the Repair, Assembly C

Refer to SPM TASK 70-11-14-300-503.

Use a paint brush and CoMat 01-005 SOLVENT CLEANER.

Chemically clean the vibro-engraved area.

SUBTASK 72-32-23-110-062 Clean the Assembly

Use CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Touch-up the damaged coating.

SUBTASK 72-32-23-350-068 Touch-up the Damaged Coating

Refer to SPM TASK 70-11-03-300-503.

Chemically clean.

SUBTASK 72-32-23-110-063 Clean the Assembly

NOTE

Only do the SUBTASKS which follow, if it is necessary to remove the surface protection.Refer to Repair VRS6113, TASK 72-32-23-300-009 (REPAIR-009).

Discard the retainer.

NOTE

Do not discard the seal ring.

Remove the retainer ring.

SUBTASK 72-32-23-320-053 Remove the Retainer and the Seal Ring

Refer to TASK 72-32-23-100-000 (CLEANING-000).

Remove the paint from the seal ring carrier.

SUBTASK 72-32-23-110-064 Remove the Paint

Refer to TASK 72-32-23-200-000 (INSPECTION/CHECK-000).

Penetrant crack test the seal ring carrier and the seal ring.

SUBTASK 72-32-23-230-066 Do a Crack Test

Refer to Figure

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-059-A00 Machine the Location Diameter, Assembly A

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-059-B00 Machine the Location Diameter, Assembly B

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to SPM TASK 70-32-00-320-501.

Machine to remove all scores.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-059-C00 Machine the Location Diameter, Assembly C

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure

SUBTASK 72-32-23-220-091-A00 Examine the Machined Surface, Assembly A

Refer to Figure

SUBTASK 72-32-23-220-091-B00 Examine the Machined Surface, Assembly B

Refer to Figure

SUBTASK 72-32-23-220-091-C00 Examine the Machined Surface, Assembly C

Refer to SPM TASK 70-23-05-230-501.

Cracks are not permitted.

Do a penetrant crack test on the machined surface.

SUBTASK 72-32-23-230-067 Do a Crack Test

Refer to SPM TASK 70-11-03-300-503.

Chemically clean the seal ring carrier.

SUBTASK 72-32-23-110-065 Clean the Assembly

Refer to Figure

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-069-A00 Mask the Area not to be Repaired, Assembly A

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-069-B00 Mask the Area not to be Repaired, Assembly B

Refer to Figure.

Use CoMat 02-001 ADHESIVE TAPE (MASKING) or CoMat 02-006 ADHESIVE TAPE ALUMINIUM FOIL or CoMat 02-198 ADHESIVE TAPE (MASKING METAL SPRAY).

NOTE

The masking tape used in this SUBTASK, permits the blast and metal spray coat to be done in one operation.

Apply masking tape.

SUBTASK 72-32-23-350-069-C00 Mask the Area not to be Repaired, Assembly C

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface for repair.

SUBTASK 72-32-23-120-057-A00 Abrasive Blast the Surface for Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface fore repair.

SUBTASK 72-32-23-120-057-B00 Abrasive Blast the Surface for Repair, Assembly B

Refer to Figure.

Refer to SPM TASK 70-12-02-120-501.

Abrasive blast the surface for repair.

SUBTASK 72-32-23-120-057-C00 Abrasive Blast the Surface for Repair, Assembly C

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimension.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-056-A00 Metal Spray the Surface for Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimension.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-056-B00 Metal Spray the Surface for Repair, Assembly B

Refer to Figure.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the necessary dimension.

Maximum thickness of metal spray to be 0.010 in. (0.26 mm).

Apply metal spray.

SUBTASK 72-32-23-340-056-C00 Metal Spray the Surface for Repair, Assembly C

Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-062-A00 Machine the Metal Sprayed Surface, Assembly A

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Use standard workshop equipment.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-062-B00 Machine the Metal Sprayed Surface, Assembly B

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure.

Use IAE IAE 3R18725 Turn/Grind Fixture 1 off with grinding machine.

Install the fixture onto the grinding machine.

Use IAE IAE 3R18729 Clamp plate 1 off.

Use dial test indicator.

Install the seal ring carrier onto the fixture.

Refer to TASK 70-34-01-340-501, SUBTASK 70-34-01-340-003.

Machine to the dimensions as shown.

Machine the seal ring carrier diameter and chamfer.

SUBTASK 72-32-23-324-062-C00 Machine the Metal Sprayed Surface, Assembly C

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.Refer to Figure

SUBTASK 72-32-23-220-094-A00 Examine the Machined Surface, Assembly A

Refer to Figure.

SUBTASK 72-32-23-220-094-B00 Examine the Machined Surface, Assembly B

Refer to Figure.

SUBTASK 72-32-23-220-094-C00 Examine the Machined Surface, Assembly C

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-071-A00 Identify the Repair, Assembly A

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-071-B00 Identify the Repair, Assembly B

Refer to Figure

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-071-C00 Identify the Repair, Assembly C

Refer to Repair, VRS6119 TASK 72-32-23-300-012 (REPAIR-012).

NOTE

It is necessary to paint the seal ring carrier before the carrier, seal ring and retainer can be assembled.

Apply the surface protection.

SUBTASK 72-32-23-380-055 Apply the Surface Protection

Refer to Repair, VRS6113 TASK 72-32-23-300-009 (REPAIR-009).

NOTE

Install new or original seal ring as appropriate.

CAUTION

DO NOT DAMAGE THE COATING ON THE OUTSIDE DIAMETER.DO NOT DAMAGE THE SURFACE PROTECTION.Assemble the seal ring carrier, seal ring and retainer.

SUBTASK 72-32-23-350-074 Install the Seal Ring and Retainer

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING and CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Re-identify the assembly part number and make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-075-A00 Identify the Repair and Part Number, Assembly A

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING and CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Re-identify the assembly part number and make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-075-B00 Identify the Repair and Part Number, Assembly B

Refer to Figure.

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-002.

Use CoMat 06-073 INK, METAL MARKING and CoMat 07-024 AEROLAC METAL PROTECTIVE VARNISH, CLEAR, applied with a paint brush.

Re-identify the assembly part number and make a mark VRS6114/2 adjacent to the assembly part number.

SUBTASK 72-32-23-350-075-C00 Identify the Repair and Part Number, Assembly C

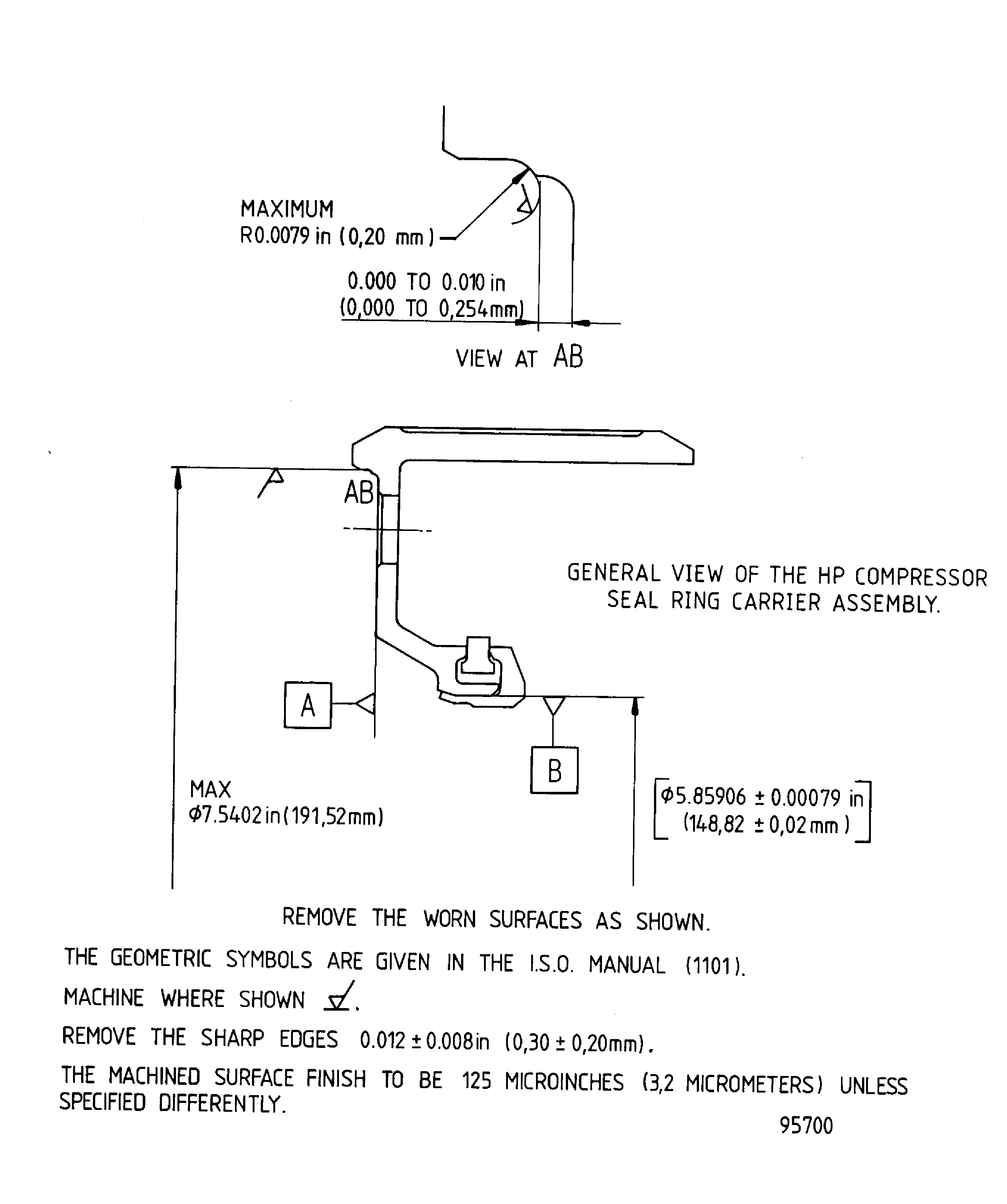

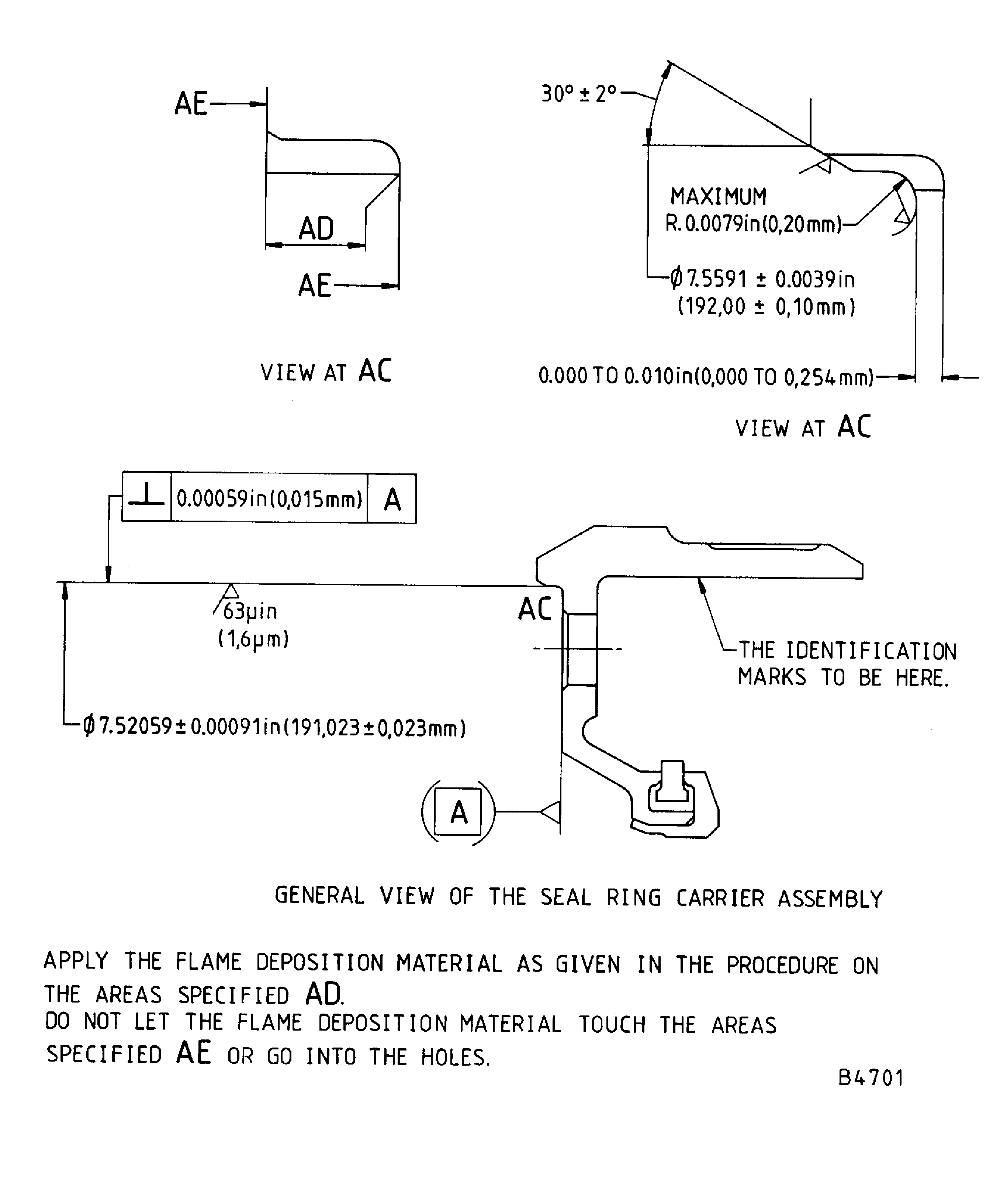

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

Figure: Repair details and dimensions - Assembly A

Repair details and dimensions - Assembly A

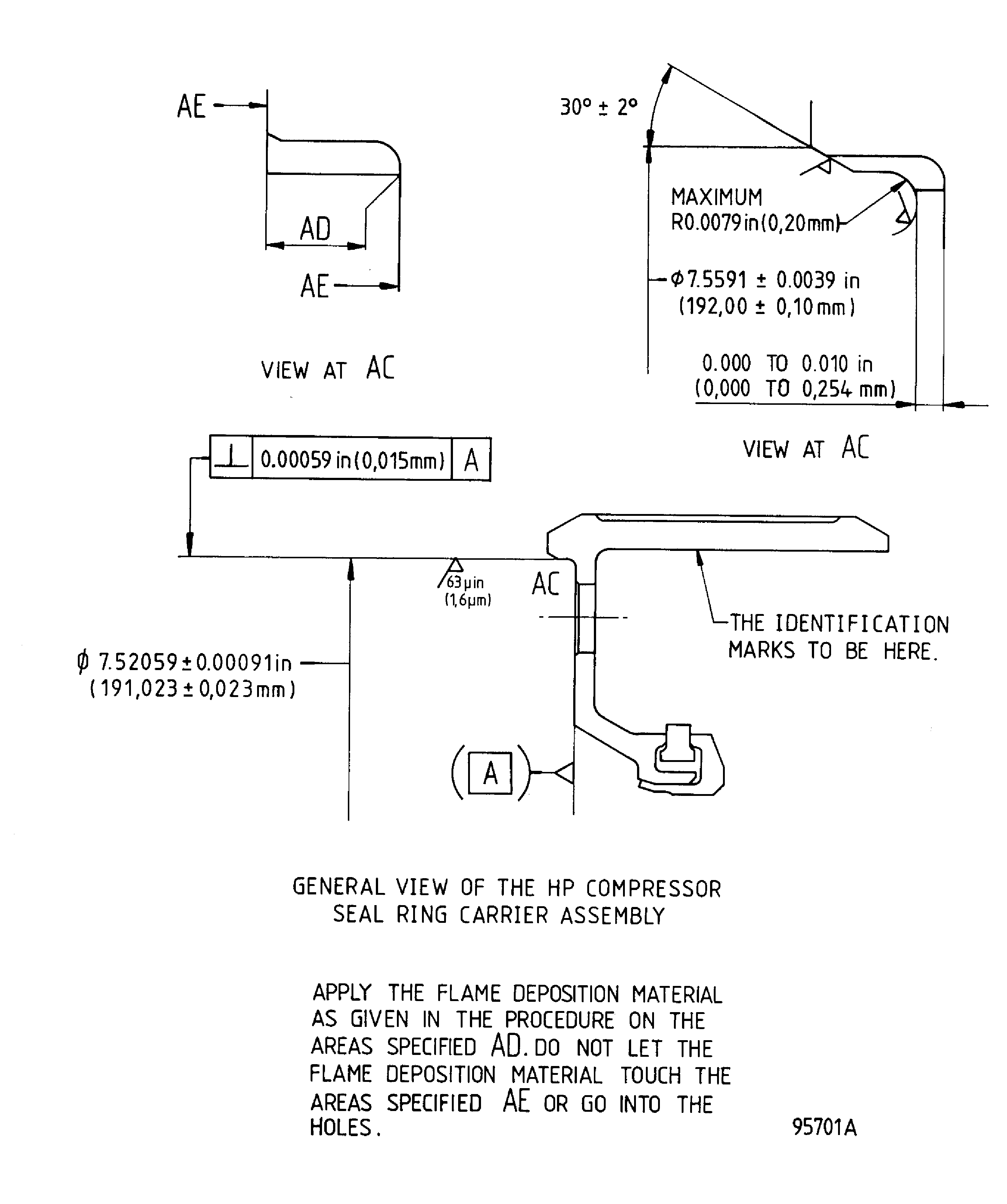

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C

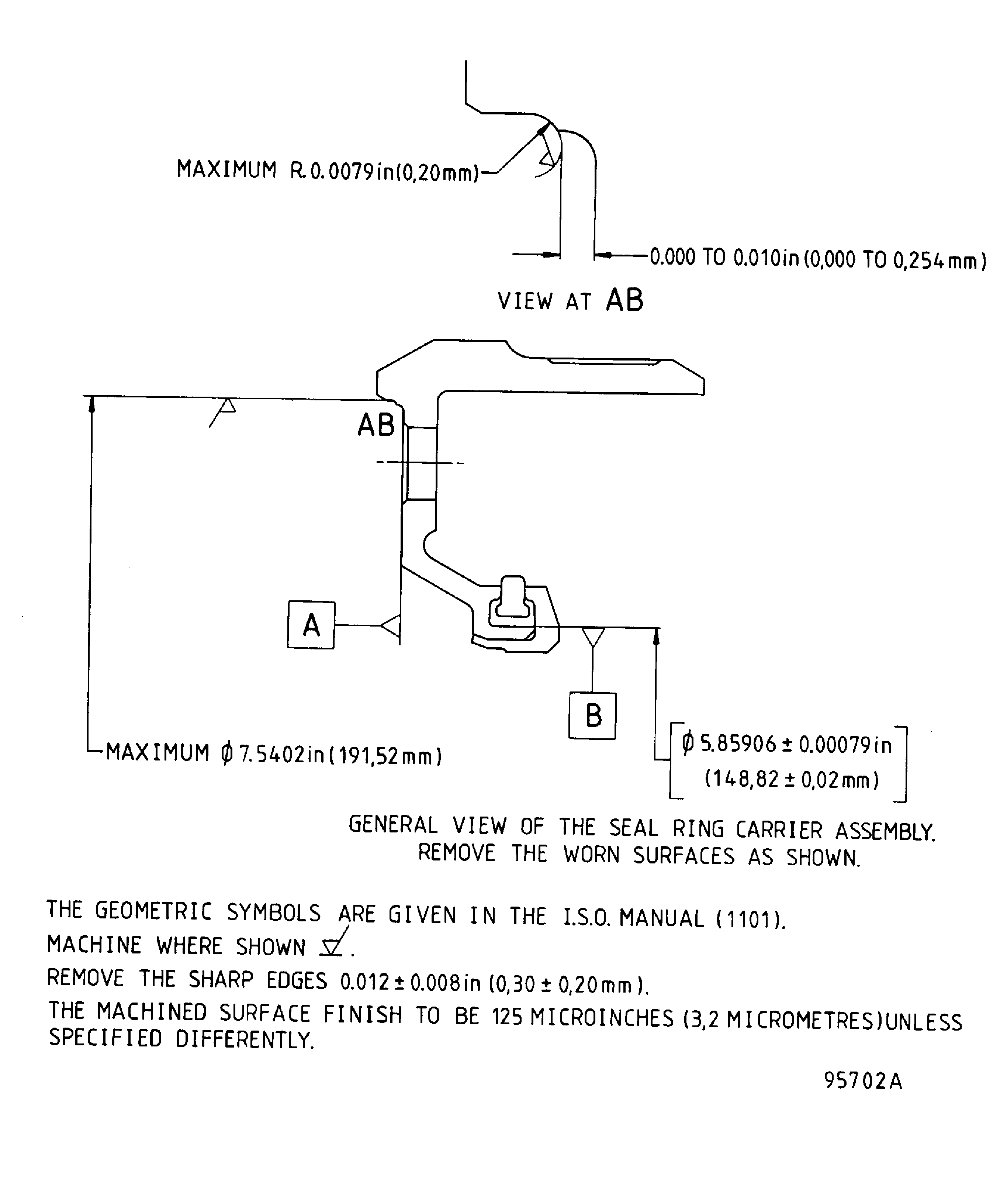

Figure: Repair details and dimensions - Assembly B

Repair details and dimensions - Assembly B

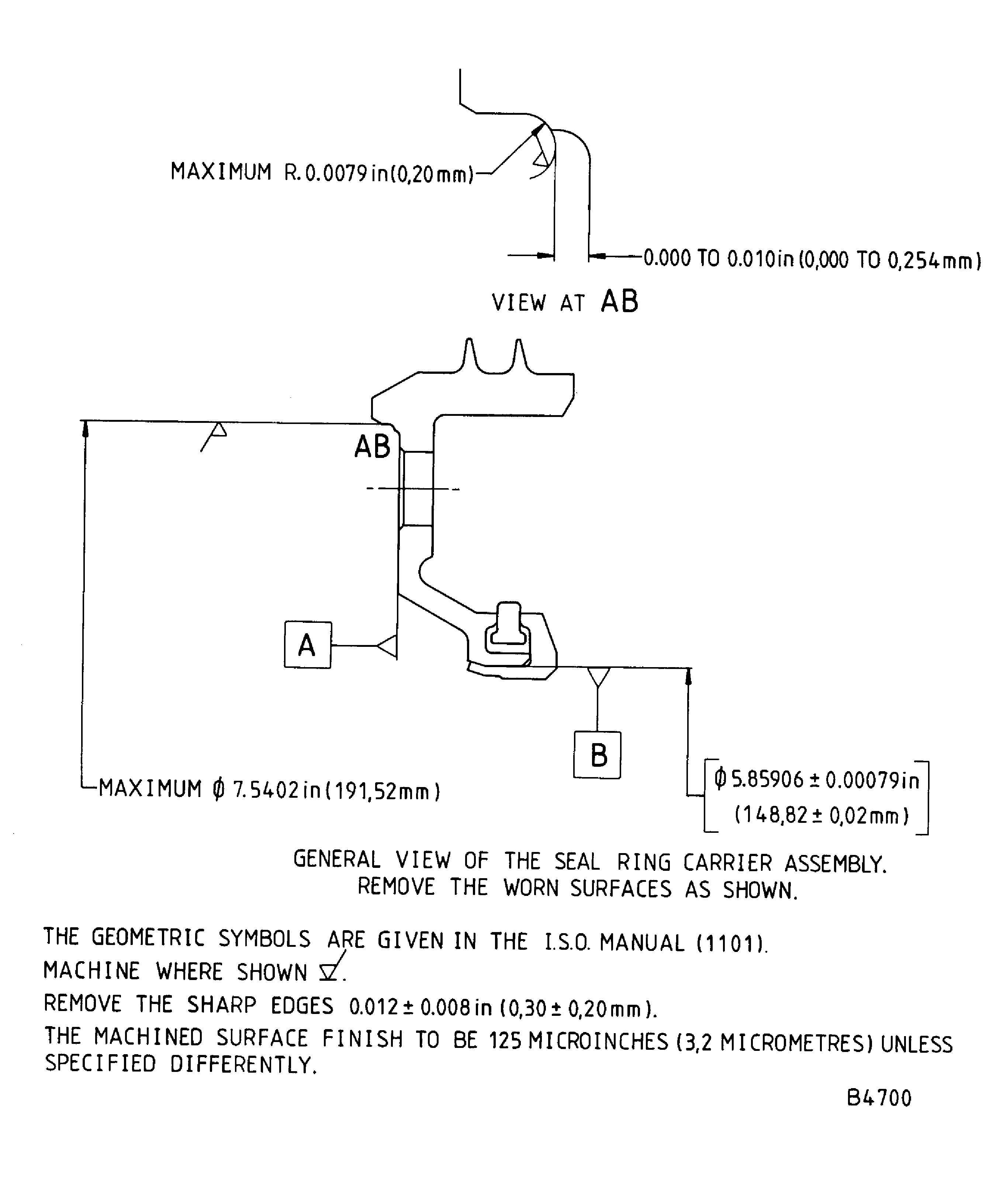

Figure: Repair details and dimensions - Assembly C

Repair details and dimensions - Assembly C