Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-53-300-024 No. 1 Bearing Face Seal - Repair The Anti-Rotation Slot Bushing, Repair-024 (VRS3750)

General

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-392 WELDING WIRE | LOCAL | CoMat 03-392 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bushing | LOCAL | Locally Fabricated | 2 | Figure 4 and Figure 5 |

| Rivet | OAM53 | 4 |

Safety Requirements

NONEProcedure

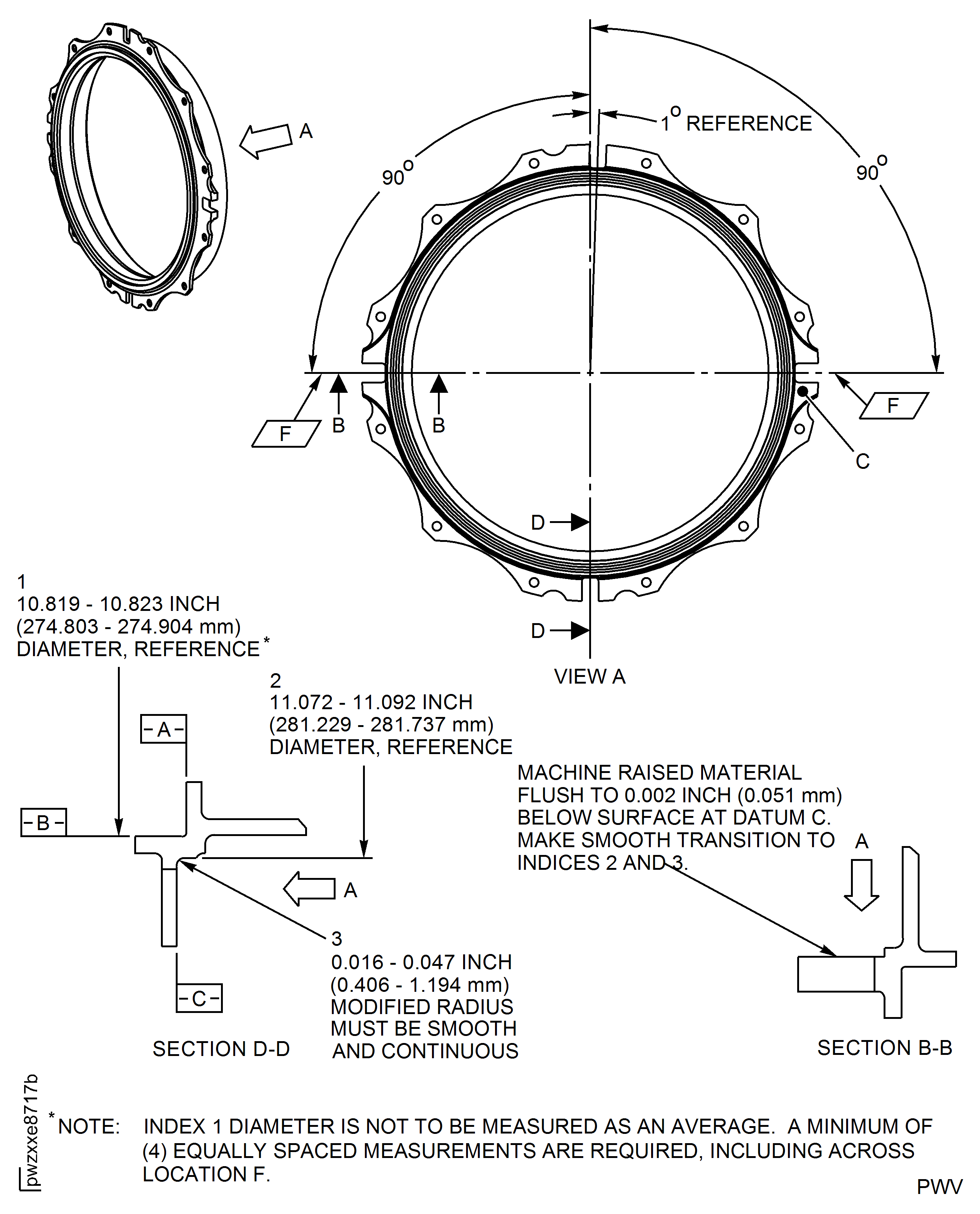

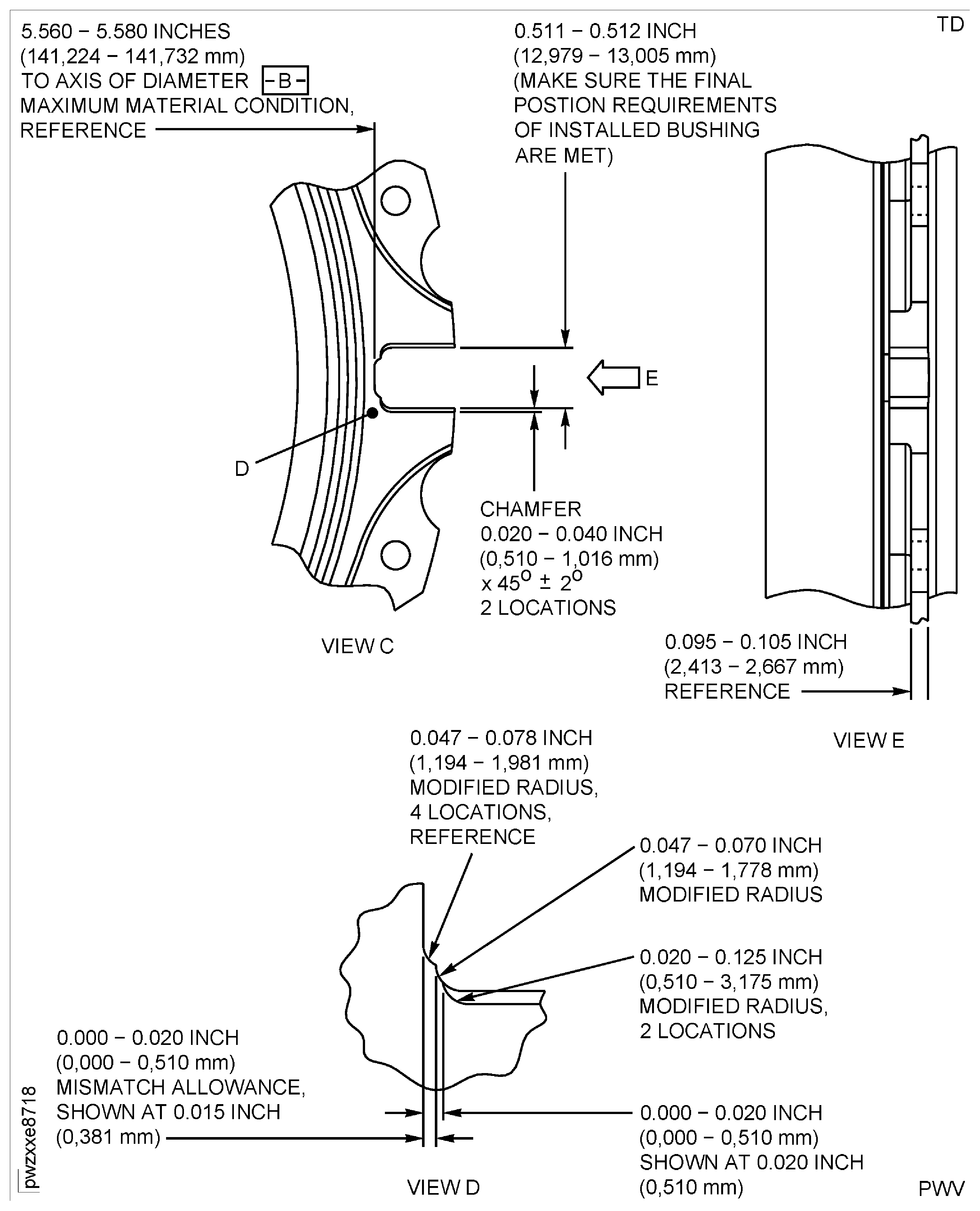

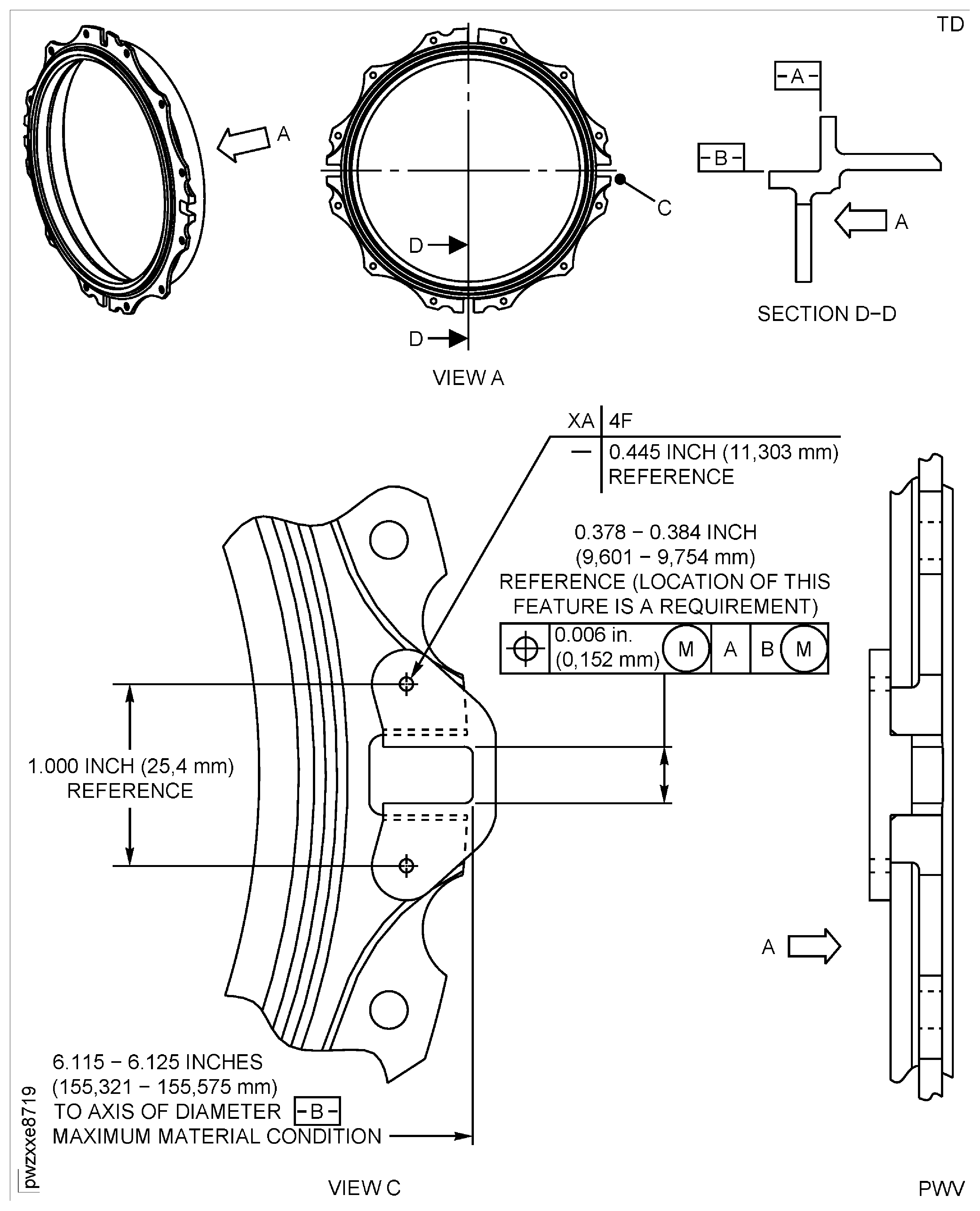

Refer to Figure.

SUBTASK 72-32-53-220-100 Examine the Slot

Refer to the SPM TASK 70-39-03-390-501.

Do an inspection of the rivet holes.

SUBTASK 72-32-53-220-101 Examine the Rivet Holes

Refer to Repair-021 (VRS3545) TASK 72-32-53-300-021.

If necessary, repair the slots.

If the slot area must be restored to repair wear or to get the correct position of the new bushings, do the following.

SUBTASK 72-32-53-350-069 Repair Slot Area for Wear or to Get the Correct Position of the New Bushings

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-016. Use CoMat 03-392 WELDING WIRE and the Manual Gas Tungsten Arc (GTAW-MA) method.

Weld the rivet holes.

Refer to the SPM TASK 70-37-07-370-501.

Do a stress relieve of the face seal assembly.

Refer to the SPM TASK 70-23-01-230-501.

Do a fluorescent penetrant inspection of the face seal assembly.

Refer to the SPM TASK 70-11-26-300-503.

Clean the repair area.

If the rivet holes must be restored to repair wear or to get the correct position of the new bushings, do the following (if necessary).

SUBTASK 72-32-53-350-070 Repair Rivet Holes for Wear or to Get the Correct Position of the New Bushings

Refer to the SPM TASK 70-37-28-370-501.

Heat treat the bushings.

Refer to the SPM TASK 70-23-02-230-501.

Do a fluorescent penetrant inspection of the bushing.

Locally fabricate the bushings from AMS 5613 material. The following apply:

SUBTASK 72-32-53-350-071 Locally Fabricate Bushings

Refer to the SPM TASK 70-11-03-300-503.

Clean the locally fabricated bushings.

SUBTASK 72-32-53-110-087 Clean the Bushings

Refer to Figure.

NOTE

It is permitted to exceed the edge distance requirements not more than 50 percent.Refer to the SPM TASK 70-39-03-390-501.

Position and clamp bushings in place at locations F. Transfer drill the bushing rivet holes into the face seal assembly and secure with rivets.

SUBTASK 72-32-53-350-072 Install the Bushings

Refer to Figure.

SUBTASK 72-32-53-220-102 Inspect the Bushings

Refer to Repair, VRS3385 TASK 72-32-53-300-007 (REPAIR-008).

Install the carbon seal element to the face seal assembly.

SUBTASK 72-32-53-350-073 Install the Carbon Seal Element

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2