Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

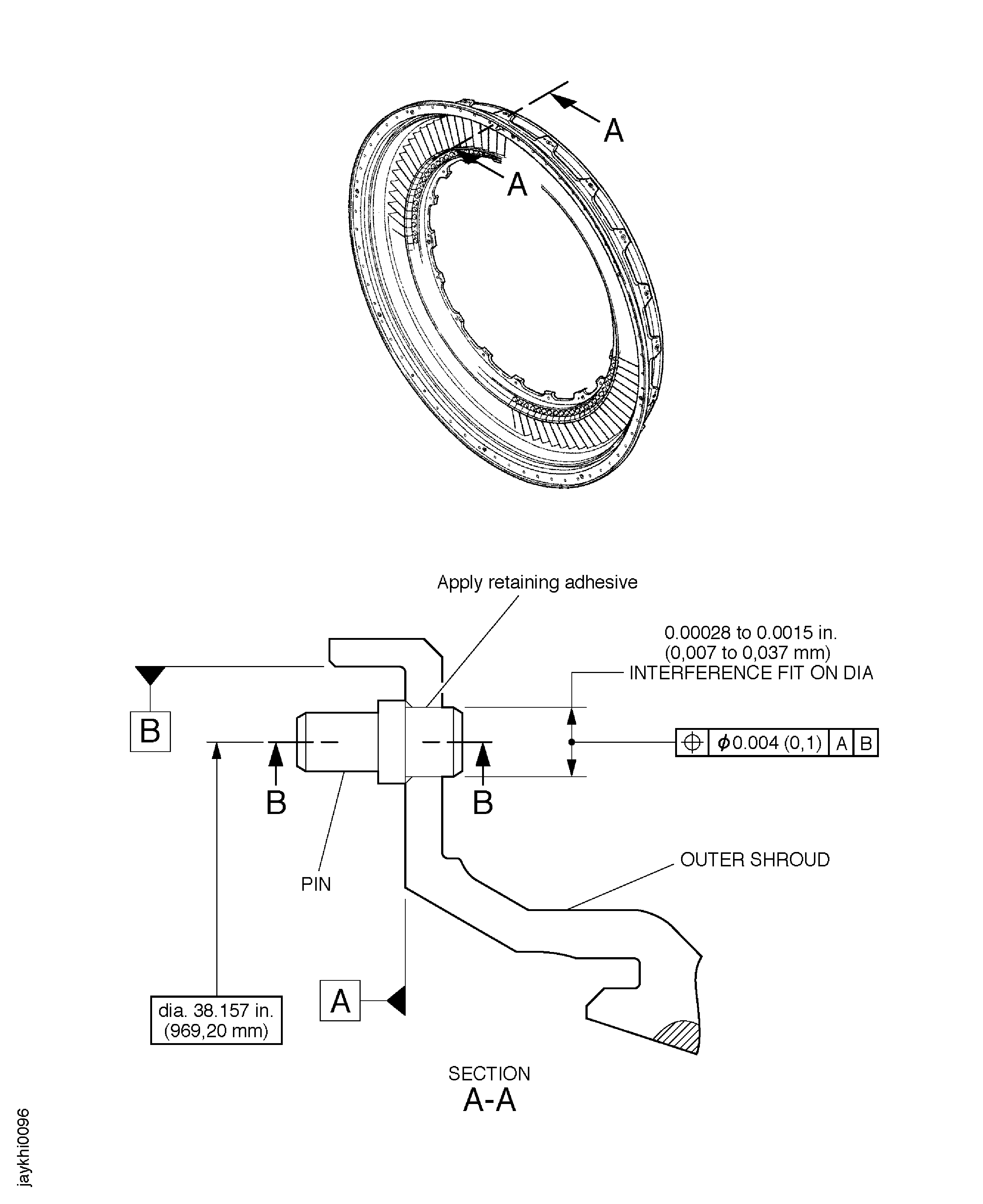

TASK 72-32-76-300-021 LPC Stage 2.5 Stator - Fill To Replace The Pin, Repair-021 (VRS1944)

General

This repair must only be done when the inspection to do so is given in the relevant inspection procedure (TASK 72-32-76-200-001-C00 or TASK 72-32-76-200-001-D00).

The TASK gives the procedure to repair the shoulder pin in the stage 2.5 vane assembly, by replacement.

Price and availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Portable blending equipment | LOCAL | Portable blending equipment | ||

| Heat resistant gloves | LOCAL | Heat resistant gloves | ||

| Portable heating equipment | LOCAL | Portable heating equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 02-100 GLOVES, LINT-FREE | LOCAL | CoMat 02-100 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 08-021 EPOXY PASTE ADHESIVE | LOCAL | CoMat 08-021 | ||

| CoMat 08-122 RETAINING ADHESIVE | 05972 | CoMat 08-122 | ||

| CoMat 02-097 LINT-FREE GLOVES | LOCAL | CoMat 02-097 | ||

| CoMat 07-028 CHROMATE CONVERSION COATING FOR ALUMINUM | LOCAL | CoMat 07-028 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Pin, shoulder | 5R0099 | 1 |

Safety Requirements

NONEProcedure

Refer to Figure.

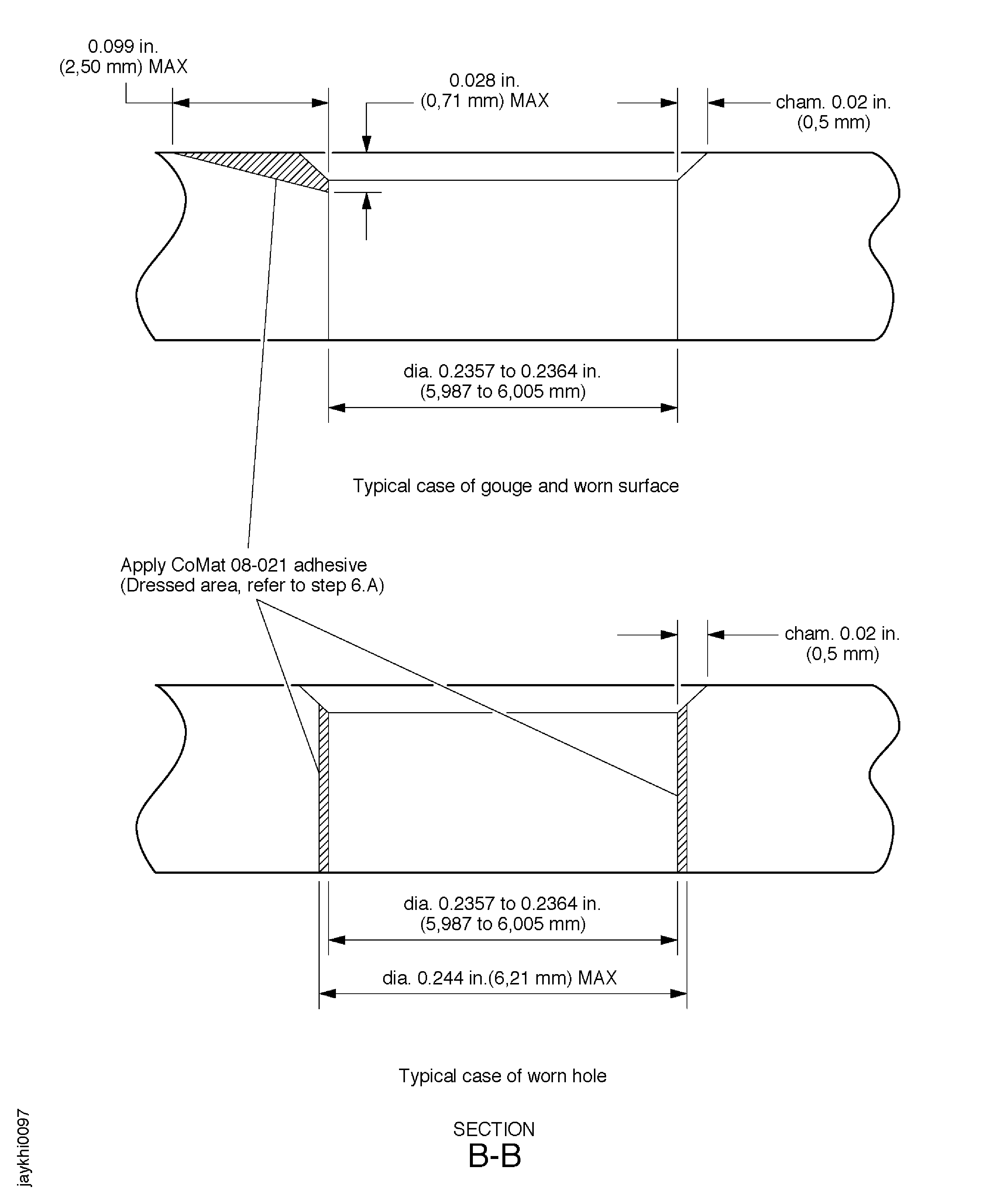

SUBTASK 72-32-76-220-148 Examine the Hole Diameter and Surface Condition

Use portable blending equipment and CoMat 05-021 WATERPROOF SILICON CARBIDE.

Remove the cracked and deformed material area.

Use CoMat 05-020 WATERPROOF SILICON CARBIDE to make the blended surface as smooth as the initial surface.

Polish the blended areas.

SUBTASK 72-32-76-320-001 Re-shape the Cracked and Deformed Area

Refer to SPM TASK 70-11-26-300-503.

Clean the blended area and permit to dry.

Degrease the blended area.

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Do Step again.

Cracked

Crack test on the blended area

SUBTASK 72-32-76-230-060 Examine the Repaired Surface

Refer to SPM TASK 70-11-26-300-503.

Clean the blended area and permit to dry.

Use CoMat 08-021 EPOXY PASTE ADHESIVE. Refer to SPM TASK 70-36-02-360-501.

NOTE

Wear CoMat 02-097 LINT-FREE GLOVES or CoMat 02-100 GLOVES, LINT-FREE before you touch the parts.

Prepare the adhesive.

Apply the adhesive.

The cure time given in Figure is determined by the selected temperature.

NOTE

Make sure the full cure time is used and correct temperature maintained.

Cure the adhesive.

Use files or CoMat 05-020 WATERPROOF SILICON CARBIDE.

Refer to Figure.

Remove unwanted adhesive.

SUBTASK 72-32-76-360-073 Molding Repair with Adhesive

Refer to Figure.

SUBTASK 72-32-76-220-150 Examine the Repaired Hole Dimension

Refer to the SPM TASK 70-11-26-300-503.

Clean the pin (removed or new).

Use CoMat 08-122 RETAINING ADHESIVE. Refer to Figure.

Apply anaerobic adhesive to the outer diameter of the pin.

SUBTASK 72-32-76-360-074 Prepare the Part for Repair

WARNING

ALWAYS MAKE SURE THAT THERE IS SUFFICIENT VENTILATION IN THE WORK AREA.

WARNING

EYE PROTECTION MUST ALWAYS BE USED.

WARNING

DO NOT LET SOLVENT CLEANER OR ITS VAPOR TOUCH YOUR EYES OR SKIN.

WARNING

PROTECTIVE CLOTHING AND FACE MASKS MUST ALWAYS BE USED.

WARNING

ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA.

WARNING

IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY DATA SHEETS FOR CONSUMABLE MATERIALS INFORMATION SUCH AS HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.Refer to Figure.

Use Portable heating equipment. Heat the flange to 120 deg F (49 deg C).

Heat the flange of the outer shroud.

SUBTASK 72-32-76-350-076 Install the Pin

Refer to Figure.

SUBTASK 72-32-76-220-151 Examine the Pin for Location

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibro-peen equipment.

Make a mark VRS1944 adjacent to the assembly number.

SUBTASK 72-32-76-350-077 Identify the Repair

Refer to SPM TASK 70-11-26-300-503.

Clean the dressed area and marked area.

Refer to SPM TASK 70-38-02-300-503.

Treat the dressed area and marked area.

SUBTASK 72-32-76-380-005 Reprotect the Dressed Area and Marked Area

WARNING

ALWAYS MAKE SURE THAT THERE IS SUFFICIENT VENTILATION IN THE WORK AREA. PROTECTIVE CLOTHING, FACE MASKS AND EYE PROTECTION MUST ALWAYS BE USED. DO NOT LET THE SOLVENT CLEANER OR ITS VAPOR TOUCH YOUR EYES OR SKIN. ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA.

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions