Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-32-85-300-040 Fan Case - Repair The Acoustic Linings, Repair-040 (VRS1822)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-100 | 5W0144 |

01-100 | 5W0149 |

01-100 | 5W0154 |

01-100 | 5W0169 |

01-100 | 5W0172 |

01-100 | 5W0194 |

01-100 | 5W0195 |

01-100 | 5W0196 |

01-100 | 5W0197 |

01-100 | 5W0198 |

01-100 | 5W0217 |

01-100 | 5W0218 |

01-100 | 5W0219 |

01-100 | 5W0220 |

01-100 | 5W0221 |

01-100 | 5W0222 |

01-100 | 5W0223 |

01-100 | 5W0224 |

01-100 | 5W0225 |

01-100 | 5W0226 |

01-100 | 5W0307 |

01-100 | 5W0313 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Casing | Titanium alloy | |

Acoustic lining | Titanium alloy | |

Acoustic lining | Aluminum alloy honeycomb |

General

Price and availability - refer to IAE

The repair scheme gives the procedure of acoustic linings by filling with blue filler.

The practices and processes referred to in the procedure by the TASK numbers are in SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand held pneumatic grinder | LOCAL | Hand held pneumatic grinder | ||

| Rotary files | LOCAL | Rotary files | ||

| Putty knife | LOCAL | Putty knife | ||

| Sealant gun | LOCAL | Sealant gun | Air powered | |

| Vacuum cleaner | LOCAL | Vacuum cleaner |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 08-006 FILLER, TWO PACK | LOCAL | CoMat 08-006 | ||

| CoMat 08-024 SEALANT | 23354 | CoMat 08-024 | ||

| CoMat 08-142 POLYSULPHIDE COMPOUND | LOCAL | CoMat 08-142 |

Spares

NONESafety Requirements

NONEProcedure

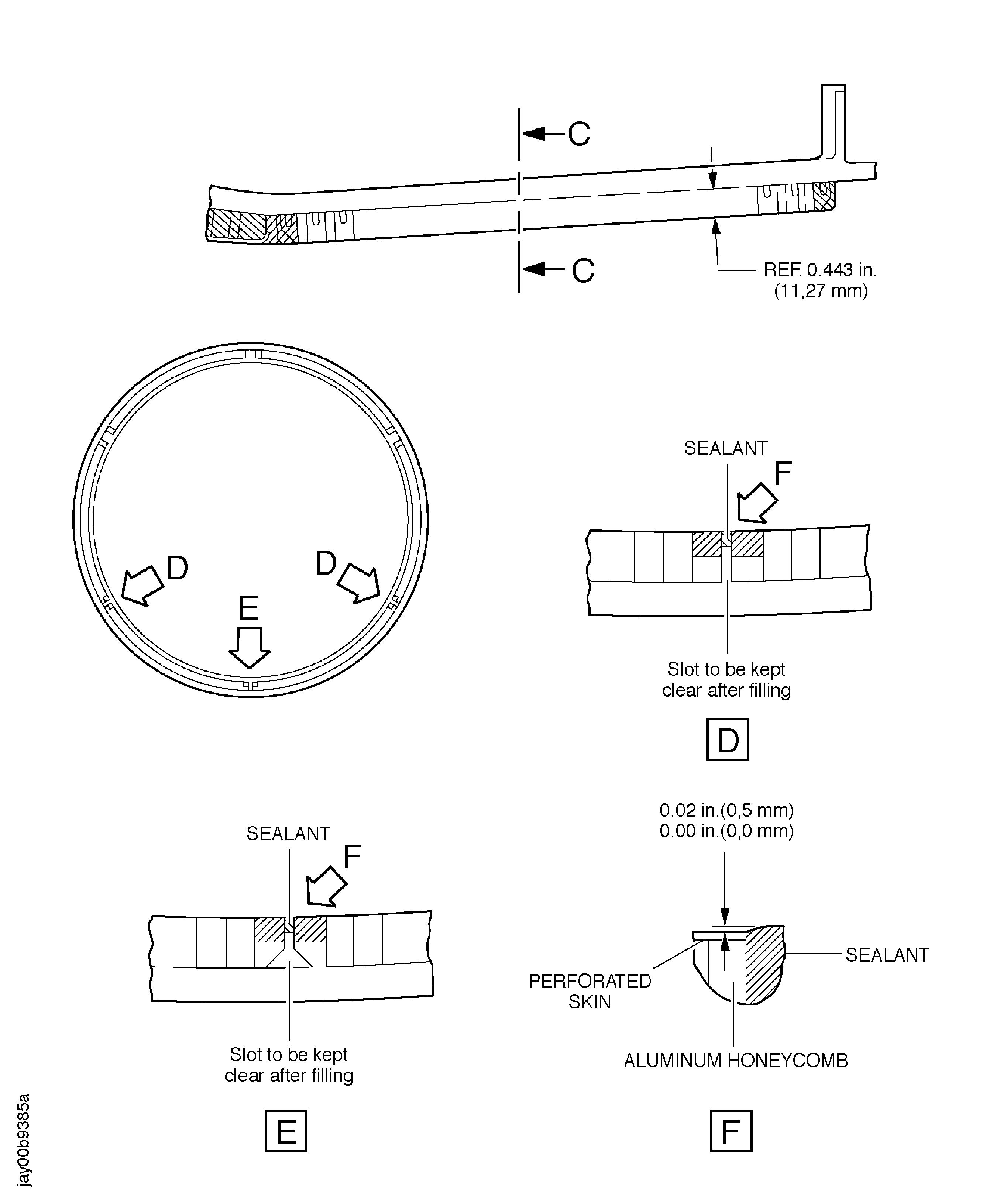

Refer to Figure.

CAUTION

TITANIUM COMPONENTS: SILICON CARBIDE TYPE WHEELS, STONES AND ABRASIVE PAPERS ARE TO BE USED FOR THIS REPAIR.

CAUTION

ALUMINUM OXIDE MUST NOT BE USED.

CAUTION

THE MATERIAL WILL OXIDIZE AND CRACK IF MECHANICAL CUTTERS ARE USED HEAVILY. THIS HAS OCCURRED IF THE COMPONENT SHOWS DARK STRAW TO BLUE DISCOLORATION. COLOR CHANGE OF THE CASING MATERIAL IS NOT ACCEPTABLE.

CAUTION

CHECK THE TOTAL REPAIR AREA PRIOR TO STARTING THE REPAIR. DO NOT CARRY OUT REPAIR BY FILLING THE ACOUSTIC LININGS IF THE TOTAL REPAIRED AREA EXCEEDS 20 PERCENT OF THE TOTAL FAN CASE ACOUSTIC LINING AREA.

CAUTION

THE FAN CASE IS MADE FROM TITANIUM ALLOY AND IS THIN IN SOME AREAS. IF YOU HIT THE FAN CASE WITH A CHISEL OR SCRAPER YOU CAN MAKE IT UNSERVICEABLE.

CAUTION

YOU MUST USE THE CHISEL, SHARP BLADE OR SCRAPER IN A CIRCUMFERENTIAL DIRECTION TO PREVENT THE EDGES OF THE BLADE SCORING THE FAN CASE.

CAUTION

YOU MUST ALWAYS TRY TO POINT THE CHISEL OR SHARP BLADE PARALLEL WITH THE SURFACE OF THE FAN CASE.

CAUTION

DO NOT OPERATE WITHOUT SAFETY GOGGLES AND OTHER GUARD EQUIPMENT. FLYING PARTICLES CAN CAUSE INJURY.

CAUTION

STOP MACHINING AS SOON AS THE FILES, CUTTERS OR MACHINING BITS ARE THROUGH THE LINING MATERIAL. USE A STOP-MACHINING OR SLEEVE OR OTHER PENETRATION LIMITING DEVICE TO PREVENT DAMAGE TO THE CASING MATERIAL.

CAUTION

DO NOT USE POWERED TOOLS WITH STEEL CHISEL OR SIMILAR BITS.Cut away area to remove broken pieces or make a hole to fill damaged area with filler.

Refer to Figure.

Edges of damaged area must be underflush.

NOTE

Keep the material removal to the minimum necessary to remove damaged area.Make surface flat, if necessary.

Refer to Figure.

Make sure that remaining skin surface is smooth.

If the total repaired area is 20 percent more than, repair, VRS1842 TASK 72-32-85-300-041 (REPAIR-041).

NOTE

It is necessary to do a replacement repair on some acoustic linings until the total filling repair area becomes less than 20 percent of the full circumference.

Examine the repaired area ratio.

If necessary, do repair, VRS1805 TASK 72-32-85-300-042 (REPAIR-042) or VRS1818 TASK 72-32-85-300-044 (REPAIR-044).

Examine the fan case inner surface of the repaired area, if necessary.

SUBTASK 72-32-85-350-092 Remove Defective Area of Damage

Refer to SPM TASK 70-11-26-300-503.

CAUTION

ALWAYS MAKE SURE THERE IS SUFFICIENT VENTILATION IN THE WORK AREA. EYE PROTECTION MUST ALWAYS BE USED. DO NOT LET THE SOLVENT CLEANER OR ITS VAPOUR TOUCH THE EYES OR SKIN. PROTECTIVE CLOTHING AND FACE MASK MUST ALWAYS BE USED. ALWAYS KEEP OPEN FLAMES AWAY FROM THE WORK AREA. IT IS THE RESPONSIBILITY OF THE OPERATOR TO OBTAIN AND OBSERVE THE MANUFACTURERS MATERIAL SAFETY SHEETS FROM THE CONSUMABLE MATERIALS INFORMATION SUCH AS, HAZARDOUS INGREDIENTS, PHYSICAL/CHEMICAL CHARACTERISTICS, FIRE, EXPLOSION, REACTIVITY, HEALTH HAZARD DATA, PRECAUTIONS FOR SAFE HANDLING, USE AND CONTROL MEASURES AND ALSO TO TAKE LOCAL REGULATIONS INTO CONSIDERATION.Fully remove the grease from the repair area.

SUBTASK 72-32-85-110-060 Remove the Grease from the Repair Area

Prepare the filler (CoMat 08-006 FILLER, TWO PACK).

Prepare the sealant (CoMat 08-024 SEALANT or CoMat 08-142 POLYSULPHIDE COMPOUND).

Use CoMat 08-024 SEALANT 75 parts of base compound and 10 parts of curing compound (accelerator) or CoMat 08-142 POLYSULPHIDE COMPOUND 100 parts of base compound and 10 parts of curing compound (accelerator) by weight.

Measure out materials by weight.

SUBTASK 72-32-85-360-080 Prepare Filler Material

Option 1: Apply the filler (CoMat 08-006 FILLER, TWO PACK).

Refer to SPM TASK 70-36-02-360-501.

Use airpowered sealant gun.

Refer to Figure. Make sure that the repair area is fully filled with no air pockets. Start at the bottom and work both side. The filler will gradually set. If any sagging is apparent, locally produced supports will be necessary.

Fill the filler slightly more than necessary level in the damaged area.

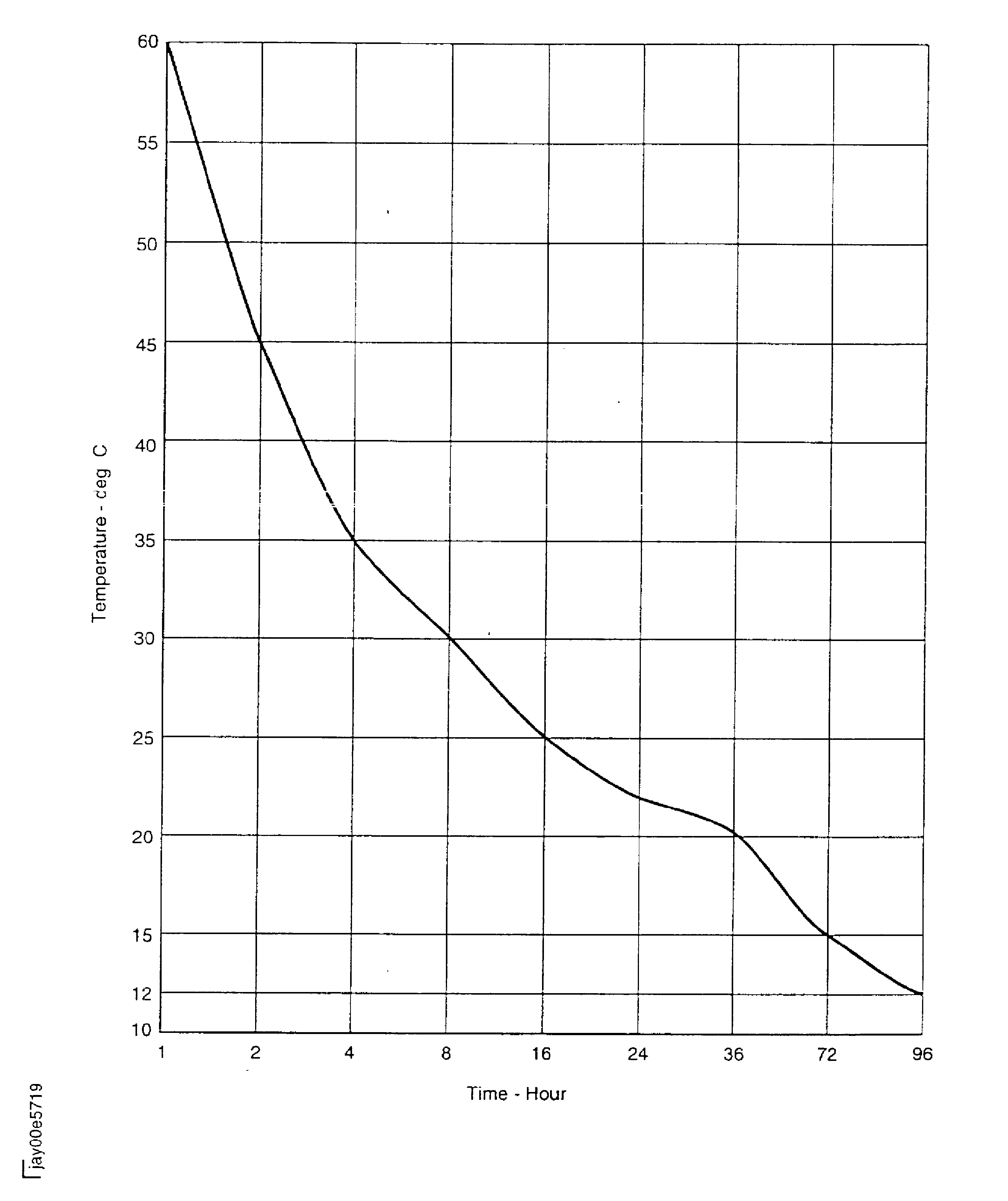

The cure times and temperatures given in Figure.

NOTE

The minimum cure time is one hour.Cure the filler.

Apply the sealant using putty knife. Remove all unwanted sealant, when it starts to feel hard. Cure the sealant for 10 hours ay 77 deg F (25 deg C). Refer to Figure.

CAUTION

THE MAXIMUM TEMPERATURE WHICH CAN BE USED TO CURE THE FILLER IS 176 DEG F (80 DEG C).Option 2: Apply the sealant (CoMat 08-024 SEALANT or CoMat 08-142 POLYSULPHIDE COMPOUND).

SUBTASK 72-32-85-360-081 Apply Filler or Sealant Material

Use CoMat 08-024 SEALANT 75 parts of base compound and 10 parts of curing compound (accelerator) or CoMat 08-142 POLYSULPHIDE COMPOUND 100 parts of base compound and parts of curing compound (accelerator) by weight.

Mix the two parts by kneading until the compound is a constant color.

No streaks permitted.

CAUTION

THE MAXIMUM TEMPERATURE WHICH CAN BE USED TO CURE THE SEALANT IS 120 DEG F (49 DEG C).NOTE

Do not put in the filler in to the three water drainage slots between the lower side acoustic linings.NOTE

The minimum cure time is 1.5 hours. Sealant cure times with a relative humidity of 50 percent.Prepare the sealant material.

Remove all unwanted sealant, when it starts to feel hard.

Cure the sealant for 10 hours at 77 deg F (25 deg C) or 1.5 hours at 113 deg F (45 deg C).

Refer to Figure.

CAUTION

THE MAXIMUM TEMPERATURE WHICH CAN BE USED TO CURE THE SEALANT IS 120 DEG F (49 DEG C).NOTE

You must use plastic gloves, during preparation and use of the sealant, to prevent contamination of the skin.NOTE

When mixed the life of the filler is approximately half an hour, at 77 deg F (25 deg C).Apply sealant material.

NOTE

The minimum cure time is 1.5 hours. Sealant cure times with a relative humidity of 50 per cent.

SUBTASK 72-32-85-360-082 If Necessary to Fill the Sealant in the Slots Between the Acoustic Linings

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions (CoMat 08-006)

Repair Details and Dimensions (CoMat 08-006)