Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-38-11-300-015 Inlet Cone Assembly - Repair The Delamination Around The Pin Hole, Repair-015 (VRS1461)

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Inlet cone | - | Fiber-reinforced plastic with polyurethane coating |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Oven | LOCAL | Oven | ||

| Spatula | LOCAL | Spatula | ||

| Vacuum cleaner | LOCAL | Vacuum cleaner |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 05-079 WATERPROOF SILICON CARBIDE | K3895 | CoMat 05-079 | ||

| CoMat 05-080 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-080 | ||

| CoMat 08-036 SILICONE RUBBER COMPOUND | LOCAL | CoMat 08-036 | ||

| CoMat 08-047 HARDENER | 0LCV8 | CoMat 08-047 | ||

| CoMat 08-048 RESIN | LOCAL | CoMat 08-048 | ||

| CoMat 08-049 FIBREGLASS CLOTH | K6835 | CoMat 08-049 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Repair, VRS1467 TASK 72-38-11-300-003 (REPAIR-003).

Remove the dowel pin as necessary.

SUBTASK 72-38-11-350-071 Remove the Dowel Pin from the Inlet Cone

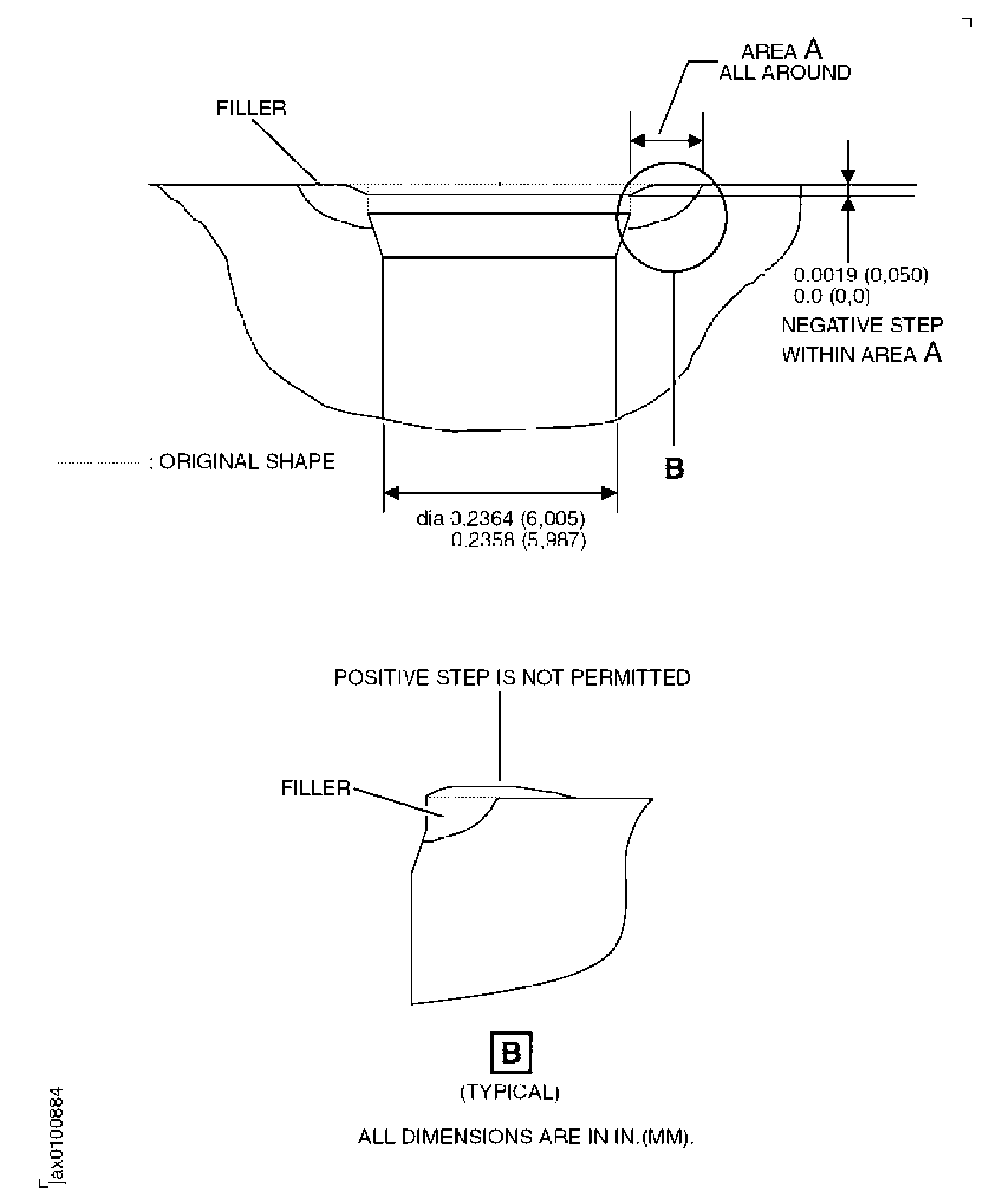

Refer to Figure.

Refer to the SPM TASK 70-36-04-360-501, SUBTASK 70-36-04-360-002 and SUBTASK 70-36-04-360-003.

Cure the compound at room temperature only.

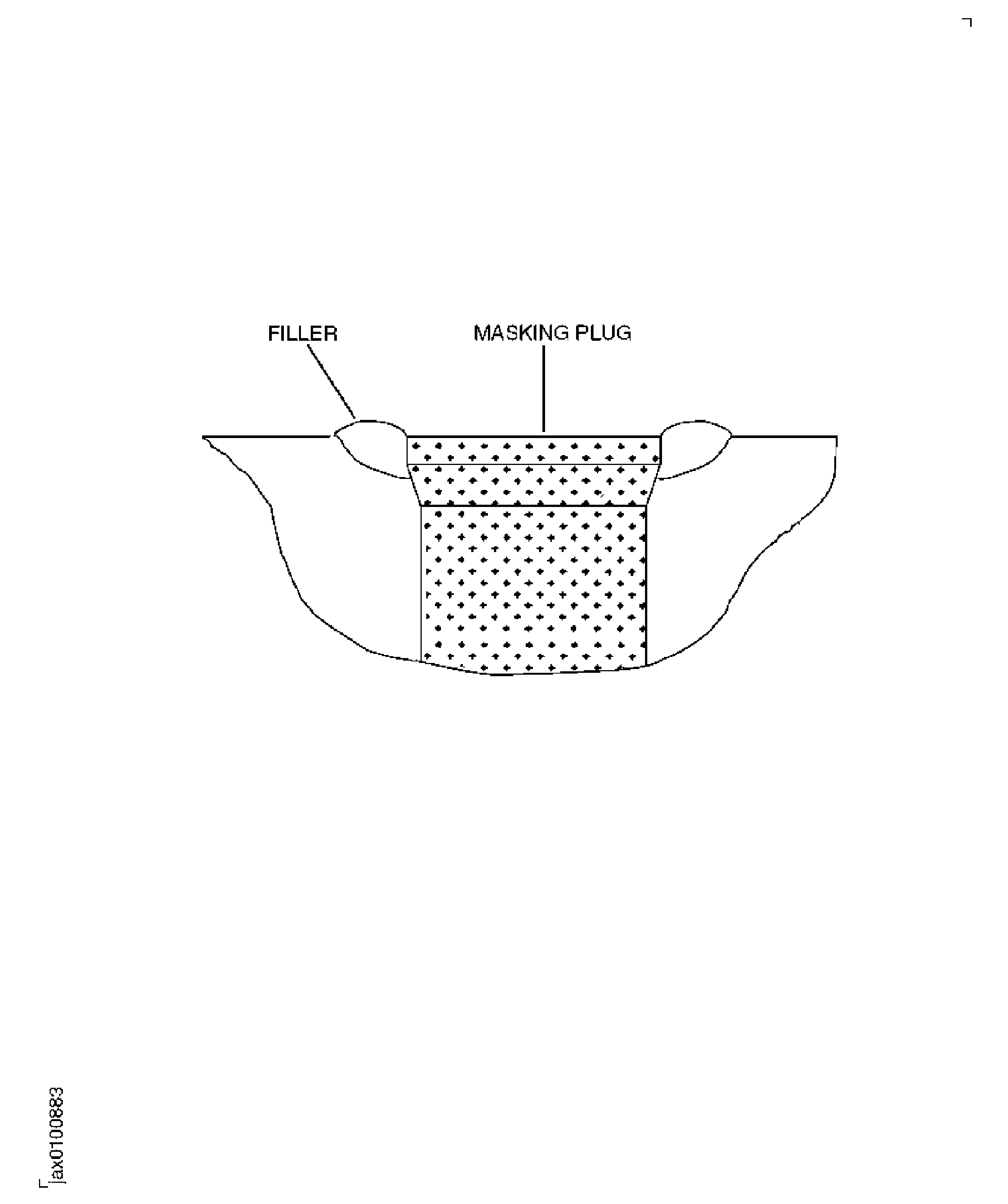

Make the masking plugs for pin holes locally.

SUBTASK 72-38-11-350-072 Make the Masking Plug for Repair

Refer to Figure.

Refer to the SPM TASK 70-35-03-300-501.

Reject the inlet cone, if the damage can not be removed completely.

Use a portable grinding equipment, CoMat 05-020 WATERPROOF SILICON CARBIDE and CoMat 05-021 WATERPROOF SILICON CARBIDE.

NOTE

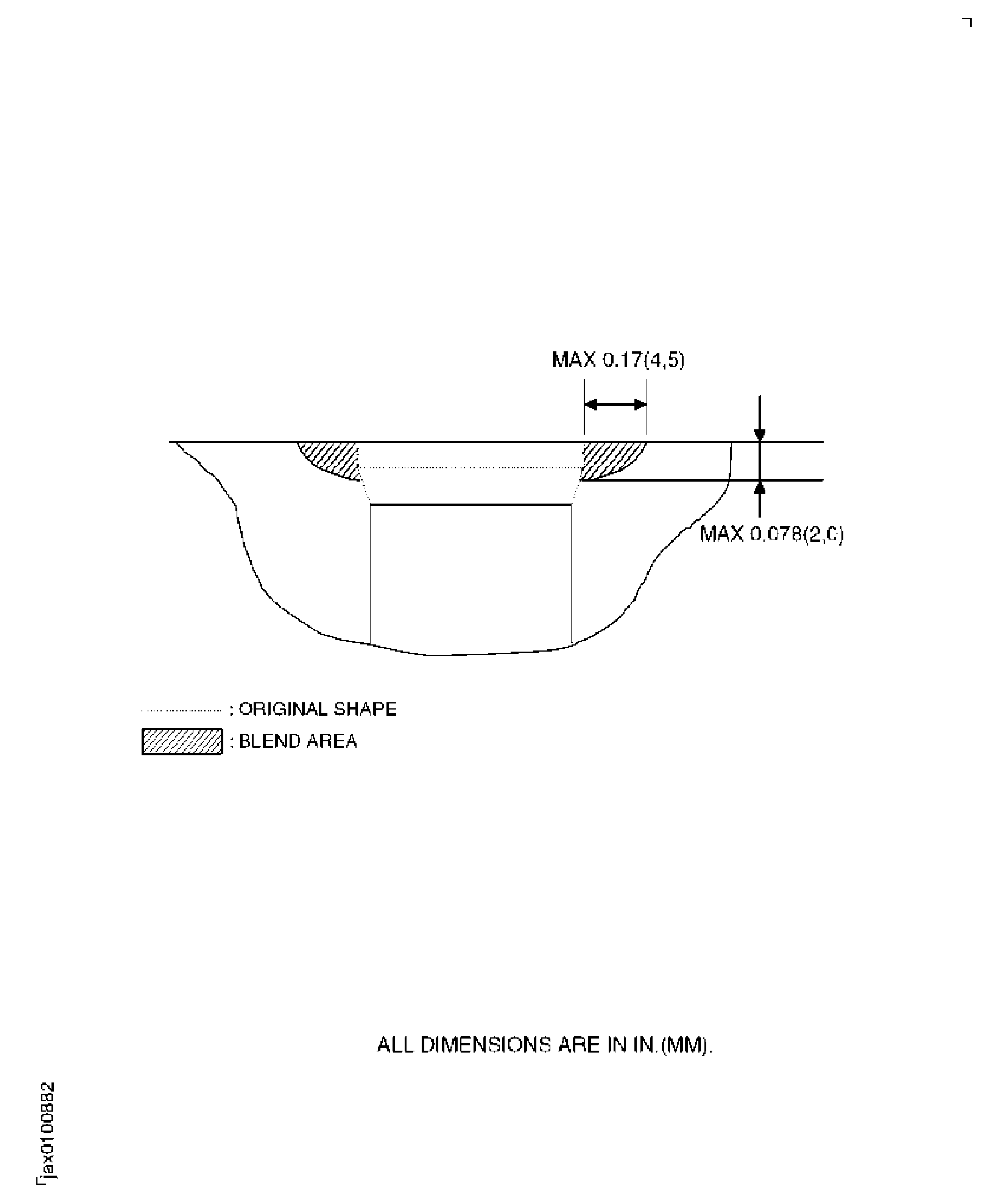

Remove the minimum quantity of material necessary to remove the damage.Blend to remove the delamination.

SUBTASK 72-38-11-350-073 Remove the Delamination around the Pin Hole of the Inlet Cone

Unravel the cloth into the individual fiber.

WARNING

DO NOT GET RESIN MIXTURE ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A FACE MASK. USE THE RESIN IN A WELL VENTILATED AREA; DO NOT BREATHE THE GAS. IF YOU GET THE RESIN ON YOUR SKIN OR IN YOUR EYES GET MEDICAL AID IMMEDIATELY.Cut the fiberglass cloth into 0.039 to 0.078 in. (1.00 to 2.00 mm) wide.

Put 3.5 oz (100 gm) of CoMat 08-048 RESIN into a container and add between 0.35 and 0.42 oz (10 and 12 gm) of CoMat 08-047 HARDENER.

Mix the two parts by using a spatula.

Prepare the adhesive.

SUBTASK 72-38-11-350-074 Prepare the Filler for Repair

Refer to Figure.

Refer to the SPM TASK 70-11-26-300-503.

CAUTION

DO NOT EAT OR SMOKE AT LOCATIONS WHERE THESE MATERIALS ARE USED.

CAUTION

AFTER PREPARATION THE MATING SURFACES MUST BE FULLY CLEANED AND MUST NOT BE TOUCHED BY HAND, TO PREVENT CONTAMINATION.

CAUTION

BONDING MUST BE DONE IMMEDIATELY AFTER THE SURFACE PREPARATION.Clean the repaired area and the masking plug.

SUBTASK 72-38-11-350-075 Apply the Filler to the Repair Area

Refer to Figure.

SUBTASK 72-38-11-350-076 Dress and Polish the Repaired Area

Refer to Repair, VRS1467, TASK 72-38-11-300-003 (REPAIR-003).

Dimensionally examine the pin hole.

SUBTASK 72-38-11-220-187 Examine the Repaired Area

Refer to Repair, VRS1467, TASK 72-38-11-300-003 (REPAIR-003).

Install the dowel pin as necessary.

SUBTASK 72-38-11-360-078 Install the Dowel Pin to the Inlet Cone

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS1461 adjacent to the part number by the ink method.

SUBTASK 72-38-11-350-077 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions