Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-10-040-001-A00 HPC Rotor Assembly - Disassemble The Rotor Assembly, Disassembly-001

General

This TASK gives the procedure to disassemble the HP compressor rotor assembly. It includes the procedure to measure the seal and stator path diameters and the blade lengths before removal.

Make sure the tip check and seal check equipment has been calibrated before you use it. Refer to the Illustrated Tools and Equipment Manual, Pub ref ITE-V2500-1IA.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved penetrating oil before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

If it is necessary to remove blades from the disks they must be correlated to the disk.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Digital read out equipment | LOCAL | Digital read out equipment | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Snap-on TM70B wrench | LOCAL | Snap-on TM70B wrench | ||

| Snap-on TMX60 extension | LOCAL | Snap-on TMX60 extension | ||

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1R18020 Build stand | 0AM53 | IAE 1R18020 | 1 | |

| IAE 1R18021 Support ring | 0AM53 | IAE 1R18021 | 1 | |

| IAE 1R18024 Geared indexing spanner | 0AM53 | IAE 1R18024 | 1 | |

| IAE 1R18025 Turnover stand adapter | 0AM53 | IAE 1R18025 | 1 | |

| IAE 1R18026 Lifting fixture | 0AM53 | IAE 1R18026 | 1 | |

| IAE 1R18027 Indexing ring | 0AM53 | IAE 1R18027 | 1 | |

| IAE 1R18029 Blanking tool | 0AM53 | IAE 1R18029 | 1 | |

| IAE 1R18059 Trolley | 0AM53 | IAE 1R18059 | 1 | |

| IAE 1R18061 Rail | 0AM53 | IAE 1R18061 | 2 | |

| IAE 1R18065 Lifter | 0AM53 | IAE 1R18065 | 1 | |

| IAE 1R18067 Extractor | 0AM53 | IAE 1R18067 | 1 | |

| IAE 1R18079 Drift | 0AM53 | IAE 1R18079 | 1 | |

| IAE 1R18080 Drift | 0AM53 | IAE 1R18080 | 1 | |

| IAE 1R18081 Beam sling | 0AM53 | IAE 1R18081 | 1 | |

| IAE 1R18089 Lifting adapter | 0AM53 | IAE 1R18089 | 1 | |

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18091 Support stand | 0AM53 | IAE 1R18091 | 1 | |

| IAE 1R18092 Support tool | 0AM53 | IAE 1R18092 | 1 | |

| IAE 1R18093 Extractor | 0AM53 | IAE 1R18093 | 1 | |

| IAE 1R18095 Universal slinging adapter | 0AM53 | IAE 1R18095 | 2 | |

| IAE 1R18097 Drift | 0AM53 | IAE 1R18097 | 1 | |

| IAE 1R18322 Turnover stand | 0AM53 | IAE 1R18322 | 1 | |

| IAE 1R18400 Protection sleeve | 0AM53 | IAE 1R18400 | 1 | |

| IAE 1R18441 Lifting adapter | 0AM53 | IAE 1R18441 | 1 | |

| IAE 1R18443 Puller | 0AM53 | IAE 1R18443 | 1 | |

| IAE 1R18451 Tip check fixture | 0AM53 | IAE 1R18451 | 1 | |

| IAE 1R18452 Bearing housing (rear) | 0AM53 | IAE 1R18452 | 1 | |

| IAE 1R18453 Bearing housing (front) | 0AM53 | IAE 1R18453 | 1 | |

| IAE 1R18454 Location block | 0AM53 | IAE 1R18454 | 2 | |

| IAE 1R18455 Location block | 0AM53 | IAE 1R18455 | 2 | |

| IAE 1R18457 Seal check beam | 0AM53 | IAE 1R18457 | 1 | |

| IAE 1R18458 Brake strap | 0AM53 | IAE 1R18458 | 1 | |

| IAE 1R18459 Axial setting gage | 0AM53 | IAE 1R18459 | 1 | |

| IAE 1R18460 Transducer carrier | 0AM53 | IAE 1R18460 | 1 | |

| IAE 1R18461 Transducer carrier | 0AM53 | IAE 1R18461 | 1 | |

| IAE 1R18462 Transducer carrier | 0AM53 | IAE 1R18462 | 1 | |

| IAE 1R18463 Transducer carrier | 0AM53 | IAE 1R18463 | 1 | |

| IAE 1R18464 Transducer carrier | 0AM53 | IAE 1R18464 | 1 | |

| IAE 1R18466 Thruster plate | 0AM53 | IAE 1R18466 | 1 | |

| IAE 1R18467 Setting block | 0AM53 | IAE 1R18467 | 1 | |

| IAE 1R18496 Setting block | 0AM53 | IAE 1R18496 | 1 | |

| IAE 1R18497 Setting block | 0AM53 | IAE 1R18497 | 1 | |

| IAE 1R78498 Setting block | 0AM53 | IAE 1R78498 | 1 | |

| IAE 1R18590 Socket end | 0AM53 | IAE 1R18590 | 1 | |

| IAE 1R18628 Extractor | 0AM53 | IAE 1R18628 | 1 | |

| IAE 1R18629 Protective cover | 0AM53 | IAE 1R18629 | 1 | |

| IAE 1R18639 Setting gage | 0AM53 | IAE 1R18639 | 1 | |

| IAE 1R18673 Dummy stub shaft | 0AM53 | IAE 1R18673 | 1 | |

| Hydraulic jack | 0AM53 | ENERPAC 102 | 1 | |

| IAE 1R18911 Drill | 0AM53 | IAE 1R18911 | 1 | |

| IAE 1R18914 Setting gage | 0AM53 | IAE 1R18914 | 1 | |

| IAE 1R18913 Setting gage | 0AM53 | IAE 1R18913 | 1 | |

| IAE 1R18912 Setting gage | 0AM53 | IAE 1R18912 | 1 | |

| IAE 1R18201 Torque spanner | 0AM53 | IAE 1R18201 | 1 | |

| IAE 1R18214 Build stand | 0AM53 | IAE 1R18214 | ||

| IAE 1R18498 Setting block | 0AM53 | IAE 1R18498 | ||

| IAE 1R18498 Setting block | 0AM53 | IAE 1R18498 | ||

| IAE 18914 Setting gage | 0AM53 | IAE 18914 | ||

| IAE 18913 Setting gage | 0AM53 | IAE 18913 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 |

Spares

NONESafety Requirements

NONEProcedure

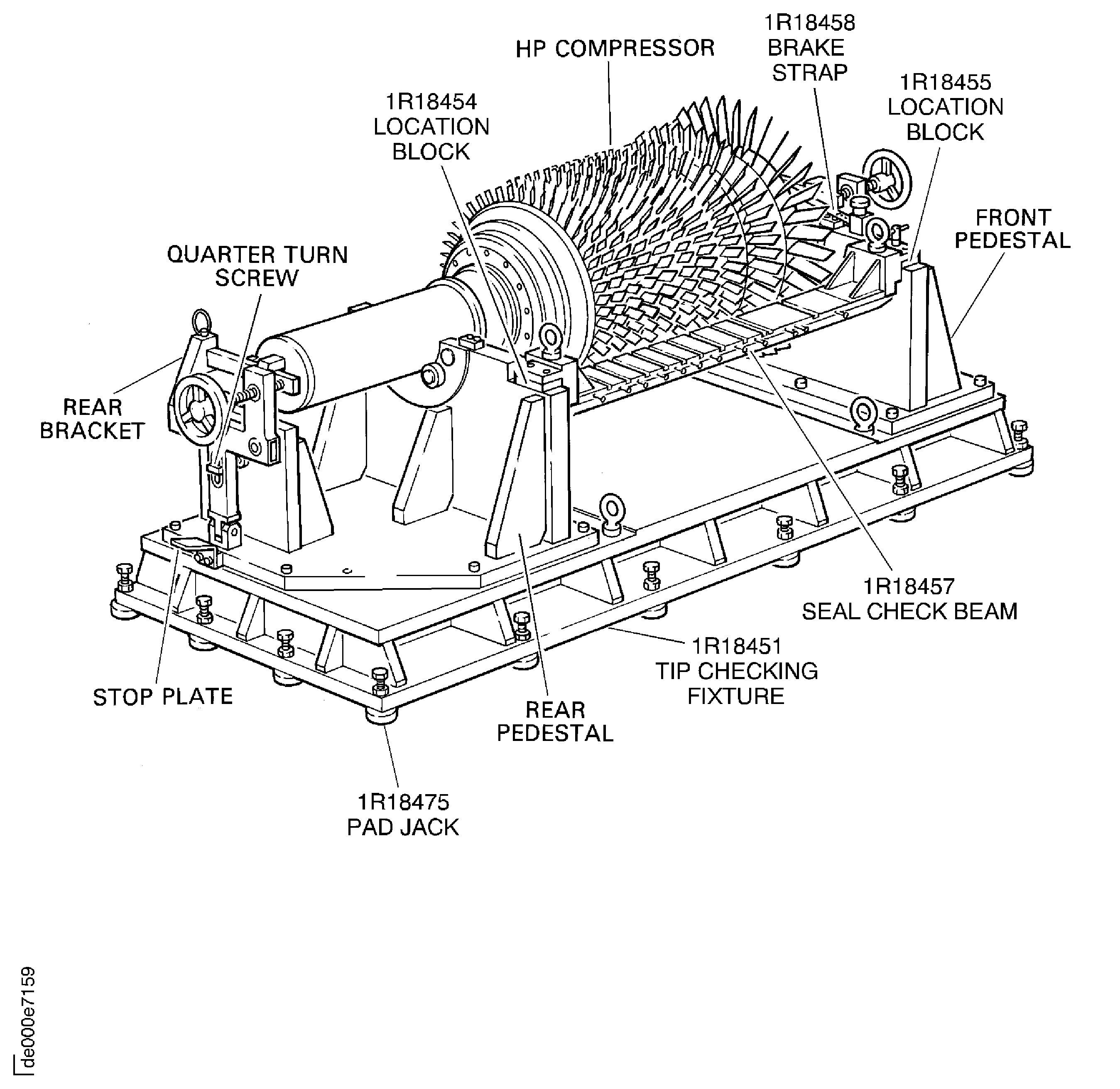

Install IAE 1R18454 Location block 2 off on to the rear pedestal of IAE 1R18451 Tip check fixture 1 off and safety.

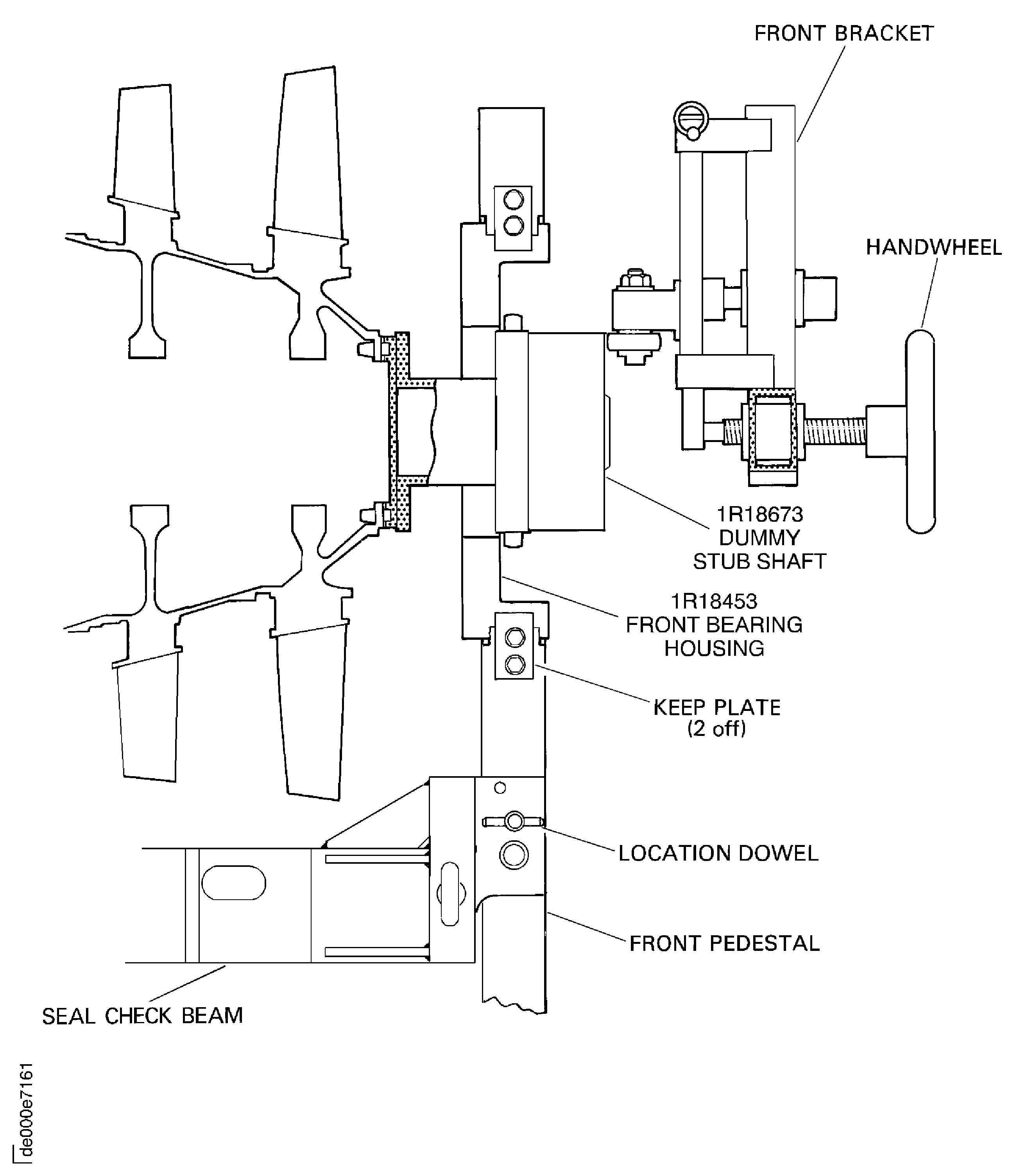

Install IAE 1R18455 Location block 2 off on to the front pedestal of the tip check fixture and safety.

Install the IAE 1R18453 Bearing housing (front) 1 off and safety with the two keep plates.

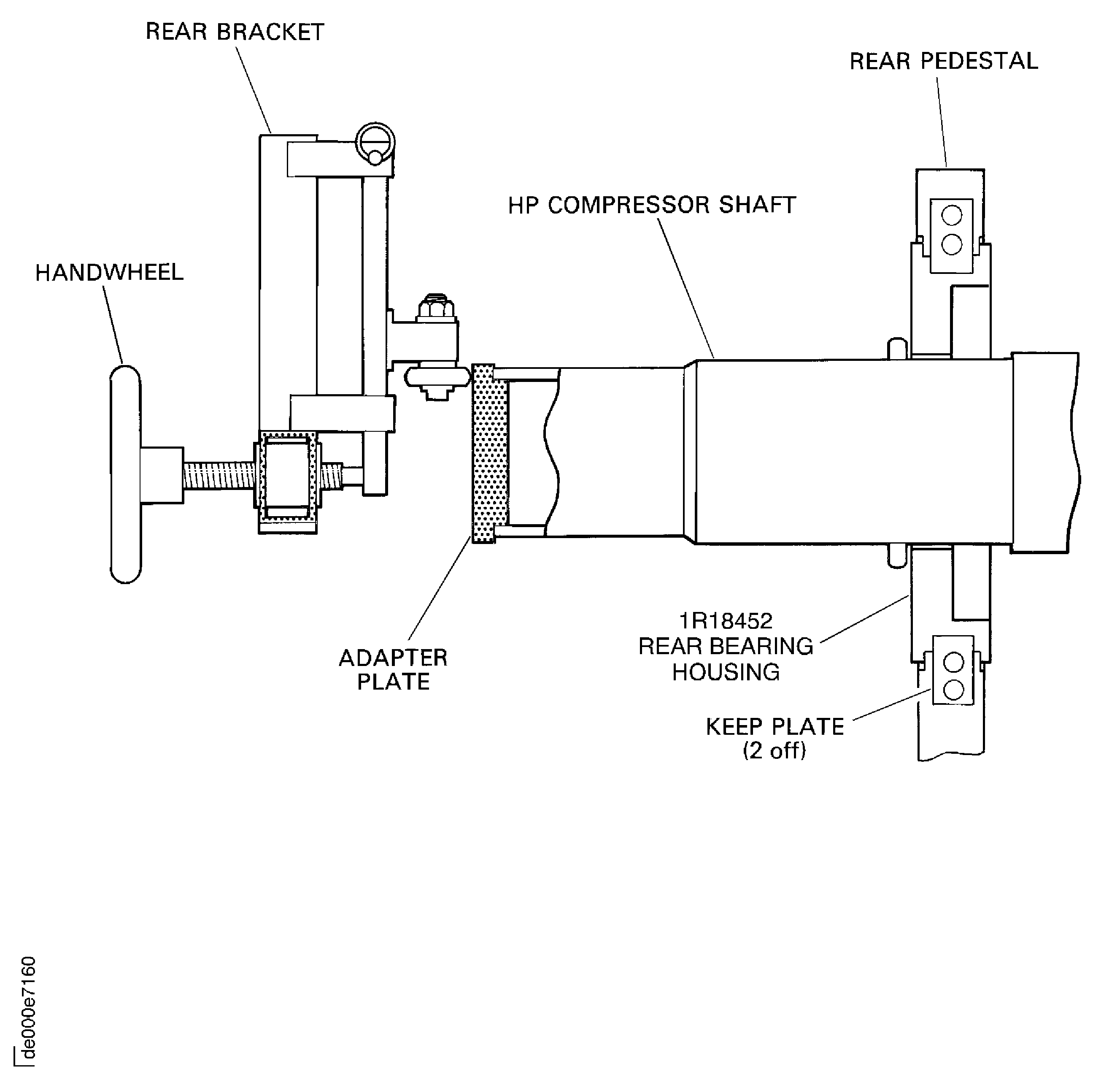

Install the IAE 1R18452 Bearing housing (rear) 1 off and safety with the two keep plates.

SUBTASK 72-41-10-040-051 Prepare the Tip Check Fixture for Installation of the HP Compressor Rotor Assembly

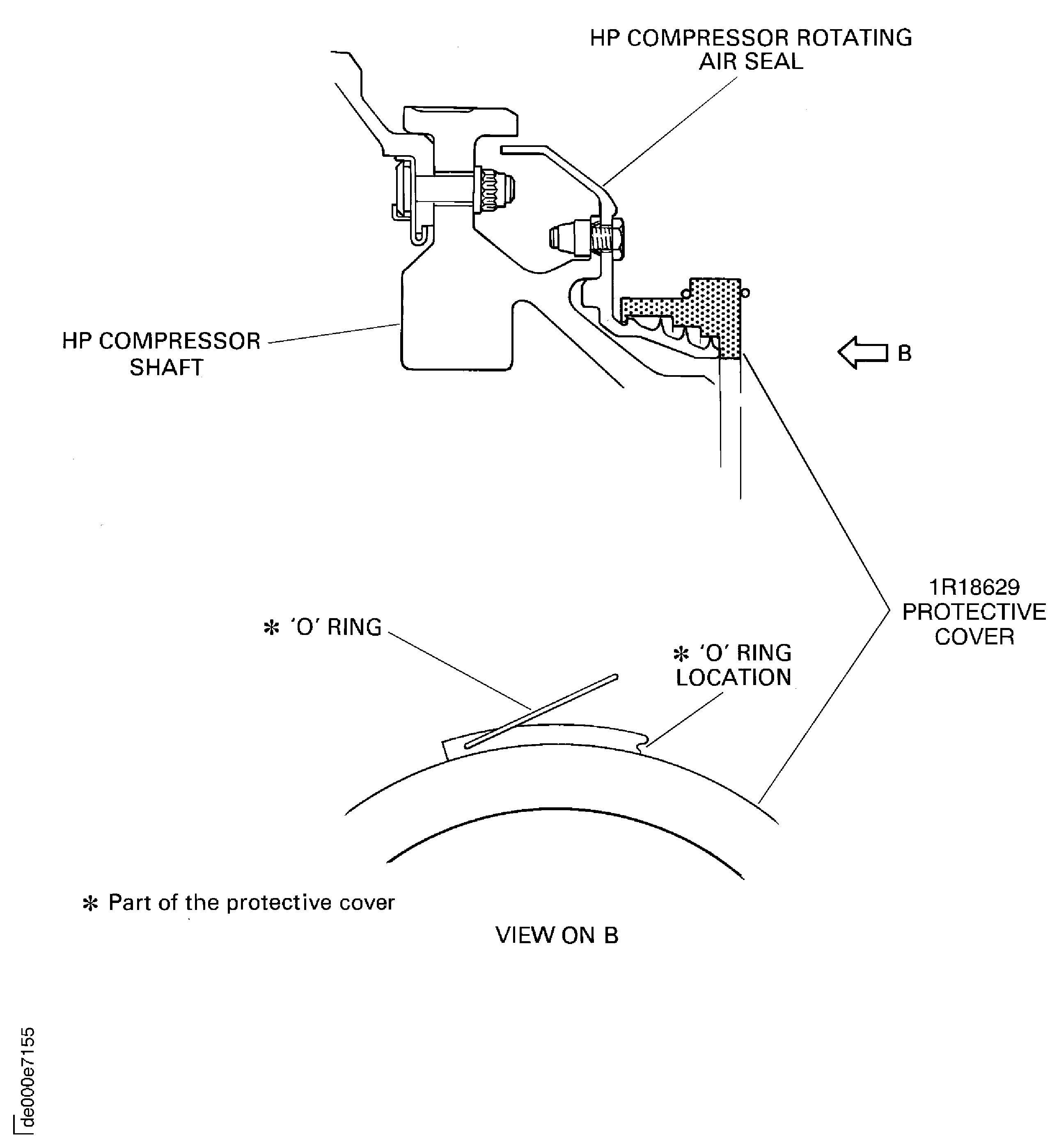

Install the IAE 1R18629 Protective cover 1 off on to the compressor rotating air seal. Refer to Figure.

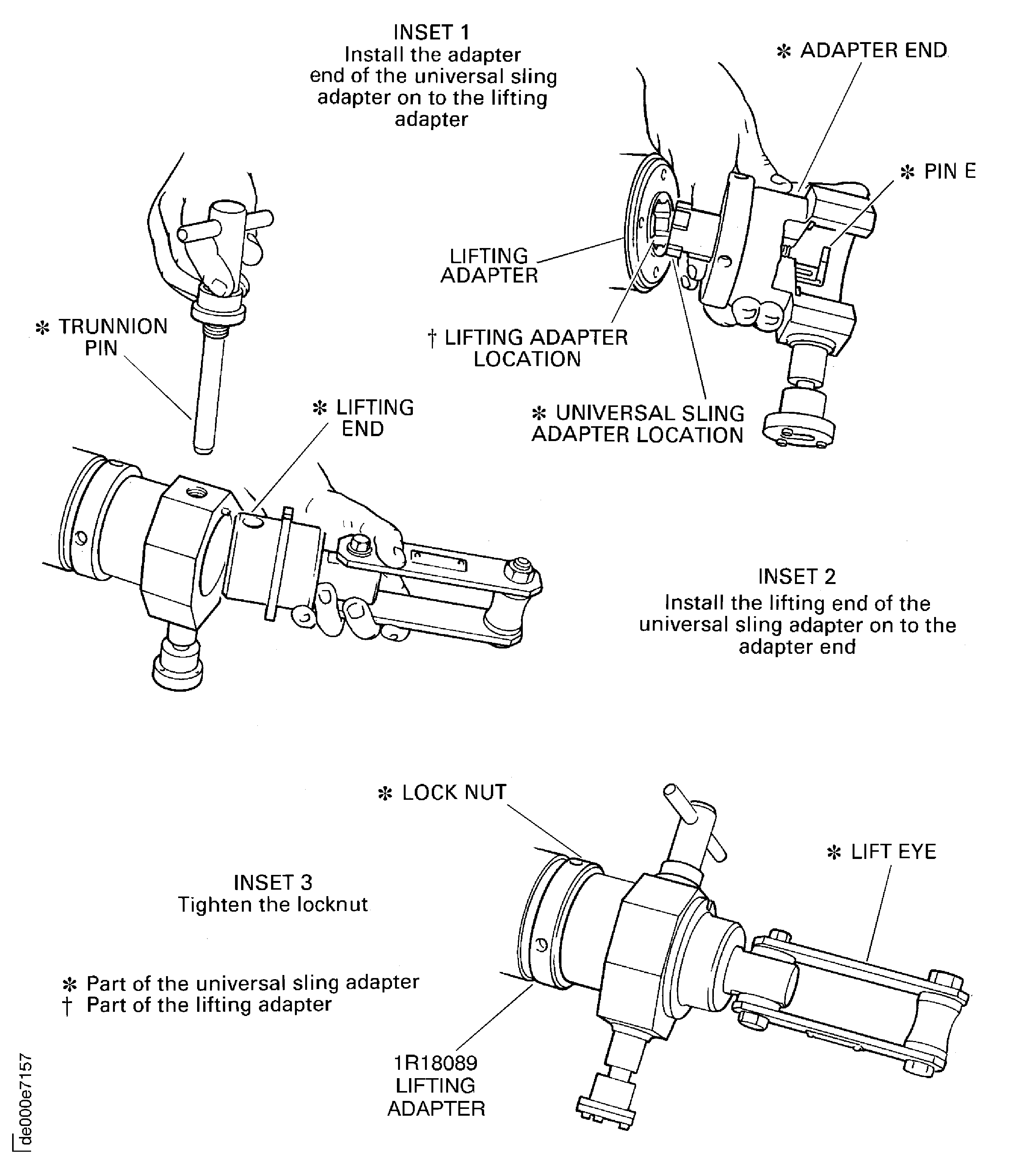

Install the IAE 1R18089 Lifting adapter 1 off on to the end of the compressor shaft and tighten.

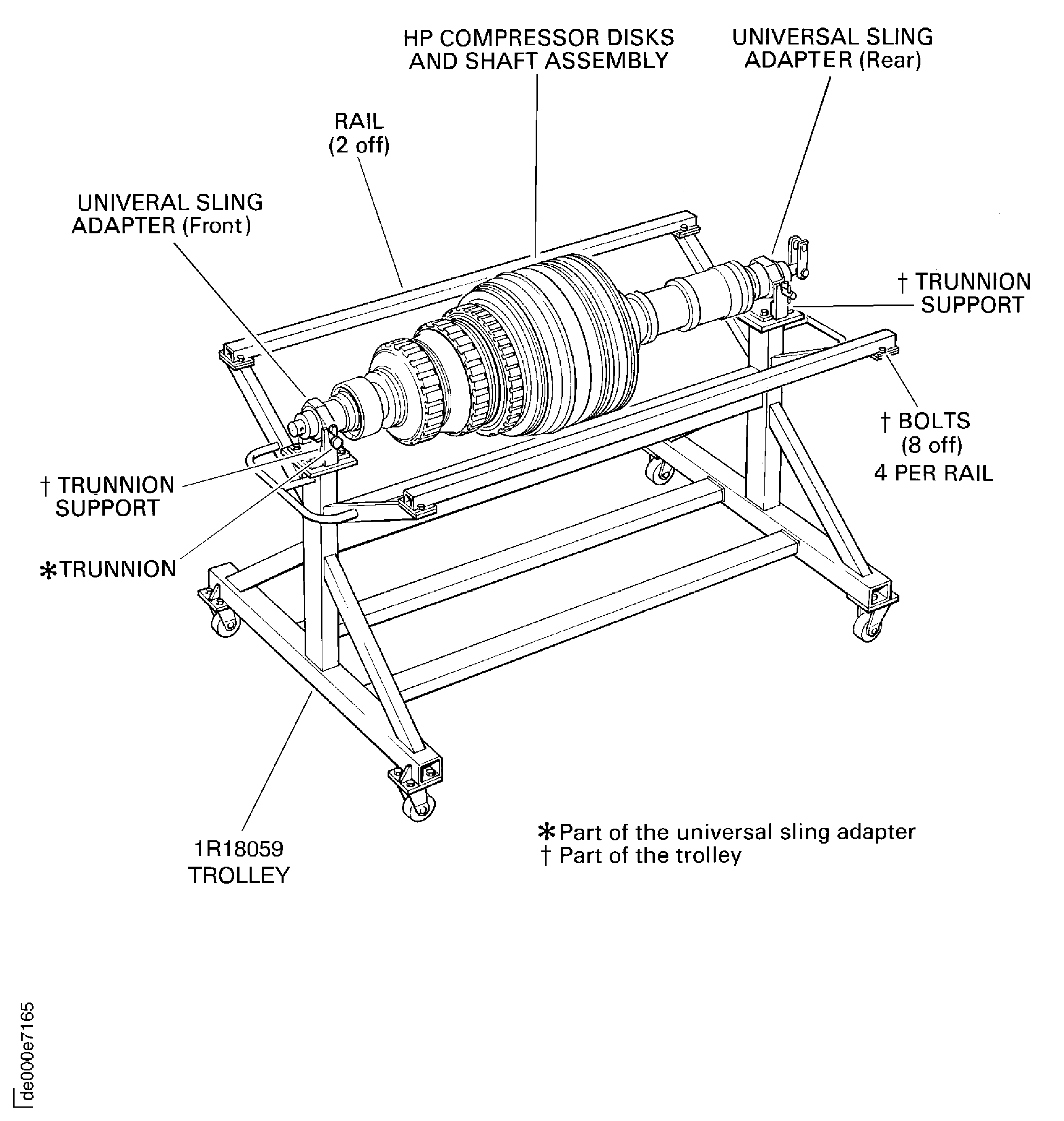

Attach IAE 1R18095 Universal slinging adapter 1 off on to the lifting adapter. Refer to Figure and Figure.

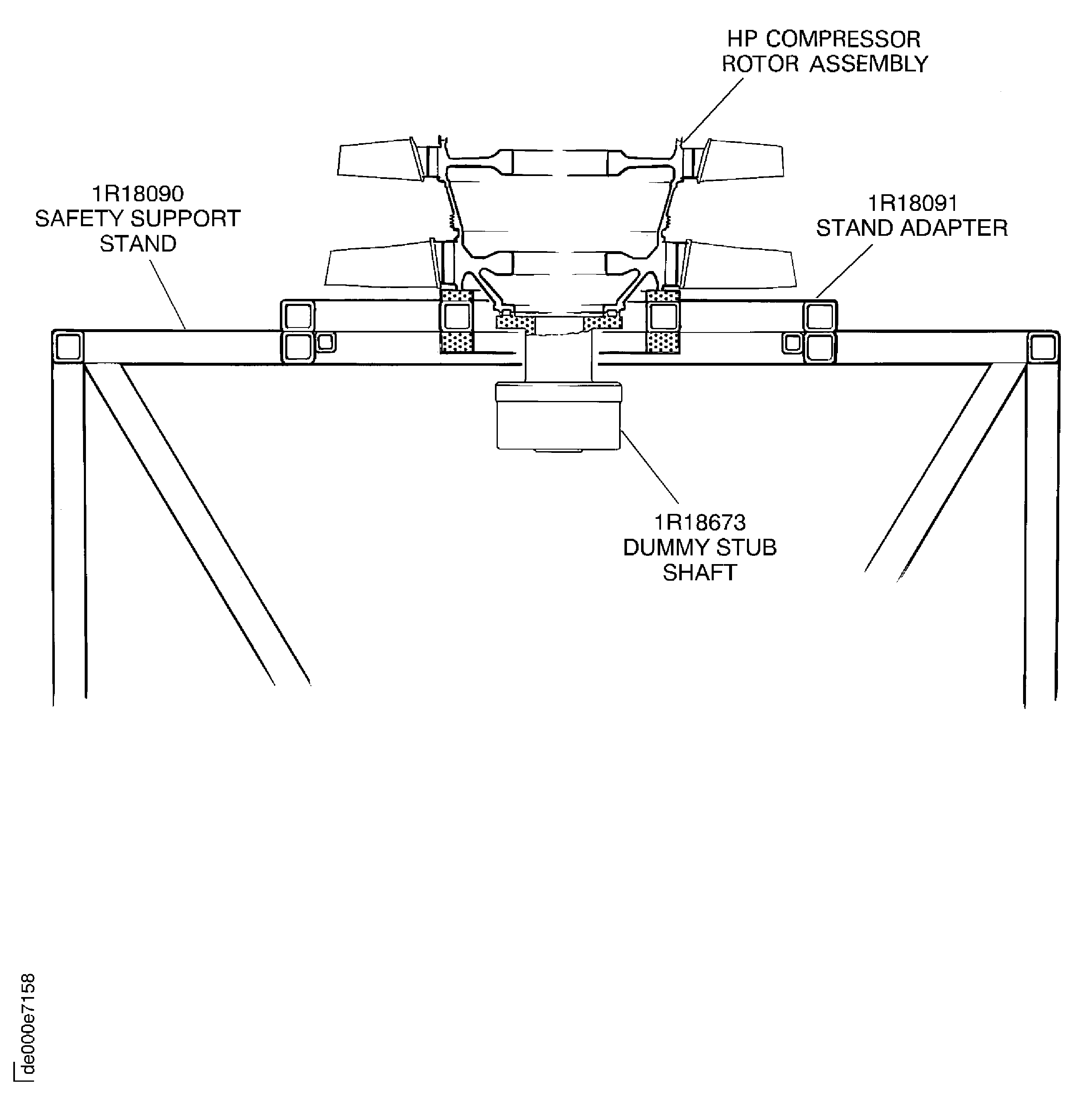

Install the IAE 1R18091 Support stand 1 off on to IAE 1R18090 Safety support stand 1 off.

Install IAE 1R18095 Universal slinging adapter 1 off on to the dummy stub shaft. Refer to Figure.

CAUTION

YOU MUST NOT LET THE COMPRESSOR ROTOR ASSEMBLY HIT THE TIP CHECK FIXTURE.Install the compressor rotor assembly in to the IAE 1R18451 Tip check fixture 1 off. Make sure the dummy stub shaft is correctly located in the front bearing housing.

Install the IAE 1R18466 Thruster plate 1 off in to the compressor shaft.

SUBTASK 72-41-10-040-052 Install the HP Compressor Rotor Assembly in to the Tip Check Fixture

NOTE

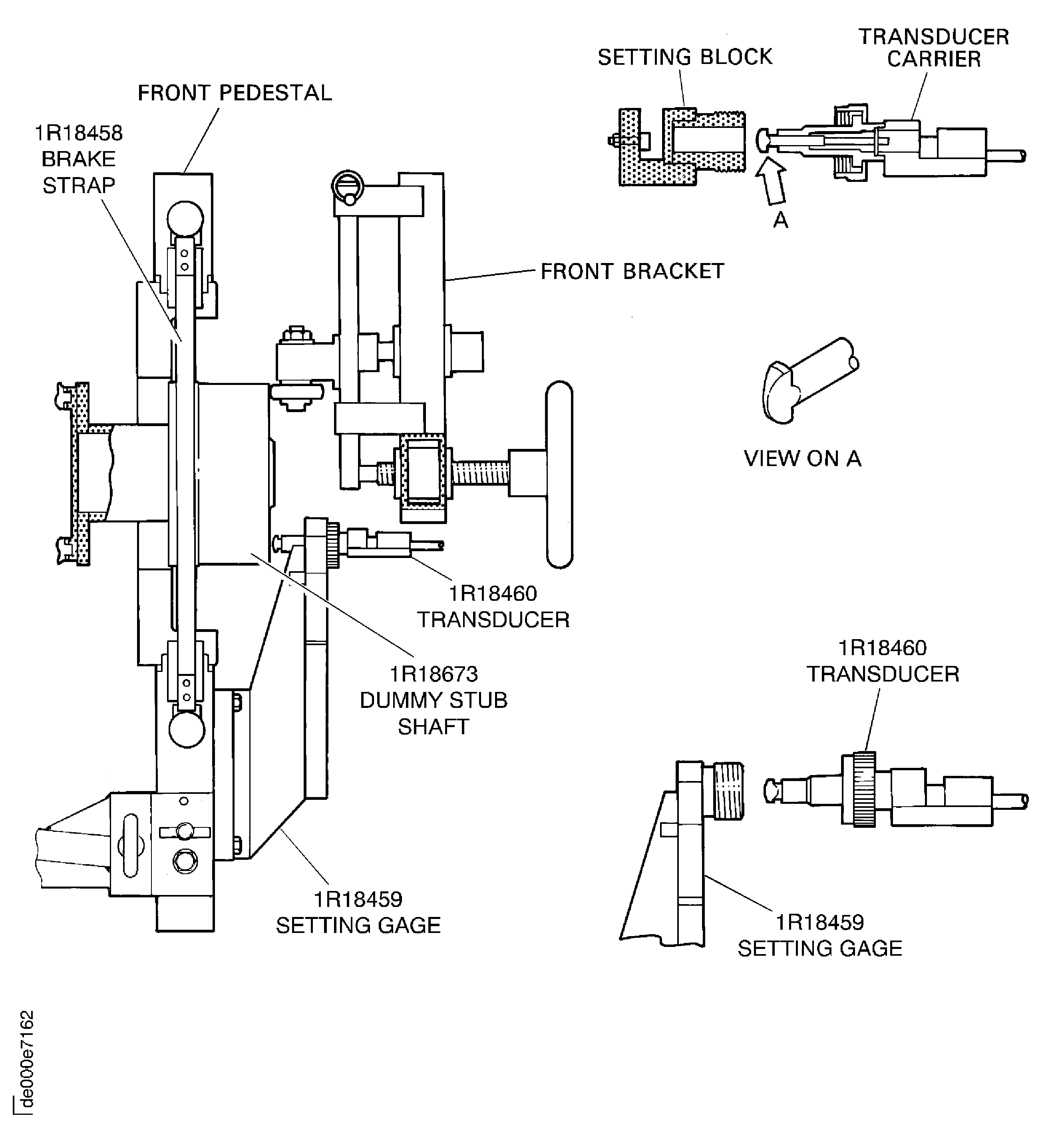

The HP compressor rotor assembly is on the build stand (IAE 1R18214 Build stand) with the dummy stub shaft installed.Install the IAE 1R18459 Axial setting gage 1 off on to the front pedestal.

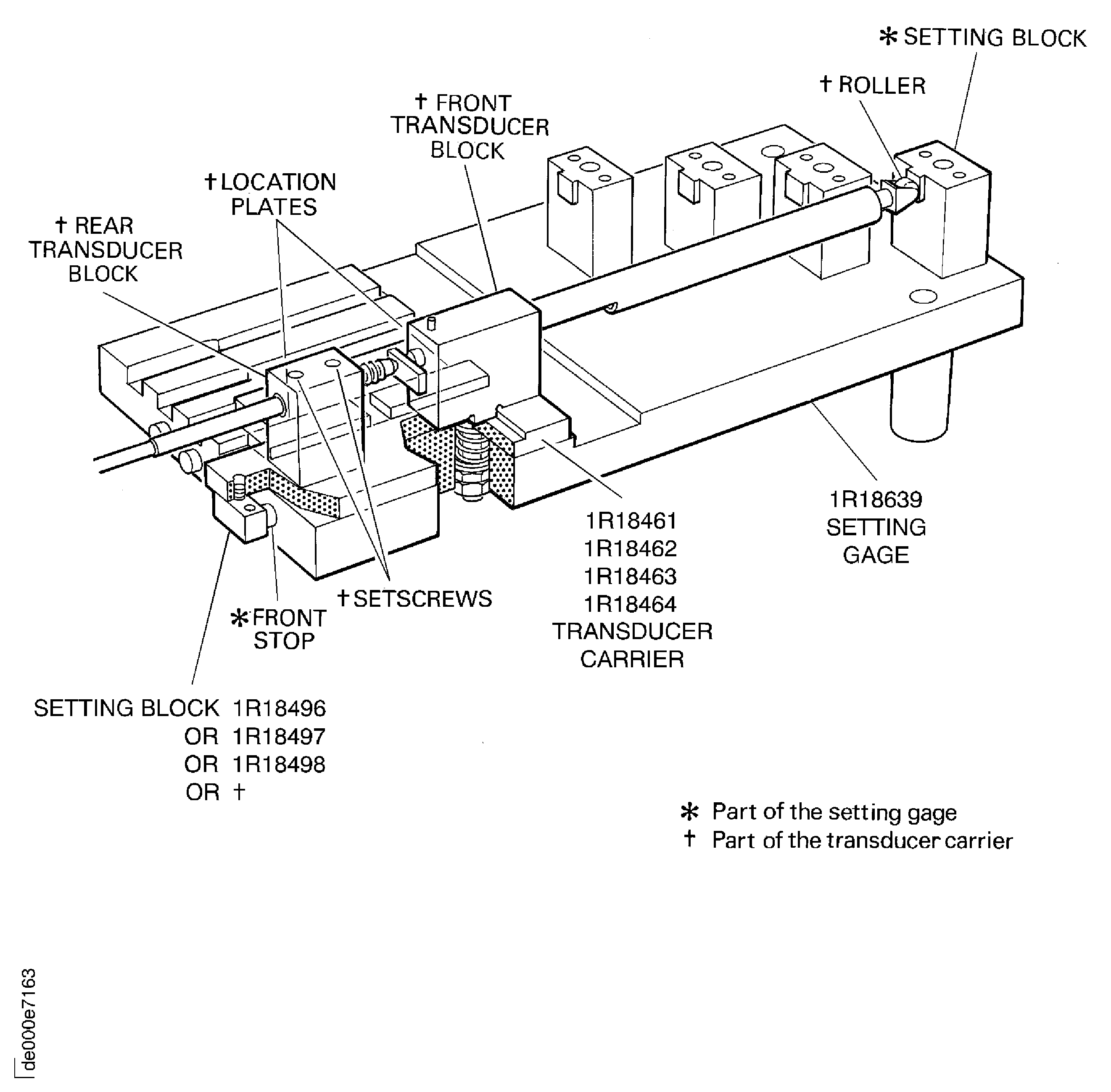

With IAE 1R18467 Setting block 1 off adjust the IAE 1R18460 Transducer carrier 1 off to the applicable zero setting on the digital read out equipment.

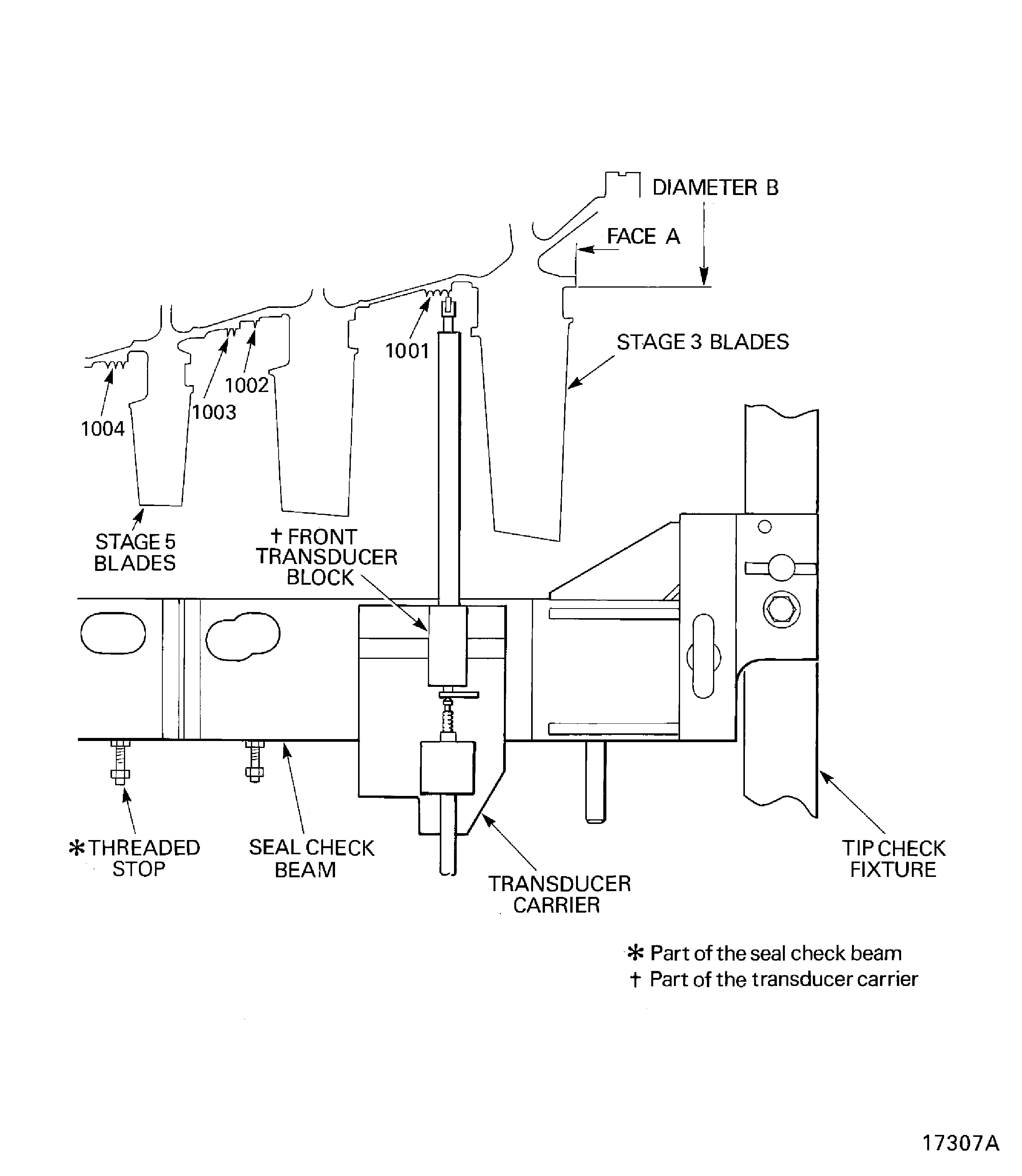

Install the IAE 1R18457 Seal check beam 1 off on the front and rear location blocks.

Install the IAE 1R18458 Brake strap 1 off on to the front pedestal and adjust.

SUBTASK 72-41-10-040-053 Set the Axial Position of the HP Compressor Rotor Assembly

Refer to: Figure

Install the IAE 1R18496 Setting block 1 off on to the carrier using a suitable bolt.

Make sure that the IAE 1R18496 Setting block touches the front stop on the setting gage.

Install the transducer carrier on to IAE 1R18639 Setting gage 1 off.

Set the zero position of the 3 to 4 seal land rear rotating seal transducer carrier. Use IAE 1R18463 Transducer carrier 1 off.

SUBTASK 72-41-10-040-079 Set the Transducer Carrier to the Zero Position

Do the procedure given in Step.

Set the zero position of the IAE 1R18463 Transducer carrier 1 off.

Move the transducer carrier in the location slot until the IAE 1R18496 Setting block 1 off touches the threaded stop on the seal check beam.

Install IAE 1R18463 Transducer carrier 1 off in the correct position on the IAE 1R18457 Seal check beam.

Measure the stage 3 to 4 seal fin diameters at location 1001.

Calculate the diameter of each of the four seal fins as follows:

Seal fin diameter = 2 (A+B)

where, A = Tool setting radius = 5.1181in. (130.00 mm)

B = Transducer reading

Example 1, where B = -0.046in.

Seal fin diameter = 2 (5.1181 + -0.046)

= 10.144in.

Example 2, where B = 0.046in.

Seal fin diameter = 2 (5.1181 + 0.046)

= 10.328in.

Write down the calculated minimum and maximum diameters for each of the four seal fins. This data is to be used in the INSPECTION/CHECK of the 3 to 8 compressor disks. Refer to TASK 72-41-11-200-000 (INSPECTION/CHECK-000).

Calculate the stage 3 to 4 seal fin diameters at location 1001.

SUBTASK 72-41-10-040-068 Measure and Calculate the Stage 3 to 4 Seal Fin Diameters at Location 1001

Refer to: Figure

Make sure that the setting block, part of the IAE 1R18462 Transducer carrier, touches the front stop on the setting gage.

Install the transducer carrier on to IAE 1R18639 Setting gage 1 off.

Set the zero position of the 4 to 5 seal transducer carrier. Use IAE 1R18462 Transducer carrier 1 off.

SUBTASK 72-41-10-040-080 Set the Transducer Carrier to the Zero Position

Do the procedure given in Step.

Set the zero position of IAE 1R18462 Transducer carrier 1 off.

Calculate the diameter of the seal fin as follows:

Seal fin diameter = 2 (A + B)

where, A Tool setting radius = 5.8858in. (149.5 mm)

B = Transducer reading

Refer to Step for calculation examples

Write down the calculated minimum and maximum diameter for the seal fin. This data is to be used in the INSPECTION/CHECK of the 3 to 8 compressor disks. Refer to TASK 72-41-11-200-000 (INSPECTION/CHECK-000).

Calculate the stage 4 to 5 seal fin diameter at location 1002.

Remove IAE 1R18462 Transducer carrier from the seal check beam.

Measure the stage 4 to 5 seal fin diameters at location 1003.

Calculate the diameter of each of the seal fins as follows:

Seal fin diameter = 2 (A + B)

where A, = Tool setting radius = 6.0827in. (154.5 mm)

B = Transducer reading

Refer to Step for calculation examples.

Write down the calculated minimum and maximum diameters for each of the two seal fins. This data is to be used in the INSPECTION/CHECK of the 3 to 8 compressor disks. Refer to TASK 72-41-11-200-000 (INSPECTION/CHECK-000).

Calculate the stage 4 to 5 seal fin diameters at location 1003.

SUBTASK 72-41-10-040-069 Measure and Calculate the Stage 4 to 5 Seal Fin Diameters at Locations 1002 and 1003

Refer to: Figure

Make sure that the setting block, part of IAE 1R18461 Transducer carrier, touches the front stop on the setting gage.

Install the transducer carrier on to IAE 1R18639 Setting gage Align the transducer with the correct setting block on the setting gage and at the same time locate the two location plates of the transducer carrier in to the location slot in the setting gage.

Set the zero position of the 3 to 4 seal transducer carrier. Use IAE 1R18461 Transducer carrier 1 off.

SUBTASK 72-41-10-040-081 Set the Transducer Carrier to the Zero Position

Do the procedure given in Step.

Set the zero position of IAE 1R18461 Transducer carrier 1 off.

Calculate the diameter of each of the seal fins as follows:

Seal fin diameter = 2 (A + B)

where A, = Tooling setting radius = 6.8898in. (175.00 mm)

B = Transducer reading

Refer to Step for calculation examples.

Write down the calculated minimum and maximum diameters for each of the four seal fins. This data is to be used in the INSPECTION/CHECK of the 3 to 8 compressor disks. Refer to TASK 72-41-11-200-000 (INSPECTION/CHECK-000).

Calculate the stage 5 to 6 seal fin diameters at location 1004.

SUBTASK 72-41-10-040-070 Measure and Calculate the Stage 5 to 6 Seal Fin Diameters at Location 1004

Refer to: Figure

Make sure that the setting block, part of IAE 1R18464 Transducer carrier, touches the front stop on the setting gage.

Install the transducer carrier on to IAE 1R18639 Setting gage 1 off.

Set the zero position of the stator vane path transducer carrier. Use IAE 1R18464 Transducer carrier 1 off.

SUBTASK 72-41-10-040-082 Set the Transducer Carrier to the Zero Position

Do the procedure given in Step.

Set the zero position of IAE 1R18464 Transducer carrier 1 off.

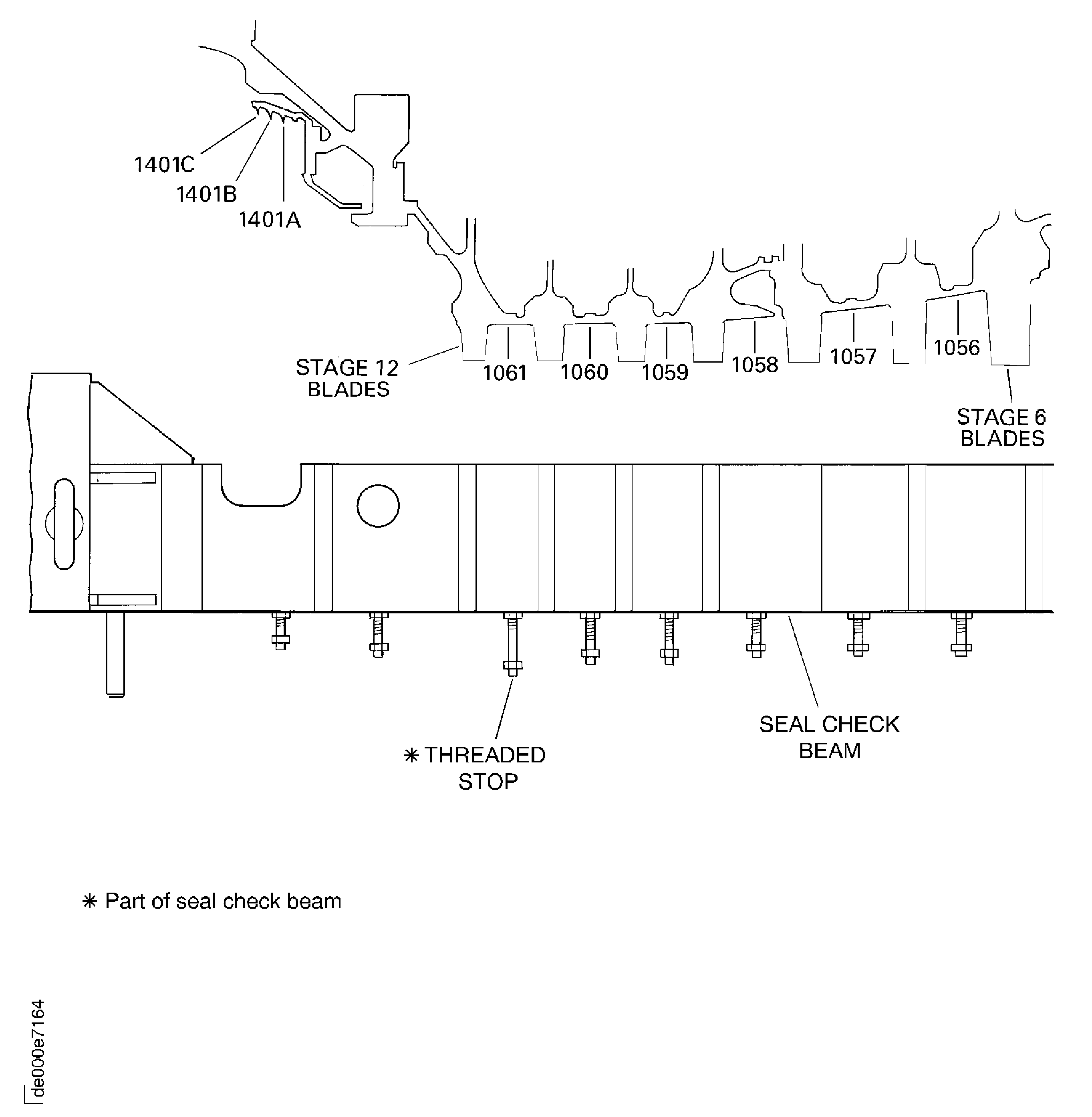

The tool setting radius values (A) used in the calculations for the different stator vane path diameters are as follows:

A = 8.5630in. (217.50 mm) for the stage 6 to 7 vane path (location 1056).

A = 8.8976in. (226.00 mm) for the stage 7 to 8 vane path (location 1057).

A = 9.1142in. (231.50 mm) for the stage 8 to 9 vane path (location 1058).

A = 9.2520in. (235.00 mm) for the stage 9 to 10 vane path (location 1059).

A = 9.2716in. (235.50 mm) for the stage 10 to 11 vane path (location 1060).

A = 9.2716in. (235.50 mm) for the stage 11 to 12 vane path (location 1061).

Refer to Step for calculation examples.

Calculate the diameter of each of the stator vane paths as follows:

Stator vane path diameter = 2 (A + B)

where, A = Tool setting radius

B = Transducer setting

Write down the calculated minimum and maximum diameters for each of the stator vane paths. The 6 to 7 and 7 to 8 stator vane path diameters are to be used in the INSPECTION/CHECK of the 3 to 8 compressor disk; refer to TASK 72-41-11-200-000 (INSPECTION/CHECK-000). The 8 to 9, 9 to 10, 10 to 11 and 11 to 12 stator vane path diameters are to be used in the INSPECTION/CHECK of the 9 to 12 compressor disk assembly; refer to TASK 72-41-12-200-000 (INSPECTION/CHECK-000).

Calculate the stator vane path diameters.

SUBTASK 72-41-10-040-071 Measure and Calculate the Stator Vane Path Diameters

Refer to: Figure

IAE 1R18496 Setting block 1 off for the rear fin diameter.

IAE 1R18497 Setting block 1 off for the middle fin diameter.

IAE 1R18498 Setting block 1 off for the front fin diameter.

Install the necessary setting block on to the transducer carrier using a suitable bolt.

Make sure that the setting block IAE 1R18496 Setting block, IAE 1R18497 Setting block or IAE 1R18498 Setting block touches the front stop on the setting gage.

Install the transducer carrier on to IAE 1R18639 Setting gage 1 off.

Set the zero position of the 3 to 4 seal and rear rotating seal transducer carrier. Use IAE 1R18463 Transducer carrier 1 off.

SUBTASK 72-41-10-040-083 Set the Transducer Carrier to the Zero Position

Do the procedure given in Step using IAE 1R18498 Setting block 1 off.

Set the zero position of IAE 1R18463 Transducer carrier 1 off.

Do the procedure given in SUBTASK 72-41-10-090-083 using IAE 1R18497 Setting block 1 off.

Set the zero position of IAE 1R18463 Transducer carrier.

Do the procedure given in SUBTASK 72-41-10-090-083 using IAE 1R18496 Setting block 1 off.

Set the zero position of IAE 1R18463 Transducer carrier.

Calculate the diameter of each of the seal fins as follows:

Seal fin diameter = 2 (A + B)

where A = Tool setting radius = 4.5669in. (116.00 mm)

B = Transducer reading

Refer to TASK 72-41-10-040-001-B00, SUBTASK 72-41-10-040-086 for calculation examples

Write down the calculated minimum and maximum diameters for each of the seal fins. This data is to be used in the INSPECTION/CHECK of the rear rotating air seal. Refer to TASK 72-41-14-200-000.

Calculate the rear rotating seal fin diameters at locations 1401A, 1401B and 1401C.

SUBTASK 72-41-10-040-072 Measure and Calculate the HP Compressor Rear Rotating Seal Fin Diameters

Install the IAE 1R18089 Lifting adapter 1 off and the IAE 1R18095 Universal slinging adapter 2 off. Refer to Step, Figure and Figure.

SUBTASK 72-41-10-040-056 Remove the HP Compressor Rotor Assembly from the Tip Check Fixture

Refer to: Figure

CAUTION

DO NOT LET THE COMPRESSOR ROTOR ASSEMBLY HIT THE TROLLEY.Install the compressor rotor assembly in to the IAE 1R18059 Trolley 1 off.

Install the IAE 1R18061 Rail 2 off on to the trolley.

SUBTASK 72-41-10-040-057 Install the HP Compressor Rotor Assembly in to the Trolley

Install IAE 1R18081 Beam sling 1 off to the HP compressor rotor assembly.

Remove the necessary tools from the HP compressor rotor assembly to permit the grinding machine adapters to be installed. Refer to Figure.

SUBTASK 72-41-10-040-074 Remove the HP Compressor Rotor Assembly from the Trolley and Install it in to the Grinding Machine

SBE 72-0370: HP compressor blades - introduction of increased stage 4 rotor blade tip clearance

NOTE

The grinding machine must use a laser to measure the blade lengths.Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to identify the blades that are too short.

SUBTASK 72-41-10-040-073 Measure the Length of the HP Compressor Blades (SBE 72-0370)

Put IAE 1R18629 Protective cover 1 off on to the end of the HP compressor shaft.

Install IAE 1R18089 Lifting adapter 1 off to the end of the HP compressor shaft. Tighten the lifting adapter.

Attach one of IAE 1R18095 Universal slinging adapter 1 off on to the lifting adapter. Refer to Figure and Figure.

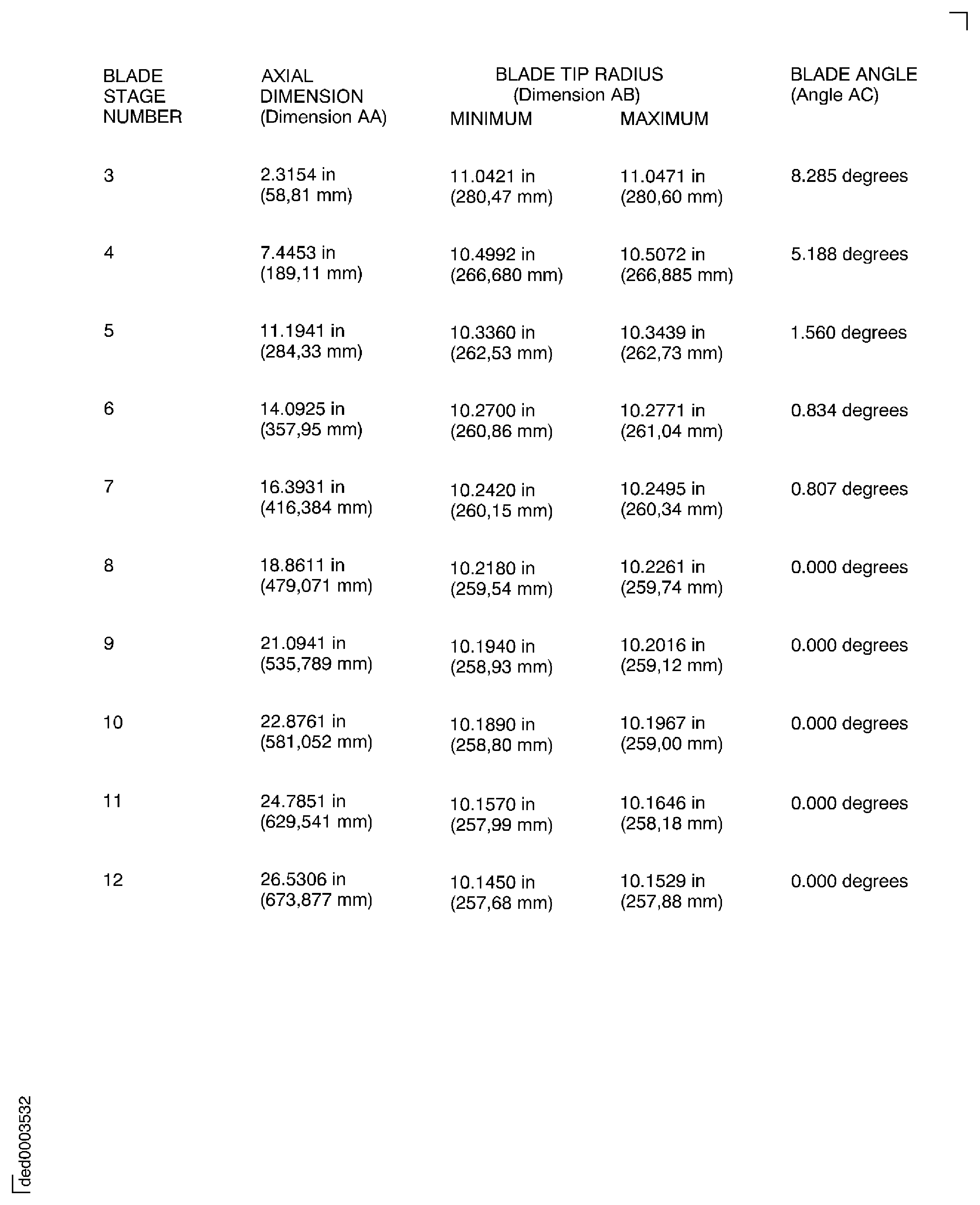

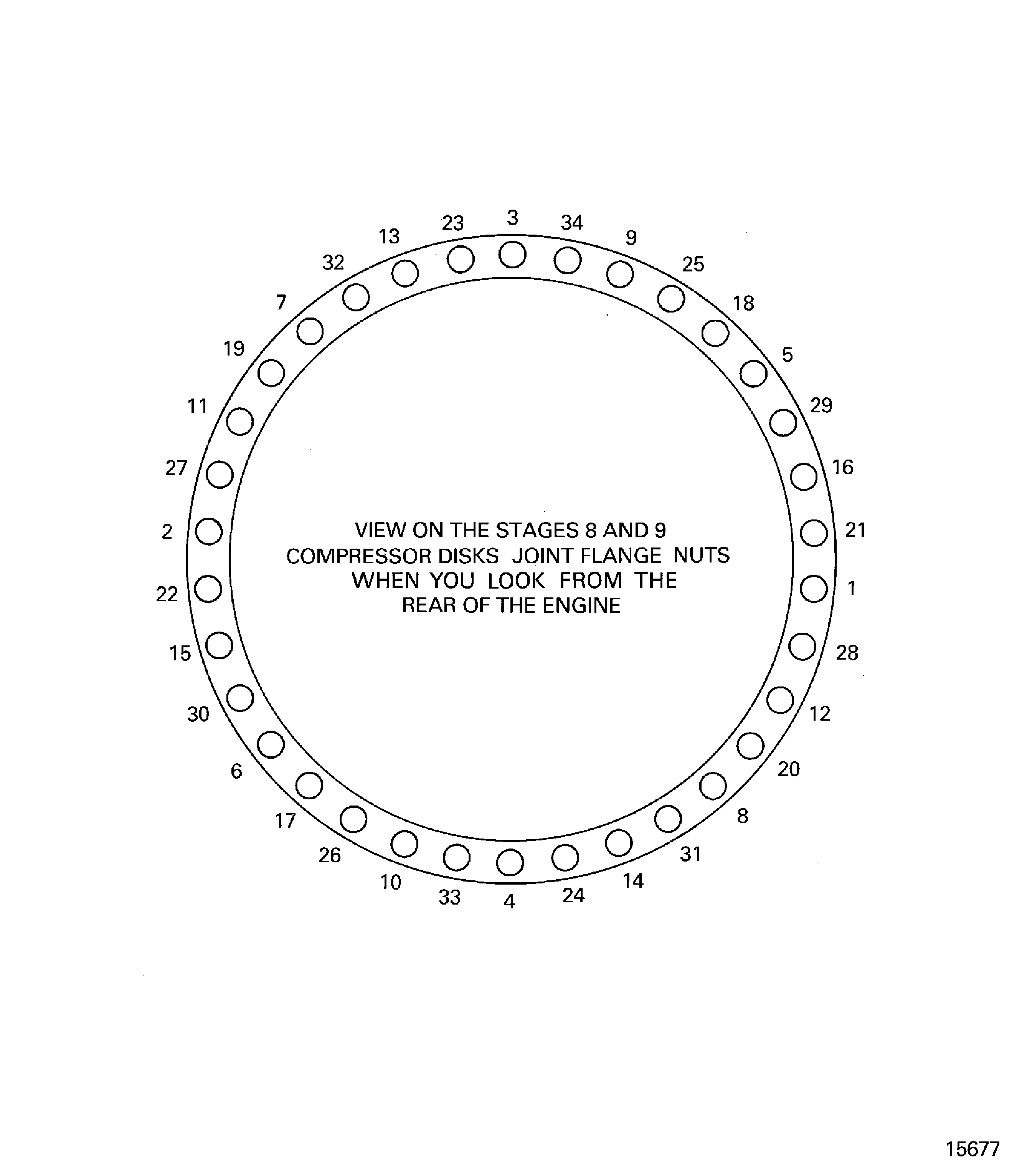

Torque all of the bolts. Do these three steps in the sequence shown. Refer to Figure.

Make sure the IAE 1R18673 Dummy stub shaft 1 off is installed to the HP compressor rotor assembly. Do the steps which follow if the dummy stub shaft was removed for the installation of the grinding machine tools.

Install IAE 1R18081 Beam sling 1 off to the HP compressor rotor assembly. Refer to Step.

Install the HP compressor rotor assembly in to IAE 1R18059 Trolley 1 off. Refer to Figure and Figure.

Make sure IAE 1R18629 Protective cover is installed on to the compressor rotating air seals. Refer to Figure.

Remove the beam sling from the compressor rotor assembly. Refer to Step.

Install IAE 1R18061 Rail 2 off on to the trolley.

SUBTASK 72-41-10-040-076 Remove the HP Compressor Rotor Assembly from the Grinding Machine and Install it in to the Trolley

With IAE 1R18590 Socket end 1 off release the two jacking screws and locknuts.

With IAE 1R18097 Drift 1 off move the blades around the disk until a blade can be removed through the loading slot.

Remove the stage 12 blades.

With IAE 1R18079 Drift 1 off move the retaining plates around the disk to close up the spaces between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 3 disk.

With IAE 1R18080 Drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-520) from all the stage 4 blades.

Remove the blades from the stage 4 disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-820) from all the stage 5 blades.

Remove the blades from the stage 5 disk.

SUBTASK 72-41-10-040-058-A00 Remove the Blades from the HP Compressor Rotor Assembly (Pre SBE 70-0064, Pre SBE 72-0161, Pre SBE 72-0300 and Pre SBE 72-0304)

NOTE

Keep the blades that were identified with a mark (in SUBTASK 72-41-10-040-073-B00) apart from the other blades during removal.Keep the blades that were identified with a mark (in SUBTASK 72-41-10-073-B00) apart from the other blades during removal.

Each nut and screw lock assembly must be kept as a set.

SBE 70-0064: Provide matched pairs of compressor blade locking bolts and jackscrews

SBE 72-0161: HP disks and blades - Stages 7 and 8 rotor blades with damping wires and stages 6, 7 and 8 blades with anti-fret coating

With IAE 1R18590 Socket end 1 off release the two nut and screw lock assemblies.

With IAE 1R18097 Drift 1 off move the blades around the disk until a blade can be removed through the loading slot.

Remove the stage 12 blades.

Do steps A.(1) thru A.(3) for each stage of blades.

NOTE

To drill out seized blade locknuts use the following tools: IAE 1R18911 Drill 1 off, IAE 18914 Setting gage 1 off (stage 6), IAE 18913 Setting gage 1 off (stage 7) and IAE 1R18912 Setting gage 1 off (stage 8).

Remove the blades from the stages 11, 10 and 9 disks.

With IAE 1R18079 Drift 1 off move the retaining plates around the disk to close up the spaces between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 3 disk.

With IAE 1R18080 Drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-520) from all the stage 4 blades.

Remove the blades from the stage 4 disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-820) from all the stage 5 blades.

Remove the blades from the stage 5 disk.

SUBTASK 72-41-10-040-058-B00 Remove the Blades from the HP Compressor Rotor Assembly (SBE 70-0064, SBE 72-0161, Pre SBE 72-0300 and Pre SBE 72-0304)

NOTE

Keep the blades that were identified with a mark (in SUBTASK 72-41-10-040-073-B00) apart from the other blades during removal.

Each nut and screw lock assembly must be kept as a set.

SBE 72-0300: HP disks and blades - Introduction of revised stage 3 to 8 disk and revised stage 7 and 8 sealing wires

With IAE 1R18590 Socket end 1 off release the two nut and screw lock assemblies.

With IAE 1R18097 Drift 1 off move the blades around the disk until a blade can be removed through the loading slot.

Remove the stage 12 blades.

Do steps A.(1) thru A.(3) for each stage of blades.

NOTE

To drill out seized blade locknuts use the following tools: IAE 1R18911 Drill 1 off, IAE 18914 Setting gage 1 off (stage 6), IAE 18913 Setting gage 1 off (stage 7) and IAE 1R18912 Setting gage 1 off (stage 8).

Remove the blades from the stages 11, 10 and 9 disks.

With IAE 1R18079 Drift 1 off move the retaining plates around the disk to close up the spaces between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 3 disk.

With IAE 1R18080 Drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-520) from all the stage 4 blades.

Remove the blades from the stage 4 disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-820) from all the stage 5 blades.

Remove the blades from the stage 5 disk.

SUBTASK 72-41-10-040-058-C00 Remove the Blades from the HP Compressor Rotor Assembly (SBE 72-0300)

CAUTION

SBE72-0300 STAGE 3-8 DISKS AND SEALING WIRES HPC Stage 3 - 8 Drum Disk And Wire Seals (72-41-11, 01-390 , HPC Stage 3 - 8 Drum Disk And Wire Seals 01-392, HPC Stage 3 - 8 Drum Disk And Wire Seals 01-394 AND HPC Stage 3 - 8 Drum Disk And Wire Seals 01-396) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.NOTE

Keep the blades that were identified with a mark (in SUBTASK 72-41-10-040-073-B00) apart from the other blades during removal.

Each nut and screw lock assembly must be kept as a set.

SBE 72-0304: HP disks and blades - Introduction of a reworked stage 3 to 8 disk with revised L shaped sealing wires

With IAE 1R18590 Socket end 1 off release the two nut and screw lock assemblies.

With IAE 1R18097 Drift 1 off move the blades around the disk until a blade can be removed through the loading slot.

Remove the stage 12 blades.

CAUTION

DO NOT REMOVE STAGE 7 AND 8 SEALING WIRES BEFORE REMOVAL OF STAGE 7 AND 8 BLADES.NOTE

To drill out seized blade locknuts use the following tools: IAE 1R18911 Drill 1 off, IAE 18914 Setting gage 1 off (stage 6), IAE 18913 Setting gage 1 off (stage 7) and IAE 1R18912 Setting gage 1 off (stage 8).Remove the blades from the stage 6, 7 and 8 disks.

With IAE 1R18079 Drift 1 off move the retaining plates around the disk to close up the spaces between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove the blades from the stage 3 disk.

With IAE 1R18080 Drift 1 off move the retaining plates around the disk to close up the space between them. This will give sufficient space to remove one blade, forwards, from the disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-520) from all the stage 4 blades.

Remove the blades from the stage 4 disk.

Remove and discard the sealing strips HPC Rotor Blades (72-41-15, 01-820) from all the stage 5 blades.

Remove the blades from the stage 5 disk.

SUBTASK 72-41-10-040-058-D00 Remove the Blades from the HP Compressor Rotor Assembly (SBE 72-0304)

CAUTION

SBE72-0304 STAGE 3-8 DISKS AND SEALING WIRES HPC Stage 3 - 8 Drum Disk And Wire Seals (72-41-11, 01-392 AND HPC Stage 3 - 8 Drum Disk And Wire Seals01-394) ARE NOT INTERCHANGEABLE WITH OTHER SERVICE BULLETIN STANDARDS.NOTE

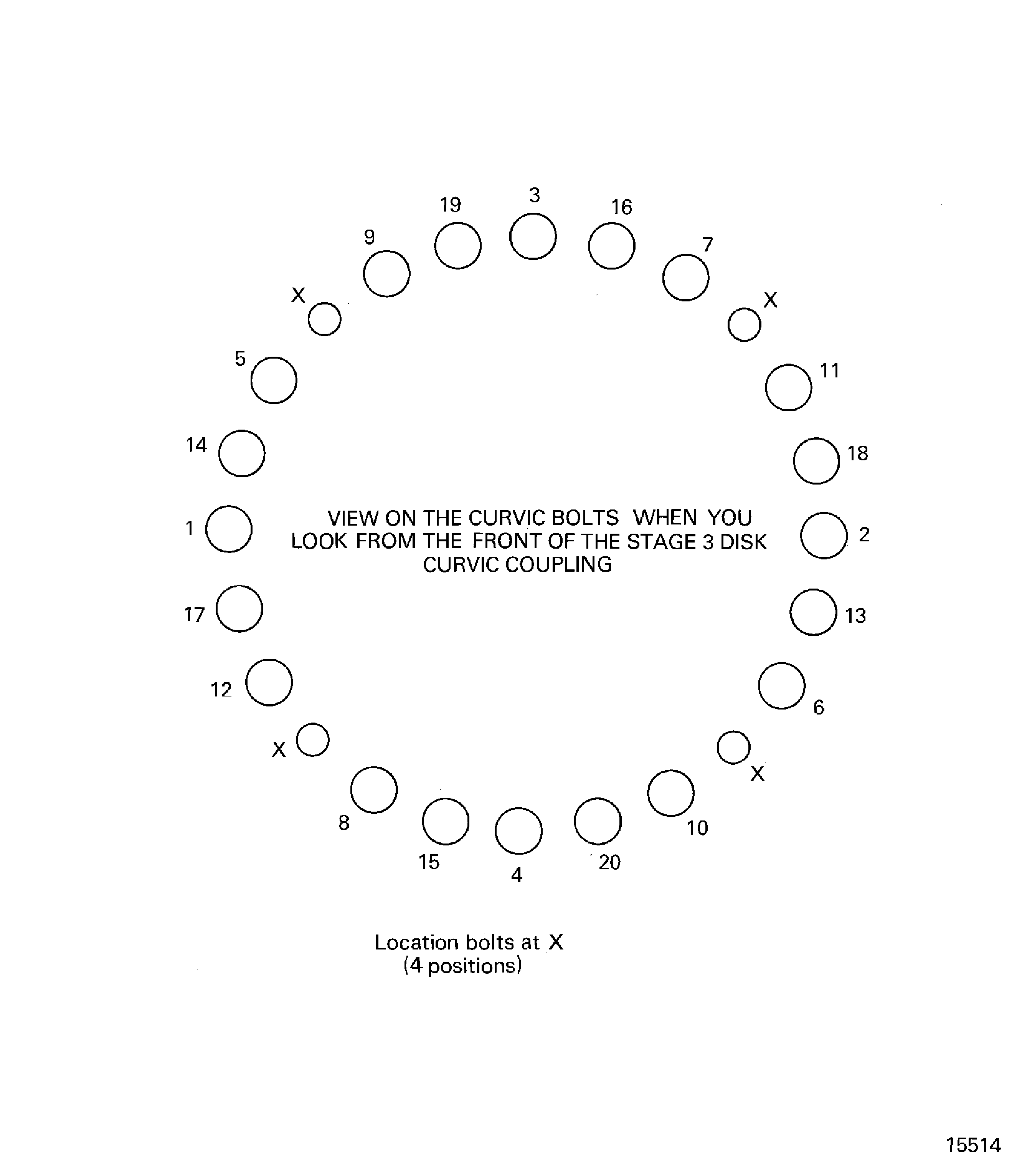

Install the IAE 1R18091 Support stand 1 off on to the IAE 1R18090 Safety support stand 1 off. Refer to Figure.

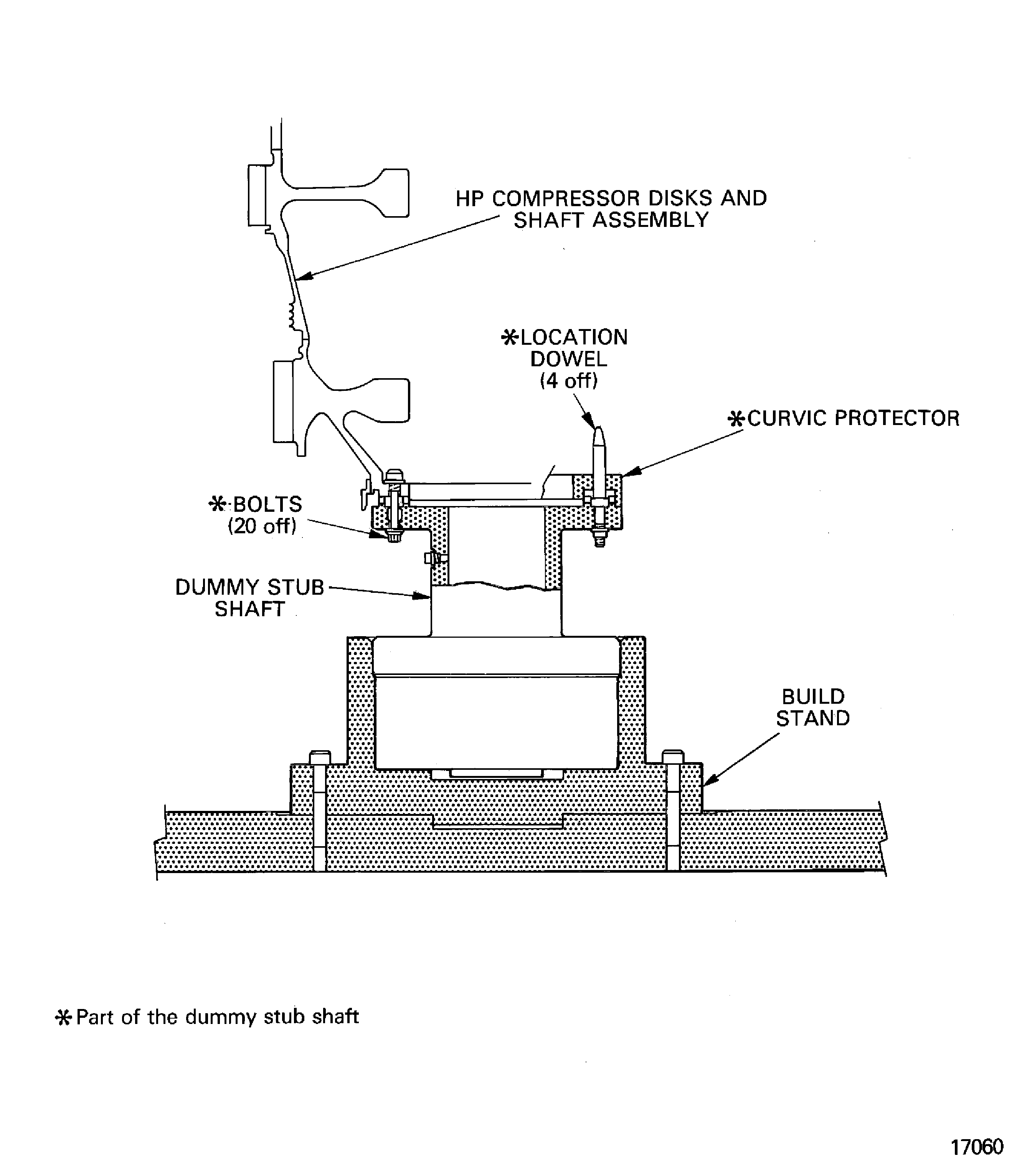

Lift the compressor disks and shaft assembly off the safety support stand and put it above the IAE 1R18020 Build stand 1 off. Refer to Figure.

Put one half of IAE 1R18021 Support ring 1 off on to the top of the build stand; align the four holes in the support ring with the four holes in the build stand. Install four of the screws through the support ring in to the build stand. Tighten the screws.

SUBTASK 72-41-10-040-059 Install the HP Compressor Disks and Shaft Assembly in to the Build Stand

Refer to: Figure

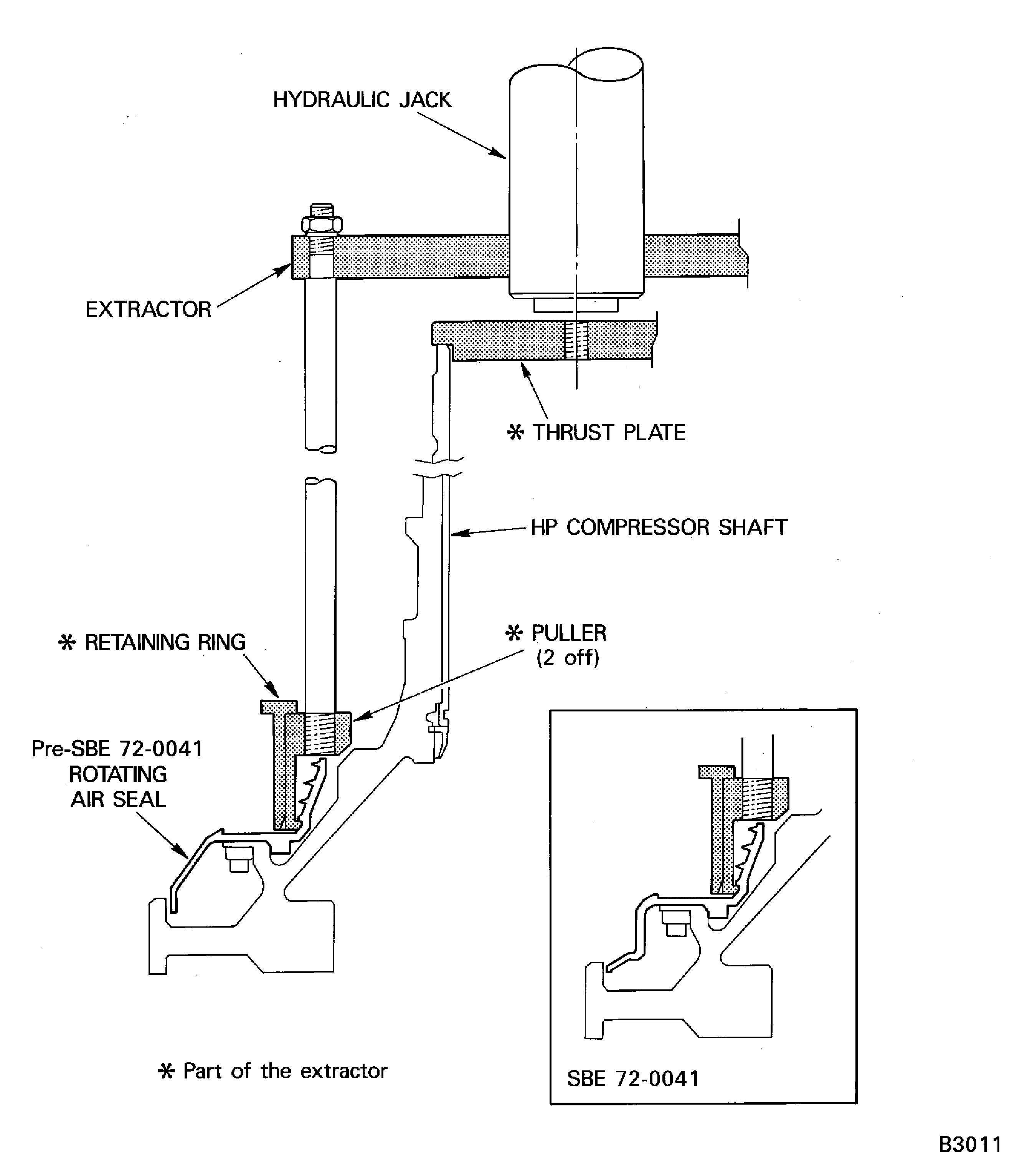

Install the Hydraulic jack 1 off in to the extractor and with IAE 1F10026 Hydraulic hand pump 1 off slowly remove the rotating air seal. Put the rotating air seal on to an applicable surface.

Install the IAE 1R18628 Extractor 1 off.

SUBTASK 72-41-10-040-060 Remove the Rotating Air Seal

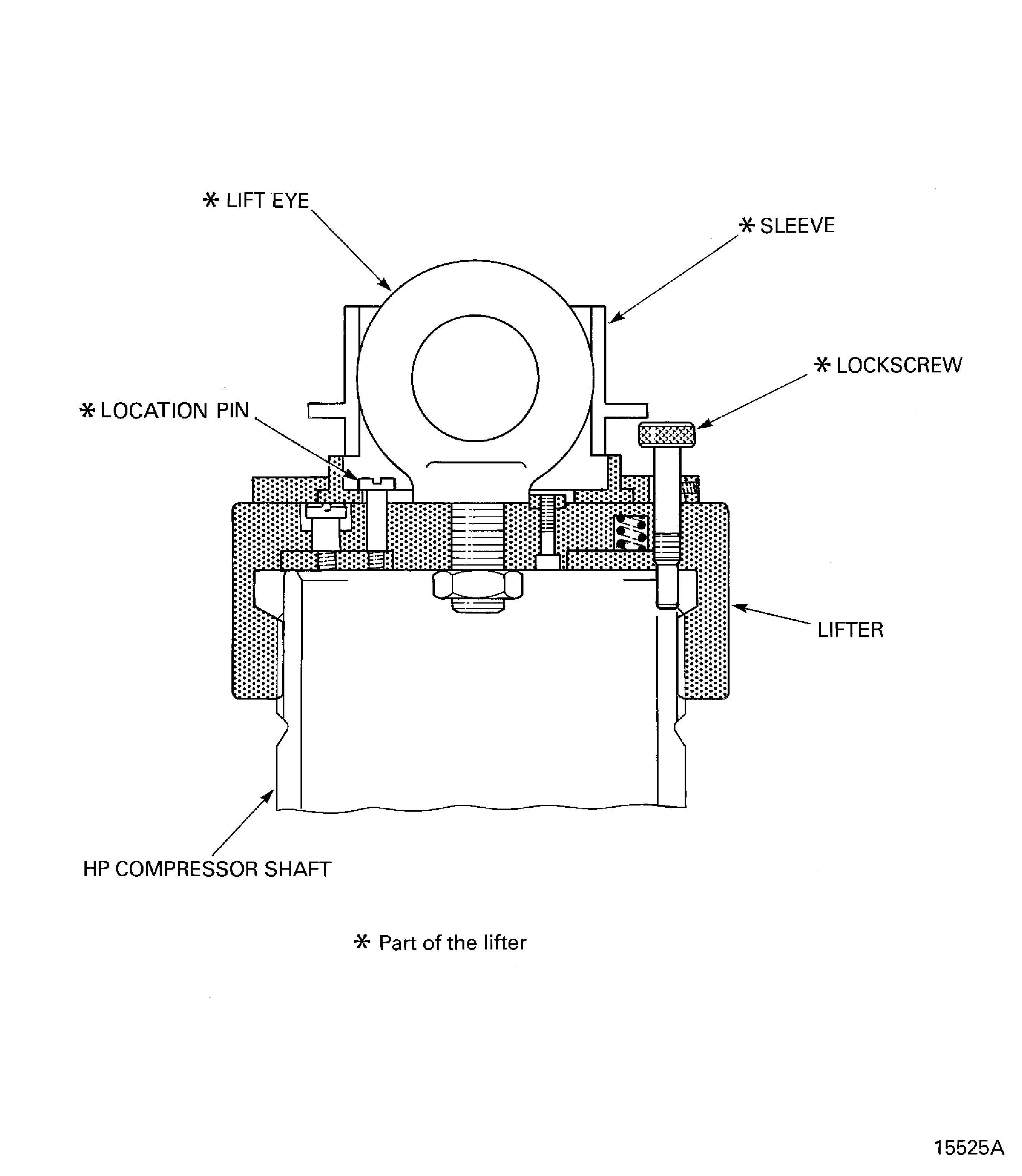

Install the IAE 1R18441 Lifting adapter 1 off on to the end of the compressor shaft. Refer to Figure.

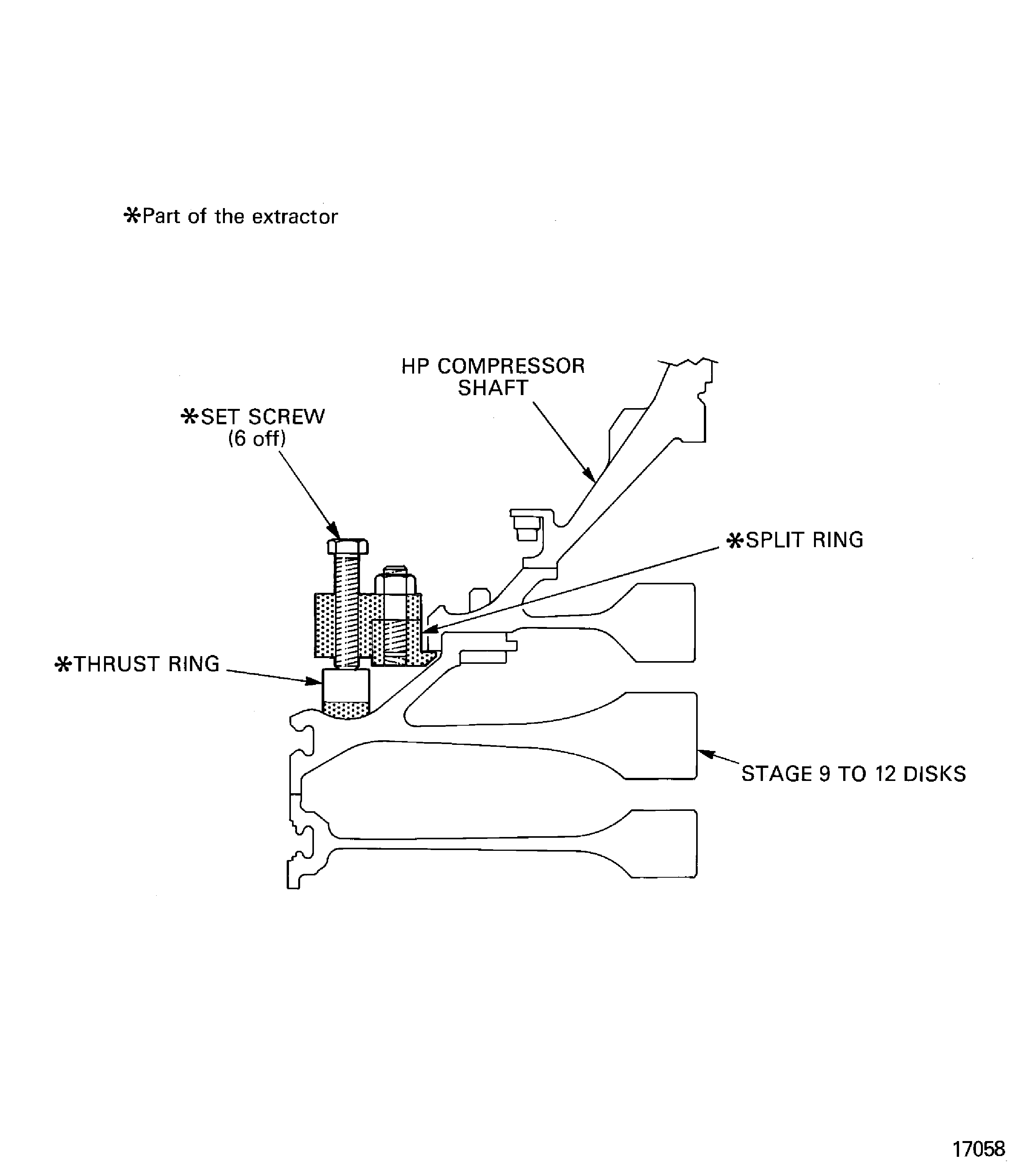

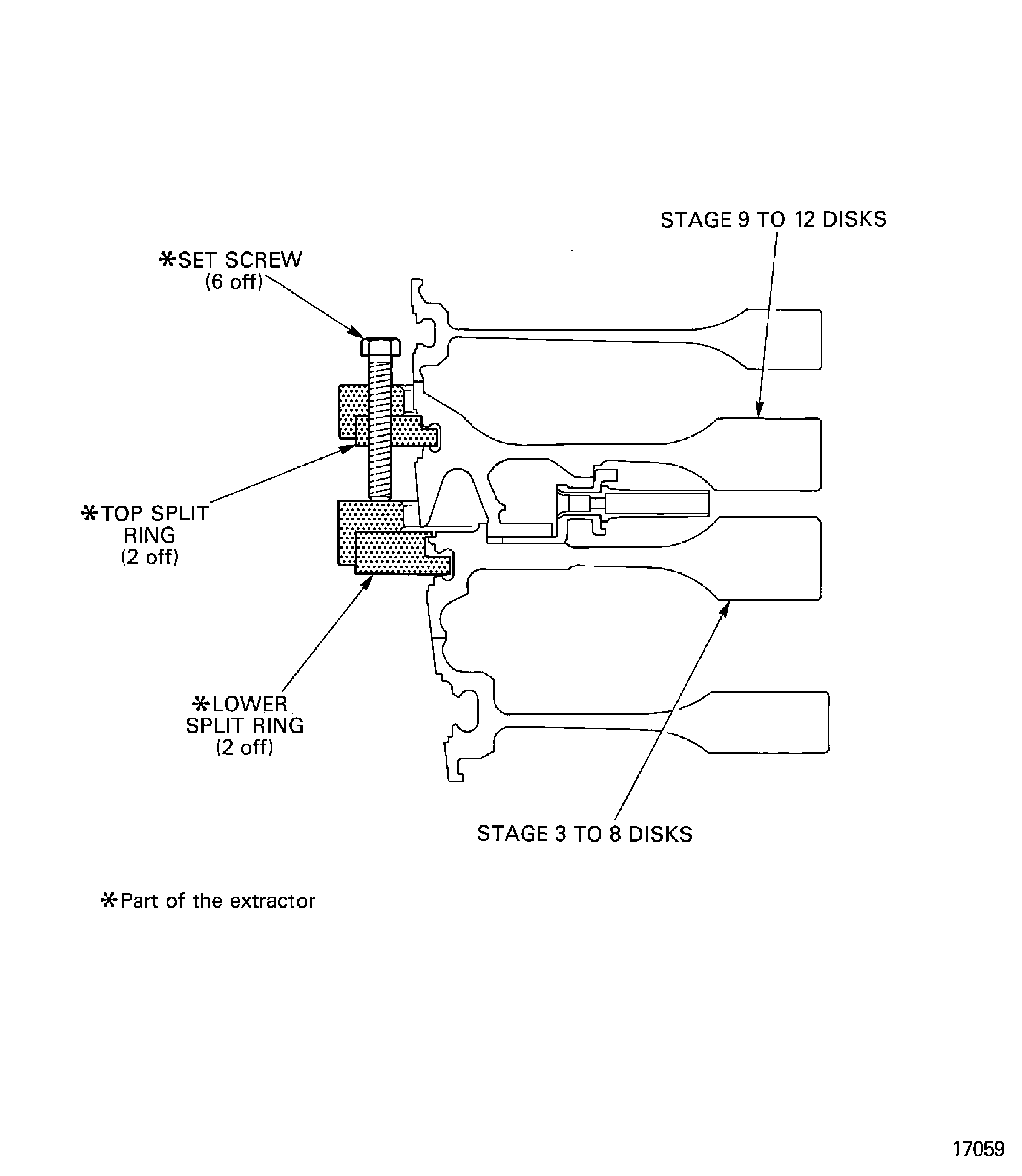

Assemble the IAE 1R18093 Extractor 1 off with the two split rings located on the front face of the shaft forward flange. Make sure the tufnol pads are correctly located on the rear face of the stage 12 disk. Refer to Figure.

SUBTASK 72-41-10-040-061 Remove the HP Compressor Shaft

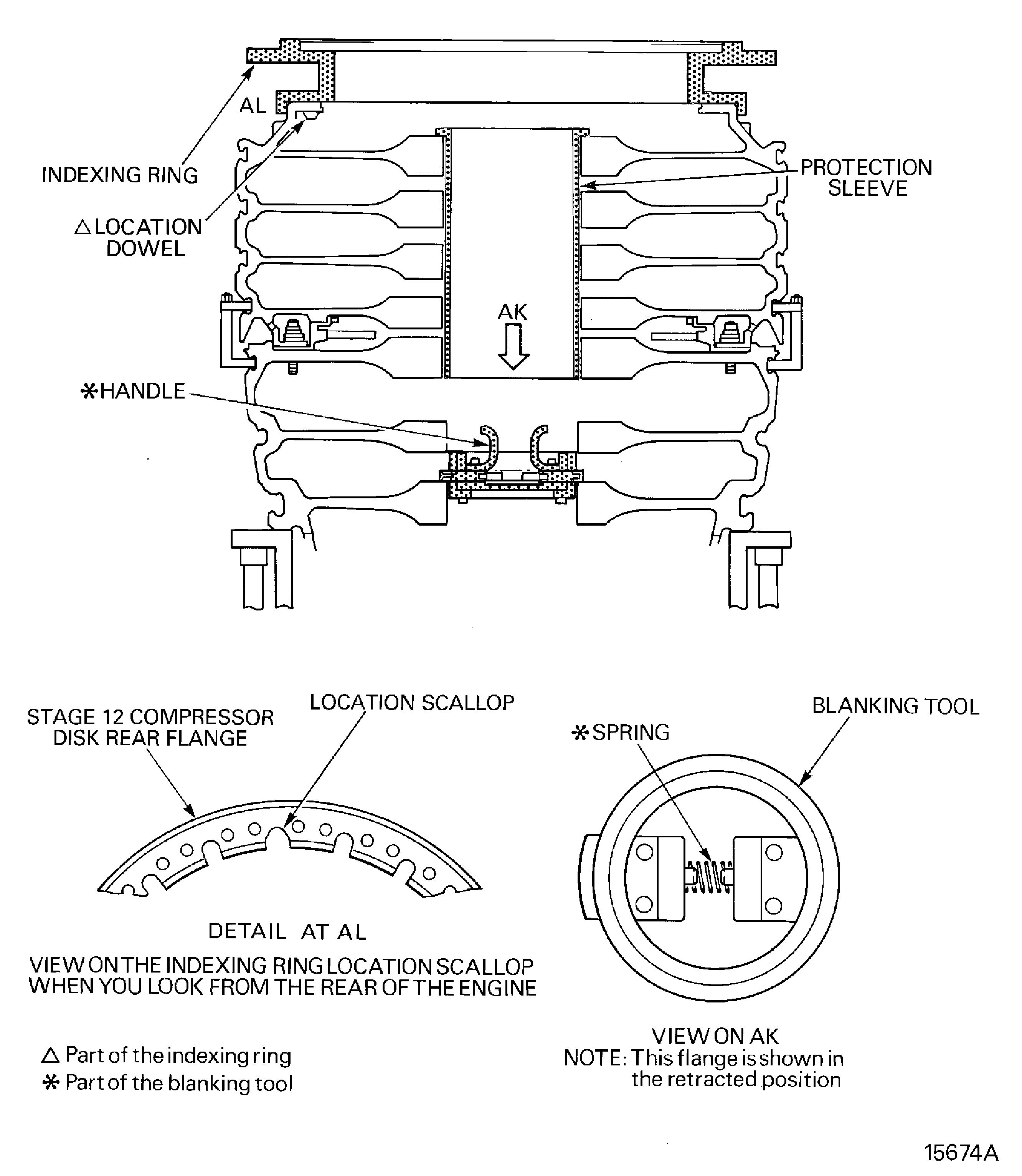

Install IAE 1R18029 Blanking tool 1 off in to the bore of the stages 3 to 12 compressor disks assembly.

Install IAE 1R18400 Protection sleeve 1 off in to the bore of the stages 3 to 12 compressor disks assembly.

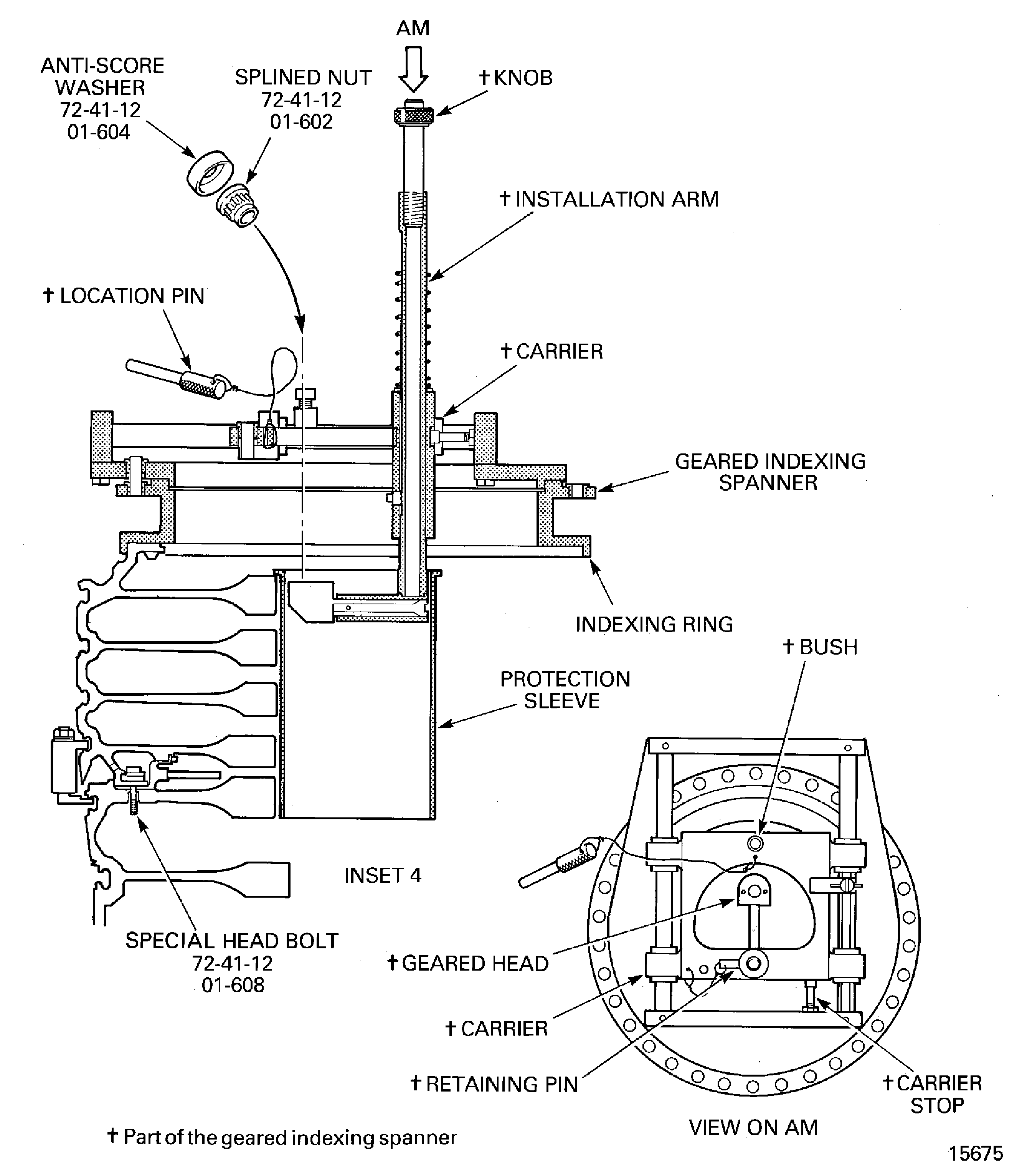

Install the IAE 1R18027 Indexing ring 1 off on to the stage 12 compressor disk rear flange.

Prepare the IAE 1R18024 Geared indexing spanner 1 off for installation.

SUBTASK 72-41-10-040-062-001 Remove the Splined Nuts and Anti-score Washers (Geared Indexing Spanner Method)

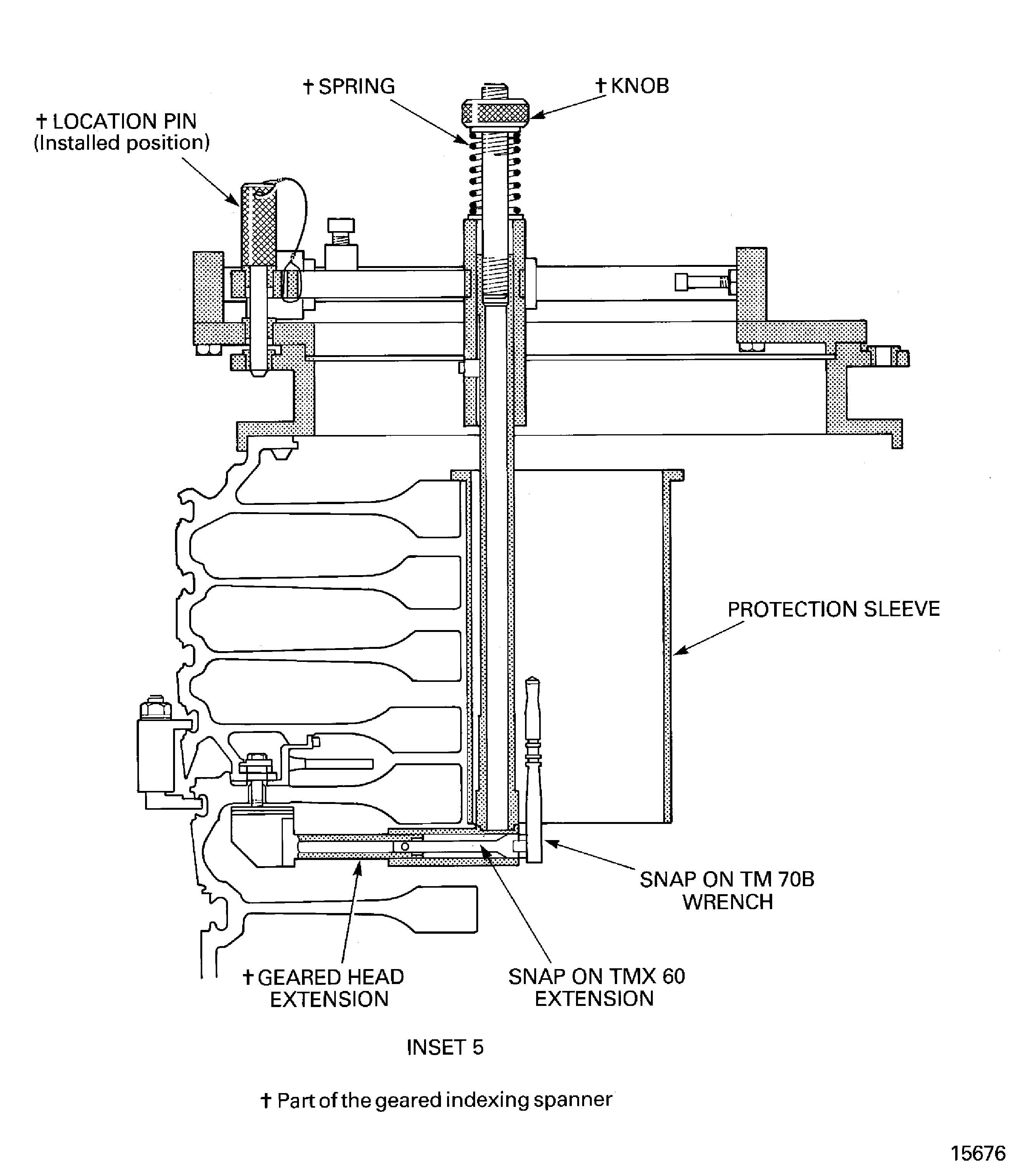

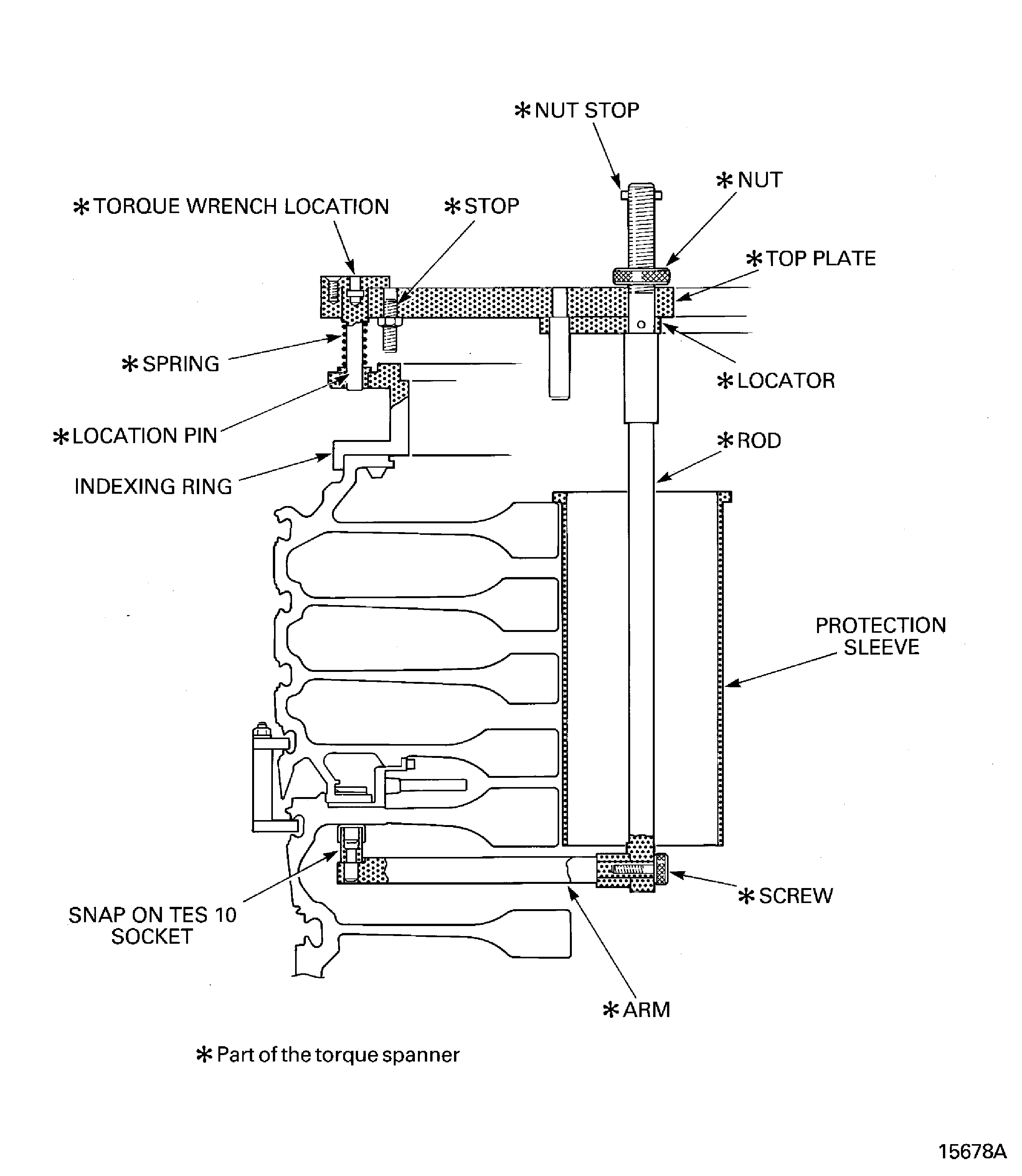

Install IAE 1R18029 Blanking tool 1 off in to the bore of the stages 3 to 12 compressor disks assembly.

Install IAE 1R18400 Protection sleeve 1 off in to the bore of the stages 3 to 12 compressor disks assembly.

Install the IAE 1R18027 Indexing ring 1 off on to the stage 12 compressor disk rear flange.

Make sure the nut (part of the IAE 1R18201 Torque spanner) is loose.

Prepare the IAE 1R18201 Torque spanner 1 off for installation.

SUBTASK 72-41-10-040-062-002 Remove the Splined Nuts and Anti-score Washers (Torque Spanner Method)

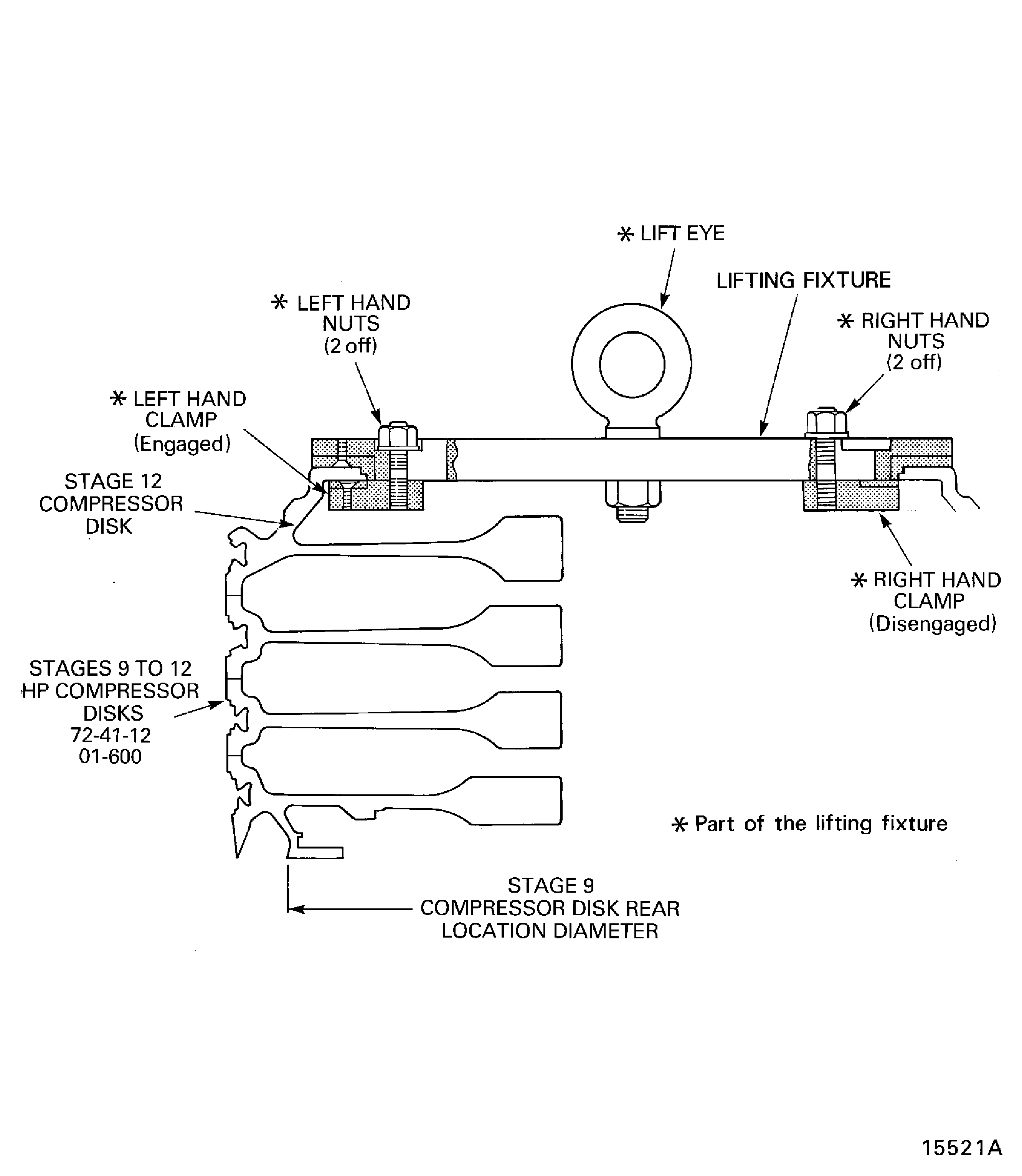

Install the IAE 1R18026 Lifting fixture 1 off on to the stage 12 disk. Refer to Figure.

Install the IAE 1R18067 Extractor 1 off on to the compressor disks assembly. Refer to Figure.

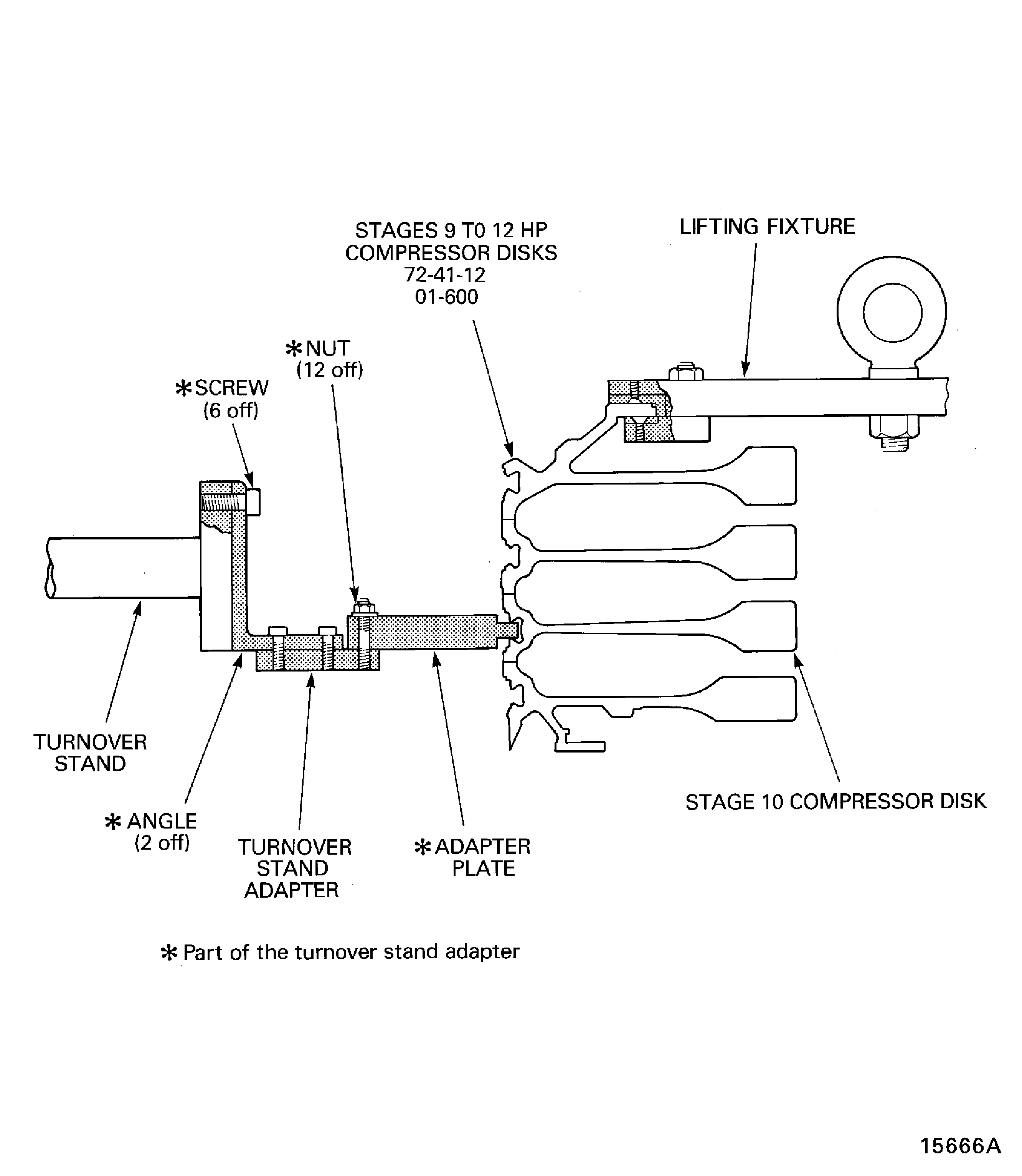

Install the IAE 1R18025 Turnover stand adapter 1 off on to the IAE 1R18322 Turnover stand 1 off. Refer to Figure.

SUBTASK 72-41-10-040-063 Remove the Stage 9 to 12 Disks and Vortex Reducer Ring from the Stage 3 to 8 Disks

Refer to: Figure

CAUTION

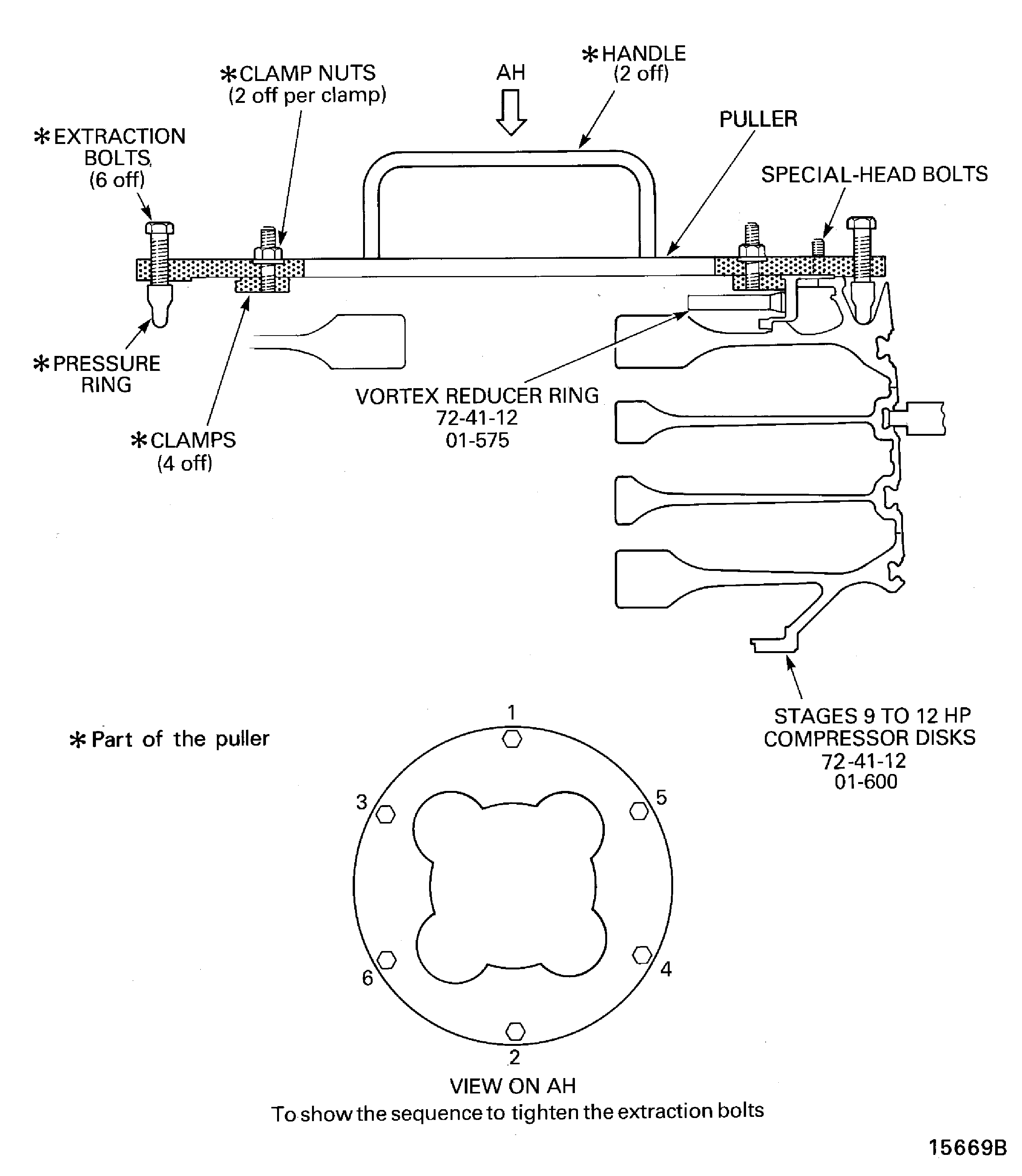

THE EXTRACTION BOLTS MUST BE TIGHTENED IN SEQUENCE AND NOT MORE THAN ONE TURN AT A TIME. YOU MUST MAKE SURE THERE IS A CLEARANCE BETWEEN THE SPECIAL HEADED BOLTS AND THE HOLES IN THE PULLER.Tighten the six extraction bolts in small increments until the vortex reducer ring is released from the stage 9 disk.

Install the IAE 1R18443 Puller 1 off on to the vortex reducer ring.

SUBTASK 72-41-10-040-064 Remove the Vortex Reducer Ring from the Stage 9 to 12 Disks

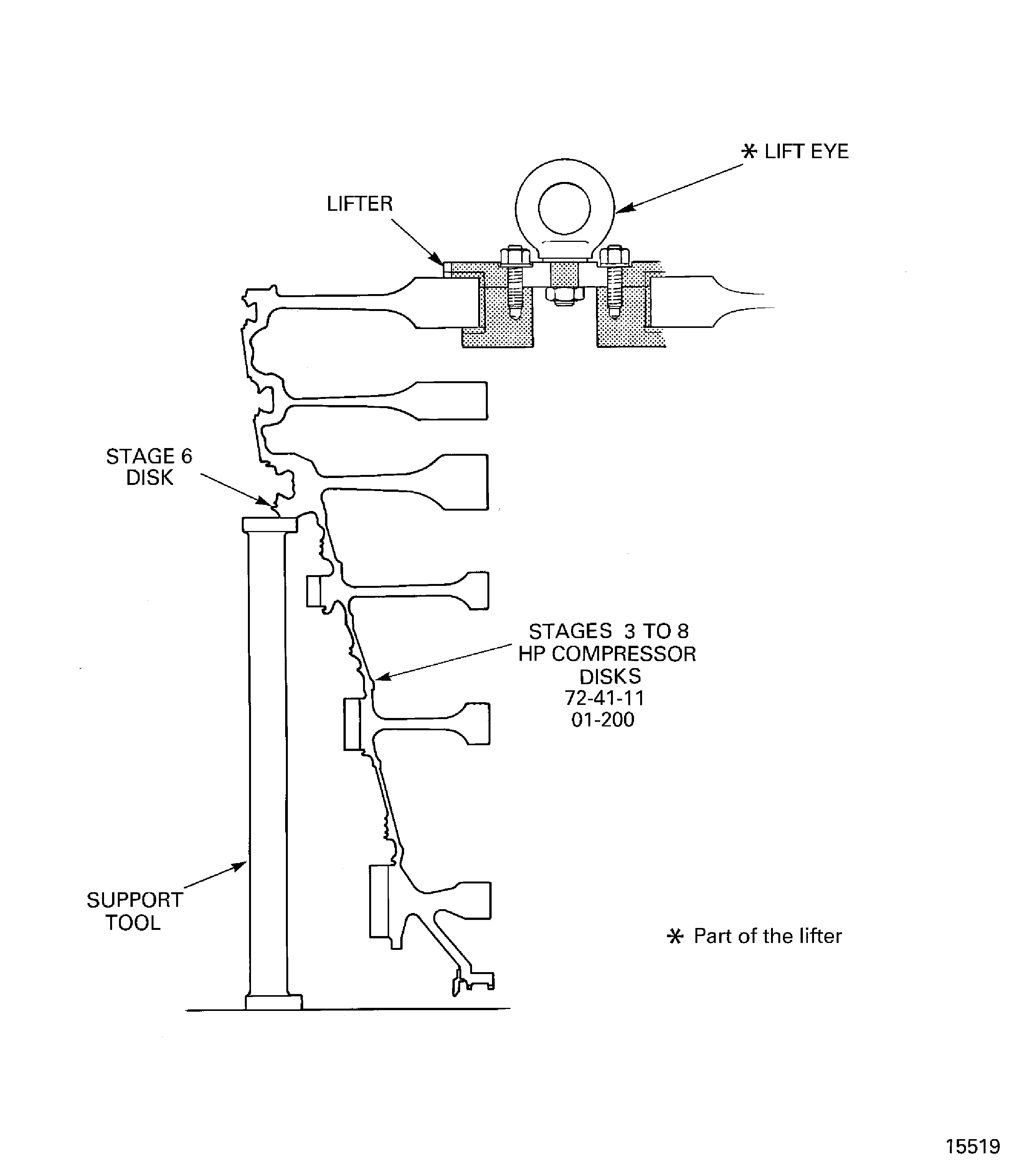

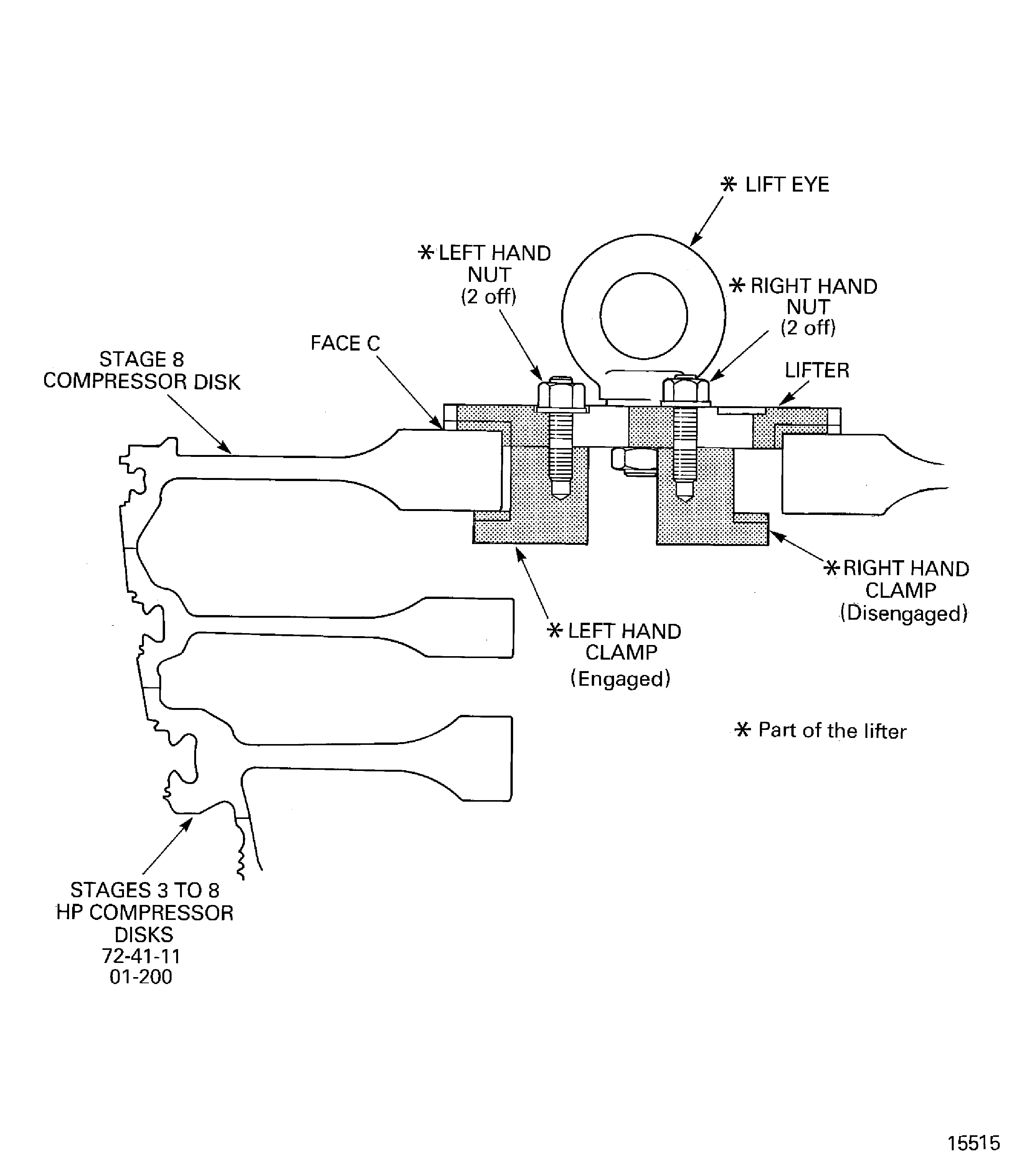

Install the IAE 1R18065 Lifter 1 off on to the stage 8 disk. Refer to Figure.

Remove the bolts that attach the dummy stub shaft to the stage 3 to 8 disks. Refer to Figure.

Attach a hoist and lift the stage 3 to 8 disks clear of the build stand and the dummy stub shaft and install it in the IAE 1R18092 Support tool 1 off. Refer to Figure.

Remove the IAE 1R18673 Dummy stub shaft and install the curvic protector.

SUBTASK 72-41-10-040-065 Remove the Stage 3 to 8 Disks from the Build Stand

Figure: Install the protective cover on the rotating air seal

Install the protective cover on the rotating air seal

Figure: Install the beam sling on to the HP compressor rotor assembly

Sheet 1

Figure: Remove/install the universal sling adapters

Sheet 2

Figure: Install the HP compressor rotor assembly on to the safety support stand

Install the HP compressor rotor assembly on to the safety support stand

Figure: Install the HP compressor rotor in to the tip check fixture

Sheet 1

Figure: Install the HP compressor rotor in to the tip check fixture

Sheet 2

Figure: Install the HP compressor rotor in to the tip check fixture

Sheet 3

Figure: Install the HP compressor rotor in to the tip check fixture

Sheet 4

Figure: Set the transducer carriers to zero

Set the transducer carriers to zero

Figure: Measure the seal and stator path diameters

Sheet 1

Figure: Measure the seal and stator path diameters

Sheet 2

Figure: Install the HP compressor rotor assembly in to the trolley

Install the HP compressor rotor assembly in to the trolley

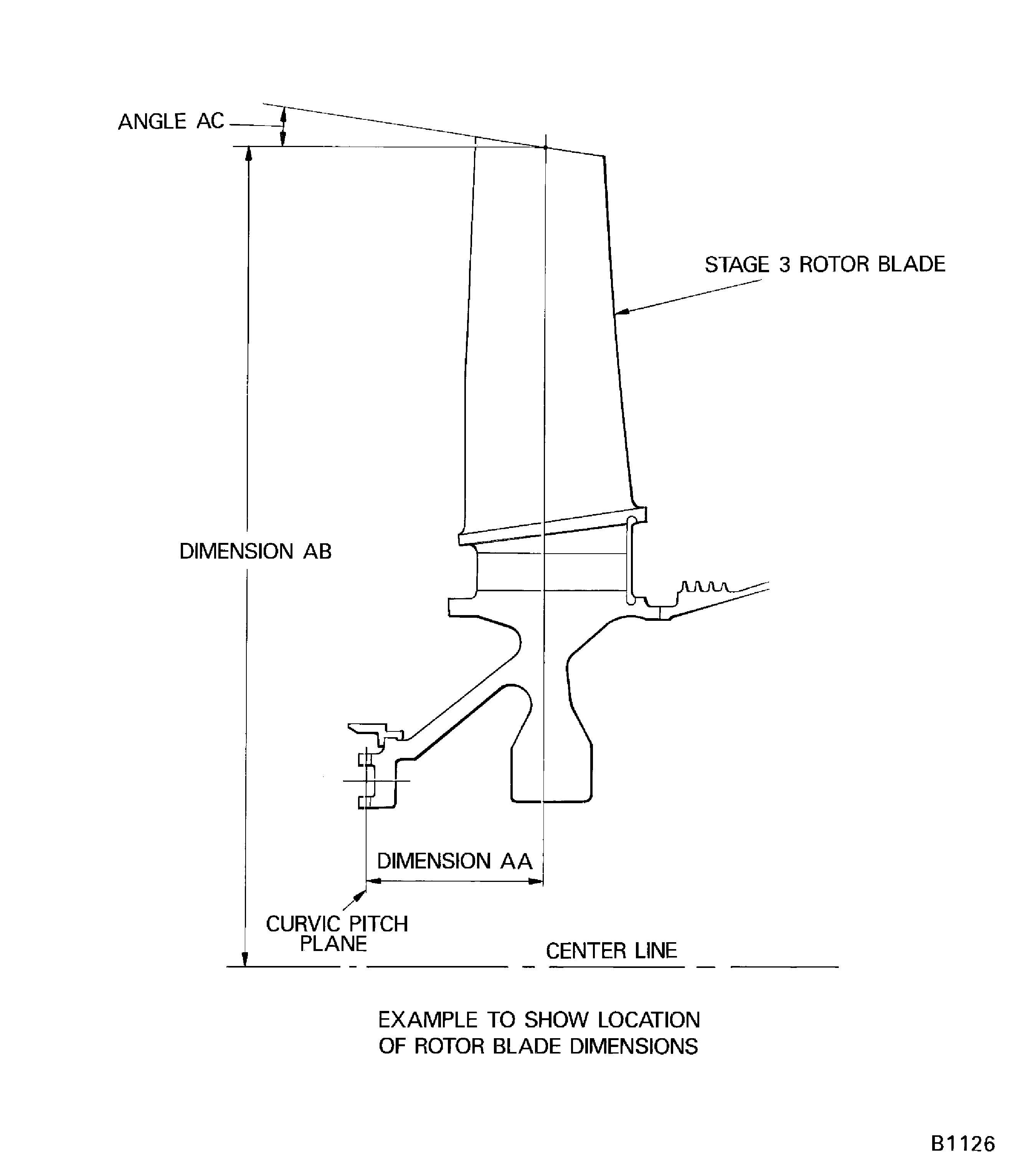

Figure: HP compressor rotor tip radius - axial position (dimension AA)

HP compressor rotor tip radius - axial position (dimension AA)

Figure: Pre SBE 72-0370 : HP compressor rotor tip radius

Pre SBE 72-0370 : HP compressor rotor tip radius

Figure: SBE 72-0370 : HP compressor rotor tip radius

SBE 72-0370 : HP compressor rotor tip radius

Figure: Stage 3 disk curvic coupling bolts torque sequence

Stage 3 disk curvic coupling bolts torque sequence

Figure: Install the HP compressor rotor assembly in to the build stand

Install the HP compressor rotor assembly in to the build stand

Figure: Remove the rotating air seal

Remove the rotating air seal

Figure: Install the lifter on the compressor shaft

Install the lifter on the compressor shaft

Figure: Remove the HP compressor shaft

Remove the HP compressor shaft

Figure: Remove the splined nuts and the anti-score washers

Sheet 1

Figure: Remove the splined nuts and the anti-score washers

Sheet 2

Figure: Remove the splined nuts and the anti-score washers

Sheet 3

Figure: Remove the splined nuts and the anti-score washers

Sheet 4

Figure: Remove the splined nuts and the anti-score washers

Sheet 5

Figure: Install the lifter on the stage 12 disk

Install the lifter on the stage 12 disk

Figure: Remove the stage 9 to 12 disks from the stage 3 to 8 disks

Remove the stage 9 to 12 disks from the stage 3 to 8 disks

Figure: Install the stage 9 to 12 disks in the turnover stand

Install the stage 9 to 12 disks in the turnover stand

Figure: Remove the vortex reducer ring from the stage 9 to 12 disks

Remove the vortex reducer ring from the stage 9 to 12 disks

Figure: Install the lifter on to the stage 8 disk

Install the lifter on to the stage 8 disk

Figure: Remove the dummy stub shaft

Remove the dummy stub shaft

Figure: Install the stage 3 to 8 disks in the support tool

Install the stage 3 to 8 disks in the support tool