Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-12-300-018 HPC Stage 9 - 12 Drum Disk - Repair The Stage 9 Disk Front Inner Location Diameter By Metal Spray, Repair-018 (VRS6135)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-600 | 6A4131 | Assembly A |

01-600 | 6A7545 | Assembly A |

01-600 | 6A7574 | Assembly A |

01-600 | 6A4156 | Assembly B |

01-600 | 6A6546 | Assembly B |

01-600 | 6A7546 | Assembly B |

01-600 | 6A7547 | Assembly B |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

HP compressor - stage 9 to 12 disk shaft assembly | QZD | Inconnel 718 |

General

This Repair must only be done when the instruction to do so is given in 72-41-12 Inspection.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers, are in the SPM.

Price and availability

Refer to International Aero Engines

Related repairs - none

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before the repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3R19387 Grinding fixture | 0AM53 | IAE 3R19387 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-019 TAPE, ADHESIVE PAPER HEAT RESISTING MASKING | 94960 | CoMat 02-019 | ||

| CoMat 03-038 METAL SPRAYING POWDER NICKEL ALUMINIUM (95/5) | IE200 | CoMat 03-038 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 00741 | CoMat 03-089 | ||

| CoMat 03-248 METAL SPRAY POWDER | LOCAL | CoMat 03-248 | ||

| CoMat 05-001 ABRASIVE MEDIUM, ALUMINIUM OXIDE, 20/30 GRADE | LOCAL | CoMat 05-001 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 |

Spares

NONESafety Requirements

NONEProcedure

Use IAE 3R19387 Grinding fixture, 1 off or a locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

Deleted.

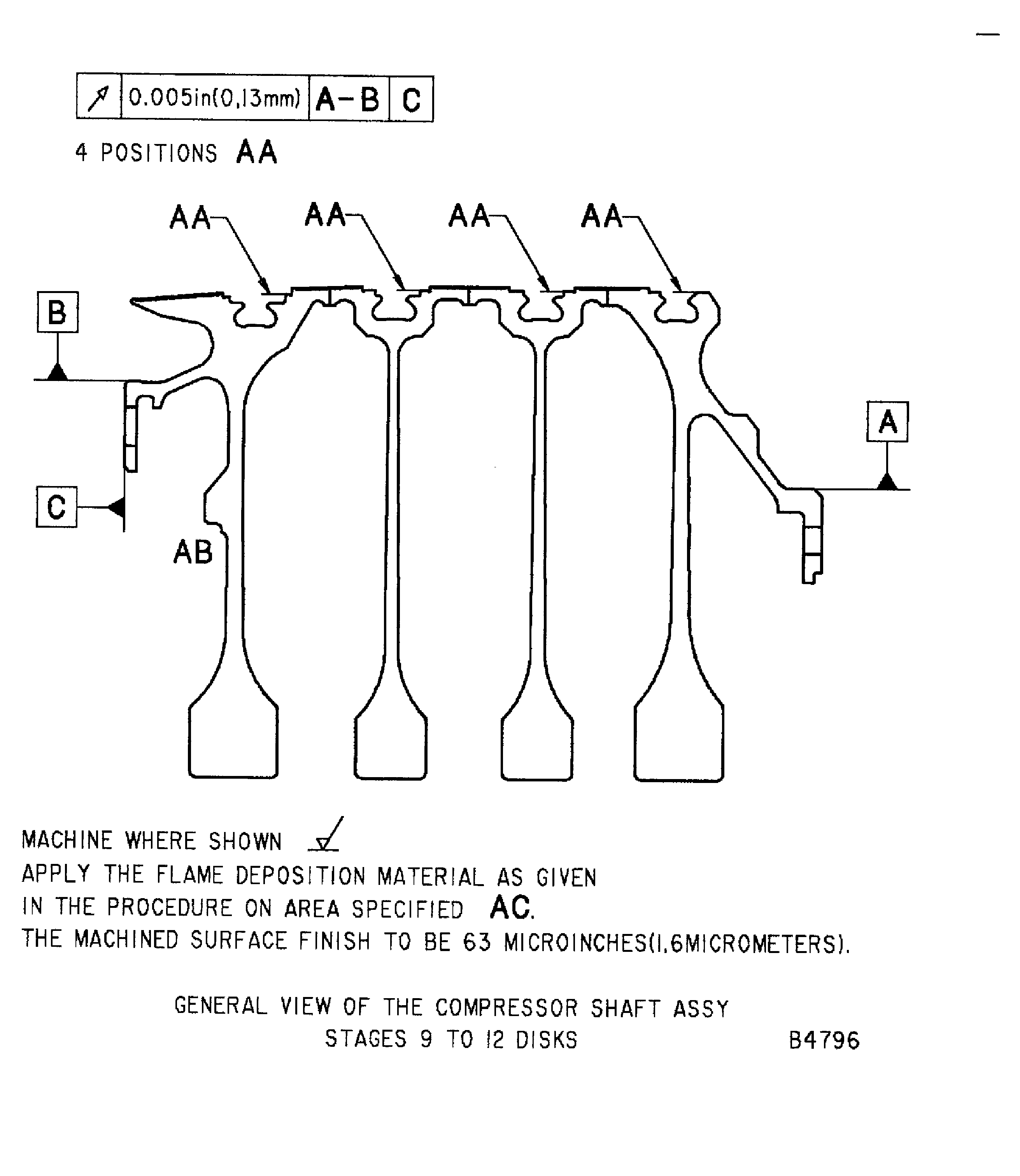

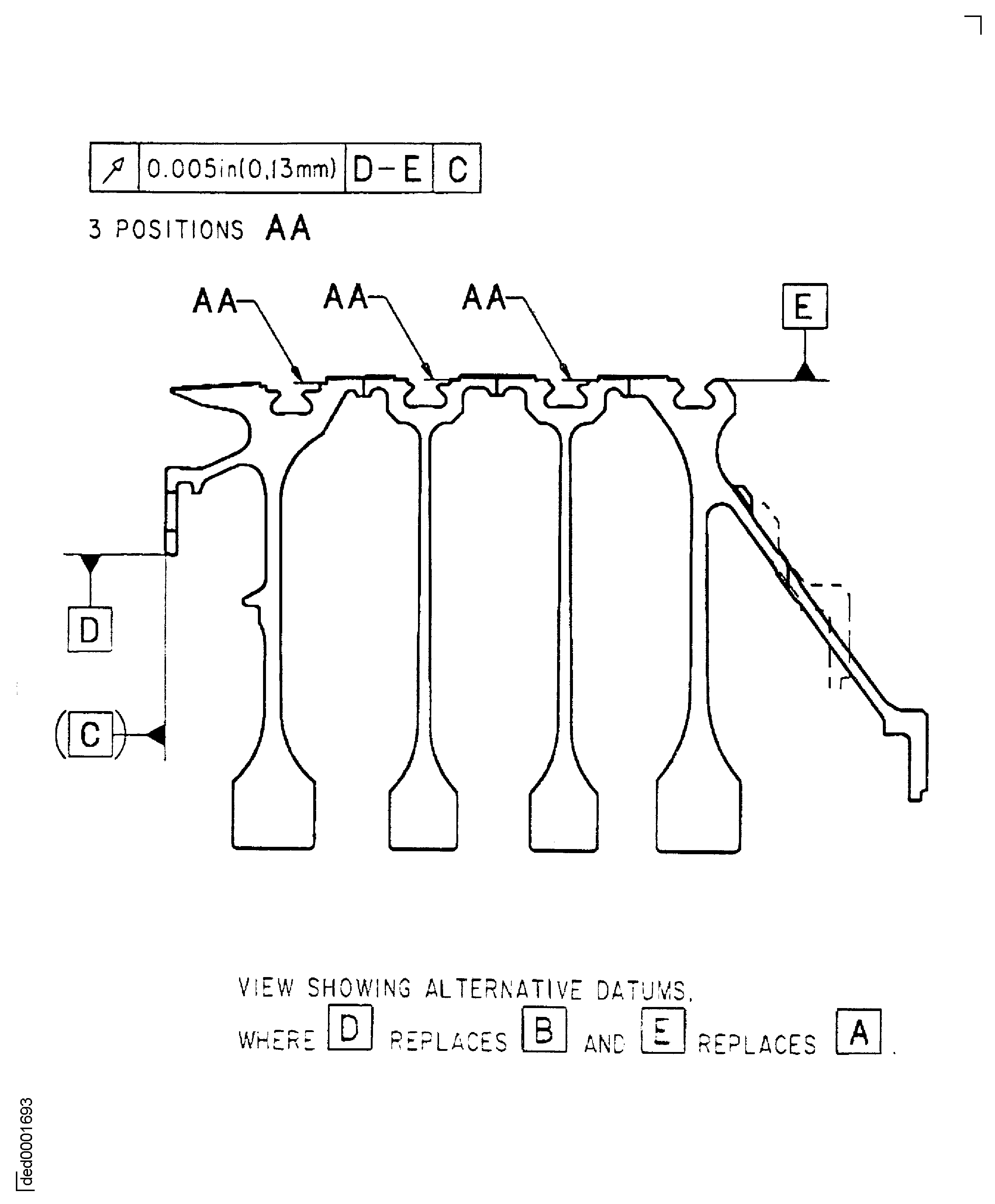

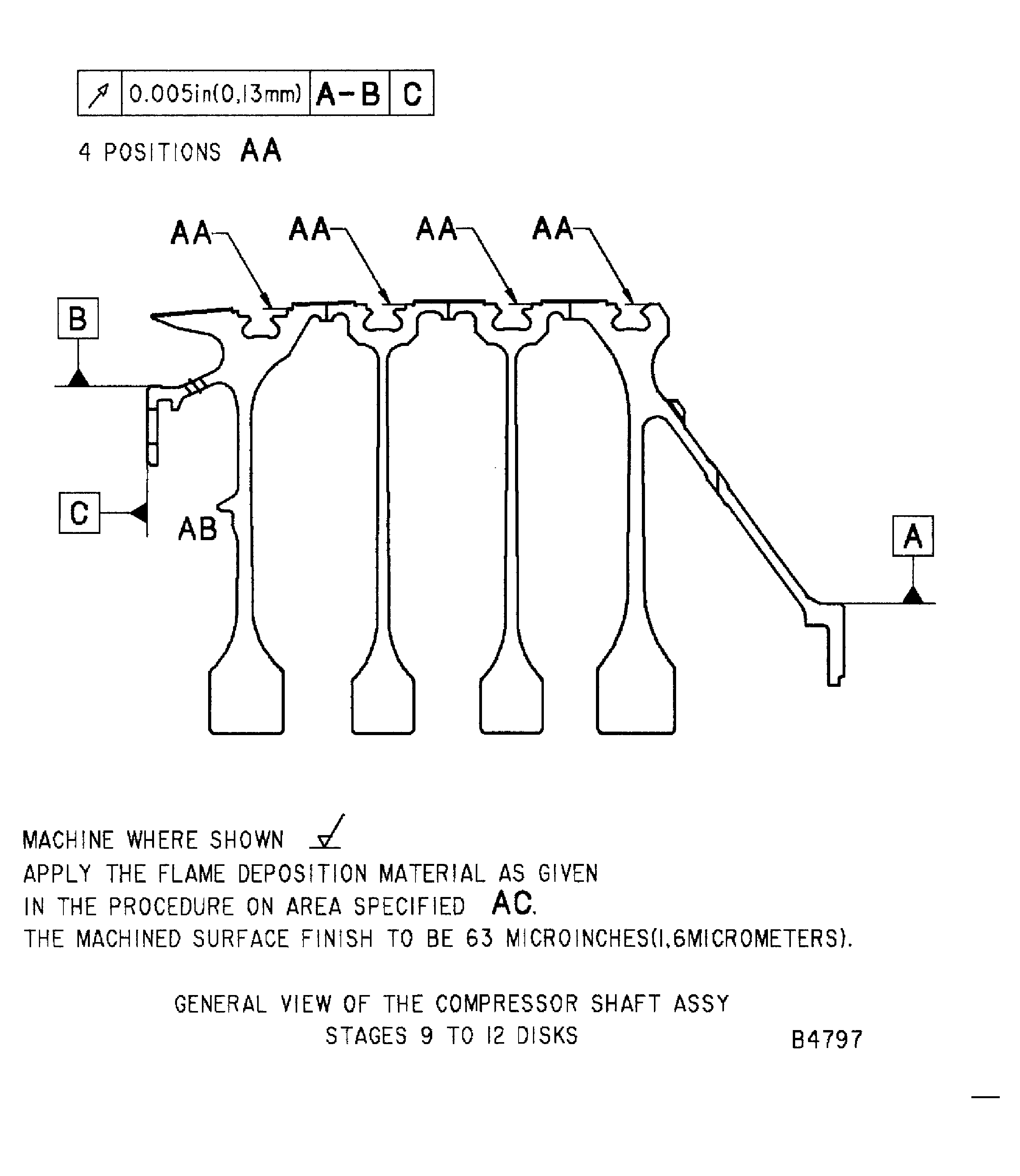

If Datum A and/or B is to be repaired, use the new Datum E and/or D. Refer to Figure.

Deleted.

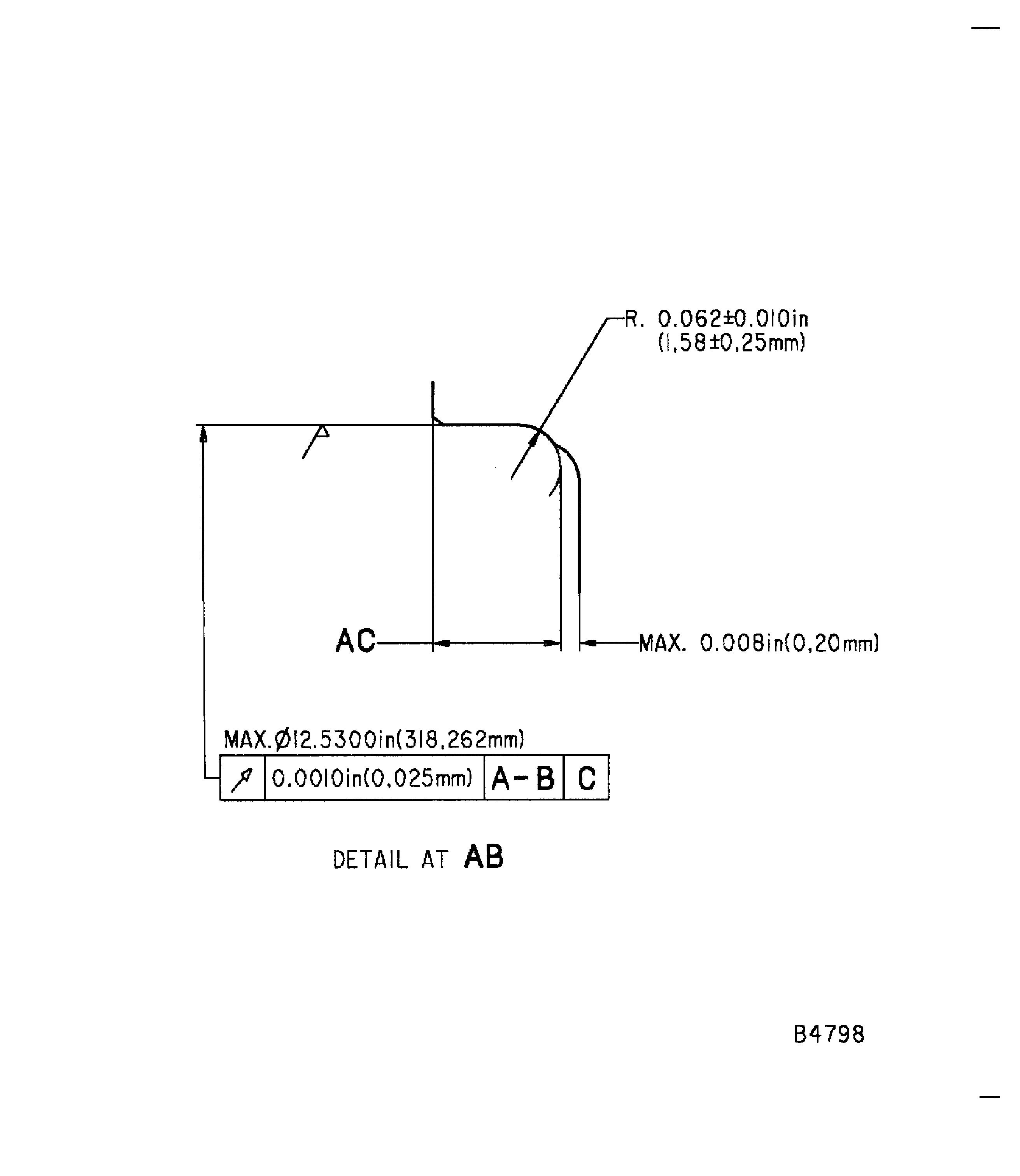

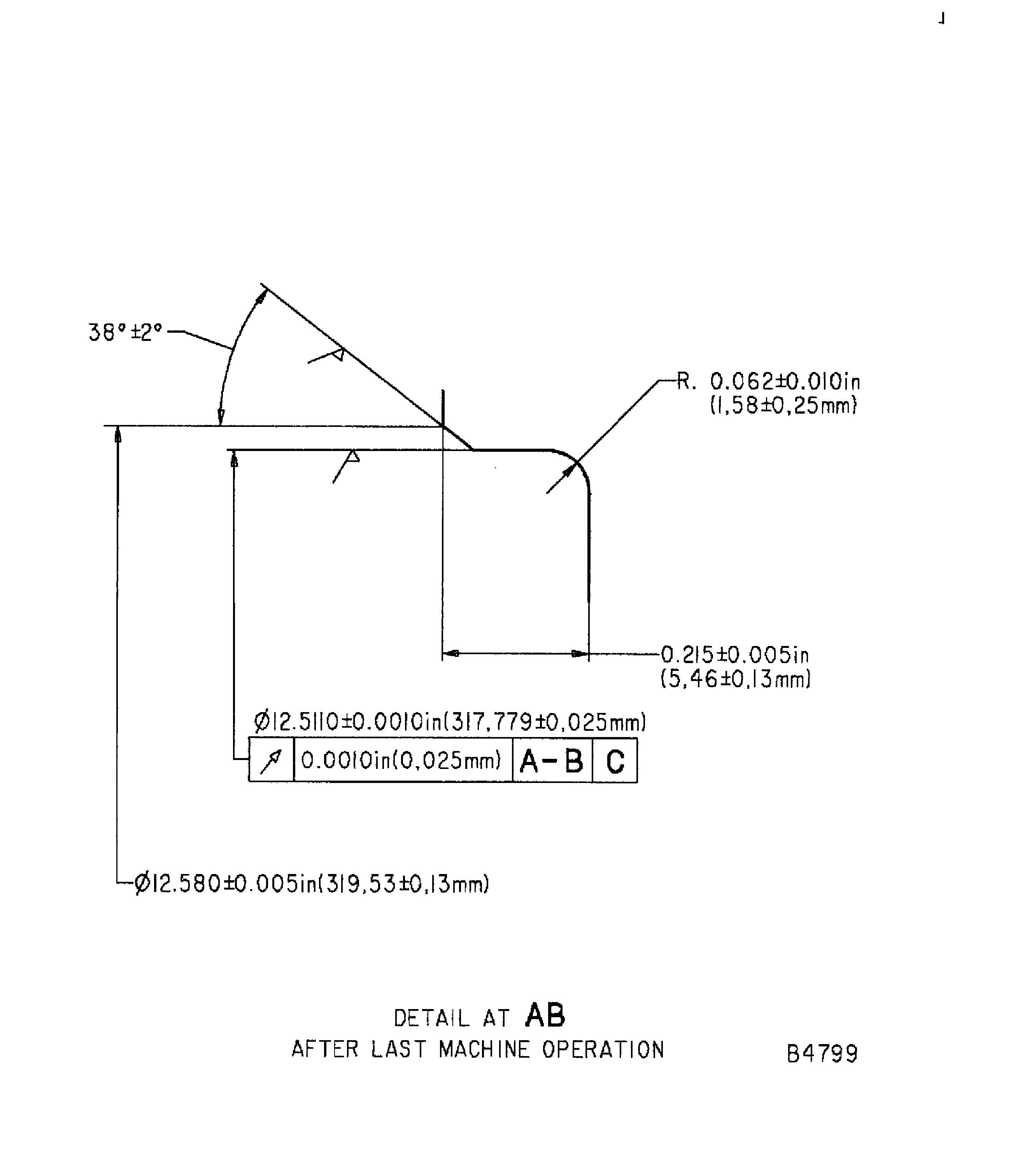

Grind/turn the front inner diameter AC to remove all damage, wear, and coat.

Deleted.

SUBTASK 72-41-12-324-053-A00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly A

Use IAE 3R19387 Grinding fixture, 1 off or a locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

Deleted.

If Datum A and/or B is to be repaired, use the new Datum E and/or D. Refer to Figure.

Deleted.

Grind/turn the front inner diameter AC to remove all damage, wear, and coat.

Deleted.

SUBTASK 72-41-12-324-053-B00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly B

Refer to Figure.

Refer to the SPM TASK 70-23-04-230-501.

Deleted.

Deleted.

Do a penetrant crack test on the front inner diameter.

SUBTASK 72-41-12-230-067 Do a Crack Test

Refer to the SPM TASK 70-11-03-300-503.

Deleted.

Chemically clean the assembly.

SUBTASK 72-41-12-110-066 Clean the HP Compressor Stage 9 to 12 Disks Shaft Assembly

Deleted.

Refer to the SPM TASK 70-38-04-300-503, SUBTASK 70-38-04-300-002.

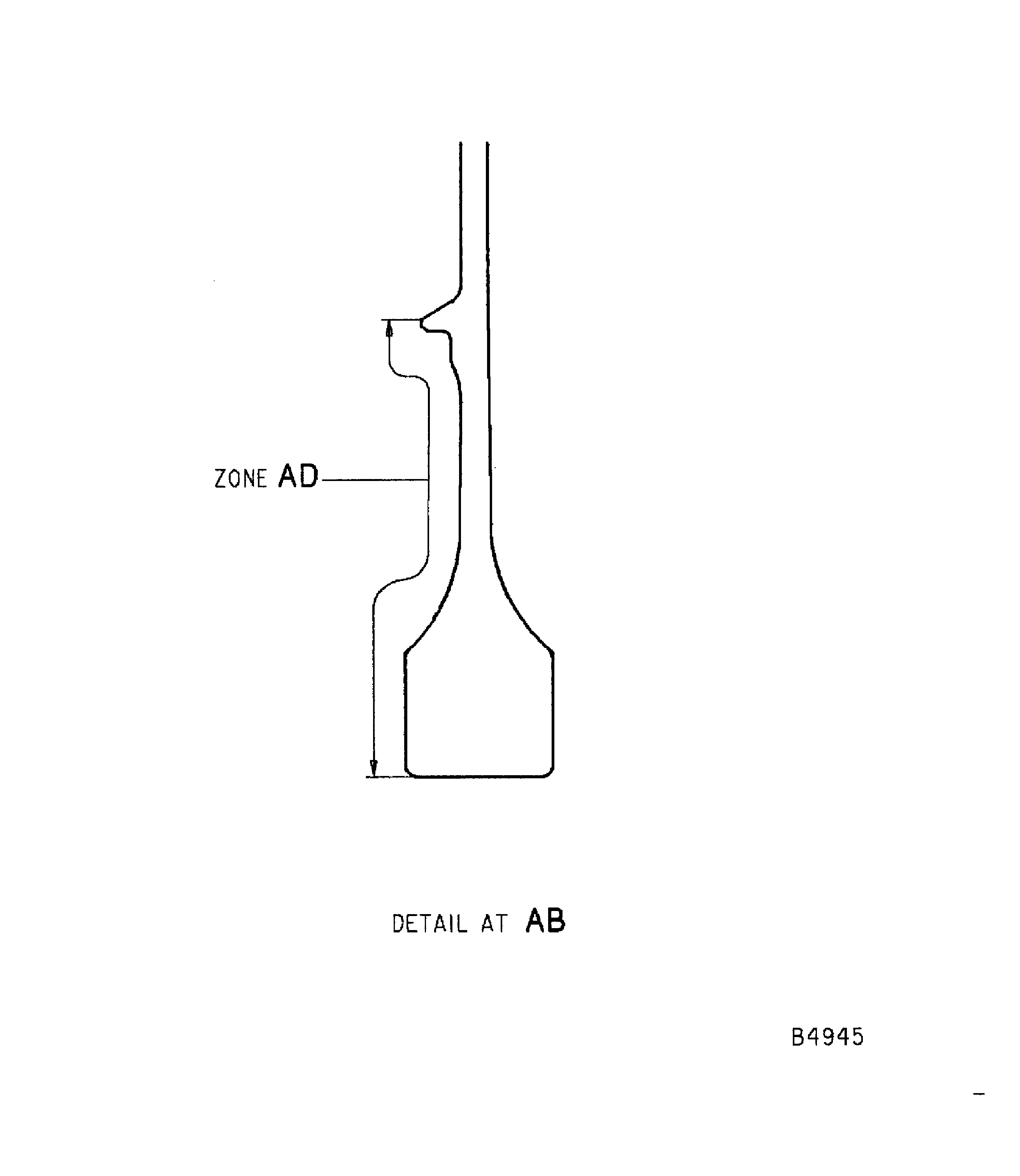

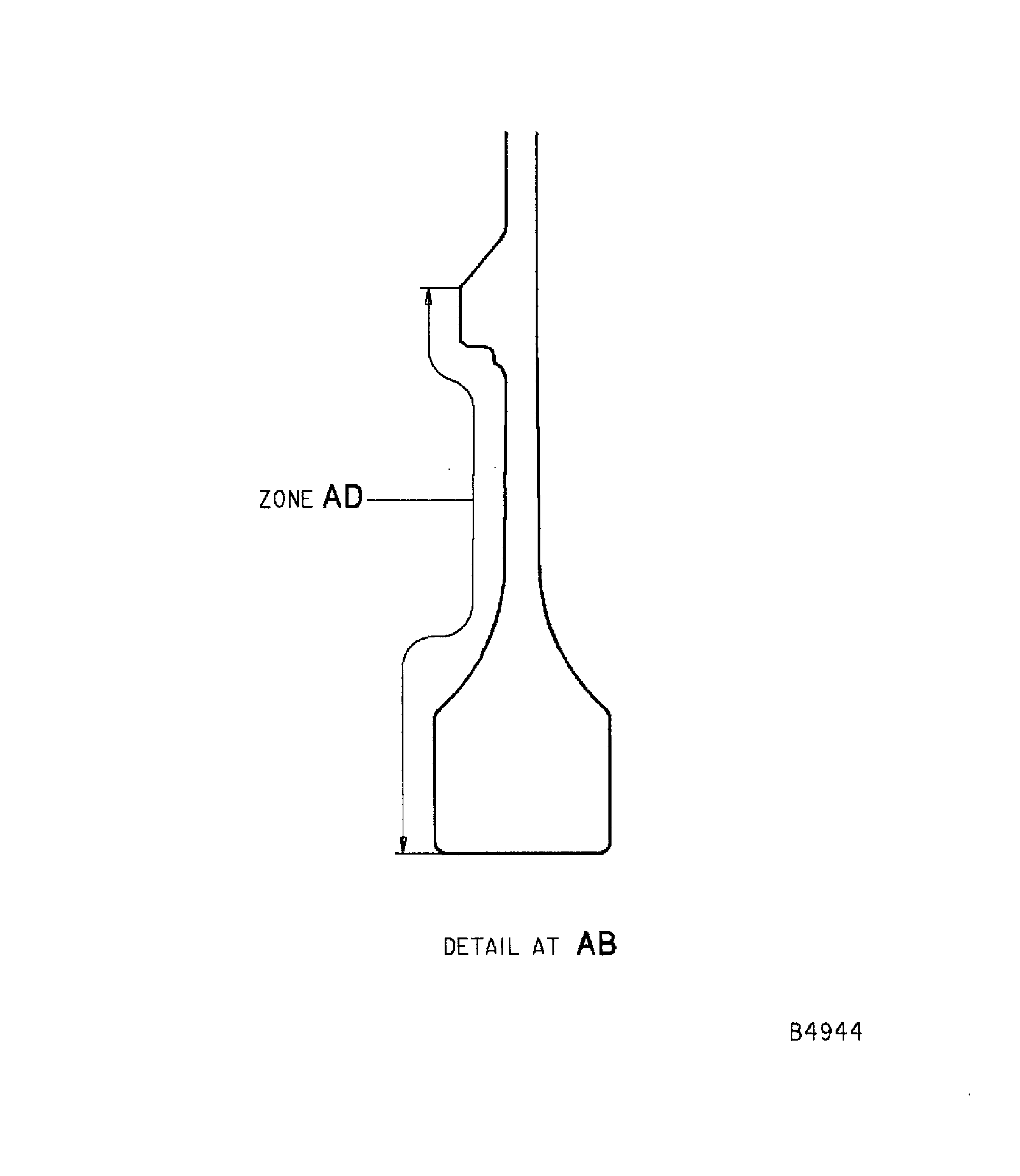

Minimum overspray is permitted in Zone AD.

Use automatic shot-peening equipment.

Shot-Peening Data

Machining type

Metal shot peen

Process type/mode

Dry/Auto

Shot type

Deleted

Deleted

Coverage

125 per cent minimum, 200 per cent maximum

Nozzle/work distance

120 mm

Number of nozzles

1

Almen intensity

0.006 to 0.009in. (0.15 to 0.23 mm) using

an 'A' type test strip

Shot-peen the HP compressor stage 9 to 12 disks shaft assembly front inner location diameter.

Deleted.

Deleted.

SUBTASK 72-41-12-380-058-A00 Shot-Peen the Area to be Repaired, Assembly A

Deleted.

Refer to SPM TASK 70-38-04-300-503 SUBTASK 70-38-04-300-002.

Minimum overspray is permitted in Zone AD.

Use automatic shot-peening equipment.

Shot Peening Data

Machine type

Metal shot peen

Process type/mode

Dry/Auto

Shot type

Deleted

Deleted

Coverage

125 per cent minimum, 200 per cent maximum

Nozzle/work distance

120 mm

Number of nozzles

1

Almen intensity

0.006 to 0.009in. (0.15 to 0.23 mm) using

an 'A' type test strip

Shot peen the HP compressor stage 9 to 12 disks shaft assembly front inner location diameter.

Deleted.

Deleted.

SUBTASK 72-41-12-380-058-B00 Shot-Peen the Area to be Repaired, Assembly B

Refer to the SPM TASK 70-11-26-300-503.

Use chemical cleaning equipment.

Locally degrease in area AB.

SUBTASK 72-41-12-350-074-B00 Seal the Surfaces Not to be Repaired, Assembly B

Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the surface to be repaired, at diameter AC.

SUBTASK 72-41-12-120-056-A00 Abrasive Blast the Surface to be Repaired, Assembly A

Refer to the SPM TASK 70-12-02-120-501.

Abrasive blast the surface to be replaced, at diameter AC.

SUBTASK 72-41-12-120-056-B00 Abrasive Blast the Surface to be Repaired, Assembly B

Refer to SPM TASK 70-34-01-340-501 SUBTASK 70-34-01-340-025 or SUBTASK 70-34-01-340-021.

Apply sufficient metal spray to get the correct dimensions when you do finish operation.

Deleted.

Apply metal spray.

SUBTASK 72-41-12-340-056-A00 Metal Spray the Location Diameter AC, Assembly A

Refer to the SPM TASK 70-34-01-340-501 SUBTASK 70-34-01-340-021 or SUBTASK 70-34-01-340-025.

Apply sufficient metal spray to get the correct dimensions when you do finish operation.

Deleted.

Apply metal spray.

SUBTASK 72-41-12-340-056-B00 Metal Spray the Location Diameter AC, Assembly B

Use IAE 3R19387 Grinding fixture, 1 off or a locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

Deleted.

If Datum A and/or B is to be repaired, use the new Datum E and/or D. Refer to Figure.

Break all the sharp edges to 0.010 in. - 0.020 in. (0.254 mm - 0.508 mm).

Grind/turn the front inner diameter.

Deleted.

SUBTASK 72-41-12-324-054-A00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly A

Use IAE 3R19387 Grinding fixture, 1 off or a locally made grinding or turning fixture.

Deleted.

Install the fixture into the lathe/grinding machine.

Deleted.

If Datum A and/or B is to be repaired, use the new Datum E and/or D. Refer to Figure.

Break all the sharp edges to 0.010 in. - 0.020 in. (0.254 mm - 0.508 mm).

Grind/turn the front inner diameter.

Deleted.

SUBTASK 72-41-12-324-054-B00 Grind/Turn the HP Compressor - Stage 9 to 12 Disks Shaft Assembly, Assembly B

Refer to the SPM TASK 70-11-03-300-503.

Deleted.

Chemically clean the assembly.

SUBTASK 72-41-12-110-067 Clean the HP Compressor Stage 9 to 12 Disks Shaft Assembly

Refer to the SPM TASK 70-09-00-400-501.

Deleted.

Mark VRS6135 adjacent to the part number, use vibration peen method.

SUBTASK 72-41-12-350-075 Identify the Repair

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly A And Assembly B

Repair Details And Dimensions - Assembly A And Assembly B

Figure: Repair Details And Dimensions - Assembly A

Repair Details And Dimensions - Assembly A

Figure: Repair Details And Dimensions - Assembly B

Repair Details And Dimensions - Assembly B