Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-21-300-069 HPC Heatshields - Replace Loose Or Damaged Rivets And/or A Damaged Plate On The Stage 7 Rear Heatshield, Repair-069 (VRS6308)

Material of component

DESCRIPTION SYMBOL MATERIAL | ||

|---|---|---|

HP Compressor Rear | EAK | Modified 12 percent |

Heatshield, Stage 7 | Chromium steel | |

OR | ||

EBL | Modified 12 percent | |

Chromium steel | ||

OR | ||

EAE | 11.5 percent Chromium, | |

3 percent Nickel, | ||

1.75 percent Molybdenum | ||

and 1.5 percent Cobalt | ||

Plate | EBQ | 11 percent Chromium and |

1 percent Molybdenum | ||

Rivet, solid | QBE ) | Nimonic 75 |

or | ||

QPK ) | Nimonic 75 | |

General

This Repair must only be done when the instruction to do so is given in 72-41-21 Inspection.

This Repair replaces loose or damaged rivets and/or a damaged plate, on the HP Compressor, stage 7, rear heatshield.

When loose or damaged rivet(s) are to be replaced do Step.

When a damaged plate is to be replaced do Step.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Price and Availability

Refer to International Aero Engines

Related repairs

HP Compressor Rear Heatshield, Stage 7 - Replace the Surface Protection, refer to TASK 72-41-21-300-073 (VRS6309).

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Vertical drilling machine | LOCAL | Vertical drilling machine | ||

| Toolmakers clamp | LOCAL | Toolmakers clamp | or equivalent | |

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rivet, solid, | AS16246 | 2 | universal head | |

| Rivet, solid, | AS16287 | 2 | universal head | |

| Plate | 6A5664 | 1 |

Safety Requirements

NONEProcedure

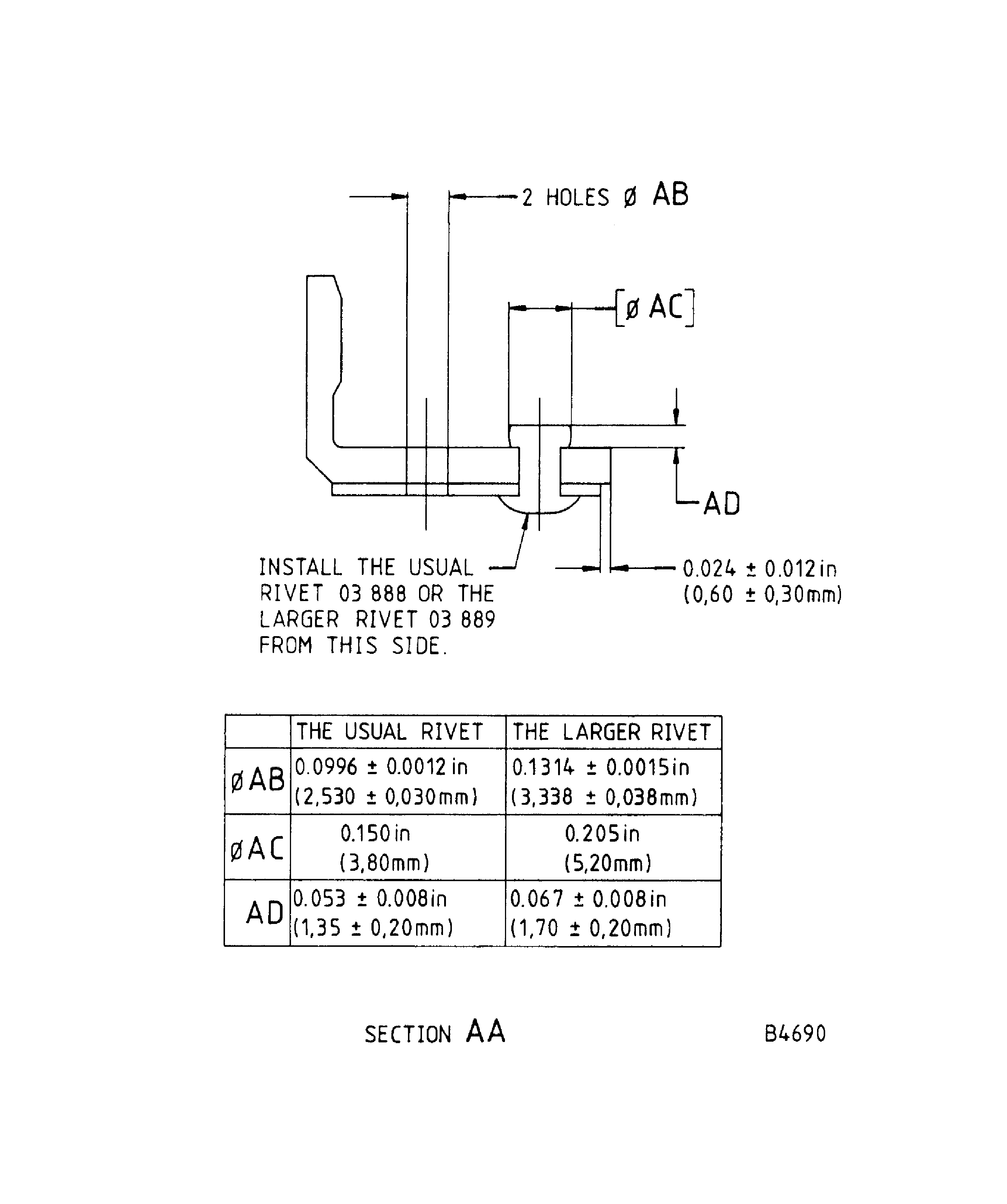

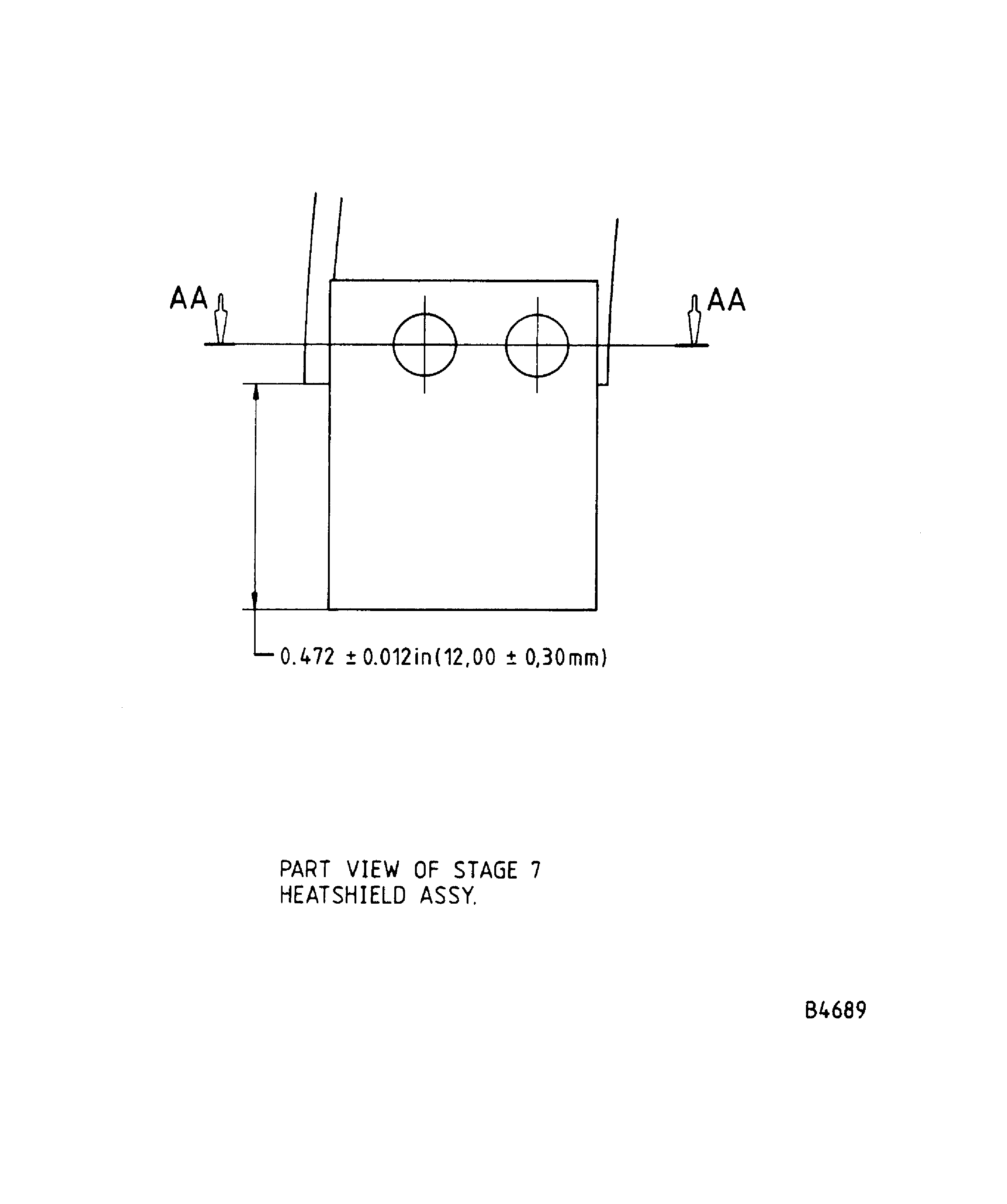

Refer to Figure.

SUBTASK 72-41-21-323-060 Remove Loose or Damaged Rivet(s)

NOTE

The SUBTASKS which follow must only be done to replace loose or damaged rivet(s).Use a vertical drilling machine.

NOTE

If the two holes are to be machined for the larger rivet, then access to one hole after the other may not be possible because of the position of the toolmakers clamp, or equivalent, on the plate and the heatshield. If this occurs do Step, Step, Step, Step and Step for the first hole, then do these SUBTASKS again for the other hole.

Drill the plate and the damaged rivet hole(s) to suit the larger rivet(s), as necessary.

SUBTASK 72-41-21-323-061 Drill the Plate and Rivet Hole(s)

NOTE

Only do this SUBTASK if the larger rivet(s) is/are to be installed.Refer to the SPM TASK 70-11-26-300-503.

Chemically clean the plate and around the rivet hole(s).

SUBTASK 72-41-21-110-154 Chemically clean

Refer to the SPM TASK 70-23-05-230-501. Cracks are not permitted.

Do a local penetrant crack test on the plate and around the rivet hole(s).

SUBTASK 72-41-21-230-175 Do a Crack Test

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivet(s) in place.

SUBTASK 72-41-21-390-059 Safety the Rivet(s) in Place

Refer to the SPM TASK 70-11-26-300-503.

Chemically clean the rivet heads and plate.

SUBTASK 72-41-21-110-155 Chemically clean

Refer to the SPM TASK 70-23-05-230-501 Cracks are not permitted.

Do a local penetrant crack test on the rivet heads and plate.

SUBTASK 72-41-21-230-176 Do a Crack Test

Refer to VRS6309, TASK 72-41-21-300-073.

Apply the surface protection to the HP compressor rear heatshield, stage 7.

SUBTASK 72-41-21-380-105 Apply the Surface Protection

Refer to Figure.

SUBTASK 72-41-21-350-158 Remove the Damaged Plate

NOTE

The SUBTASKS which follow must only be used to replace the damaged plate.Use 6A5664 , 1 off, 03-891 with a toolmakers clamp or equivalent.

Safety the plate to the heatshield.

Position the heatshield with plate side down.

Use a vertical drilling machine.

NOTE

Drill the rivet hole(s) to suit the larger rivet, if necessary.If a toolmakers clamp or equivalent is used to hold the new plate in position then access to one hole after the other may not be possible. If this occurs do SUBTASK 72-41-21-323-062, SUBTASK 72-41-21-110-156, SUBTASK 72-41-21-230-177, SUBTASK 72-41-21-350-159 and SUBTASK 72-41-21-390-060 for the first hole then do these SUBTASKS again for the other hole.

Drill the plate and the rivet hole(s).

SUBTASK 72-41-21-323-062 Drill the Plate and Rivet Hole(s)

Refer to the SPM TASK 70-11-26-300-503.

Chemically clean the plate and around the rivet holes.

SUBTASK 72-41-21-110-156 Chemically clean

Refer to the SPM TASK 70-23-05-230-501. Cracks are not permitted.

Do a local penetrant crack test on the plate and around the rivet holes.

SUBTASK 72-41-21-230-177 Do a Crack Test

Refer to the SPM TASK 70-39-03-390-501.

Use standard workshop equipment.

Cold squeeze the rivets in place.

SUBTASK 72-41-21-390-060 Safety the Rivets in Place

Refer to the SPM TASK 70-11-26-300-503.

Chemically clean the rivet heads and plate.

SUBTASK 72-41-21-110-157 Chemically clean

Refer to the SPM TASK 70-23-05-230-501 Cracks are not permitted.

Do a local penetrant crack test on the rivet heads and plate.

SUBTASK 72-41-21-230-178 Do a Crack Test

Refer to VRS6309, TASK 72-41-21-300-073.

Apply the surface protection to the HP compressor rear heatshield, stage 7.

SUBTASK 72-41-21-380-106 Apply the Surface Protection

Figure: Repair details and dimensions

Repair details and dimensions

Figure: Repair details and dimensions

Repair details and dimensions