Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-41-31-300-020 HPC Front Cases - Repair The Stage Linings, Repair-020 (VRS6500)

General

This Repair must only be done when the instruction to do so is given in 72-41-31 Inspection-002.

The practices and processes referred to in the procedure by the TASK/SUBTASK numbers are in the SPM.

Make sure that all the cleaning and inspection procedures are done before this repair.

After this Repair the rotor path lining(s) will be machined to final dimensions during assembly.

Price and Availability

Refer to International Aero Engines.

Related repairs

None

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-036 METAL SPRAYING WIRE, Ni,Al | LOCAL | CoMat 03-036 | ||

| CoMat 03-057 ALUMINIUM ALLOY/POLYESTERCOMPOSITE | LOCAL | CoMat 03-057 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 33870 | CoMat 03-089 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE WHEELS, STONES AND ABRASIVE PAPERS TO REMOVE AND POLISH MATERIAL.TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL BECOMES TOO HOT.TITANIUM COMPONENT - IF THE MATERIAL SHOWS COLOR CHANGE, BECAUSE OF HEAT, OTHER THAN LIGHT STRAW, THE COMPONENT MUST BE REJECTED.Ensure that both correlated half casings of the HP Compressor front case assembly are assembled together. Safety the HP Compressor front case assembly together with seven slave bolts, nuts and washer to each side.

Machine to remove the defective abradable lining and bond coat. Refer to SPM TASK 70-34-01-340-501.

Remove the defective abradable lining and bond coat using high pressure water blasting. Use a locally manufactured fixture Refer to SPM TASK 70-15-01-160-501.

SUBTASK 72-41-31-325-055-A00 Remove the Abradable Lining and Bond Coat, Assembly A

Do a concentricity check of the assembled casing.

CAUTION

TITANIUM COMPONENT - YOU MUST USE SILICON CARBIDE WHEELS, STONES AND ABRASIVE PAPERS TO REMOVE AND POLISH MATERIAL.TITANIUM COMPONENT - DO NOT USE FORCE WITH MECHANICAL CUTTERS OR THE MATERIAL BECOMES TOO HOT.TITANIUM COMPONENT - IF THE MATERIAL SHOWS COLOR CHANGE, BECAUSE OF HEAT, OTHER THAN LIGHT STRAW, THE COMPONENT MUST BE REJECTED.Ensure that both correlated half casings of the HP Compressor front case assembly are assembled together. Safety the HP Compressor front case assembly together with seven slave bolts, nuts and washer to each side.

Machine to remove the defective abradable lining and bond coat. Refer to SPM TASK 70-34-01-340-501.

Remove the defective abradable lining and bond coat using high pressure water blasting. Use a locally manufactured fixture Refer to SPM TASK 70-15-01-160-501.

SUBTASK 72-41-31-325-055-B00 Remove the Abradable Lining and Bond Coat , Assembly B

Refer to the SPM TASK 70-11-08-300-503, SUBTASK 70-11-08-300-002.

Swab etch the repaired area(s).

SUBTASK 72-41-31-110-081 Do a Swab Etch

Refer to the SPM TASK 70-23-01-230-501 or TASK 70-23-02-230-501.

Cracks are not permitted.

Do a penetrant crack test of the repaired area(s).

SUBTASK 72-41-31-230-079 Do a Crack Test

Refer to the SPM TASK 70-11-01-300-503 or TASK 70-11-03-300-503.

Chemically clean the casings.

SUBTASK 72-41-31-110-082 Clean the Casings

Refer to SPM TASK 70-34-18-380-501.

Mask the surfaces not to be sprayed.

SUBTASK 72-41-31-350-080 Mask the Surfaces not to be Repaired

Refer to the SPM TASK 70-34-18-380-501.

Prepare the area(s) to be sprayed.

Refer to the SPM TASK 70-34-18-380-501.

Be careful not to touch prepared surfaces before plasma spraying.

Remove the masks.

SUBTASK 72-41-31-120-060 Prepare the Area(s) to be Sprayed

Refer to Figure.

SUBTASK 72-41-31-350-081-A00 Assemble the Half Casings, Assembly A

Refer to the SPM TASK 70-34-18-380-501.

Mask the area(s) not to be repaired.

SUBTASK 72-41-31-350-082 Mask the Surfaces not to be Repaired

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 and/or SUBTASK 70-34-01-340-010.

For powder feed plasma spray use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for wire feed combustion spray use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Apply a thickness of 0.003 in. to 0.005 in (0.076 mm to 0.127 mm).

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-020.

Apply the abradable lining.

SUBTASK 72-41-31-340-055-A00 Apply the Abradable Lining, Assembly A

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-025 and/or SUBTASK 70-34-01-340-010.

For powder feed plasma spray use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Alternatively for wire feed combustion spray use CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5).

Apply a thickness of 0.003 to 0.005 in (0.076 to 0.127 mm).

Apply the bond coat.

Refer to the SPM TASK 70-34-01-340-501, SUBTASK 70-34-01-340-020.

Apply the abradable lining.

SUBTASK 72-41-31-340-055-B00 Apply the Abradable Lining, Assembly B

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the sprayed coating on the casings.

Refer to the SPM TASK 70-34-01-340-501.

Average hardness must be 55 to 85 R15Y, outer limits 50 min, 90 max.

Do a hardness test on the sprayed coating.

SUBTASK 72-41-31-220-207-A00 Examine the Rotor Path Lining(s), Assembly A

Refer to the SPM TASK 70-34-01-340-501.

Visually examine the sprayed coating on the casings.

Refer to the SPM TASK 70-34-01-340-501.

Average hardness must be 55 to 85 R15Y, outer limits 50 min, 90 max.

Do a hardness test on the sprayed coating.

SUBTASK 72-41-31-220-207-B00 Examine the Rotor Path Lining(s), Assembly B

Refer to the SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Use vibropeen.

Make a mark VRS6500 adjacent to the part number.

SUBTASK 72-41-31-350-084 Identify the Repair

Refer to TASK 72-41-30-440-002-A00.

Machine and examine the rotor path lining.

SUBTASK 72-41-31-325-056-A00 Machine and Examine the Rotor Path Lining, Assembly A

Refer to TASK 72-41-30-440-002-B01.

Machine and examine the rotor path lining.

SUBTASK 72-41-31-325-056-B00 Machine and Examine the Rotor Path Lining, Assembly B

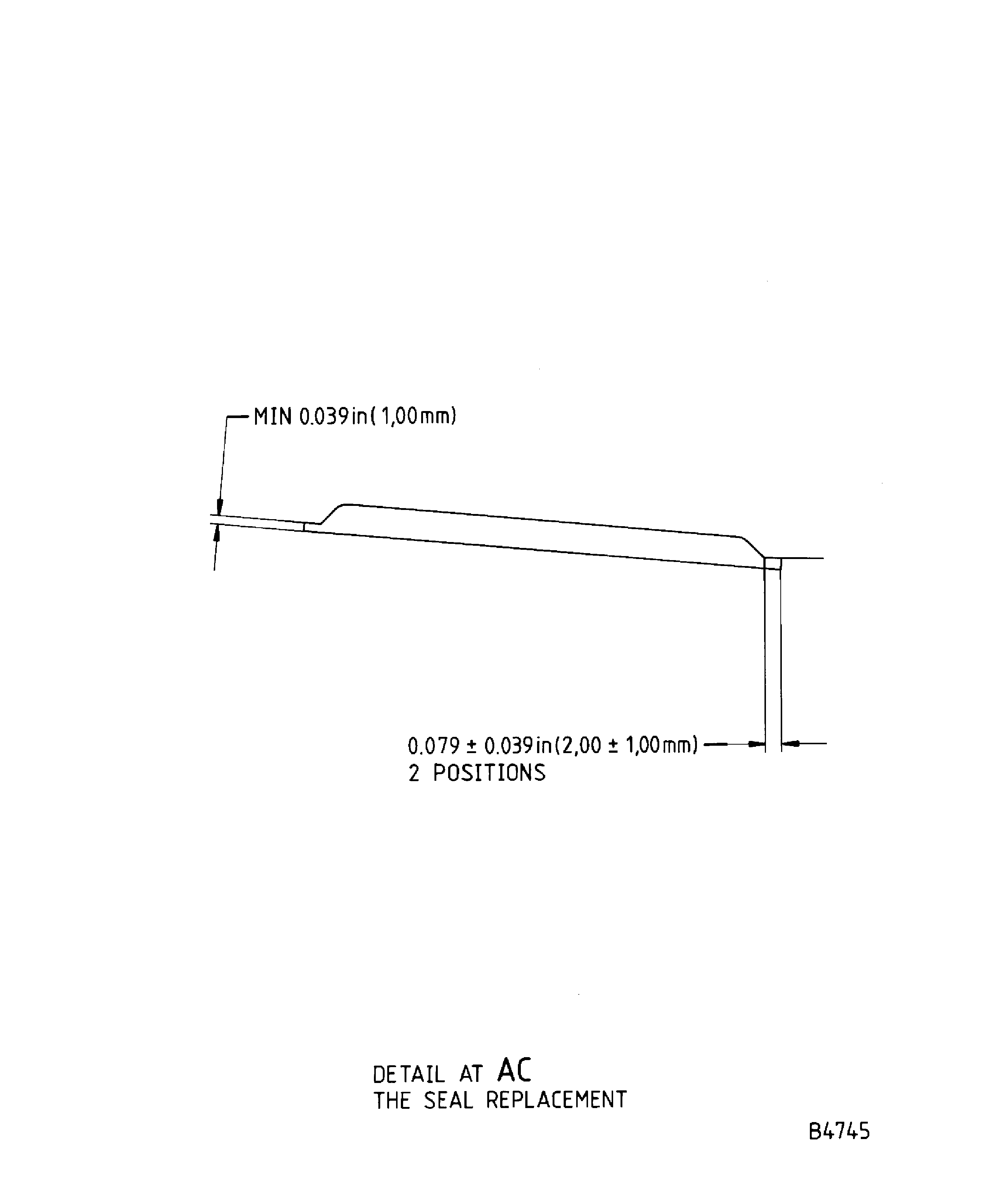

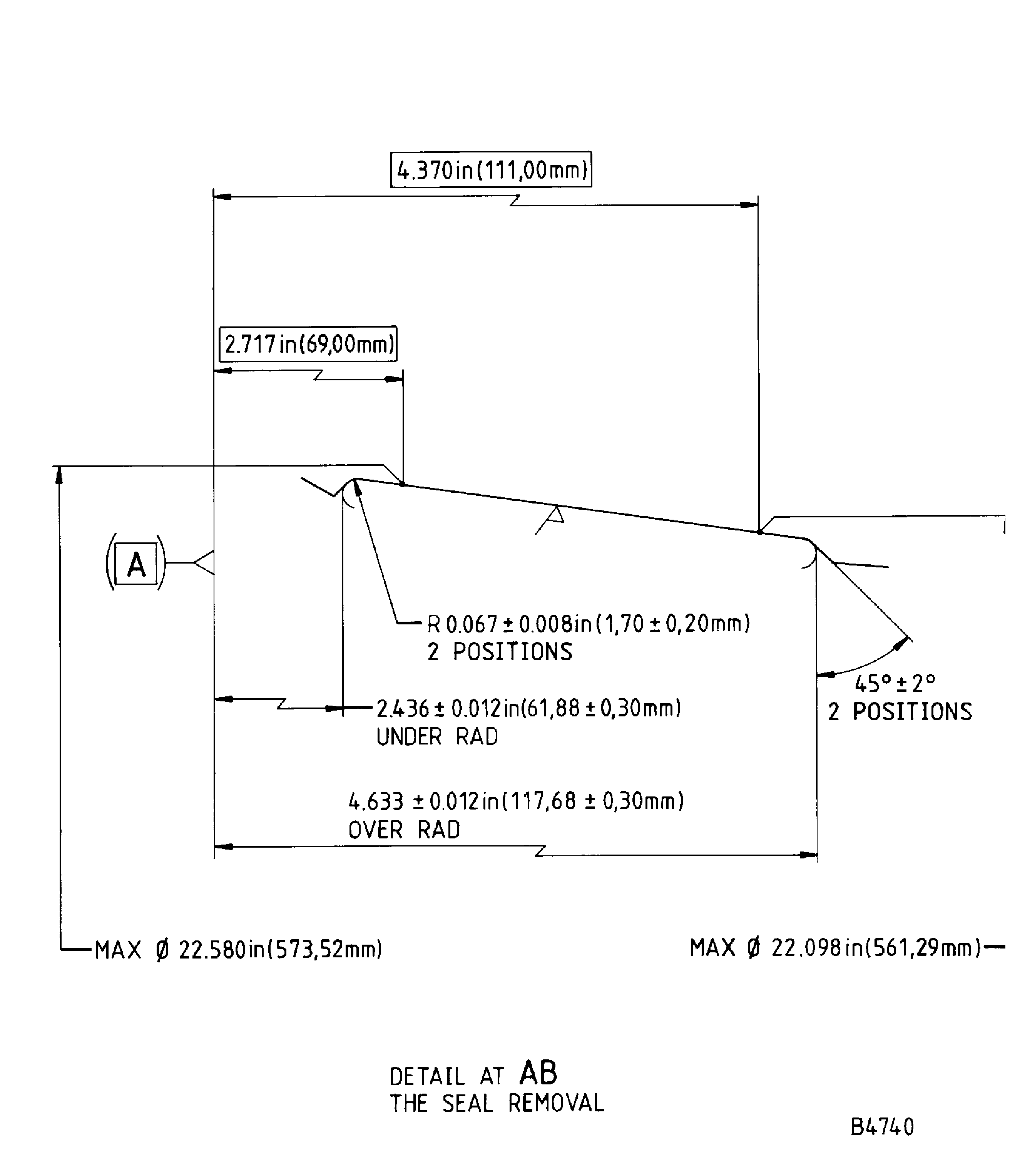

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

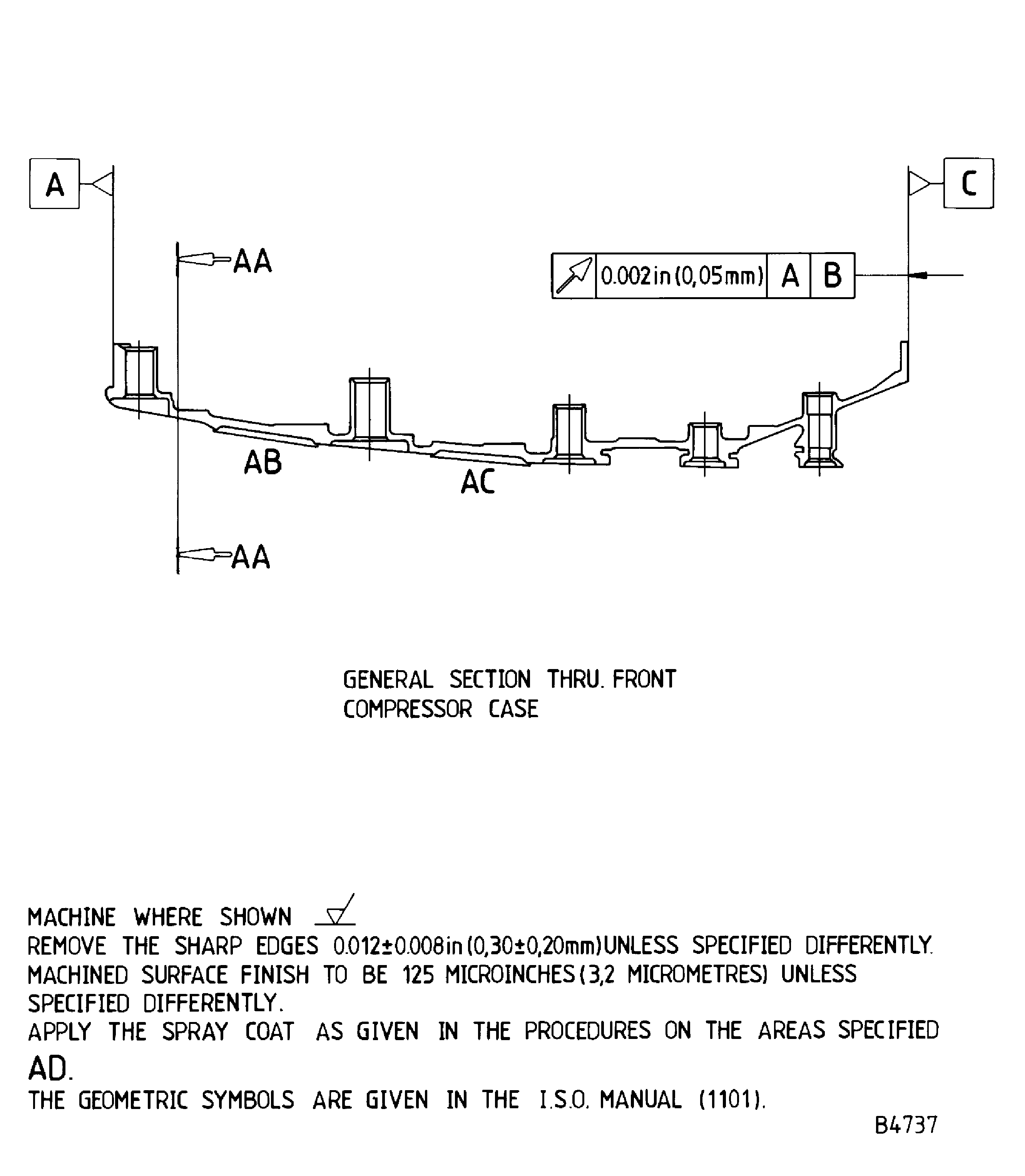

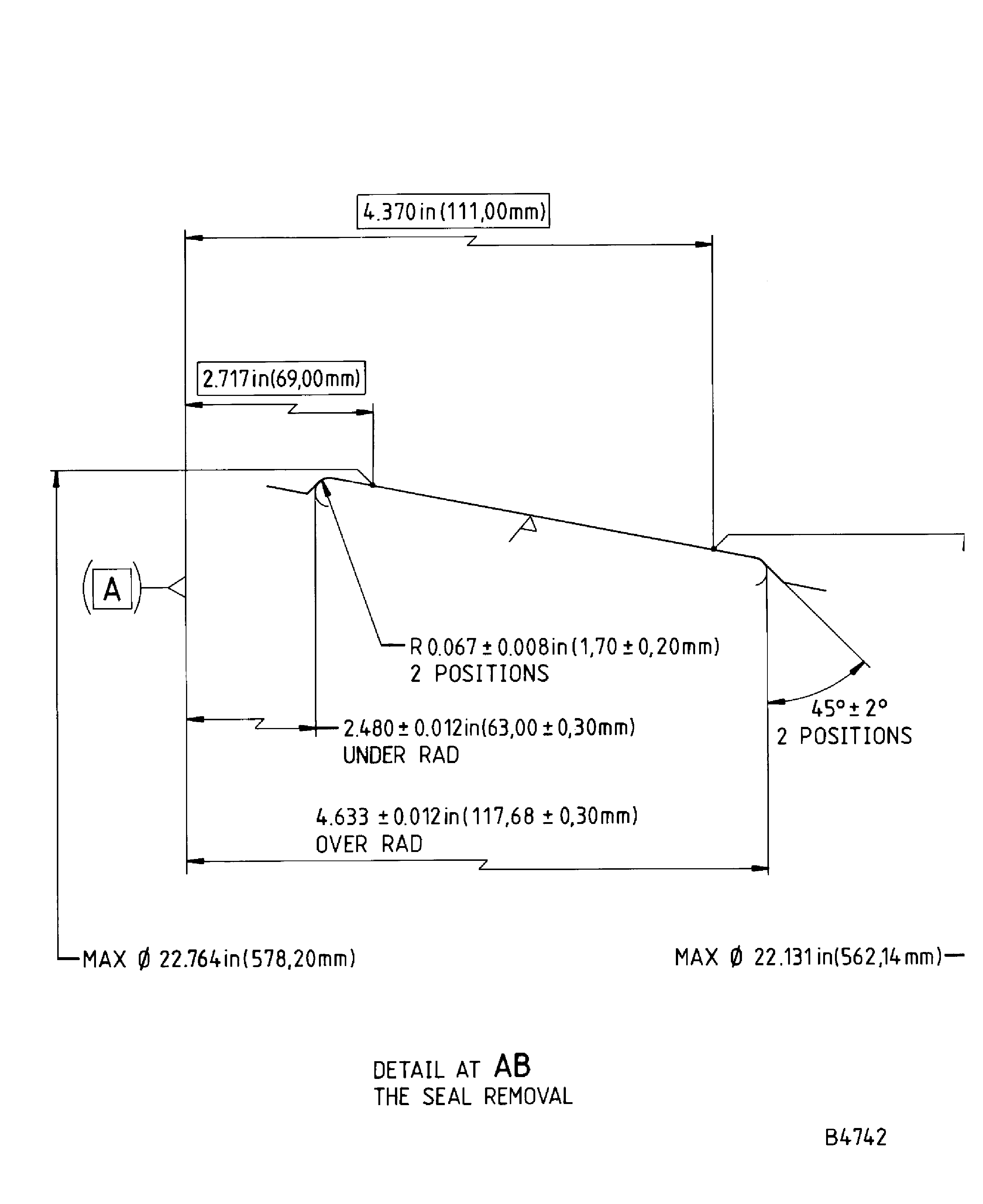

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

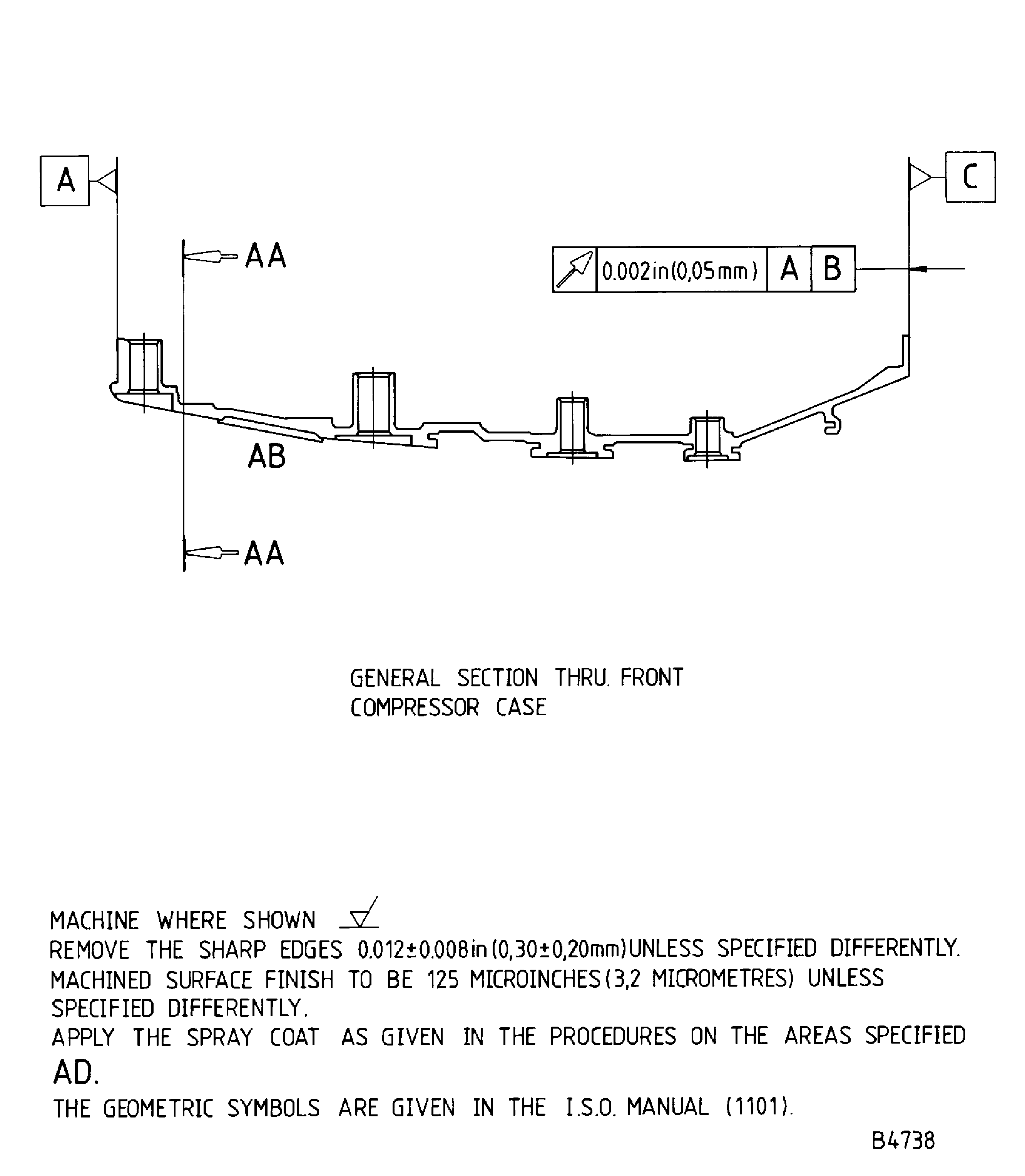

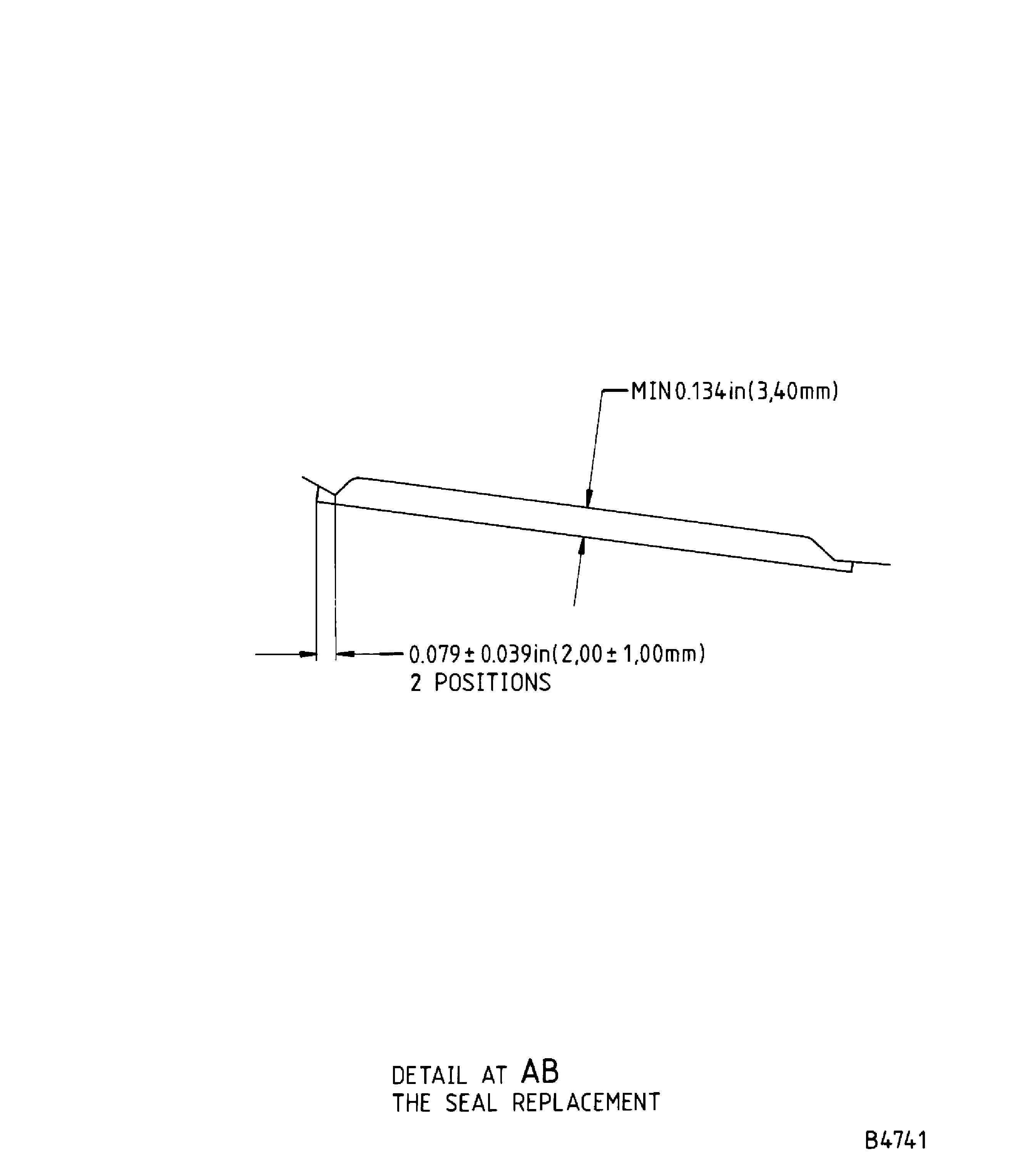

Figure: Repair details and dimensions

Repair details and dimensions

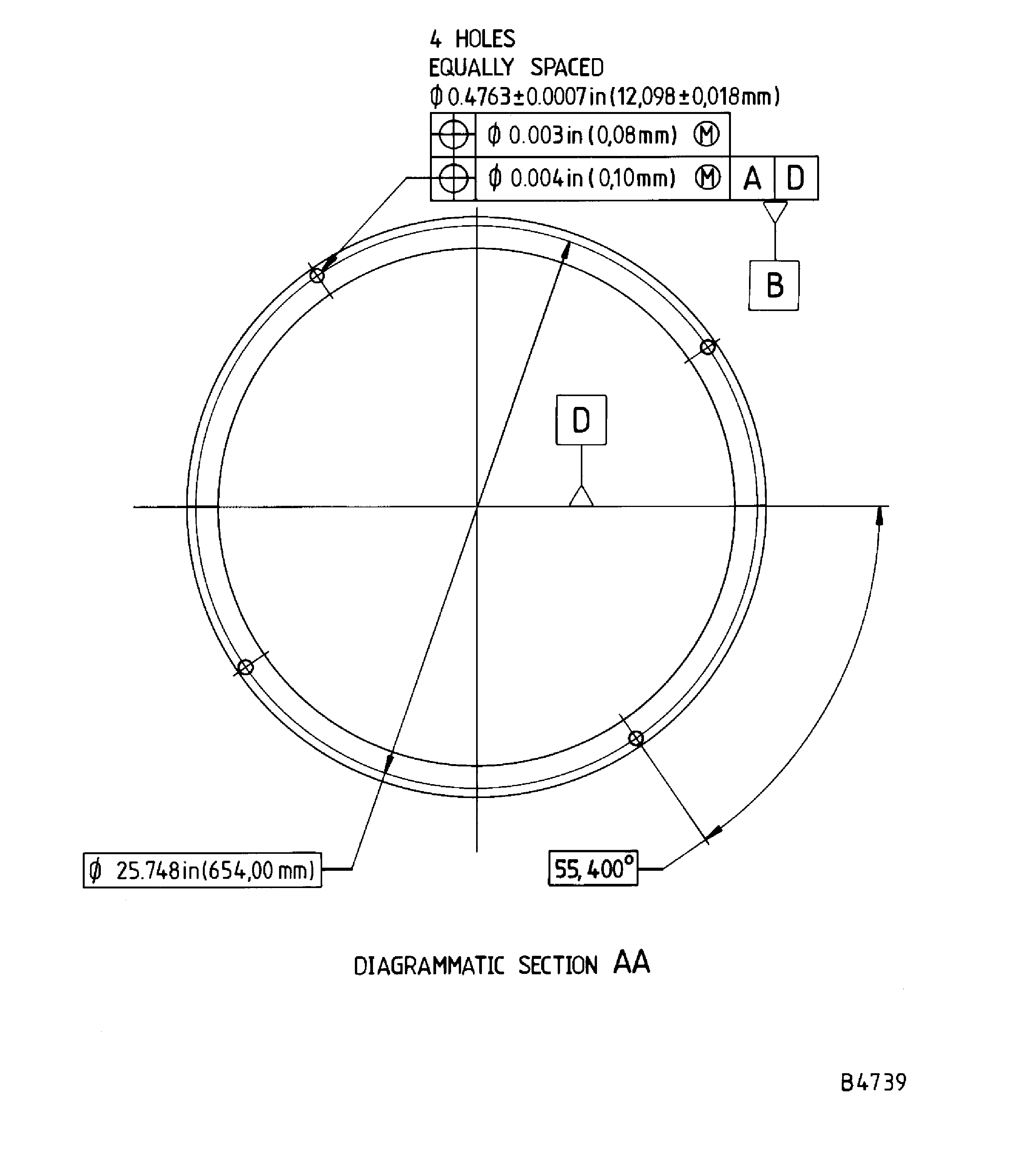

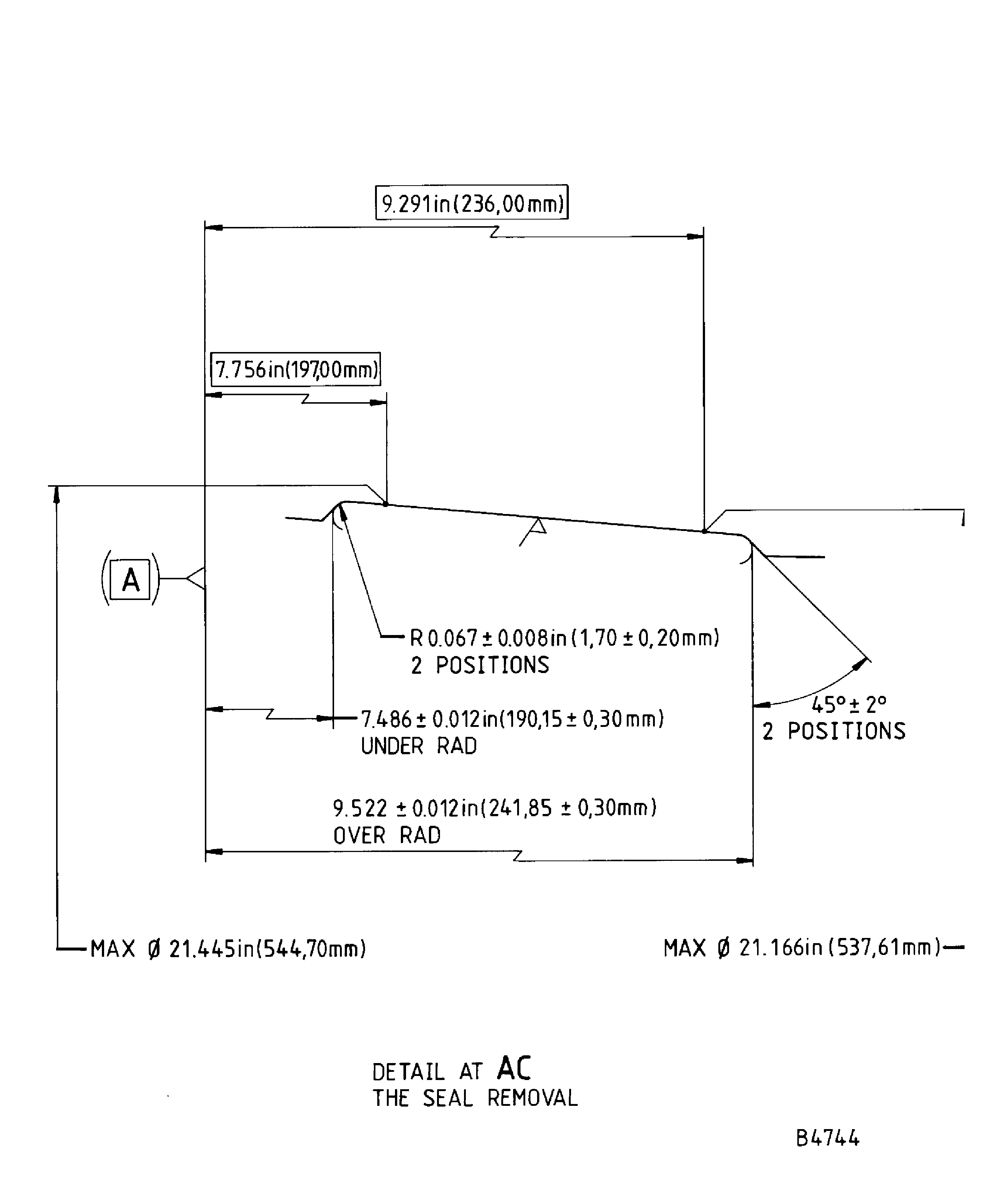

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

Figure: Repair details and dimensions - Assy B

Repair details and dimensions - Assy B

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A

Figure: Repair details and dimensions - Assy A

Repair details and dimensions - Assy A