Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-43-30-300-010 No. 4 Bearing Rear Cooling Duct - Replace Studs, Repair-010 (VRS3561)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A0891-01 |

01-010 | 2A0891-001 |

01-010 | 2A1205-01 |

01-010 | 2A1205-001 |

01-010 | 2A3078-01 |

01-010 | 2A3808-01 |

General

Price and Availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Silicon carbide wheel | LOCAL | Silicon carbide wheel | ||

| Stress-relief equipment | LOCAL | Stress-relief equipment | ||

| Welding equipment | LOCAL | Welding equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SPACER - NO. 4 BEARING COOLING DUCT | 0AM53 | 2A3383 | AR |

Safety Requirements

NONEProcedure

Use Comat 03-284 welding wire. Refer to the SPM TASK 70-31-13-310-501.

Weld the new studs into position.

SUBTASK 72-43-30-310-054 Weld the New Studs

Refer to the SPM TASK 70-35-21-350-501.

Blend the weld repaired area to the contour of the adjacent areas.

SUBTASK 72-43-30-350-063 Blend the No. 4 Bearing Cooling Duct after Weld Repair

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant inspect the cooling duct.

SUBTASK 72-43-30-230-059 Examine the No. 4 Bearing Cooling duct

Refer to the SPM TASK 70-37-01-370-501.

Stress-relieve the cooling duct.

SUBTASK 72-43-30-350-064 Stress-Relieve the No. 4 Bearing Cooling Duct

Refer to the SPM TASK 70-23-01-230-501 or SPM TASK 70-23-02-230-501.

Fluorescent penetrant inspect the cooling duct for cracks.

SUBTASK 72-43-30-230-060 Examine the No. 4 Bearing Cooling Duct for Cracks

Refer to the SPM TASK 70-09-00-400-501.

Mark VRS3561 next to part number using vibropeen method.

SUBTASK 72-43-30-380-052 Mark the Repair

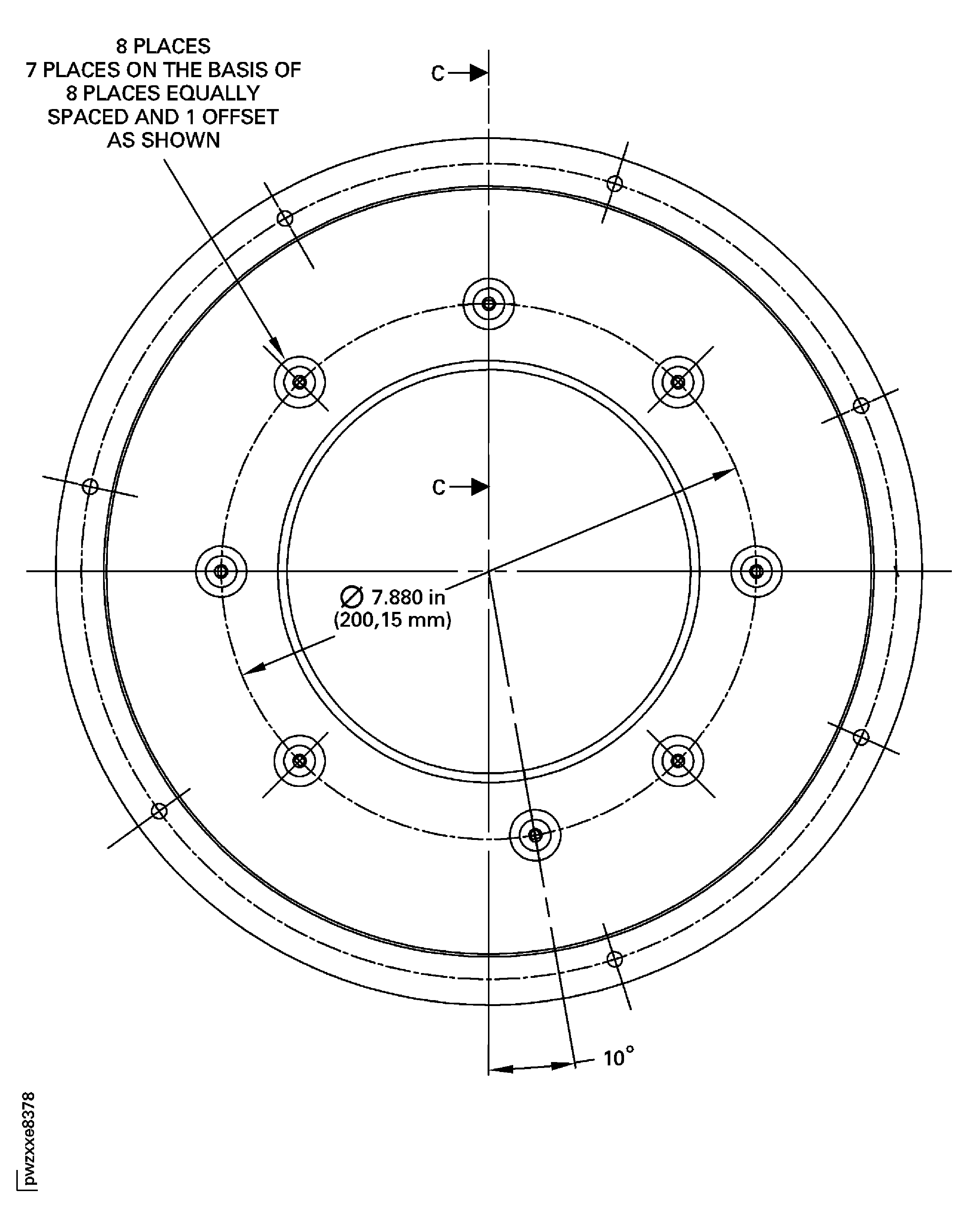

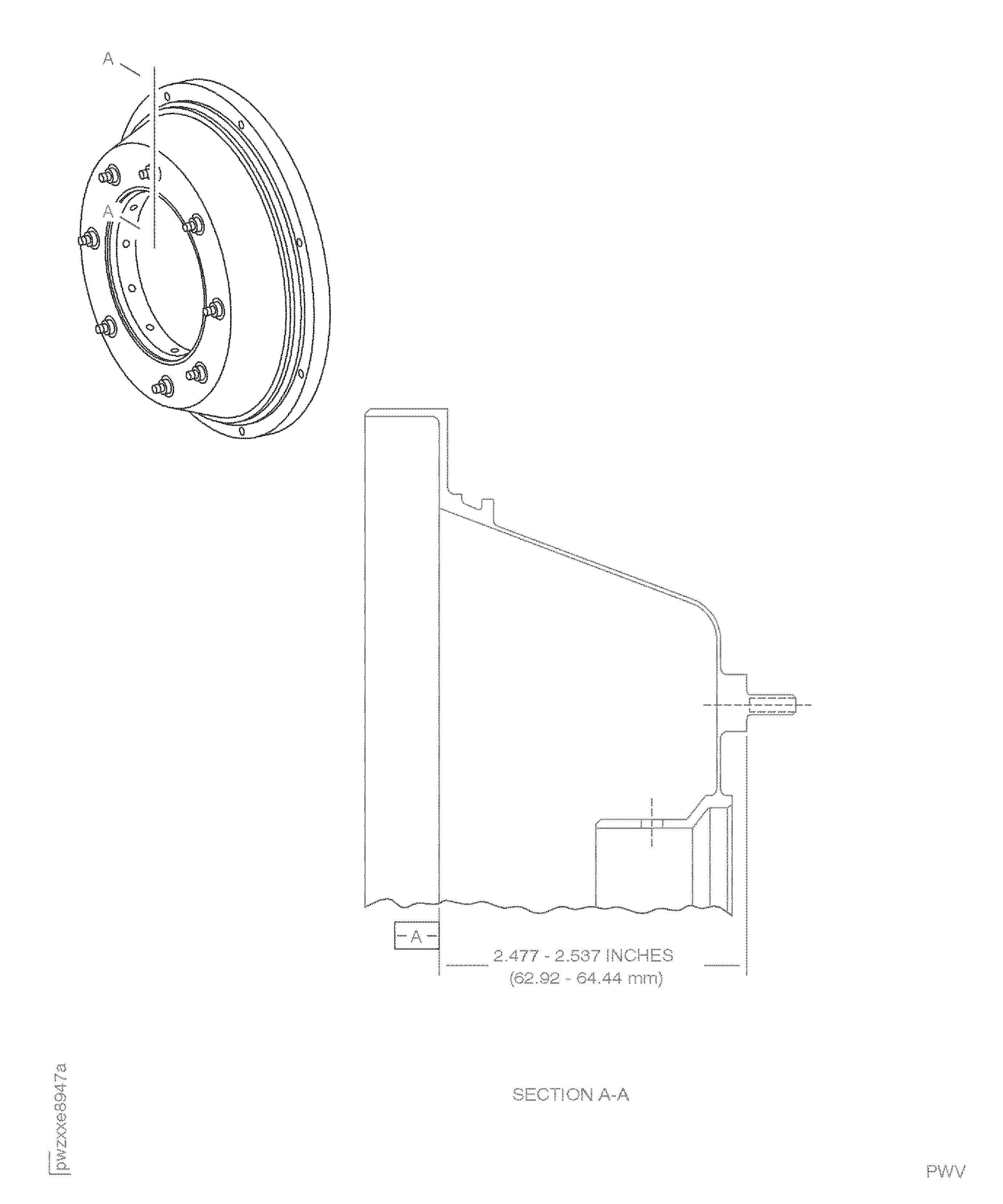

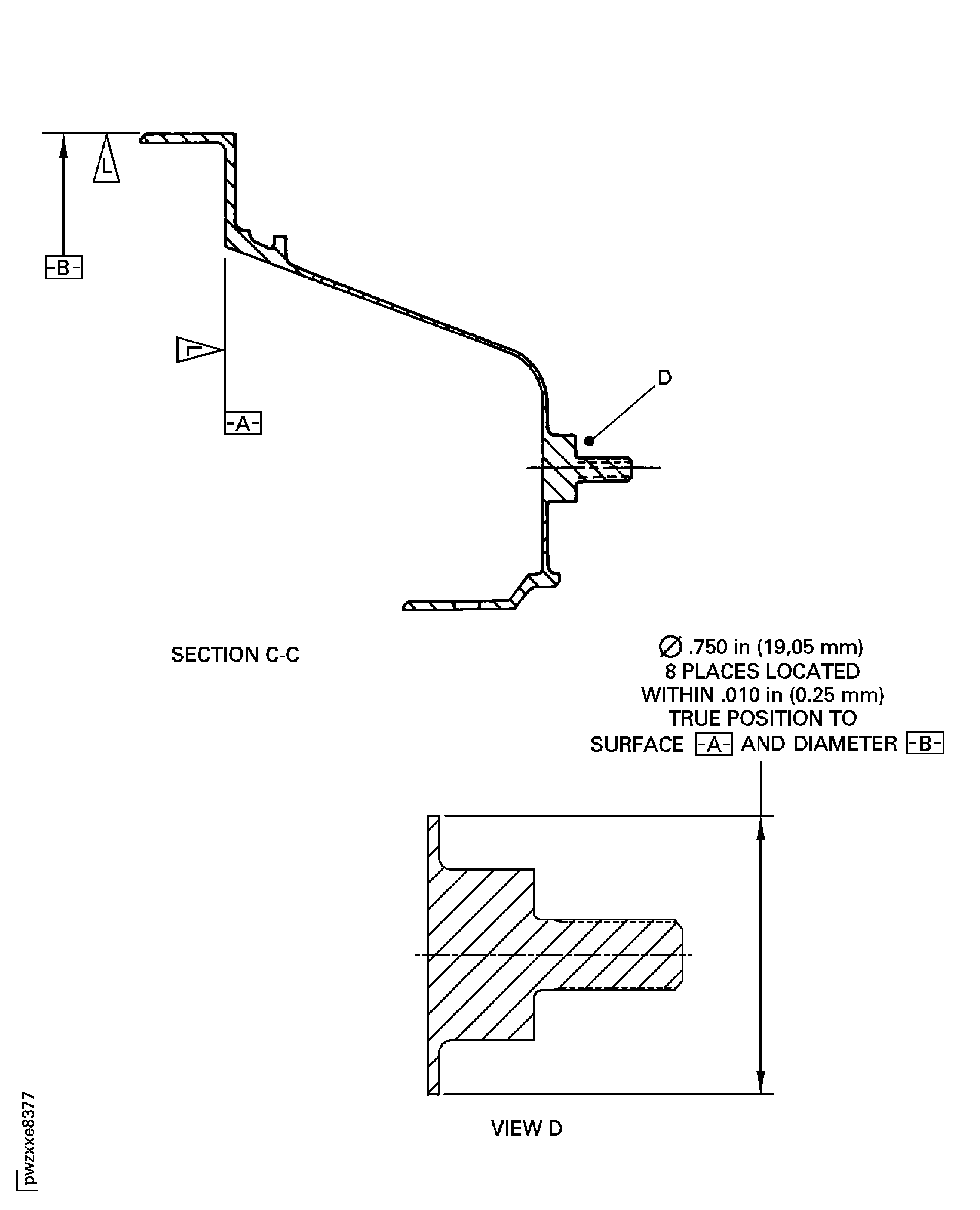

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions