Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-20-300-021 HPT Stage 1 Vane - Repair Plugged Airfoil And Platform Cooling Air Holes, Repair-021 (VRS3498)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-250 | 2A0091CL21 |

01-251 | 2A0091CL22 |

01-252 | 2A0091CL23 |

01-253 | 2A0091CL24 |

01-254 | 2A0091CL25 |

01-255 | 2A0091CL26 |

01-256 | 2A0091CL27 |

01-257 | 2A0091CL28 |

01-258 | 2A0091CL29 |

01-259 | 2A0091CL30 |

01-260 | 2A0091CL31 |

01-261 | 2A0091CL32 |

01-262 | 2A0091CL33 |

01-263 | 2A0091CL34 |

01-264 | 2A0091CL35 |

01-265 | 2A0091CL36 |

01-266 | 2A0091CL37 |

01-267 | 2A0091CL38 |

01-268 | 2A0091CL39 |

01-269 | 2A0091CL40 |

01-270 | 2A0091CL41 |

01-271 | 2A0091CL42 |

01-272 | 2A0091CL43 |

01-273 | 2A0091CL44 |

01-274 | 2A0091CL45 |

01-275 | 2A0091CL46 |

01-276 | 2A0091CL47 |

01-277 | 2A0091CL48 |

01-278 | 2A0091CL48-5 |

01-279 | 2A0091CL49 |

01-280 | 2A0091CL49-5 |

01-240 | 2A0561 |

01-250 | 2A2591CL21 |

01-251 | 2A2591CL22 |

01-252 | 2A2591CL23 |

01-253 | 2A2591CL24 |

01-254 | 2A2591CL25 |

01-255 | 2A2591CL26 |

01-256 | 2A2591CL27 |

01-257 | 2A2591CL28 |

01-258 | 2A2591CL29 |

01-259 | 2A2591CL30 |

01-260 | 2A2591CL31 |

01-261 | 2A2591CL32 |

01-262 | 2A2591CL33 |

01-263 | 2A2591CL34 |

01-264 | 2A2591CL35 |

01-265 | 2A2591CL36 |

01-266 | 2A2591CL37 |

01-267 | 2A2591CL38 |

01-268 | 2A2591CL39 |

01-269 | 2A2591CL40 |

01-270 | 2A2591CL41 |

01-271 | 2A2591CL42 |

01-272 | 2A2591CL43 |

01-273 | 2A2591CL44 |

01-274 | 2A2591CL45 |

01-275 | 2A2591CL46 |

01-276 | 2A2591CL47 |

01-277 | 2A2591CL48 |

01-279 | 2A2591CL49 |

01-284 | 2A2591CL50 |

01-286 | 2A2591CL51 |

01-240 | 2A2761 |

01-240 | 2A4201 |

01-240 | 2A4271 |

Material of component

RR | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

Stage 1 HPT vane cluster | - | Cast cobalt alloy |

assembly | ||

Stage 1 HPT vane cover | - | Nickel alloy |

Baffle assembly | - | Nickel alloy |

Cover | - | Nickel alloy |

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - not applicable

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Pin vise | LOCAL | Pin vise | ||

| Pencil blaster | LOCAL | Pencil blaster | ||

| Reamers | LOCAL | Reamers | ||

| Spring wire | LOCAL | Spring wire | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Ultrasonic cleaning equipment | LOCAL | Ultrasonic cleaning equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-155 ALUMUNUM OXIDE ABRASIVE,27 MICRON | LOCAL | CoMat 05-155 | ||

| CoMat 10-058 PENETRATING OIL | 0AM53 | CoMat 10-058 | ||

| CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE) | LOCAL | CoMat 01-339 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Cover, HPT stage 1 | 2A0033 | AR | (V2500-A1) | |

| Baffle assembly | 2A0024-01 | AR | (V2500-A1) | |

| Baffle assembly | 2A0027-01 | AR | (V2500-A1) | |

| Cover | 2A0030 | AR | (V2500-A1) | |

| Cover | 2A0031 | AR | (V2500-A1) | |

| Cover | 2A0032 | AR | (V2500-A1) | |

| Baffle assembly | 2A0534-01 | AR | (V2500-A5) | |

| Cover | 2A0536 | AR | (V2500-A5) | |

| Cover | 2A0537 | AR | (V2500-A5) | |

| Cover | 2A0538 | AR | (V2500-A5) (PN 2A0561) | |

| Cover | 2A2765 | AR | (V2500-A5) (PN 2A2761) |

Safety Requirements

NONEProcedure

Refer to Figure.

Do the procedure given in TASK 72-44-20-100-000 (CLEANING-000).

If necessary, clean the vane assembly.

Do the procedure given in TASK 72-44-20-300-005 (VRS3152) (REPAIR-005).

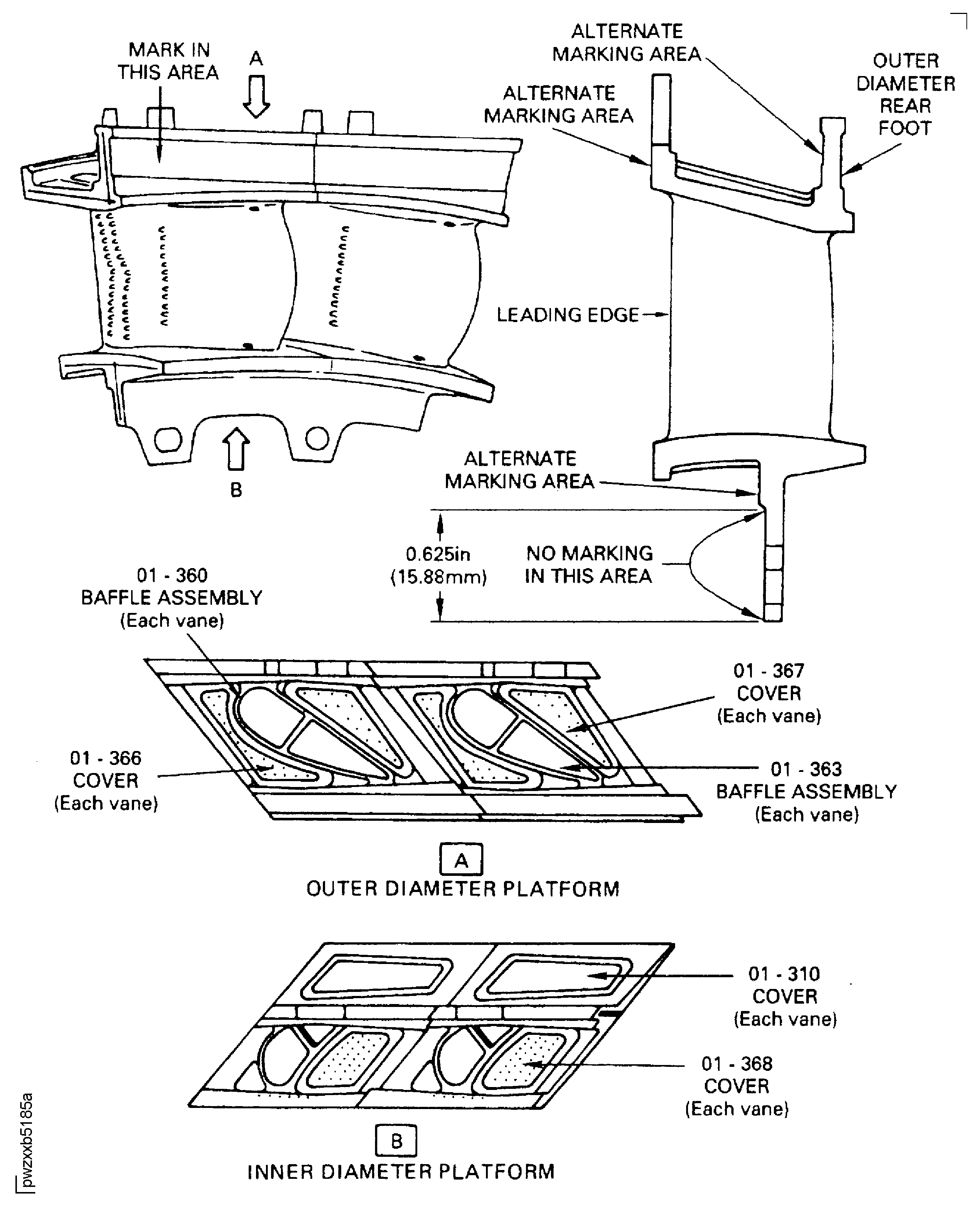

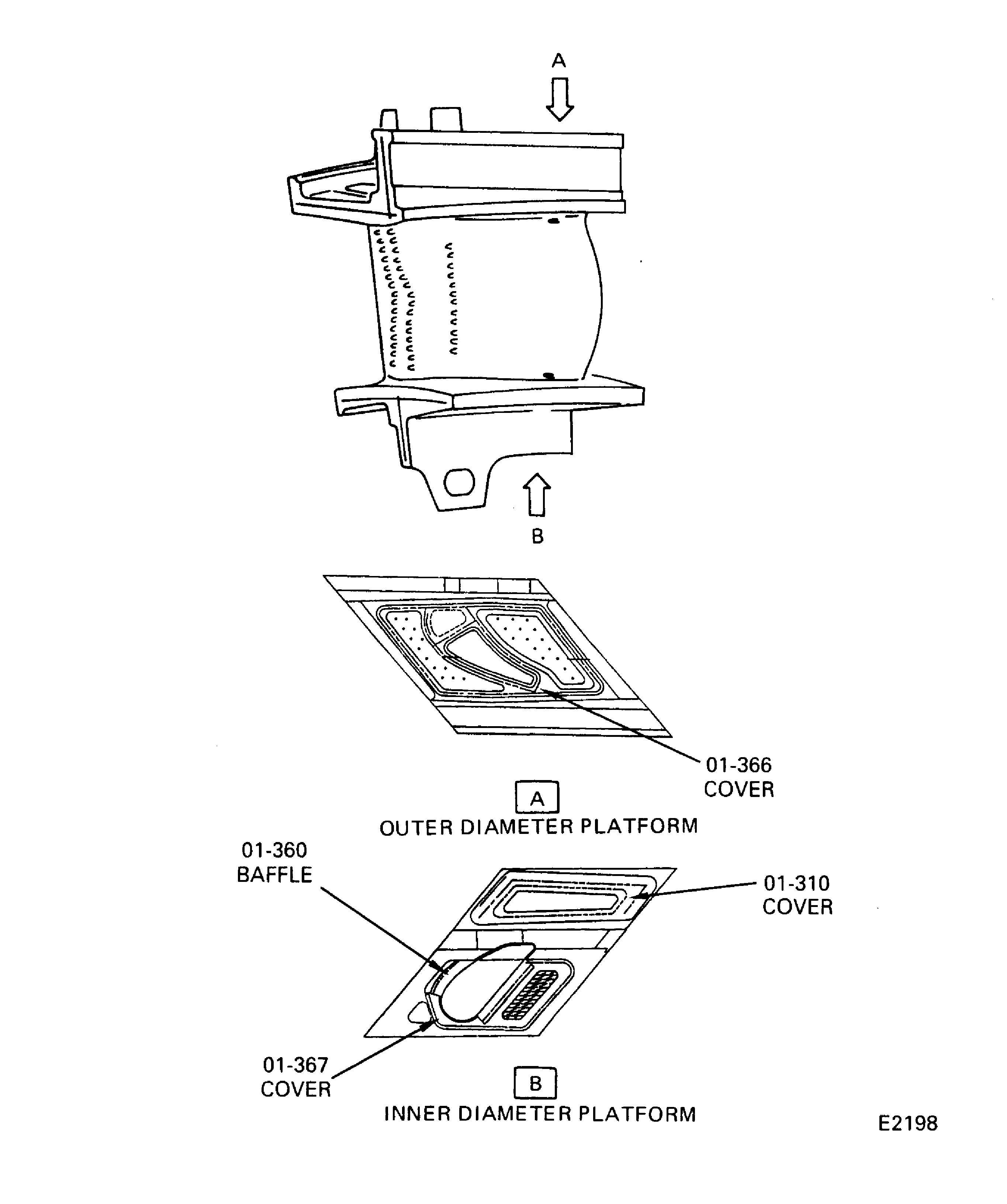

If necessary, remove the vane covers.

Do the procedure given in TASK 72-44-20-300-014 (VRS3153) (REPAIR-014).

If necessary, remove the vane baffle assemblies.

SUBTASK 72-44-20-350-058-A00 V2500-A1 Prepare the Vane Cluster for Unplugging the Cooling Air Holes

Refer to Figure.

Do the procedure given in TASK 72-44-20-100-000 (CLEANING-000).

If necessary, clean the vane assembly.

Do the procedure given in TASK 72-44-20-300-022 (VRS3541) (REPAIR-022).

If necessary, remove the vane baffle assemblies.

SUBTASK 72-44-20-350-058-B00 V2500-A5 Prepare the Vane for Unplugging the Cooling Air Holes

If necessary, apply CoMat 10-058 PENETRATING OIL to vane cooling air hole areas.

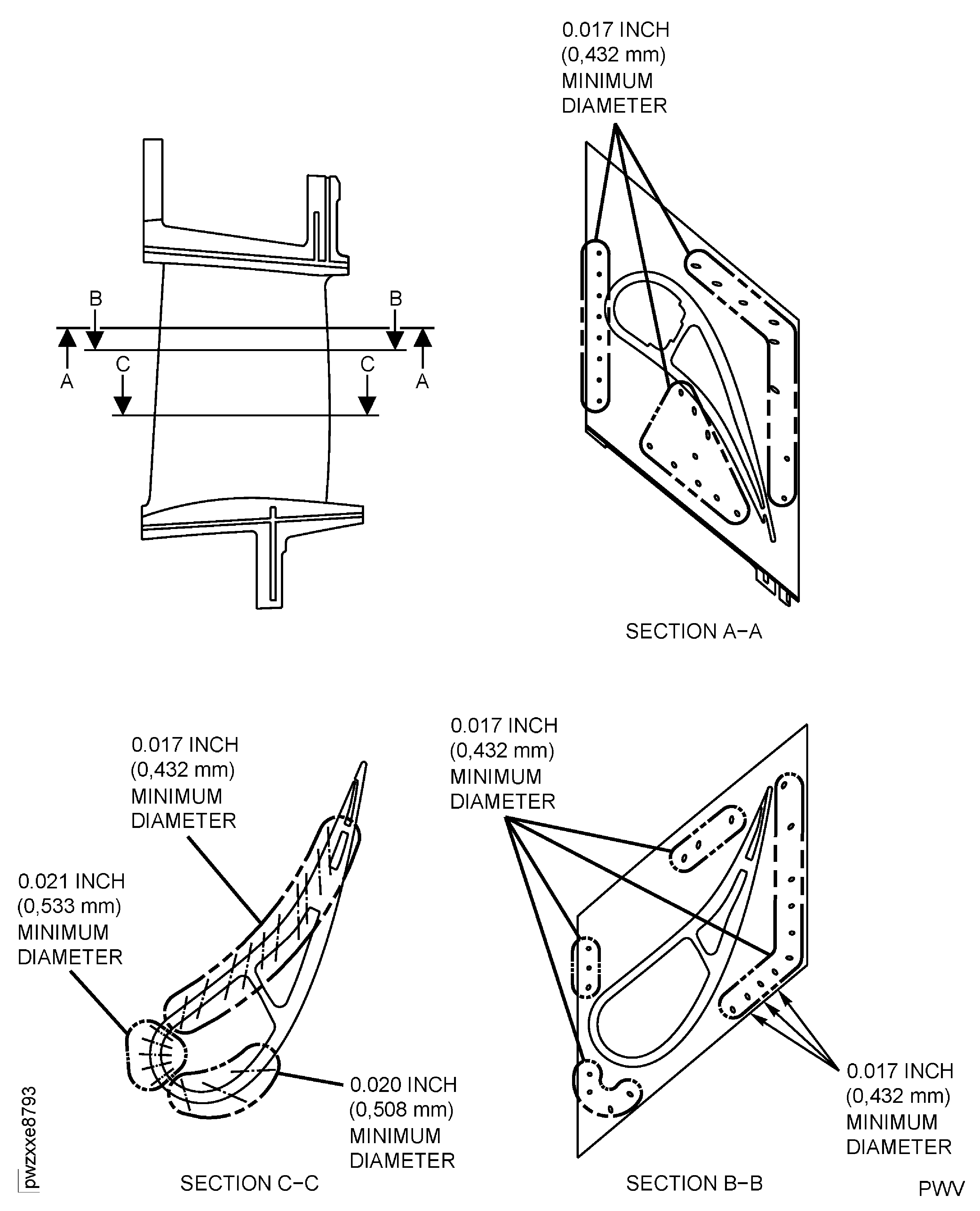

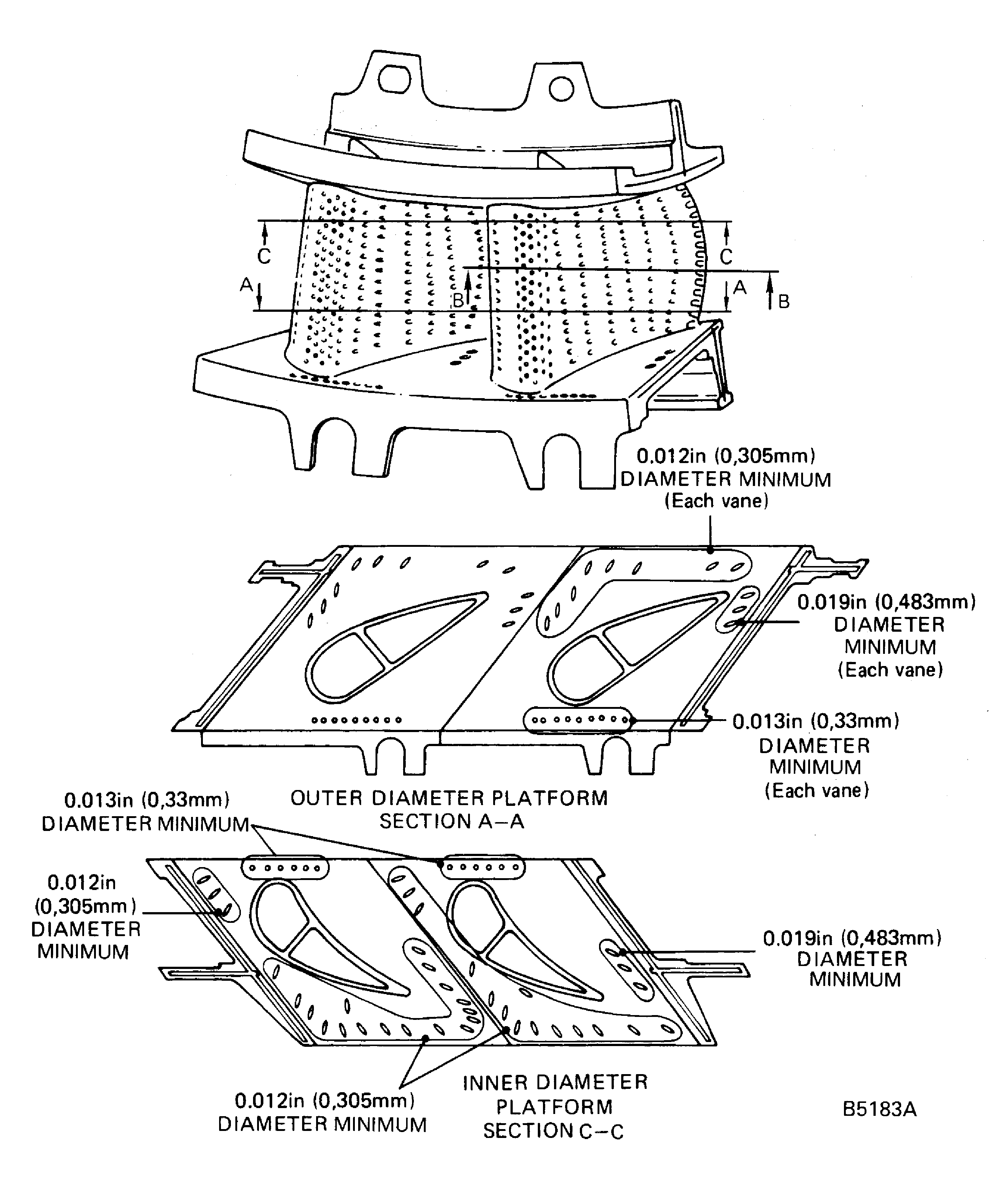

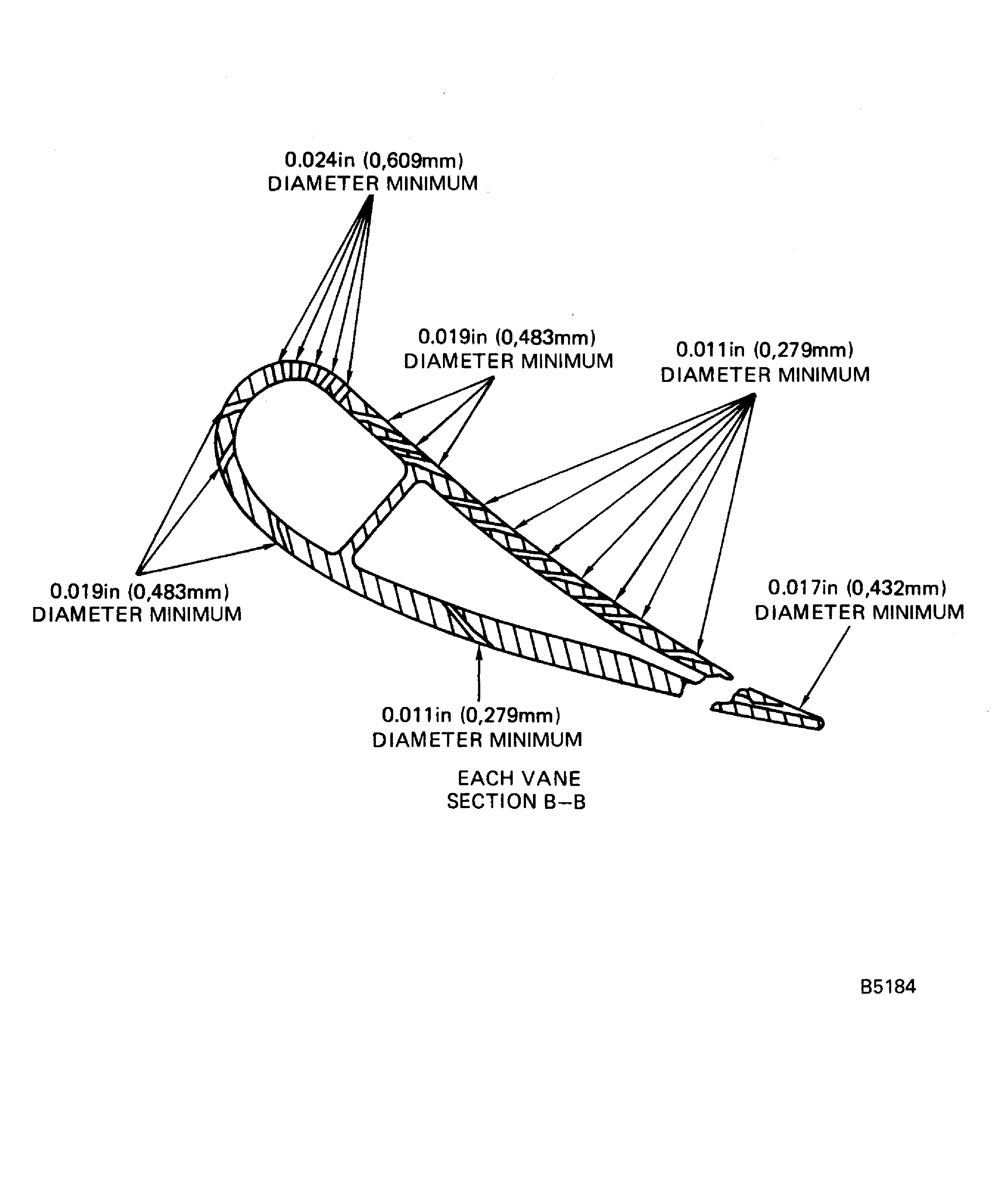

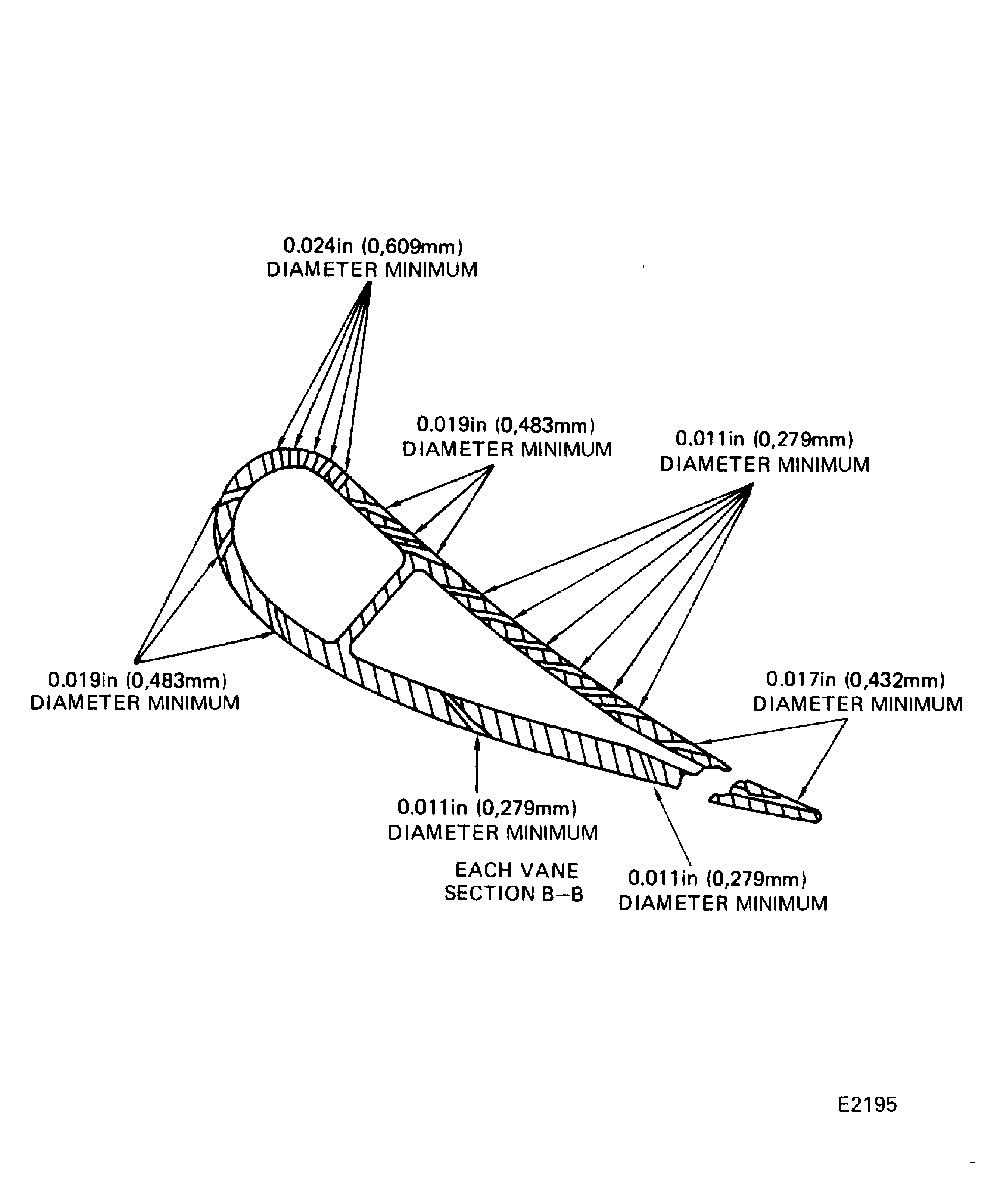

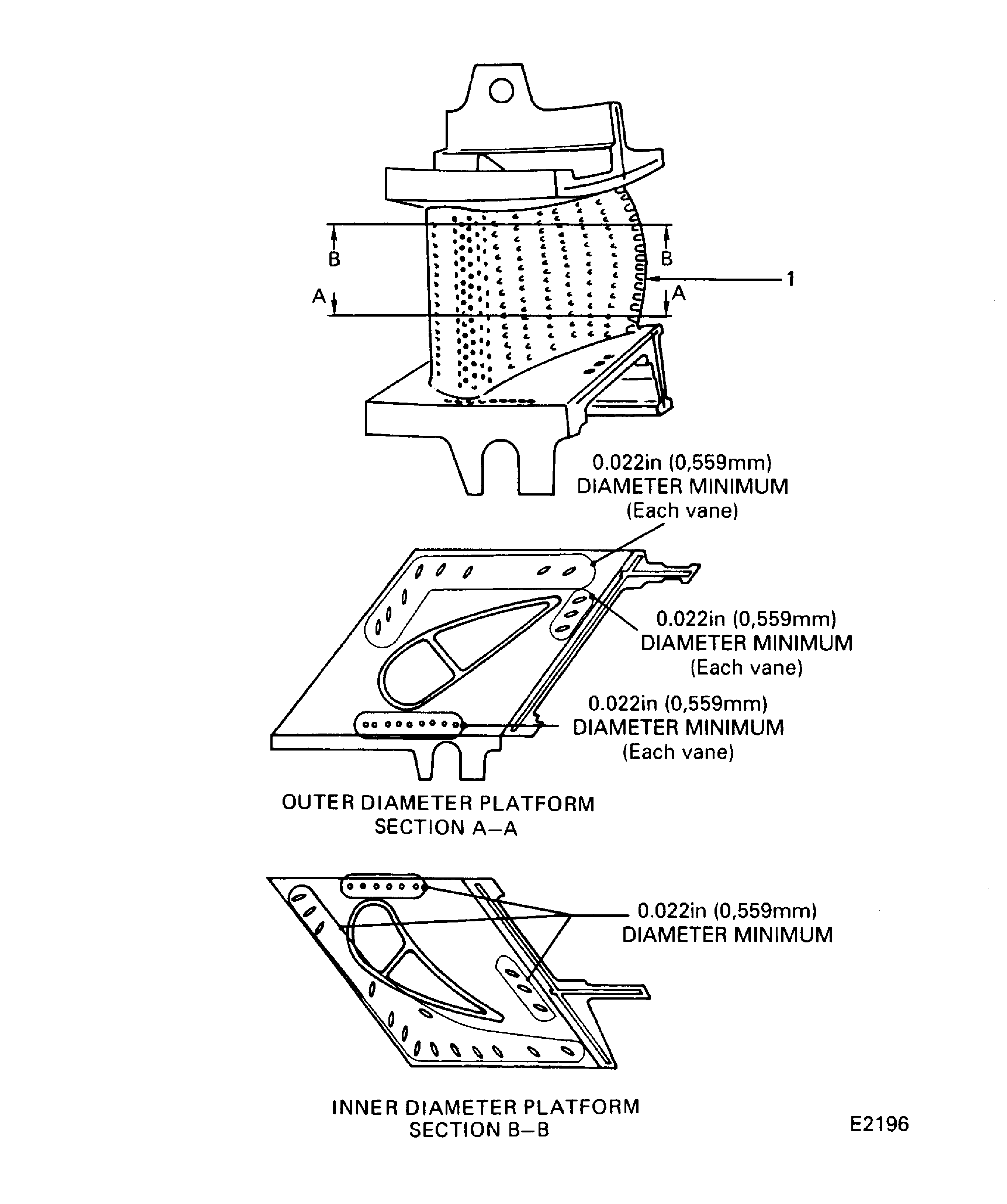

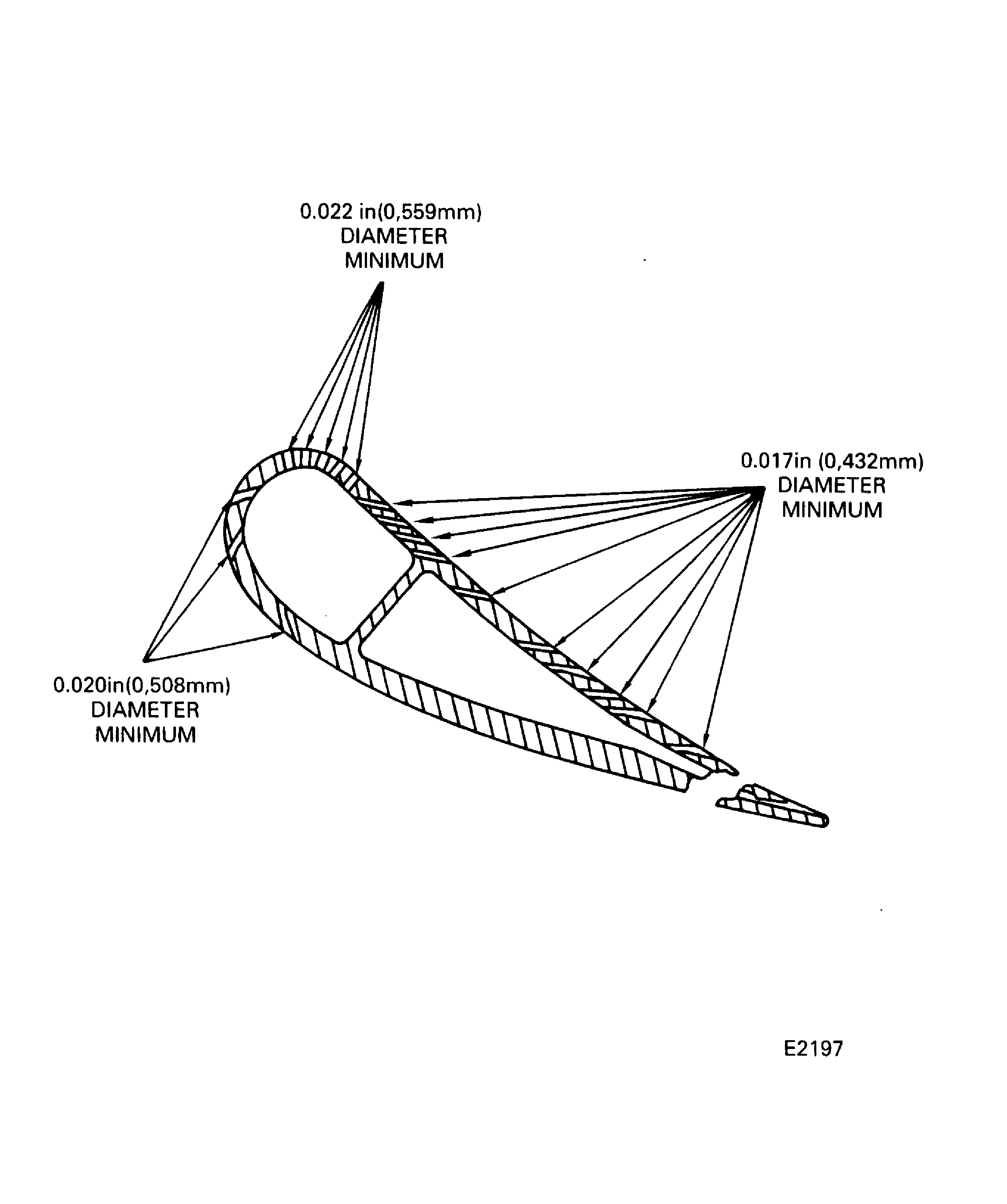

Use a reamer or spring wire with the correct diameter for each of the holes given in the figure.

If the covers and baffles are removed, be careful not to force debris in the interior of the vane.

The use of spring wire with a pin vise can be used between the airfoils if a longer range is necessary.

Cut the end of the spring wire at an angle.

Hand probe the holes and use a rotary motion. Move the reamer or wire slowly into the hole while probing. Remove the tool intermittently and hold the vane with the cooling air holes down to permit the debris to fall out.

Do not damage the coating when you hand probe the holes.

Hand probe the cooling air holes with reamers and/or spring wire to remove the foreign material or blockage.

SUBTASK 72-44-20-350-059-001 Unplug the Vane Airfoils and Platforms Cooling Air Holes (Hand Probe)

If necessary, apply CoMat 10-058 PENETRATING OIL to vane cooling air hole areas.

If the covers and baffles are not removed, the internal vane surfaces must be dry before you do the grit blast procedure.

Do the procedure given in TASK 72-44-20-100-000 (CLEANING-000).

If necessary, clean the vane assembly to remove the penetrating oil.

Use a Pencil blaster with a 0.011 in. (0.28 mm) nozzle to blast the blockage.

If the covers and baffles are removed, be careful not to force debris in the interior of the vane.

Grit blast the cooling air holes to remove the foreign material or blockage.

The use of Spring wire with a Pin vise can be used between the airfoils if a longer range is necessary.

Cut the end of the spring wire at an angle.

Hand probe the holes and use a rotary motion. Move the reamer or wire slowly into the hole while probing. Remove the tool intermittently and hold the vane with the cooling air holes down to permit the debris to fall out.

If necessary, hand probe the airfoil and platform holes to the diameter given in the figure.

SUBTASK 72-44-20-350-059-002 Unplug the Vane Airfoils and Platforms Cooling Air Holes (Grit Blast)

Do the procedure given in the SPM TASK 70-13-02-300-503 at a maximum of 150 deg F (65.6 deg C). Use CoMat 01-339 ALKALI CLEANER (GENERAL PURPOSE). Mix the solution by the procedure given in the SPM TASK 70-11-48-110-501.

Position the vane assembly at different angles when you clean the vane to flush out the unwanted material located inside the internal cavities.

NOTE

The ultrasonics will increase the temperature of the solution.Ultrasonic clean the internal vane passages to remove the debris.

SUBTASK 72-44-20-130-055 Clean the Internal Passages on the Vane Assembly

Refer to Figure.

Do the procedure given in the SPM TASK 70-28-01-280-501.

The ceramic platform coating cannot be seen by the heat tint check.

Do a heat tint check on the airfoils and platforms. This is an optional procedure.

SUBTASK 72-44-20-220-068 V2500-A1 Examine the Vane Cluster Assembly by Heat Tint

Refer to Figure.

Do the procedure given in TASK 72-44-20-300-007 (VRS3165) (REPAIR-007).

Try to prevent the coating from going into the cooling air holes when you do the touch-up. If necessary, after the coating is baked, pierce the thin coating over the holes with spring wire.

If necessary, touch-up the coating on the airfoils.

Do the procedure given in TASK 72-44-20-300-015 (VRS3164) (REPAIR-015).

If necessary, touch-up the coating on the platforms.

SUBTASK 72-44-20-350-060-A00 V2500-A1 Touch-up the Airfoils and Platforms Coating

Refer to Figure.

Do the procedure given in TASK 72-44-20-300-015 (VRS3164) (REPAIR-015).

If necessary, touch-up the coating on the platforms.

SUBTASK 72-44-20-350-060-B00 V2500-A5 Touch-up the Platforms Coating

Refer to Figure.

Do the procedure given in TASK 72-44-20-300-005 (VRS3152) (REPAIR-005).

If necessary, install the vane covers.

Do the procedure given in TASK 72-44-20-300-014 (VRS3153) (REPAIR-014).

If necessary, install the vane baffle assemblies.

SUBTASK 72-44-20-350-061-A00 V2500-A1 Install the Vane Cluster Covers and Baffles

Refer to Figure.

Do the procedure given in TASK 72-44-20-300-022 (VRS3541) (REPAIR-022).

If necessary, install the vane baffle assemblies.

SUBTASK 72-44-20-350-061-B00 V2500-A5 Install the Vane Covers and Baffles

Do the procedure given in TASK 72-44-20-200-000 (INSPECTION/CHECK-000) except you can correct the airflow that is under the limits by hand probing or grit blasting. Increase the hole size in small increments. Do not hand probe or grit blast all the holes at one time or you can create an airflow that is over the limits.

Any vane airflow that is higher than the limit given is not acceptable.

Do an airflow check on the airfoil cooling air holes.

SUBTASK 72-44-20-220-069 Examine the Vane Cluster Assembly by the Airflow Check

Mark a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501.

Use the vibration peen method.

Mark VRS3498 adjacent to the part number or on one of the alternate marking areas.

SUBTASK 72-44-20-350-062 Mark the Repair

Figure: Repair Details and Dimensions (V2500-A1)

Repair Details and Dimensions (V2500-A1)

Figure: Repair Details and Dimensions (V2500-A5)

Repair Details and Dimensions (V2500-A5)

Figure: Repair Details and Dimensions (V2500-A1)

Sheet 1

Figure: Repair Details and Dimensions (PN 2A0091) (V2500-A1)

Sheet 2

Figure: Repair Details and Dimensions (PN 2A2591) (V2500-A1)

Sheet 3

Figure: Repair Details and Dimensions (V2500-A5)

Sheet 1

Figure: Repair Details and Dimensions (V2500-A5)

Sheet 2

Figure: Repair Details and Dimensions (PN 2A4271) (V2500-A5)

Repair Details and Dimensions (PN 2A4271) (V2500-A5)