Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-50-300-011 HPT Stage 1 Cooling (TOBI) Duct - Weld Repair Cracks And/Or Burns on The Outer Flange, Repair-011 (VRS3558)

Effectivity

FIG/ITEM | PART NO. | |

|---|---|---|

01-010 | 2A0008-01 | |

01-010 | 2A1997-01 | |

01-010 | 2A1997-001 | |

01-010 | 2A1997-002 | |

01-010 | 2A1997-003 | |

01-010 | 2A2141-01 | |

01-010 | 2A3180-01 | |

01-010 | 2A3329-01 | |

01-010 | 2A3487-01 | |

01-010 | 2A3487-001 | |

01-010 | 2A3491-01 | |

01-010 | 2A3914-01 | |

01-010 | 2A3914-001 | |

01-010 | 2A4086 |

General

The practices and processes referred to in this procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Welding equipment | LOCAL | Welding equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 | ||

| CoMat 05-146 WHEEL, SILICON CARBIDE ABRASIVE COAT DELETED | 0AM53 | CoMat 05-146 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Locating Pin | 2A0869 | AR |

Safety Requirements

NONEProcedure

Refer to Figure.

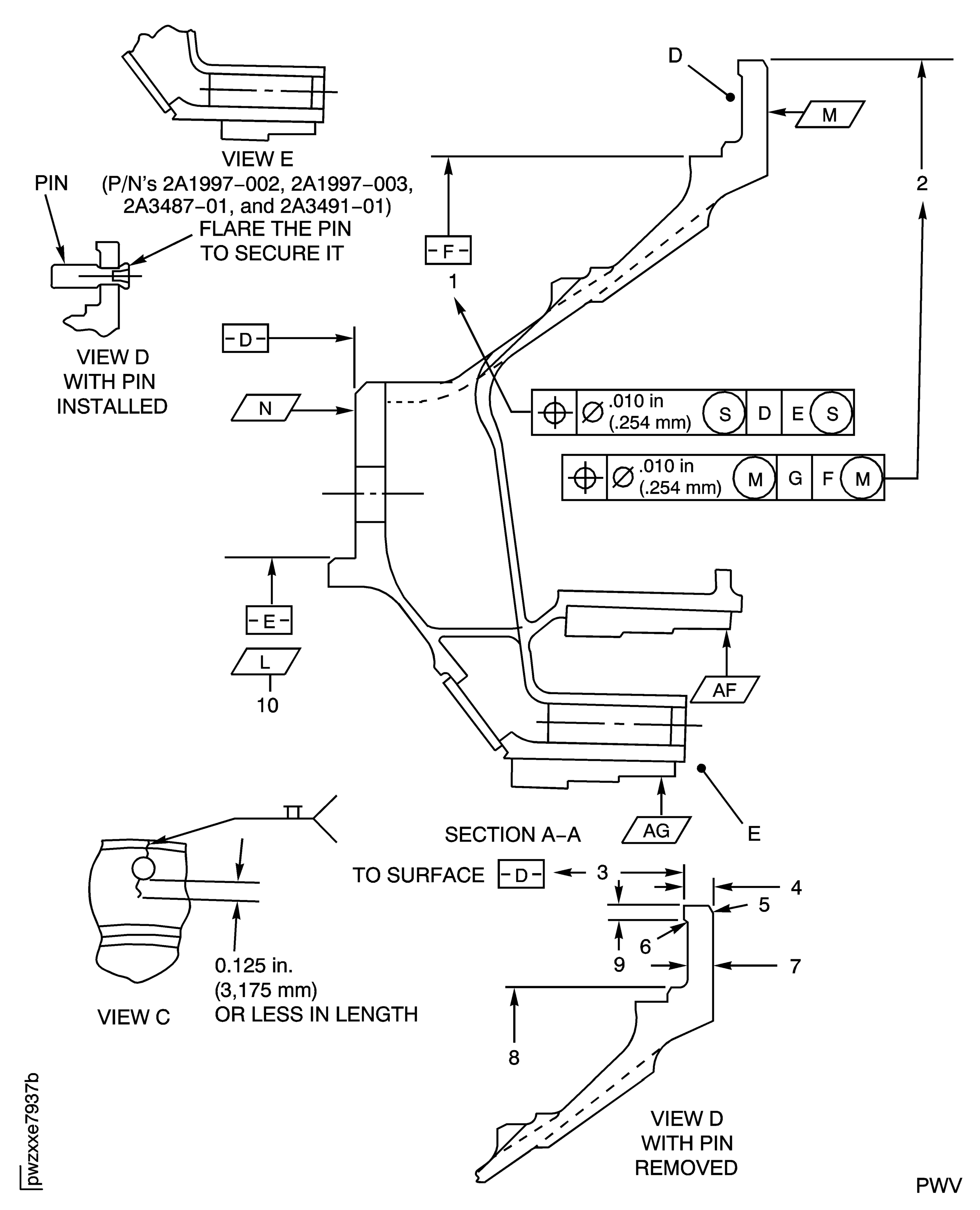

SUBTASK 72-44-50-350-077 Remove the Locating Pin from the Stage 1 HPT Cooling Duct

Refer to the SPM TASK 70-31-02-310-501-011.

Prepare the part for weld.

SUBTASK 72-44-50-350-078 Remove Cracks or Burns in the Flange before Weld Repair and Weld Preparation

Refer to the SPM TASK 70-23-05-230-501.

Use fluorescent penetrant (medium post-emulsified).

Fluorescent penetrant inspect the repair area. No cracks permitted.

SUBTASK 72-44-50-230-065 Fluorescent Penetrant Inspect the Stage 1 HPT Cooling Duct

Refer to the SPM TASK 70-11-26-300-503.

Clean the area to be welded.

SUBTASK 72-44-50-120-051 Clean the Area to be Welded

Refer to Figure for dimensional requirements for the duct flange.

It is recommended that you use a one inch (25.400 mm) thick steel plate as a fixture to minimize distortion during welding.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE and the manual gas tungsten arc weld method.

Refer to the SPM TASK 70-31-02-310-501-011.

Weld to repair the cracks and burns you routed out.

SUBTASK 72-44-50-310-052 Weld to Repair Damage in the Stage 1 HPT Cooling Duct

Refer to the SPM TASK 70-23-05-230-501.

Use fluorescent penetrant (medium post-emulsified).

Do a fluorescent penetrant inspection of the repaired area. No cracks permitted.

SUBTASK 72-44-50-370-057 Optional, Fluorescent Penetrant Inspect the Stage 1 HPT Cooling Duct

NOTE

Solution heat treat may be done concurrent with honeycomb brazing cycle in VRS3179, TASK 72-44-50-300-003 (REPAIR-003).Hold at 1125 to 1175 deg F (607.222 to 635 deg C) for eight hours.

SUBTASK 72-44-50-370-058 Solution Heat Treat and Precipitation Harden the Stage 1 HPT Cooling Duct

Refer to the SPM TASK 70-23-05-230-501.

Use fluorescent penetrant (medium post-emulsified).

Refer to the SPM TASK 70-23-01-230-501.

Do a fluorescent penetrant inspection of the part. No cracks permitted.

SUBTASK 72-44-50-230-067 Fluorescent Penetrant Inspect the Stage 1 HPT Cooling Duct

Refer to Figure.

SUBTASK 72-44-50-220-077 Examine the Stage 1 HPT Cooling Duct for Hardness

Refer to the dimensions given in the figure and TASK 72-44-50-200-000 (INSPECTION-000).

Finish machine the bolt holes and flange.

SUBTASK 72-44-50-320-077 Machine the Bolt Holes and Flange of the Stage 1 HPT Cooling Duct

Refer to TASK 72-44-50-200-000 (INSPECTION-000).

Examine the repair.

SUBTASK 72-44-50-220-108 Examine the Repair

Refer to Figure.

SUBTASK 72-44-50-350-070 Install a New Locating Pin to the Stage 1 HPT Cooling Duct

Refer to Figure.

SUBTASK 72-44-50-350-079 Remove the Locating Pin from the Stage 1 HPT Cooling Duct

Refer to Figure for dimensional requirements for the duct flange.

It is recommended that you use a one inch (25.400 mm) thick steel plate as a fixture to minimize distortion during welding.

Use CoMat 03-284 WELDING FILLER WIRE, NiBASE and the manual gas tungsten arc method.

Refer to TASK 70-31-02-310-501-001.

Weld to repair the cracks and burns you routed out.

SUBTASK 72-44-50-310-056 Weld to Repair Damage in the Stage 1 HPT Cooling Duct

Refer to Figure.

SUBTASK 72-44-50-220-077 Examine the Stage 1 HPT Cooling Duct for Hardness

Refer to the SPM TASK 70-23-05-230-501.

Fluorescent penetrant inspect the duct for stress cracks in the welded areas and the flange areas adjacent to the welds. No cracks are permitted.

SUBTASK 72-44-50-230-069 Fluorescent Penetrant Inspect the Stage 1 HPT Cooling Duct after Heat Treat

Refer to the dimensions given in the figure and TASK 72-44-50-200-000 (INSPECTION-000).

Finish machine the bolt holes and flange.

SUBTASK 72-44-50-320-078 Machine the Bolt Holes and Flange of the Stage 1 HPT Cooling Duct

Refer to Figure.

SUBTASK 72-44-50-350-080 Install a New Locating Pin to the Stage 1 HPT Cooling Duct

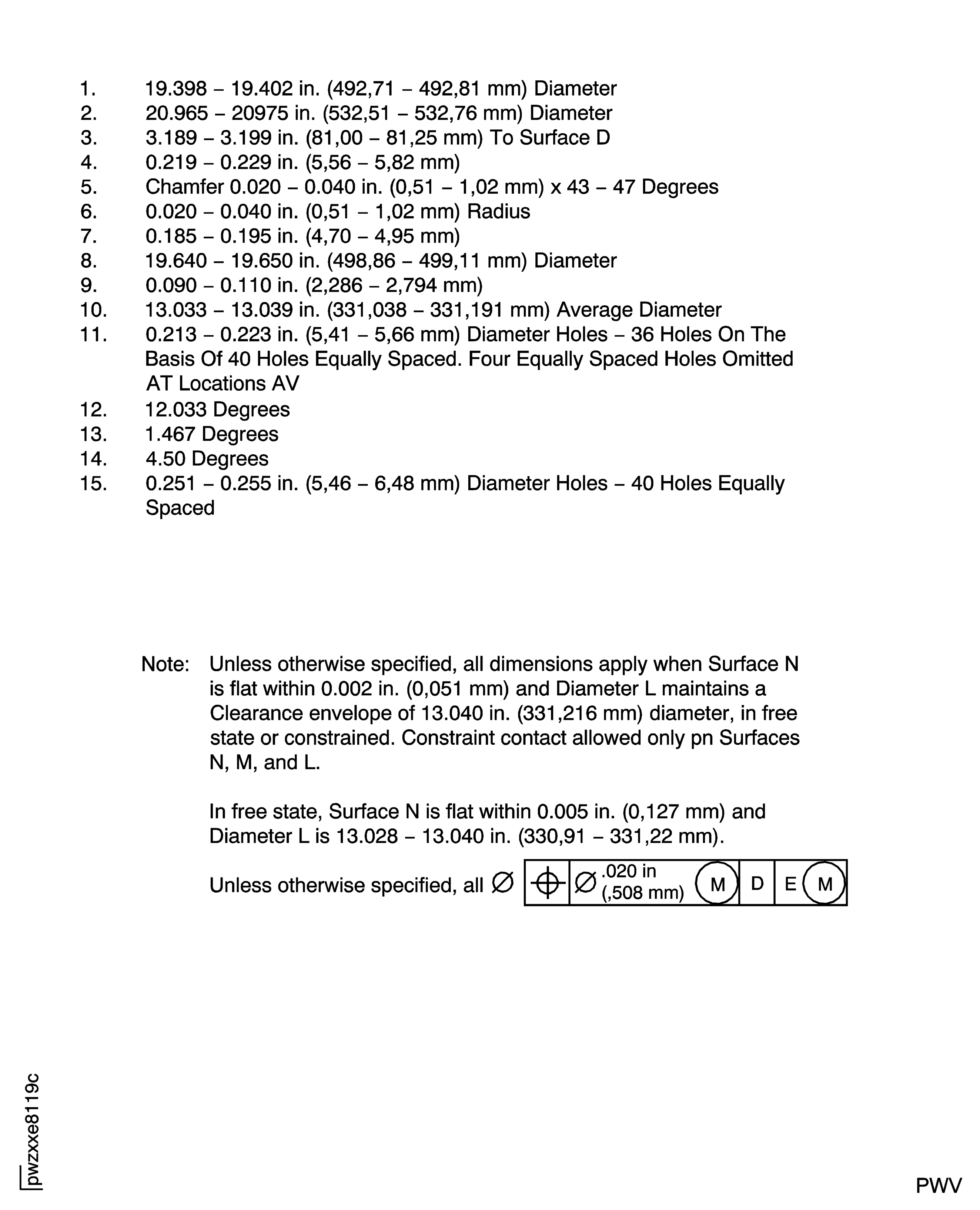

Figure: Repair Details and Dimensions (for all PNs except 2A3487-001)

Sheet 1

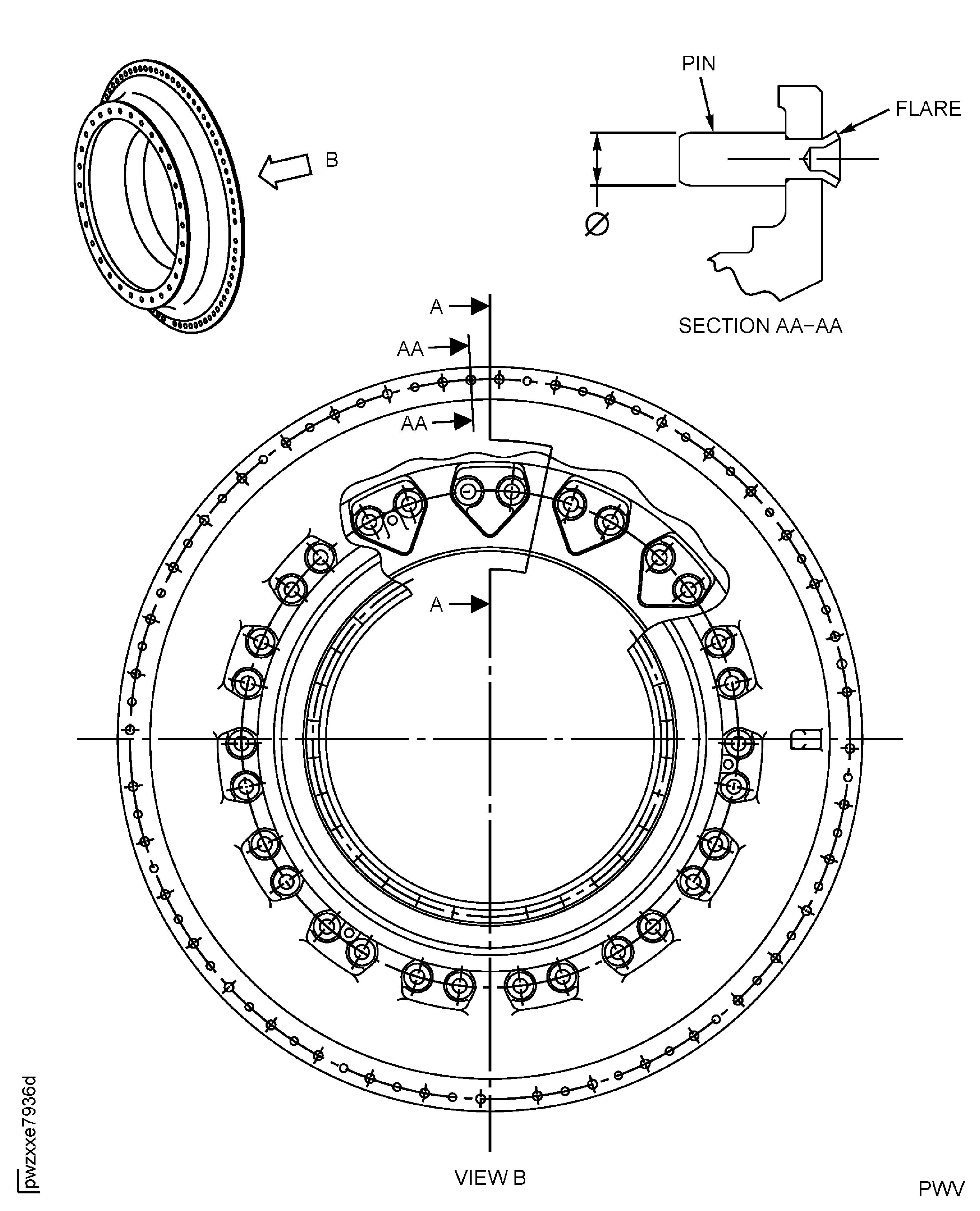

Figure: Repair Details and Dimensions (for PN 2A3487-001)

Sheet 2

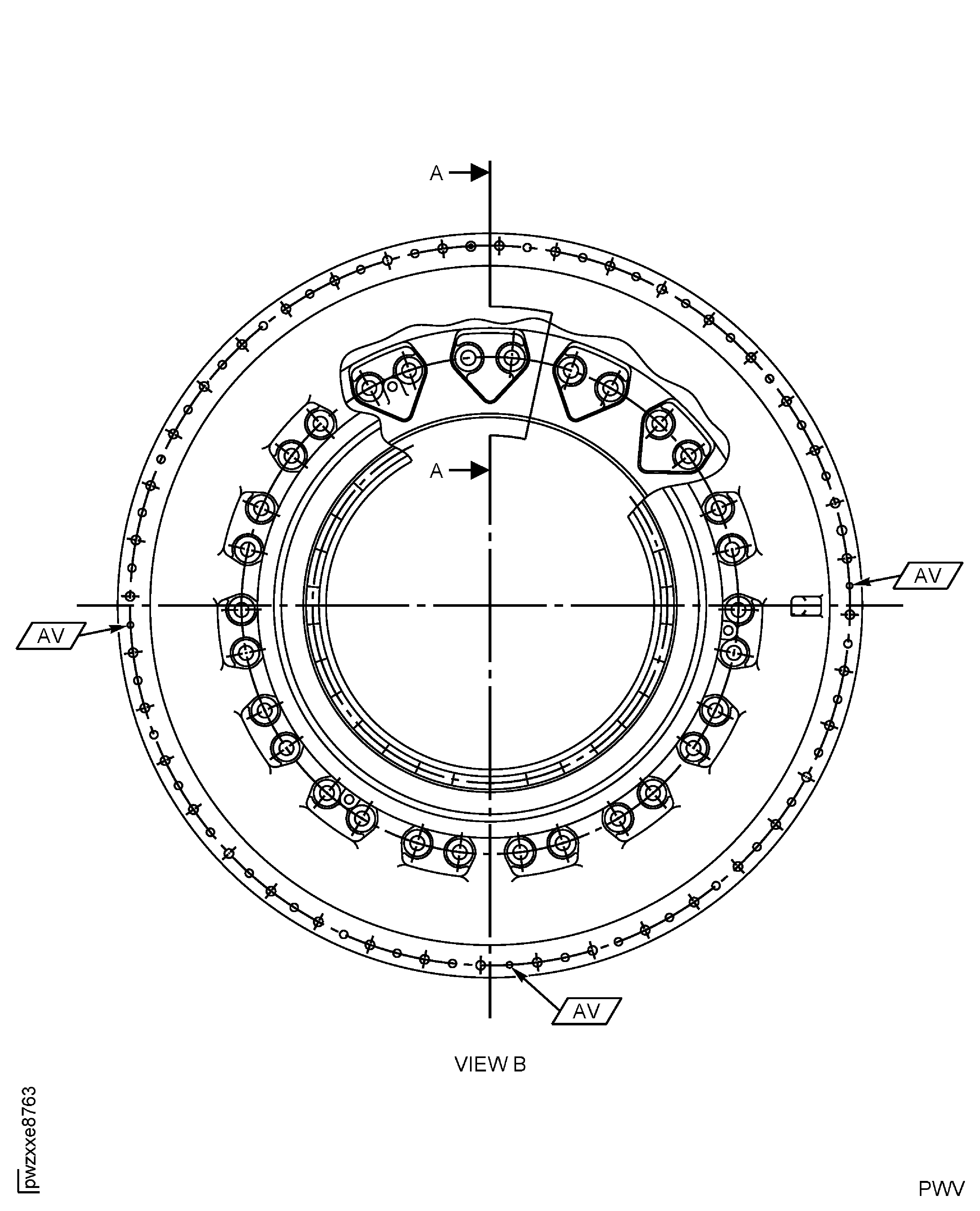

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Repair Details and Dimensions