Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-50-300-017 HPT Stage 1 Cooling (TOBI) Duct - Weld The Air Pressure Passage Cracks, Repair-017 (VRS3808)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A0008-01 |

01-010 | 2A1997-01 |

01-010 | 2A1997-001 |

01-010 | 2A1997-002 |

01-010 | 2A1997-003 |

01-010 | 2A2141-01 |

01-010 | 2A3180-01 |

01-010 | 2A3329-01 |

01-010 | 2A3487-01 |

01-010 | 2A3487-001 |

01-010 | 2A3491-01 |

01-010 | 2A3914-01 |

01-010 | 2A3914-001 |

01-010 | 2A4086 |

General

Price and availability - Refer to IAE

The practices and processes referred to in this procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-284 WELDING FILLER WIRE, NiBASE | LOCAL | CoMat 03-284 |

Spares

NONESafety Requirements

CAUTION

Procedure

Repair, VRS3179 TASK 72-44-50-300-003 (REPAIR-003).

Remove the honeycomb ring from the Stage 1 HPT Duct Assembly.

SUBTASK 72-44-50-350-083 Remove the Honeycomb Ring

Refer to the SPM TASK 70-23-05-230-501. Use high sensitivity procedure.

NOTE

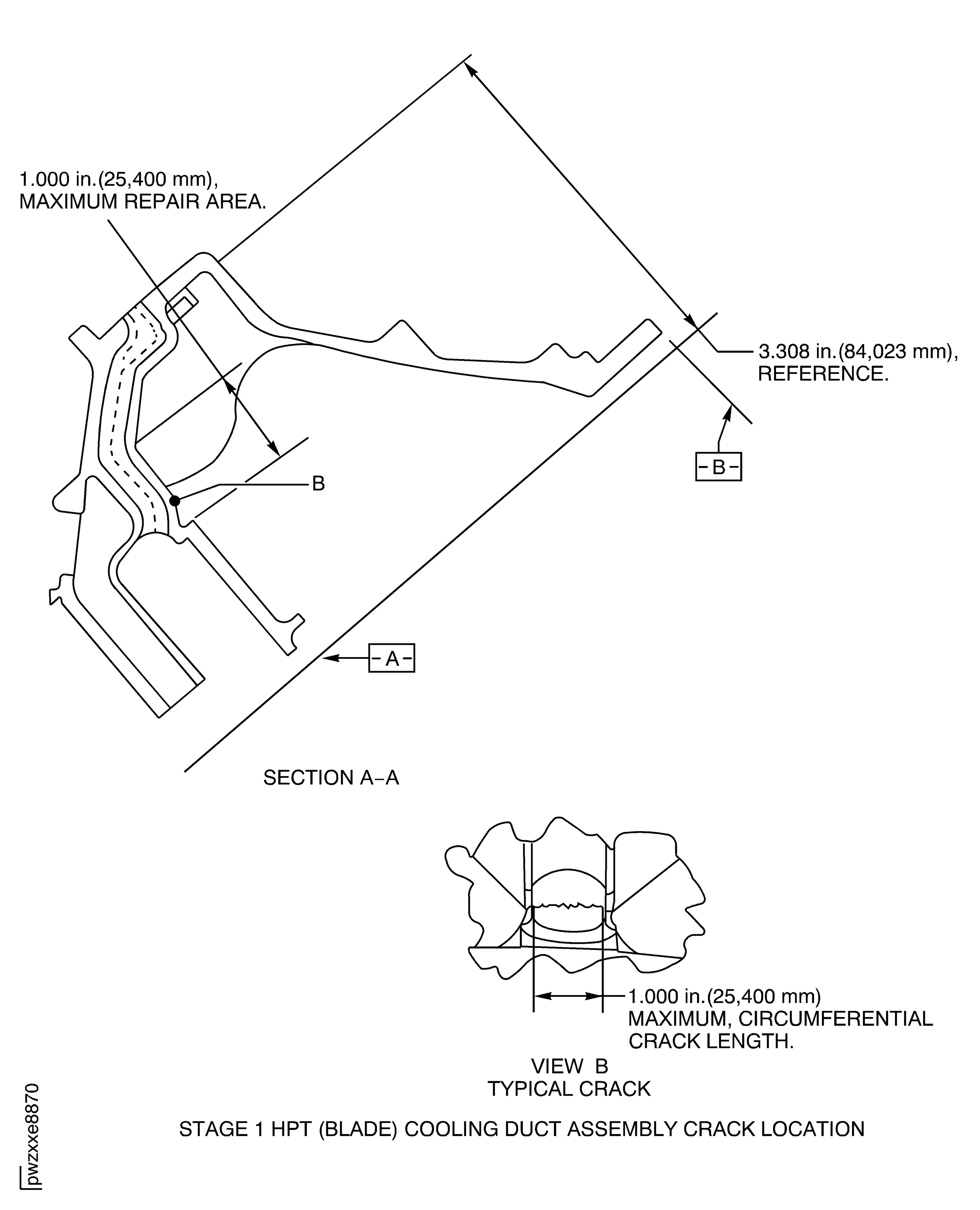

Crack can be removed before weld. It can be done by a certified welder. It is not necessary to get certification from a fluorescent penetrant inspector.Do a fluorescent penetrant inspection of the repair area.

SUBTASK 72-44-50-230-070 Examine the Repair Area

Refer to the SPM TASK 70-11-26-300-503.

Solvent wipe the area to be welded.

SUBTASK 72-44-50-110-063 Clean the Repair Area

NOTE

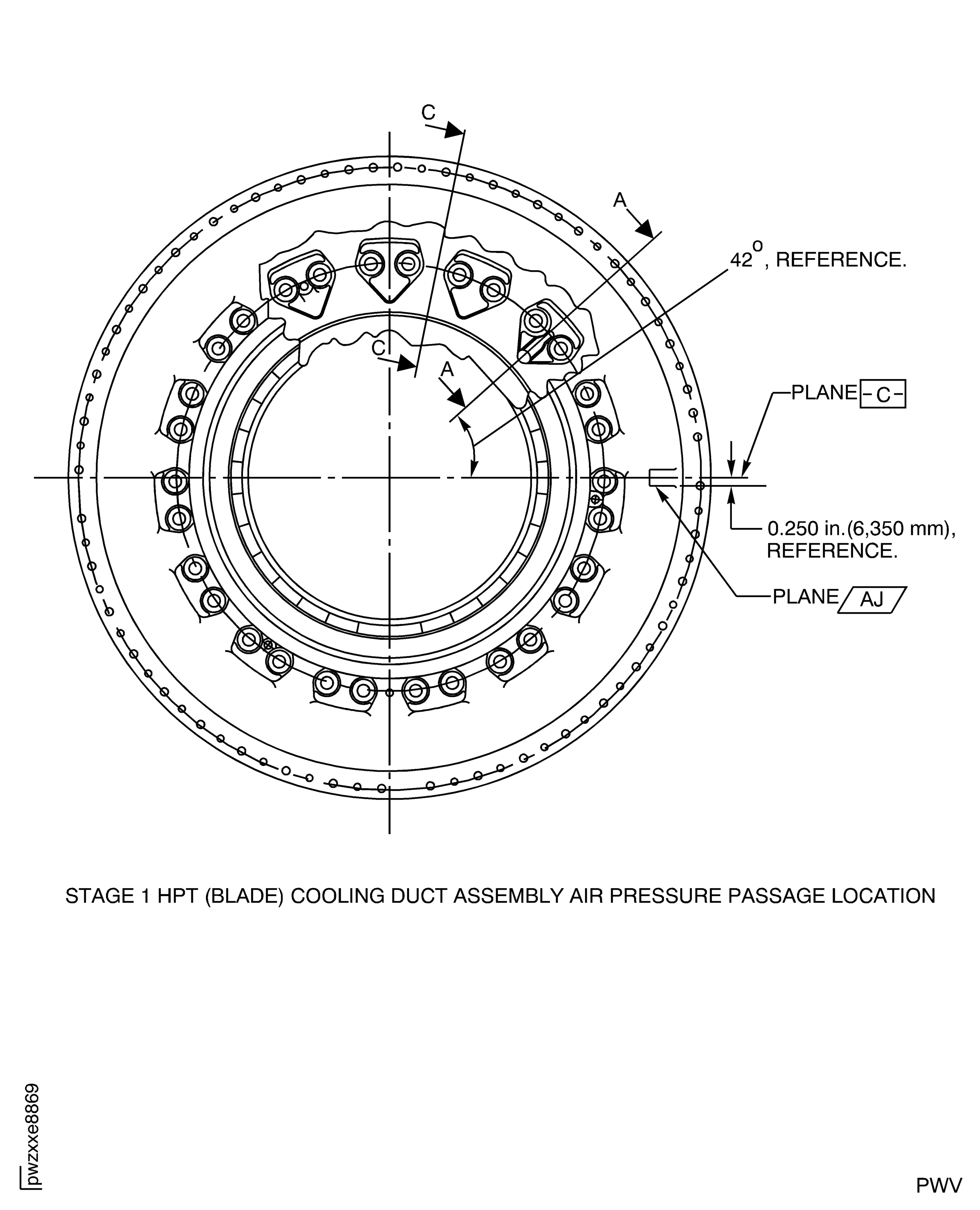

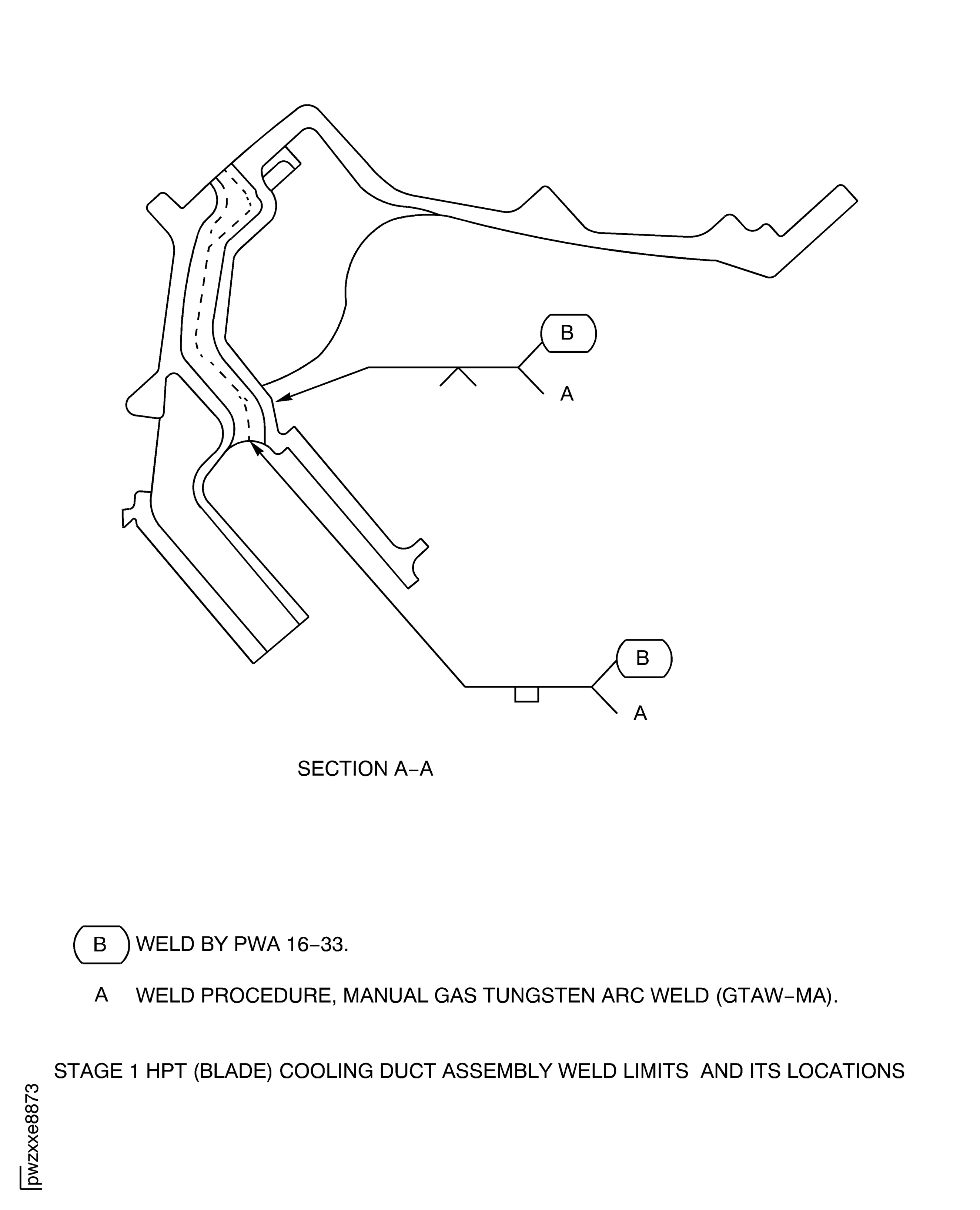

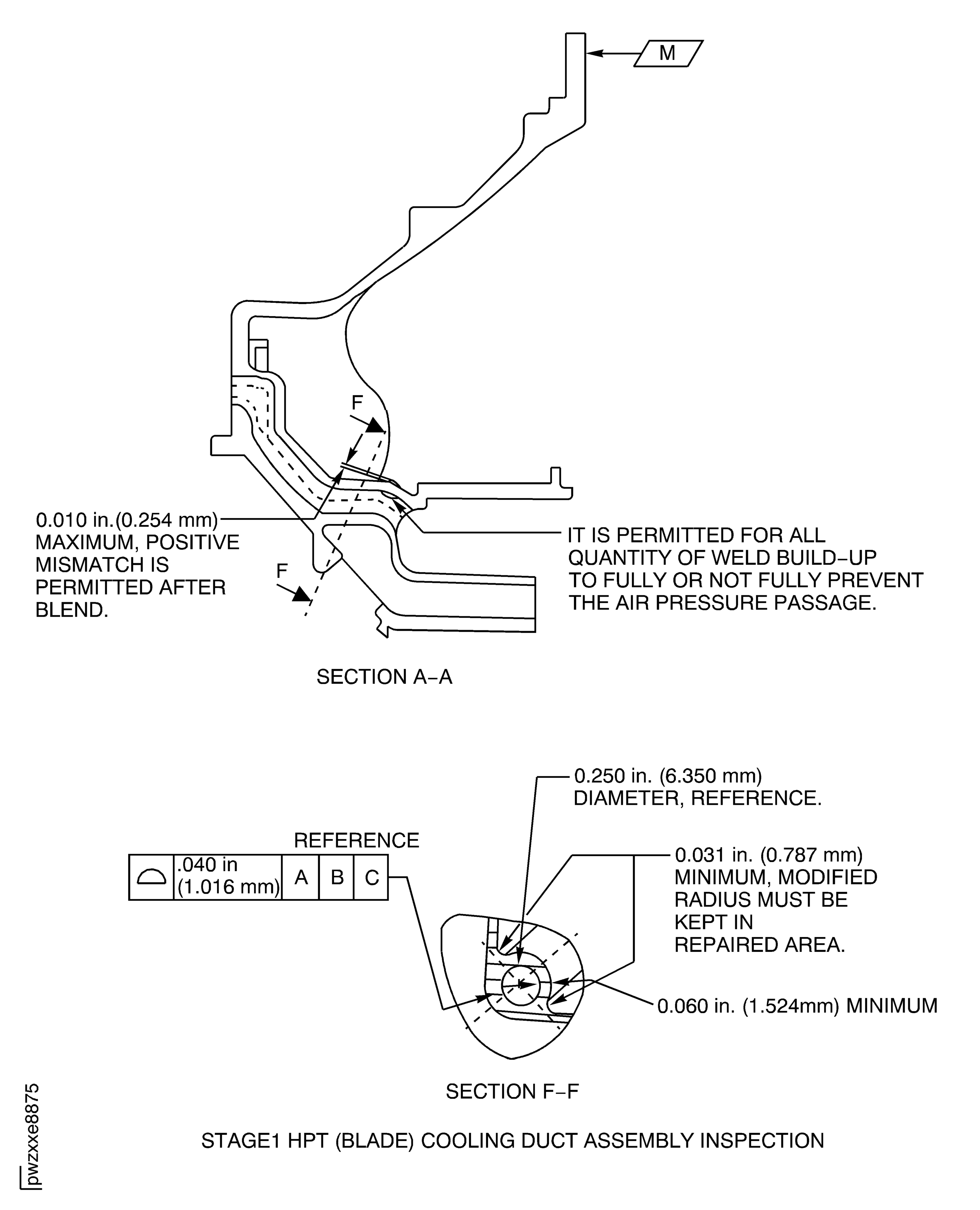

Locally manufacture suitable tooling to minimize weld distortion.When you repair cracks, the air passage must be plug welded.Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501. Use CoMat 03-284 WELDING FILLER WIRE, NiBASE.

Weld build up the routed area. Use the Manual Gas Tungsten Arc Weld (GTAW-MA) procedure.

Refer to the SPM TASK 70-31-13-310-501. Use CoMat 03-284 WELDING FILLER WIRE, NiBASE.

Plug weld opening of the air pressure passage. Use the Manual Gas Tungsten Arc Weld (GTAW-MA) procedure.

SUBTASK 72-44-50-310-057 Weld Repair

Refer to the SPM TASK 70-37-32-370-501.

NOTE

Heat treatment can be done with the honeycomb installation by Repair, VRS3179 TASK 72-44-50-300-003 (REPAIR-003).Solution heat treat and precipitation harden the stage 1 HPT cooling duct.

SUBTASK 72-44-50-370-059 Heat Treat the Repaired Area

Refer to the SPM TASK 70-23-03-230-501.

Do a fluorescent penetrant inspection of the duct.

SUBTASK 72-44-50-230-071 Examine the Part

Refer to Figure.

Refer to the SPM TASK 70-35-03-300-501.

NOTE

It is not necessary to blend the inner diameter of the air pressure passage since the rear opening of the passage will be plug welded.Blend the repaired area. A mismatch of +0.010 in. (+0.25 mm) is permitted.

SUBTASK 72-44-50-350-085 Blend the Repaired Area

Refer to the SPM TASK 70-11-26-300-503.

Clean the duct.

SUBTASK 72-44-50-110-064 Clean the Repaired Area

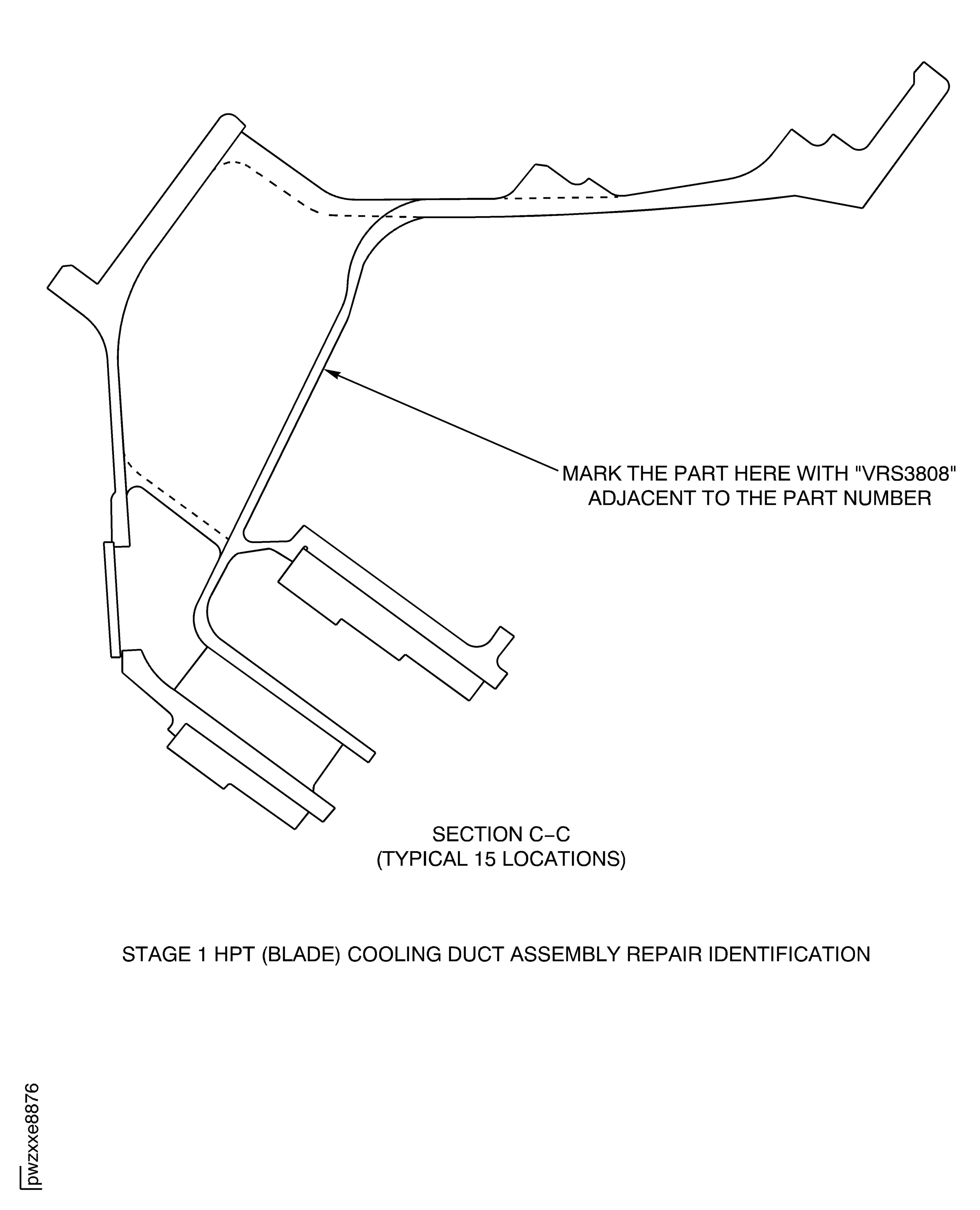

Refer to Figure.

Refer to TASK 72-44-50-200-000 (INSPECTION-000).

Do a dimensional inspection of the part.

SUBTASK 72-44-50-220-125 Examine the Part

Refer to Figure.

Make a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501.

Make a mark "VRS3808" adjacent to the part number.

SUBTASK 72-44-50-350-086 Identify the Repair

Repair, VRS3179 TASK 72-44-50-300-003 (REPAIR-003).

Install the honeycomb ring to the Stage 1 HPT Duct Assembly.

SUBTASK 72-44-50-350-087 Install the Honeycomb Ring

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions