Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-14-300-022 HPT Stage 1 Blade - Blend Repair To Remove Cracks From The Underplatform Cooling Holes, Repair-022 (VRS3616)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A2621 |

01-010 | 2A2621-001 |

01-010 | 2A2621-002 |

01-010 | 2A2621-003 |

01-010 | 2A8321 |

01-010 | 2A8321-001 |

01-010 | 2A8321-002 |

01-010 | 2A8321-003 |

01-010 | 2A8521 |

01-010 | 2A8521-001 |

01-010 | 2A8521-002 |

01-010 | 2A8521-003 |

01-010 | 2A8701 |

01-010 | 2A8701-001 |

01-010 | 2A8701-002 |

01-010 | 2A8801 |

01-010 | 2A9001 |

01-010 | 2A9101 |

01-010 | 2A9201 |

General

This Repair must only be done when the instruction to do so is given in TASK 72-45-14-200-000 (INSPECTION-000).

Price and availability - none

Prerequisites

Stress-relieve the blade by SPM TASK 70-37-26-370-501.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-155 ALUMUNUM OXIDE ABRASIVE,27 MICRON | LOCAL | CoMat 05-155 | ||

| CoMat 05-025 ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON) | 0KZS2 | CoMat 05-025 | ||

| CoMat 05-025A ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON) | 1E1X8 | CoMat 05-025A | ||

| Aluminum oxide grit | LOCAL | PMC3164 |

Spares

NONESafety Requirements

NONEProcedure

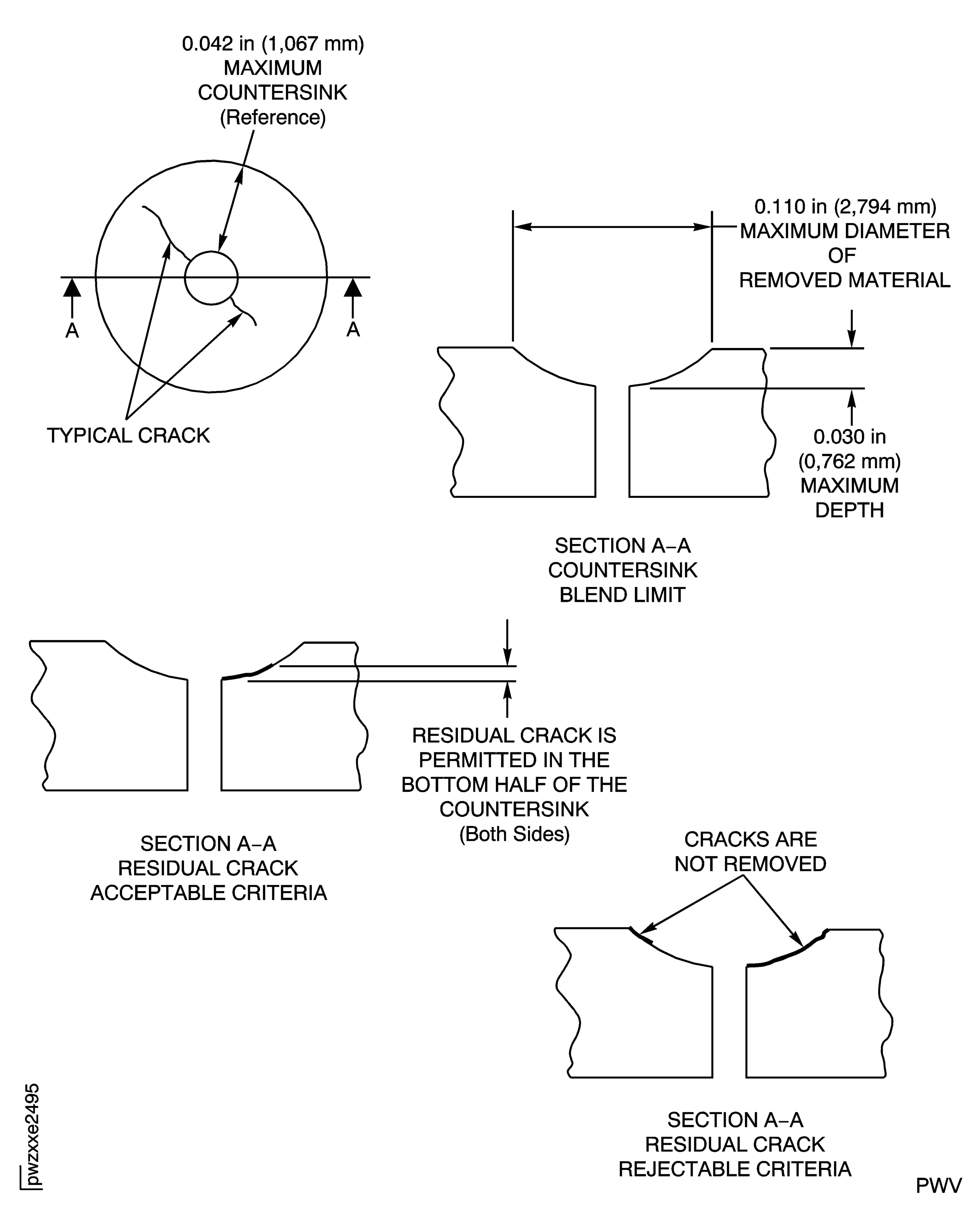

Refer to Figure.

Cracks can be a maximum of 0.042 in. (1.067 mm) in length.

Cracks that go from one cooling hole to another cooling hole are not permitted.

NOTE

The countersink must be centered on the initial cooling hole exit. Due to the angle of some cooling holes, the final cooling hole exit can be offset by a maximum of 0.010 in. (0.254 mm).

Countersink cooling holes that have cracks which are on the non-gaspath side of the platform.

SUBTASK 72-45-14-350-068 Countersink Cooling Holes that have Cracks

Polish or pencil blast.

Use the parameters that follow:

Nozzle diameter: 0.018 - 0.050 in. (0.457 - 1.27 mm).

Aluminum oxide grit: CoMat 05-155 ALUMUNUM OXIDE ABRASIVE,27 MICRON (27 micron).

CoMat 05-025 ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON) (50 micron).

CoMat 05-025 ALUMINUM OXIDE ABRASIVEGRIT (50 MICRON)A (50 micron).

PMC3164 (50 micron).

Pressure: plus or minus 100.25 psig.

Dwell time: 2 seconds maximum.

Remove sharp edges.

SUBTASK 72-45-14-120-056 Remove Sharp Edges from the Cooling Holes

Refer to the SPM TASK 70-37-26-370-501.

Stress-relieve the blade.

SUBTASK 72-45-14-370-056 Stress-Relieve the Stage 1 HPT Blade

Refer to: Figure

Refer to the SPM TASK 70-23-05-230-501 or SPM TASK 70-23-08-230-501, high sensitivity.

You can visually inspect the blended area with a white light and 10x magnification instead of FPI.

Fluorescent penetrant inspect the blended area.

SUBTASK 72-45-14-230-063 Fluorescent Penetrant Inspect the Blended Area

Do the procedure given in REPAIR, VRS3581 TASK 72-45-14-300-020 (REPAIR-020).

Apply protective coating to the blade.

SUBTASK 72-45-14-300-002 Apply Protective Coating to the Stage 1 HPT Blade

Do the procedure in the SPM TASK 70-37-27-370-501.

Heat at 1600 deg F (871.1 deg C) for 32 hours in an air or argon atmosphere.

Precipitation heat treat the blade.

Do the procedure given in REPAIR, VRS3484 TASK 72-45-14-300-011 (REPAIR-011).

Shotpeen the blade root.

Refer to TASK 72-45-14-200-000.

Do an airflow inspection.

SUBTASK 72-45-14-350-069 Close Up

Figure: Stage 1 HPT blade cooling hole crack removal

Stage 1 HPT blade cooling hole crack removal