Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-27-300-001 HPT Stage 2 Support Seal - Restore The Coating, Repair-001 (VRS3322)

General

The repair must only be done when the instruction to do so is given in 72-45-27 Inspection/Check.

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - none

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-047 TAPE, HEAT REFLECTIVE | 52152 | CoMat 02-047 | ||

| CoMat 02-050 HIGH TEMPERATURE GLASS CLOTH TAPE | 76381 | CoMat 02-050 | ||

| CoMat 03-079 PLASMA SPRAY POWDER | IE426 | CoMat 03-079 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Mask the seal by the procedure given in the SPM TASK 70-34-18-380-501.

Apply masking tape to the seal.

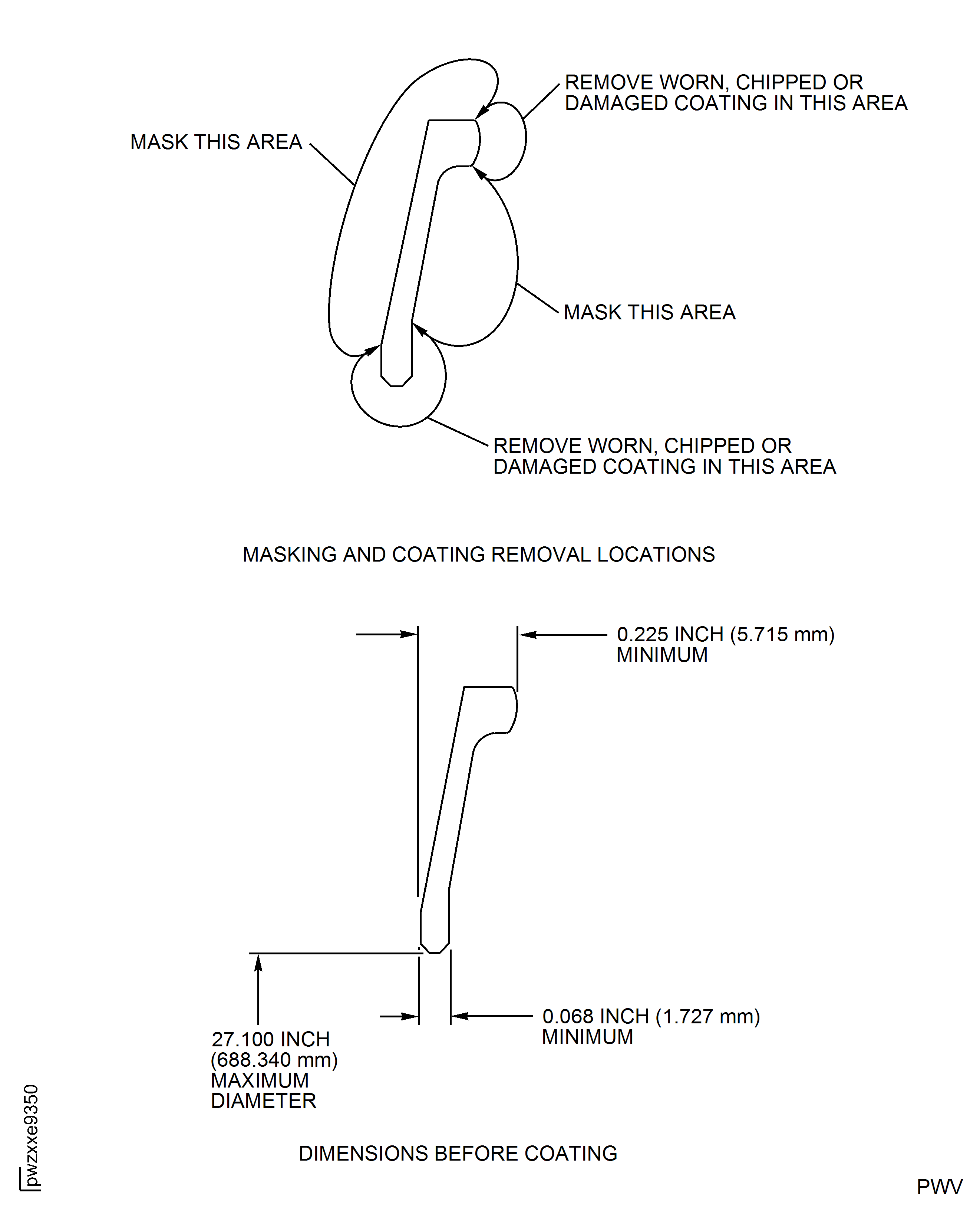

Refer to Figure.

Grind by the procedure given in SPM TASK 70-32-07-100-501.

Remove the minimum amount of parent material necessary to do the repair.

Machine or grind to remove worn, chipped or damaged coating from the seal contact surfaces.

Refer to Figure.

The proprietary nature of this repair requires that any facility not authorized to accomplish this repair either utilize the Authorized Repair Vendors listed below or contact the IAE Repair Development Group to determine if a qualification program can be initiated at their facility.

IAE - International Aero Engines AG

400 Main Street, MailStop 121-10

East Hartford, CT 06118

USA

Email: gpiaecomms@iaev2500.com

ATTN: Manager, Maintenance Operations

Authorized repair vendors for Repair VRS3322 are listed below.

None

The designation by IAE of an authorized vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor, other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

CAUTION

REMOVAL OF COATING BY MANUAL GRIT BLASTING METHOD IS NOT PERMITTED.Remove worn, chipped or damaged coating by automated grit blasting. (Optional)

Refer to Figure.

High pressure water blast by the procedure given in SPM TASK 70-15-01-160-501.

Remove worn, chipped or damaged coating by high pressure water blasting. (Optional)

Clean the seal by the procedure given in SPM TASK 70-11-03-300-503.

If a grinding procedure was done, clean the seal.

Refer to INSPECTION-001 TASK 72-45-27-200-001-A00.

If a grinding procedure was done, do a fluorescent penetrant inspection of the seal.

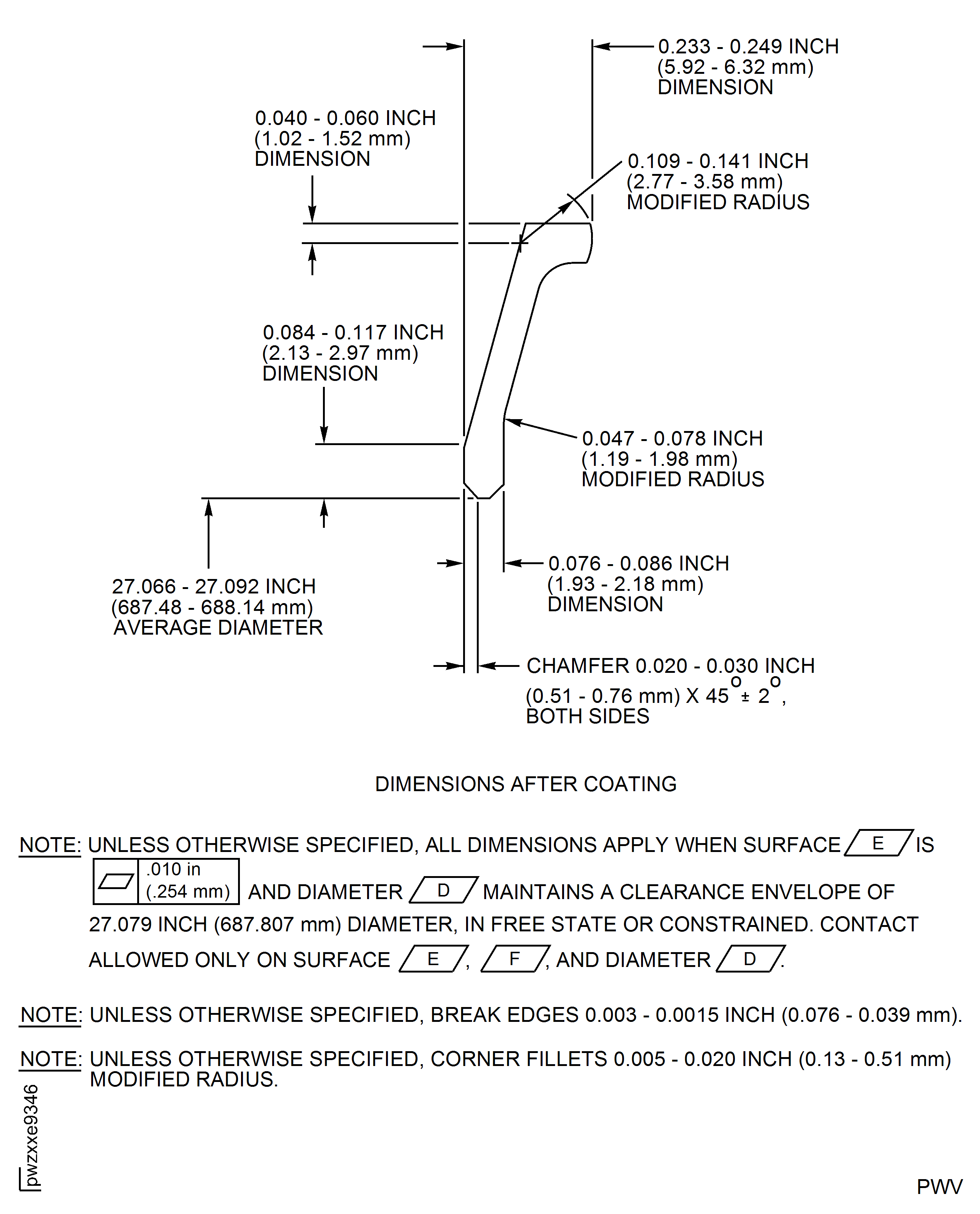

Refer to Figure.

Examine the seal for the correct diameter and dimensions.

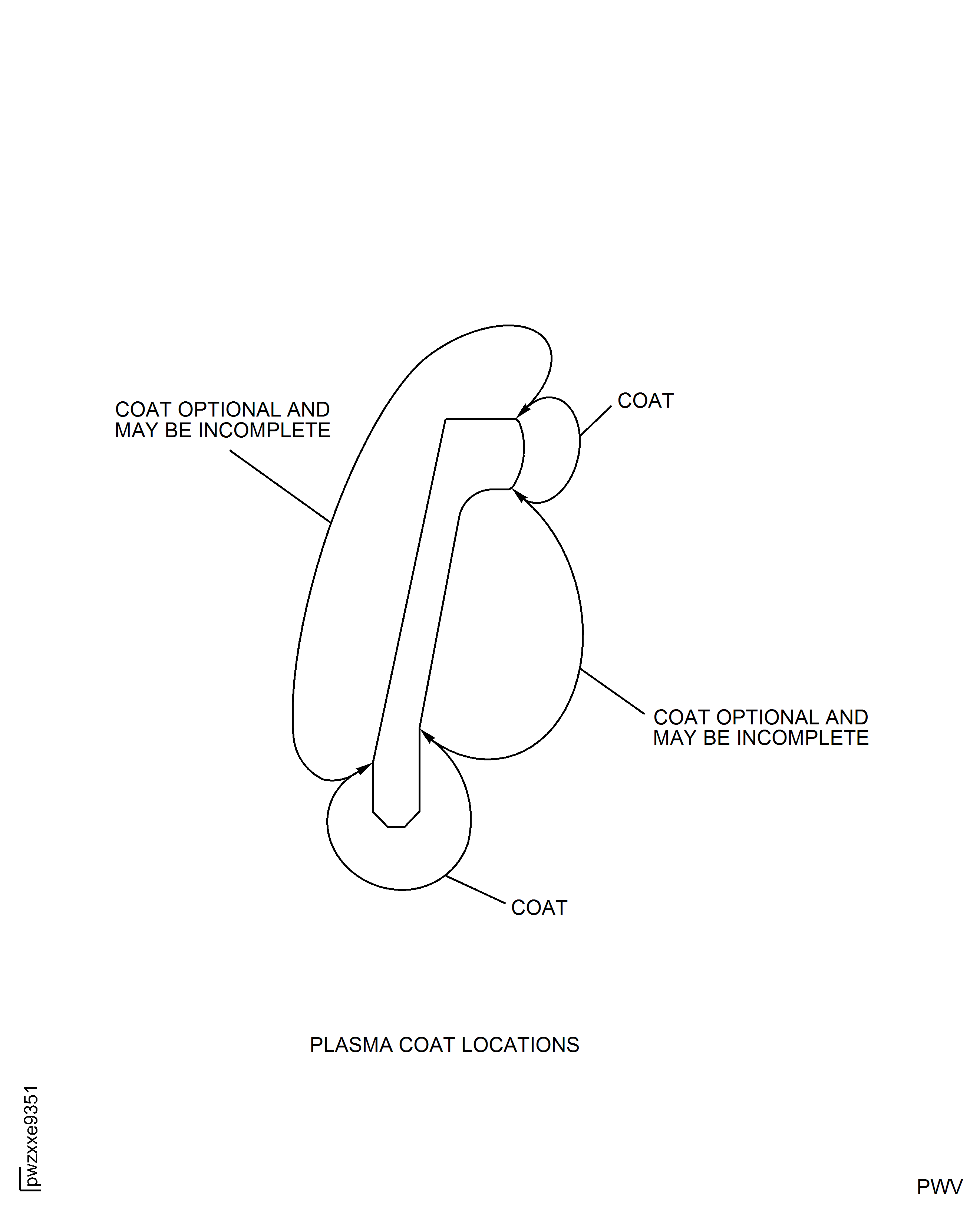

Refer to Figure.

Grit blast the repair area by the procedure given in SPM TASK 70-34-18-380-501.

Grit blast out of the repair area is not permitted.

Prepare the repair area for plasma coat.

Refer to Figure.

Plasma coat the repair area by the procedure given in SPM TASK 70-34-03-340-501.

Coat out of the repair area is not permitted.

Apply CoMat 03-079 PLASMA SPRAY POWDER to the area to be coated.

Remove the masking tape by the procedure given in SPM TASK 70-34-03-340-501.

Remove masking from the seal after it is cool.

Refer to Figure.

Finish grind by the procedure given in SPM TASK 70-32-07-100-501.

If necessary, finish grind the plasma coating to achieve between 0.004 and 0.007 in. (0.102 and 0.177 mm) coating thickness and dimensional requirements.

Clean the seal by the procedure given in SPM TASK 70-11-03-300-503.

Clean the seal.

Examine the plasma coating by the procedure given in SPM TASK 70-34-03-340-501.

Examine the plasma coating.

Refer to Figure.

Examine the seal for the correct diameter and dimensions.

Make a permanent mark by the procedure given in SPM TASK 70-09-00-400-501.

Identify the repair. Make a mark VRS3322 adjacent to the part number.

SUBTASK 72-45-27-350-051 Restore the Stage 2 HPT Seal Coating

Figure: Stage 2 HPT Seal - Before Coating

Stage 2 HPT Seal - Before Coating

Figure: Stage 2 HPT Seal - Plasma Coat Locations

Stage 2 HPT Seal - Plasma Coat Locations

Figure: Stage 2 HPT Seal - Dimensions After Coating

Stage 2 HPT Seal - Dimensions After Coating