Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-038 LPT Inner Diffuser Duct Support Ring - Replace Spacer Key, Repair-038 (VRS4356)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Milling machine | LOCAL | Milling machine | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Drilling machine | LOCAL | Drilling machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-148 BRAZING FILLER POWDER | LOCAL | CoMat 03-148 | ||

| CoMat 03-227 WHITE STOP OFF | D3309 | CoMat 03-227 | ||

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 | ||

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 | optional |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SPACER KEY | 3A0115 | 29 |

Safety Requirements

NONEProcedure

Use Milling machine or Drilling machine.

Electrical discharge machine according to the SPM TASK 70-32-03-320-501 is permitted.

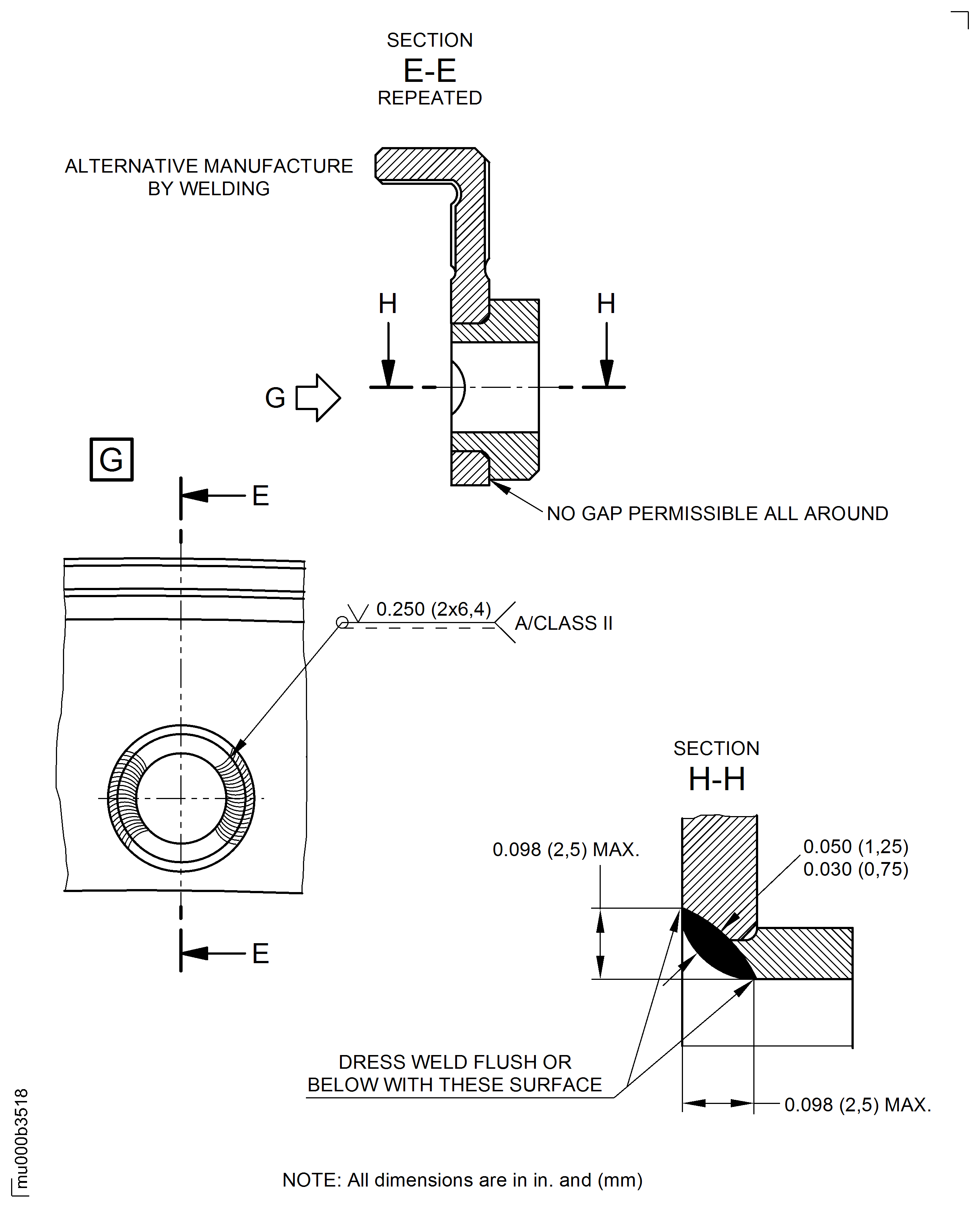

Refer to Figure.

Do not remove parent material.

Remove traces of original braze filler before you braze in new 3A0115 .

Machine off the worn 3A0115 .

SUBTASK 72-50-24-325-058 Remove the Worn Spacer Key

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degreas

SUBTASK 72-50-24-110-078 Clean the Support Ring

Refer to Figure for dimensions.

Examine dimensionally.

SUBTASK 72-50-24-220-117 Examine the Machined Areas

Refer to the SPM TASK 70-33-06-300-503.

Nickel plate is permitted to make the following braze cycle easier.

Coating must be 0.0001 to 0.0003 in. (0.003 to 0.008 mm).

Nickel plate the mating surfaces if necessary.

Clamp the 3A0115 to prevent movement.

Refer to Figure.

Refer to the SPM TASK 70-31-09-310-501 and SPM TASK 70-31-06-310-501 for braze cycle except steps 2E, 3A, 3B, 3C of the brazing procedure.

Increase temperature of 1904 to 1940 deg F (1040 to 1060 deg C) and hold for 10 to 15 minutes.

Cool at a minimum rate of 25 deg F per minute (14 deg C per minute ) to 1750 deg F (954 deg C).

Cool at a rate of 45 deg F per minute (25 deg C per minute) or faster to 1112 deg F (600 deg C).

Further cooling is optional.

Braze the 3A0115 in position.

Put the support ring into a furnace at 1450 to 1500 deg F (788 to 816 deg C) for eight hours.

Heating rate is not important.

Cool in still or shaken in air or inert gas.

NOTE

Cooling cycle of Step can be mixed with precipitation heat treat cycle.

Precipitation heat treat the support ring.

SUBTASK 72-50-24-310-057-001 Install the New Spacer Key

Refer to the SPM TASK 70-31-13-310-501. Use CoMat 03-184 WELDING FILLER WIRE, NICKEL or CoMat 03-287 WELDING FILLER WIRE. Refer to Figure. No head treatment required after weld repair.

Weld the 3A0115 in position.

SUBTASK 72-50-24-310-057-002 Install the New Spacer Key

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease

SUBTASK 72-50-24-110-079 Clean the Support Ring

Refer to the SPM TASK 70-23-01-230-501 or SPM TASK 70-23-02-230-501.

If 3A0115 have been welded only, SPM TASK 70-23-05-230-501, medium sensitivity is also acceptable.

No cracks are permitted.

Do the test for cracks.

SUBTASK 72-50-24-230-069 Examine the Support Ring for Cracks

No damage permitted.

Refer to Repair-039, VRS4309 TASK 72-50-24-300-039 and Repair-053, VRS4466 TASK 72-50-24-300-053 for hardface coating replacement.

Examine area for damaged or missing hardface coating.

SUBTASK 72-50-24-220-119 Examine the Hardface Coating for Damage

SUBTASK 72-50-24-370-053 Heat Treat the Support Ring

NOTE

Heat treatment is only required if hardness is less than the minimum specified. Refer to Step.

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2