Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-026 Turbine Exhaust Case (TEC) - Remove/Install (Or Replace) The 5 Bearing Carbon Seal Housing, Repair-026 (VRS5410)

Material of component

IAE | ||

|---|---|---|

DESCRIPTION | SYMBOL | MATERIAL |

Turbine exhaust case | - | Corrosion and heat resistant iron base alloy |

General

Price and availability - none

The oil/air seal lands must be machined to the last dimensions, after the seal housing has been installed on the turbine exhaust case. Refer to VRS5330, TASK 72-50-53-300-003 and VRS5331, TASK 72-50-53-300-004.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Solid CSK head rivet | AS16489 | 15 | ||

| Solid CSK head rivet | AS16529 | AR | ||

| Solid CSK head rivet | AS125009 | AR |

Safety Requirements

NONEProcedure

Refer to: Figure

SUBTASK 72-50-53-350-072 Remove the Damaged Carbon Seal Housing

Refer to Repair, VRS5329, TASK 72-50-53-300-002.

Repair, VRS5330, TASK 72-50-53-300-003.

Repair, VRS5331, TASK 72-50-53-300-004.

Repair the Carbon seal as necessary.

SUBTASK 72-50-53-350-073 Repair the Carbon Seal Housing

Refer to: Figure

Rivet heads must be flush with, or below the surface of, seal housing. You can use optional oversized rivets (AS16529 or AS125009 ), if necessary.

Repair, VRS5405, TASK 72-50-53-300-021 (REPAIR-021).

Fit the new rivets.

SUBTASK 72-50-53-350-074 Install the Carbon Seal Housing

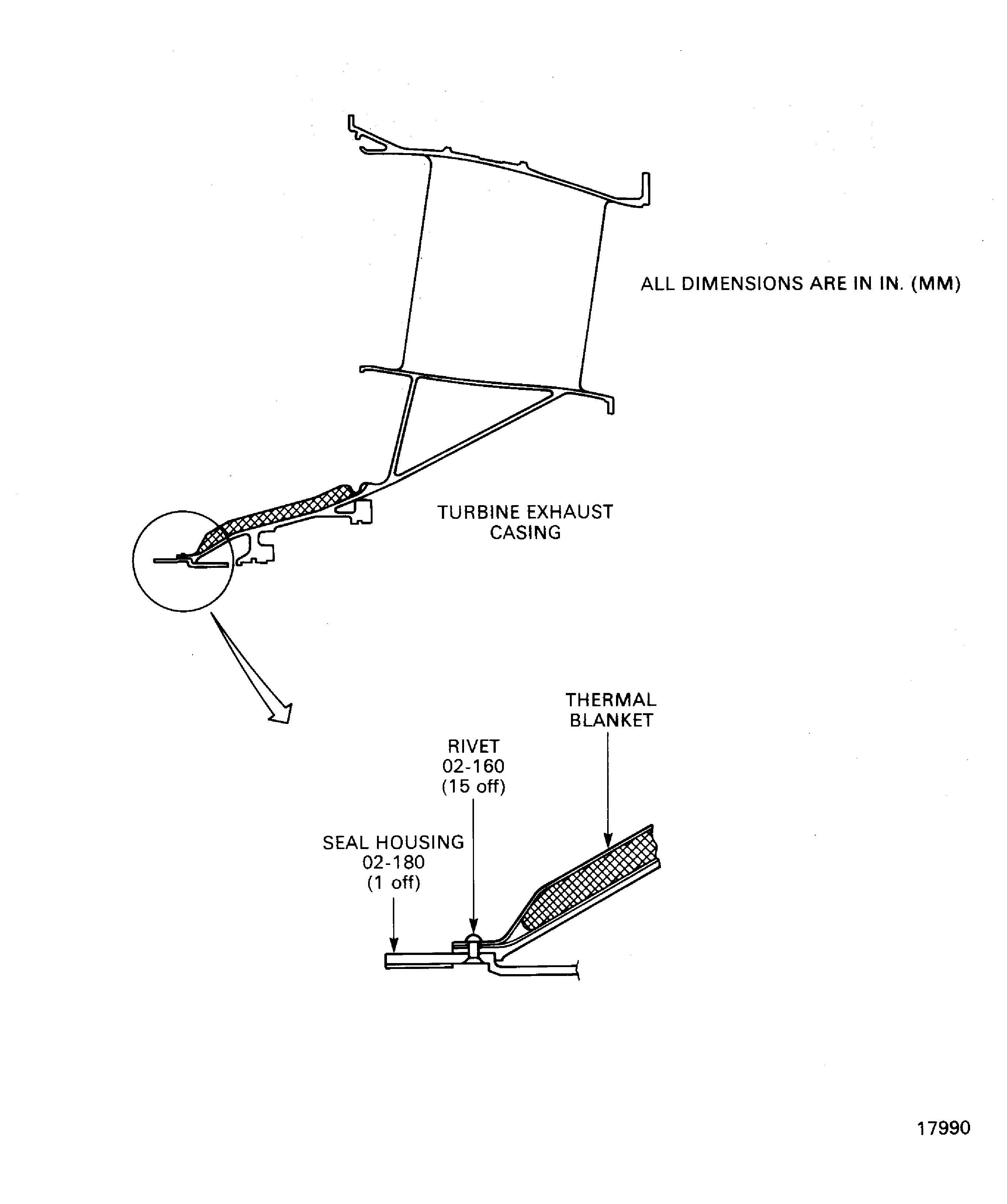

Figure: Remove/install the carbon seal housing in the turbine exhaust case

Remove/install the carbon seal housing in the turbine exhaust case

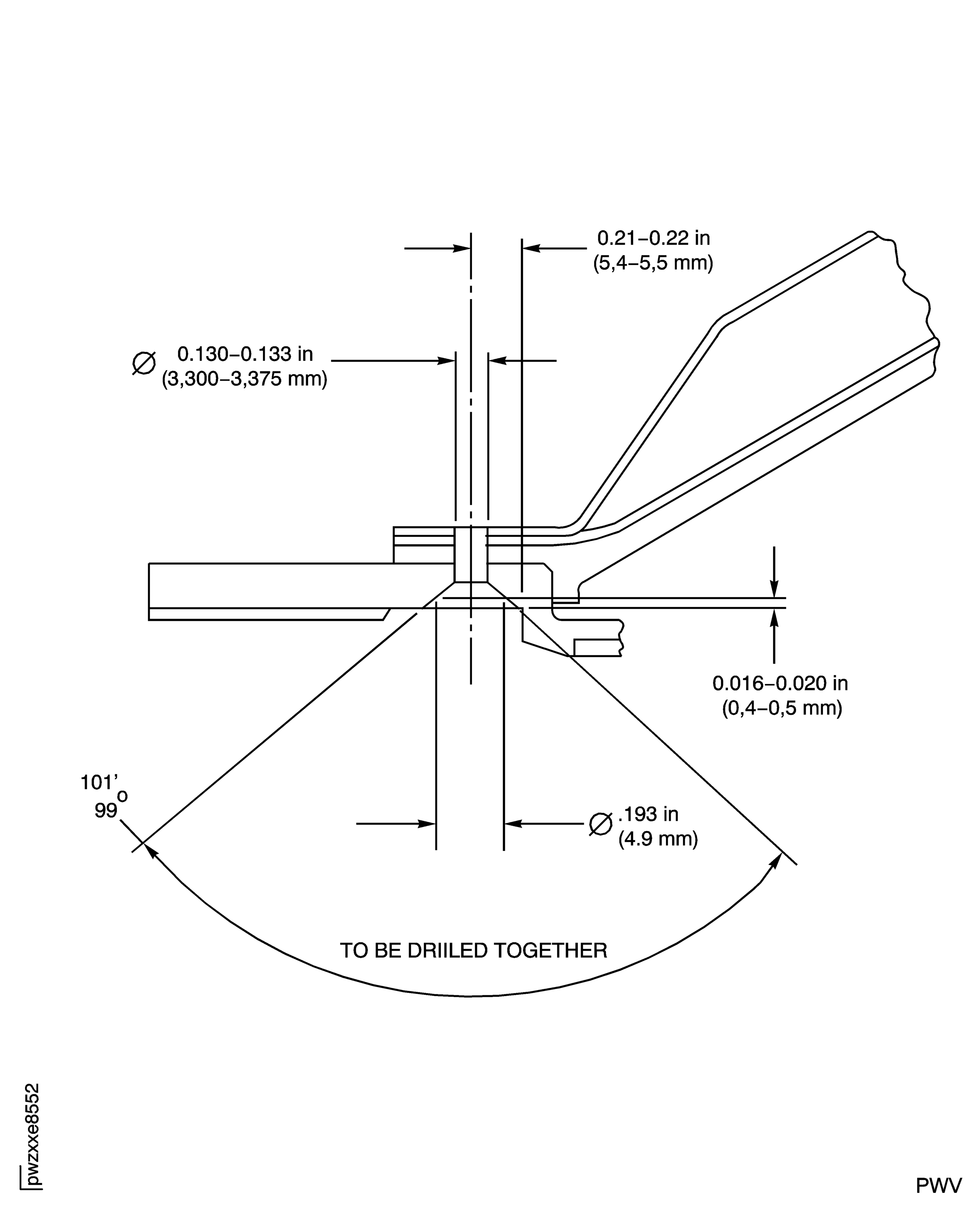

Figure: Match drill the carbon seal housing (PN 4P8036) rivet holes in the turbine exhaust case

Match drill the carbon seal housing (PN 4P8036) rivet holes in the turbine exhaust case