Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-060 Main Gearbox Casing - Repair The Crank Cover Stud Holes By Oversize Stud, Repair-060 (VRS5713)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-050 | 4B0053 |

02-050 | 4B0054 |

02-050 | 4B0055 |

02-050 | 4B0057 |

02-050 | 4B0400 |

02-050 | 4B0402 |

02-050 | 4B0423 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Casing, Main Angle Gearbox | A357/T61 (AMS4219) | Aluminum alloy |

General

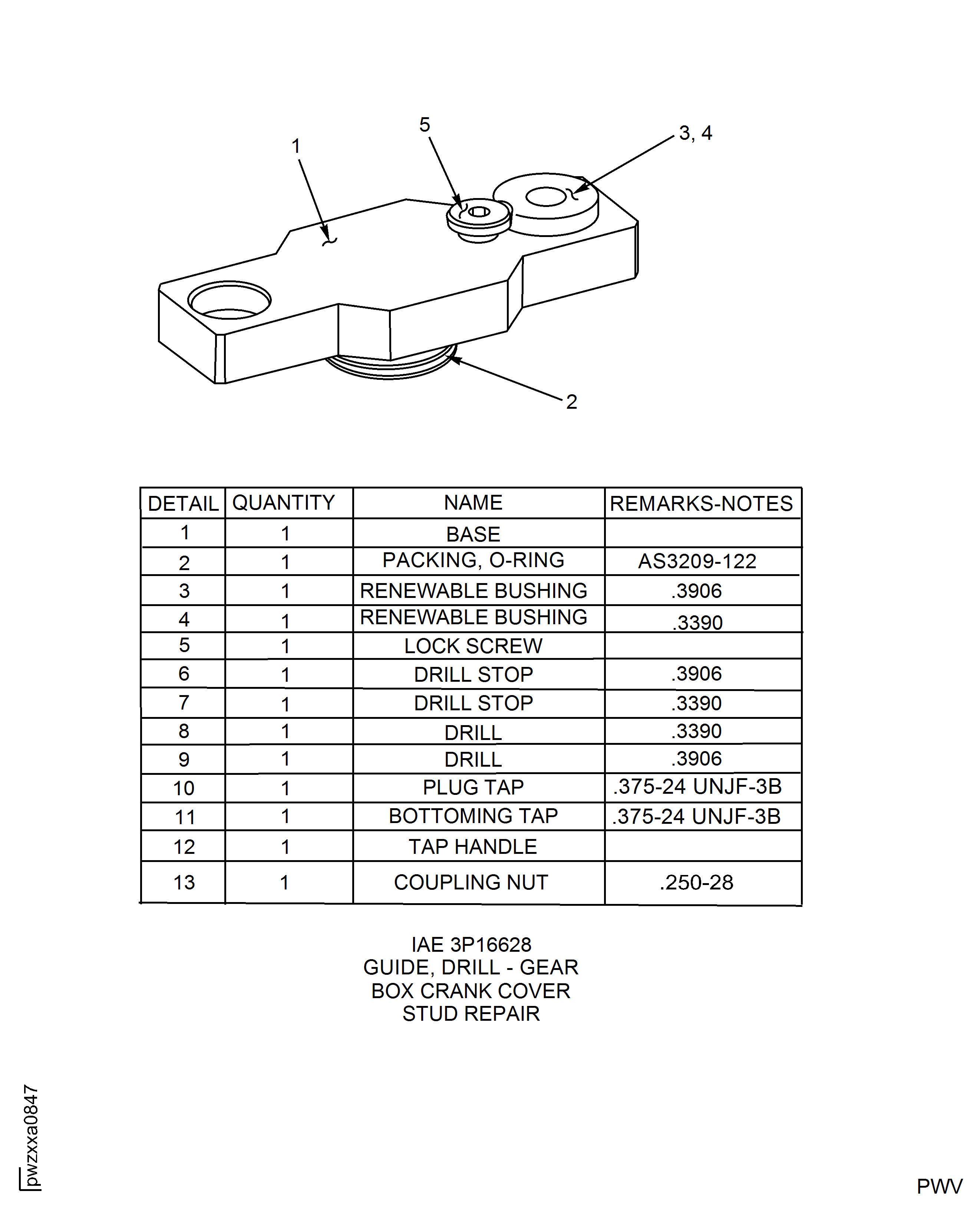

This repair can be performed on a Gearbox Casing in either the fully disassembled piece-part level or as part of an assembled Gearbox Assembly. When at piece-part level, a milling machine must be used to machine the Gearbox Casing. When installed in a Gearbox Assembly, the IAE 3P16628 Guide, Drill must be used to machine the Gearbox Casing.

For the removal of lock rings and studs, refer to Repair, VRS5255 TASK 72-60-21-300-004 (REPAIR-004), SUBTASK 72-60-21-320-054 and SUBTASK 72-60-21-350-057. For the installation of studs and lock rings, refer to Repair, VRS5255 TASK 72-60-21-300-004 (REPAIR-004), SUBTASK 72-60-21-350-058 and SUBTASK 72-60-21-350-059.

The standard practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3P16628 Guide, Drill | 0AM53 | IAE 3P16628 | ||

| Drive Tool | LOCAL | SF5902-3D | ||

| Wrench | LOCAL | R1105W | ||

| Removal tool | LOCAL | SM101-18 | ||

| Magnifying Glass | LOCAL | Magnifying Glass | ||

| Vibration peen equipment | LOCAL | Vibration peen equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-459 AQUEOUS WIPE CLEANER | 71410 | CoMat 01-459 | ||

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | ||

| CoMat 07-028 CHROMATE CONVERSION COATING FOR ALUMINUM | LOCAL | CoMat 07-028 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| STUD | 96906 | MS51992C503-11 | ||

| STUD | 96906 | MS51992C643-11 | ||

| RING - LOCKING | 96906 | MS51997E103P |

Safety Requirements

NONEProcedure

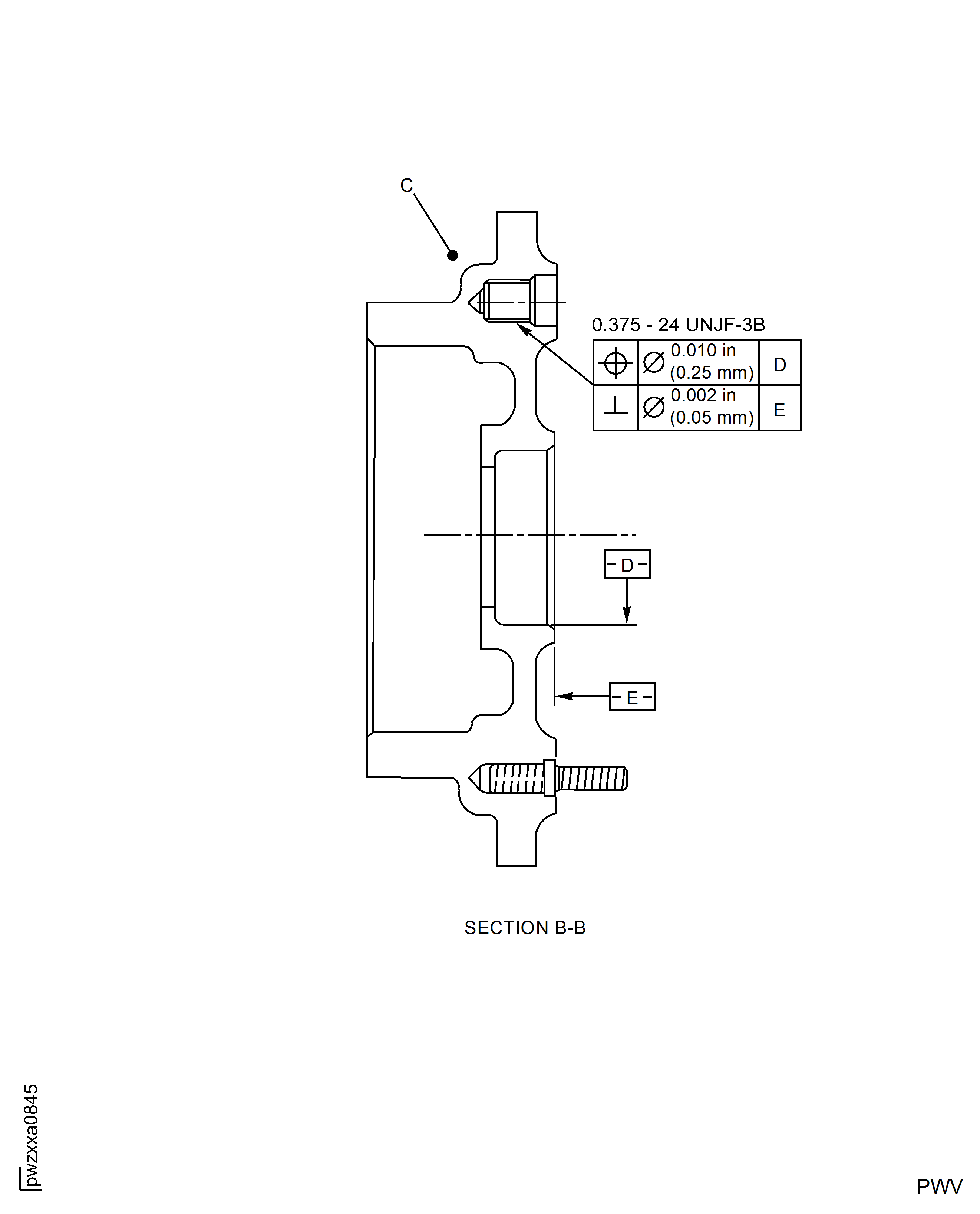

Refer to Figure.

Reference Repair, VRS5679 TASK 72-60-21-300-053 (REPAIR-053).

This repair cannot be done if you find a threaded bushing at the repair location. Examine each stud location separately.

SUBTASK 72-60-21-220-200 Examine the Repair Area

Use CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER (masking tape or similar).

Apply a mask or maskants to all bores, holes, and passage ways in the proximity of the repair area.

SUBTASK 72-60-21-380-004 Mask the Gearbox Casing

Lift tool frequently to permit clearing metal chips from the cutting teeth.

It is not necessary to mill fully through the MS51997E103P RING - LOCKING. Only milling through the serrations is necessary.

Mill through the serrations of the MS51997E103P RING - LOCKING. Use Removal tool.

Continuous pressure of withdrawn stud must cause lock ring to be forced out from its location.

Apply the removal torque to the stud.

SUBTASK 72-60-21-350-221 Remove the Stud, if Necessary

NOTE

Only remove one stud at a time. An installed stud is necessary opposite the repair area to properly locate the IAE 3P16628 Guide, Drill.Refer to Figure.

Set the Detail 8 Drill and the Detail 7 Drill Stop to produce the applicable depth tap drill hole. See Figure.

Set the Detail 9 Drill and the Detail 6 Drill Stop to produce the applicable depth counterbore. See Figure.

Remove the tape from the crank port that was applied before.

Install the Detail 4 Bushing to the Detail 1 Base. Lock in place with the Detail 5 Lock Screw.

Install the Detail 2 packing onto the Detail 1 Base.

Attach the Detail 1 Base to the gearbox casing at the manual crank pad location, use the Detail 13 Coupling Nut. Align the drill bushing end of the drill guide over the hole to be repaired. Make sure the conical end of the coupling nut mates with the countersink feature of the base.

Drill the hole with the Detail 8 Drill, Detail 7 Drill Stop, and a hand drill.

Remove the Detail 4 Bushing from the Detail 1 Base and install the Detail 3 Bushing.

Drill the counterbore for the lock ring with the Detail 9 Drill, Detail 6 Drill Stop, and a hand drill.

Tap the hole with the Detail 10 Plug Tap and Detail 12 Tap Handle.

Tap the hole with the Detail 11 Bottoming Tap and Detail 12 Tap Handle.

Remove any machining debris from the hole and the drill guide.

Remove the Detail 13 Coupling Nut and remove the Detail 1 Base from the gearbox casing.

Apply tape to the crank port to prevent debris entering the gearbox.

SUBTASK 72-60-21-320-178 Machine the Gearbox Casing using the IAE 3P16628 Drill Guide (Assembled Gearbox Module Method)

Use CoMat 01-031 ACETONE (CH3)2CO or similar.

Locally degrease the repaired area.

Use a 10X Magnifying Glass. Refer to SPM TASK 70-21-00-220-501.

Cracks are not permitted.

Examine the gearbox casing for cracks in the repair area.

Break-through is not permitted.

Examine for break-through into the internal cavity of the gearbox casing.

Refer to SPM TASK 70-38-02-300-503.

Locally repair the surface protection.

SUBTASK 72-60-21-220-201 Examine the Repair Area

Refer to Figure.

Lubricate the larger threads of the stud.

SUBTASK 72-60-21-350-222 Install the Oversize Stud

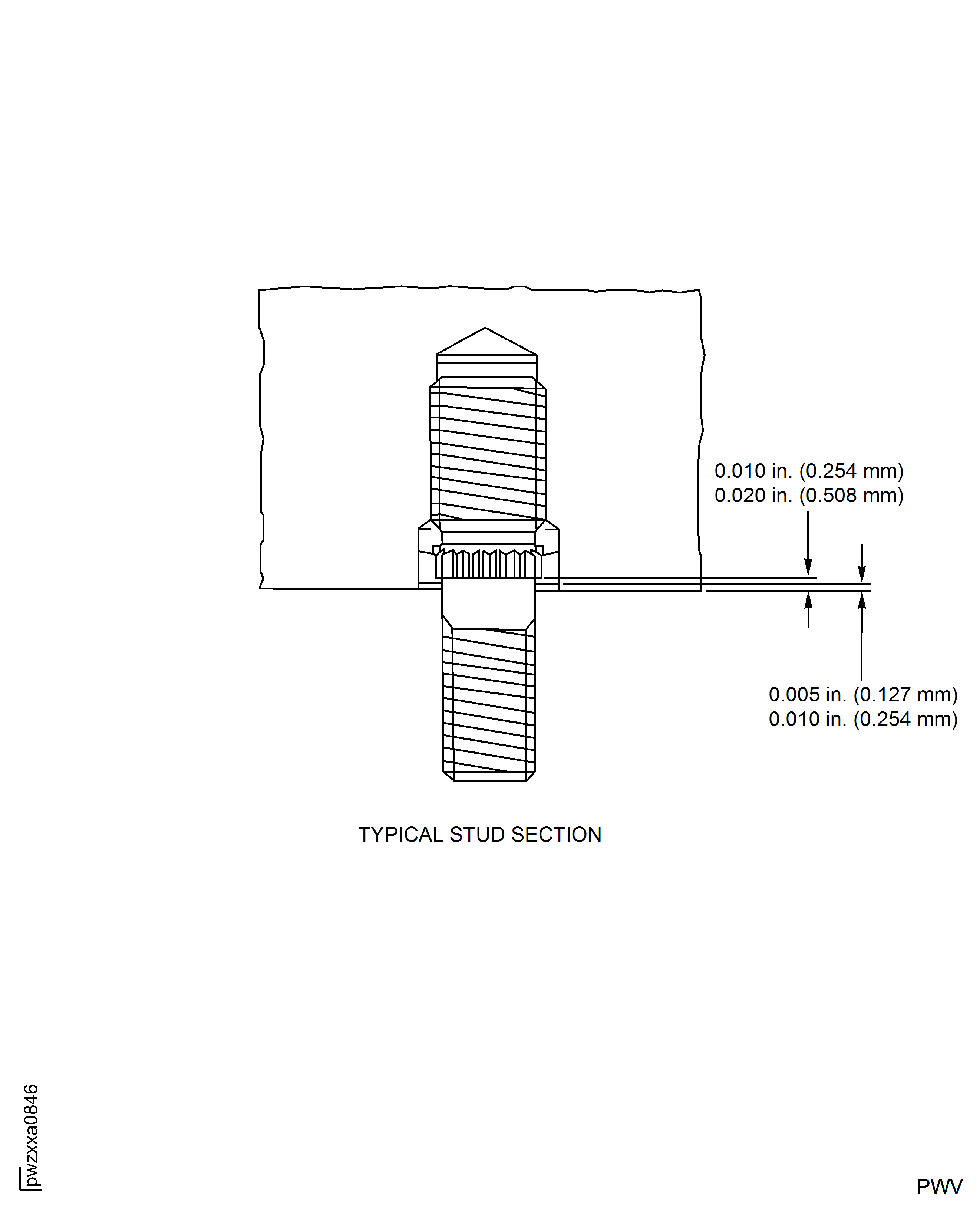

Refer to Figure.

Align the staking serrations in the directions having the most wall thickness to the edge of the boss.

Install the new MS51997E103P RING - LOCKING.

Seat the new MS51997E103P RING - LOCKING to depth given in Figure.

Use the Drive Tool.

Seat the new MS51997E103P RING - LOCKING.

SUBTASK 72-60-21-350-223 Install the Lock Ring

Use vibro engraving equipment. Refer to Repair, VRS5679 TASK 70-09-00-400-501 (REPAIR-053) and SUBTASK 70-09-00-400-001.

Make a mark VRS5713 adjacent to the part number.

Do the touch up process. Refer to SPM TASK 70-38-02-300-503.

Protect the marked area.

SUBTASK 72-60-21-350-224 Identify the Repair

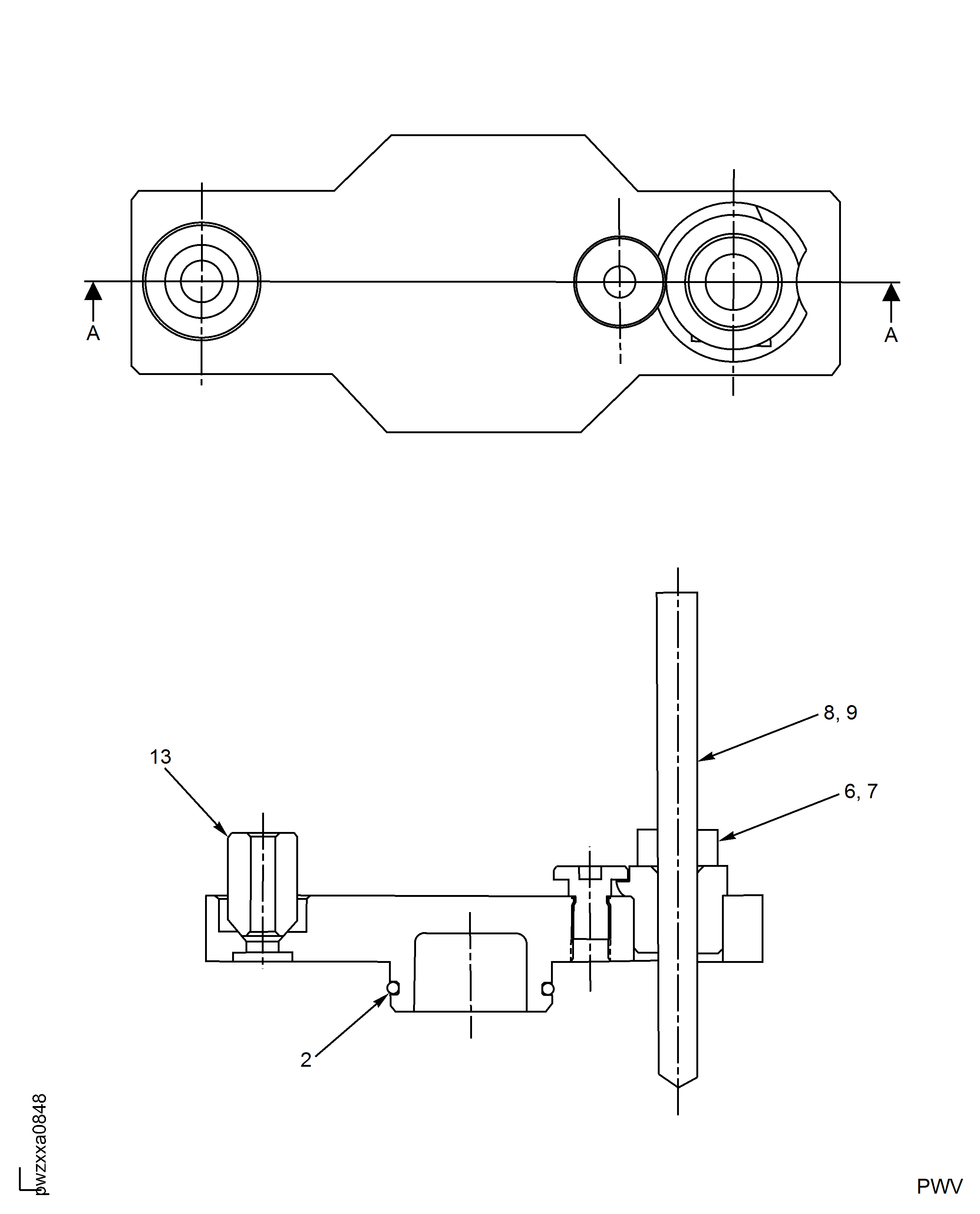

Figure: Repair Location

Repair Location

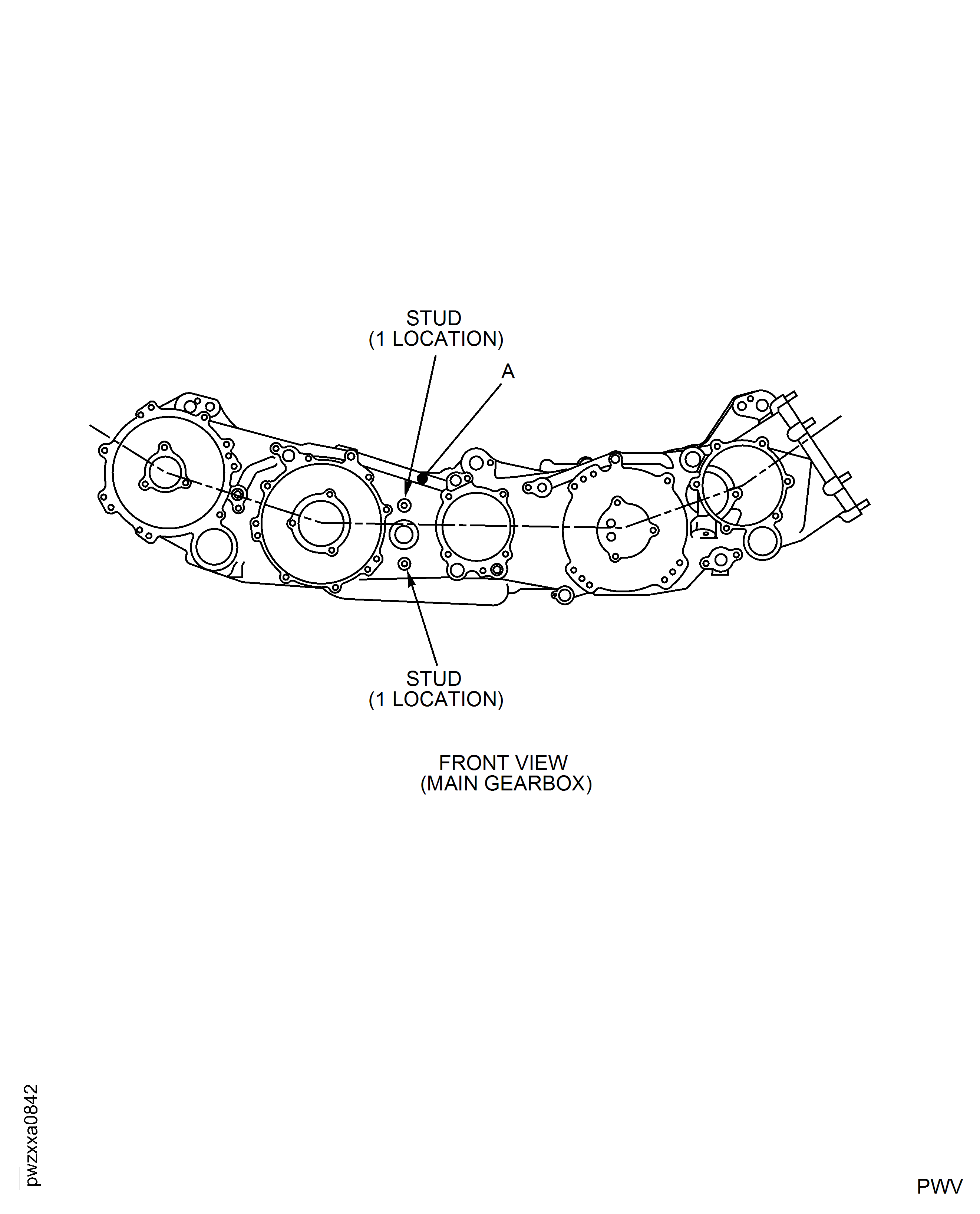

Figure: Stud Position

Stud Position

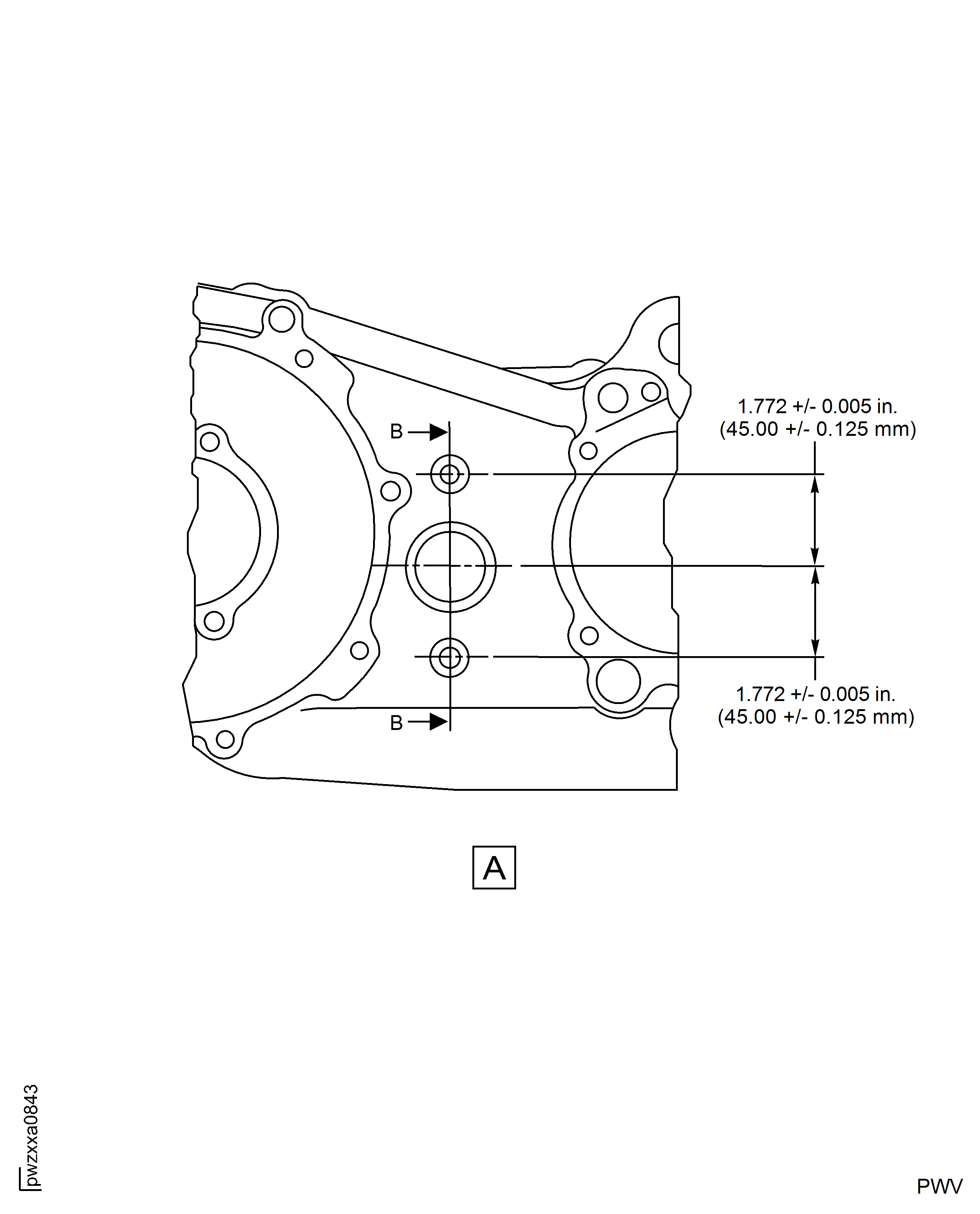

Figure: Hole Preparation

Hole Preparation

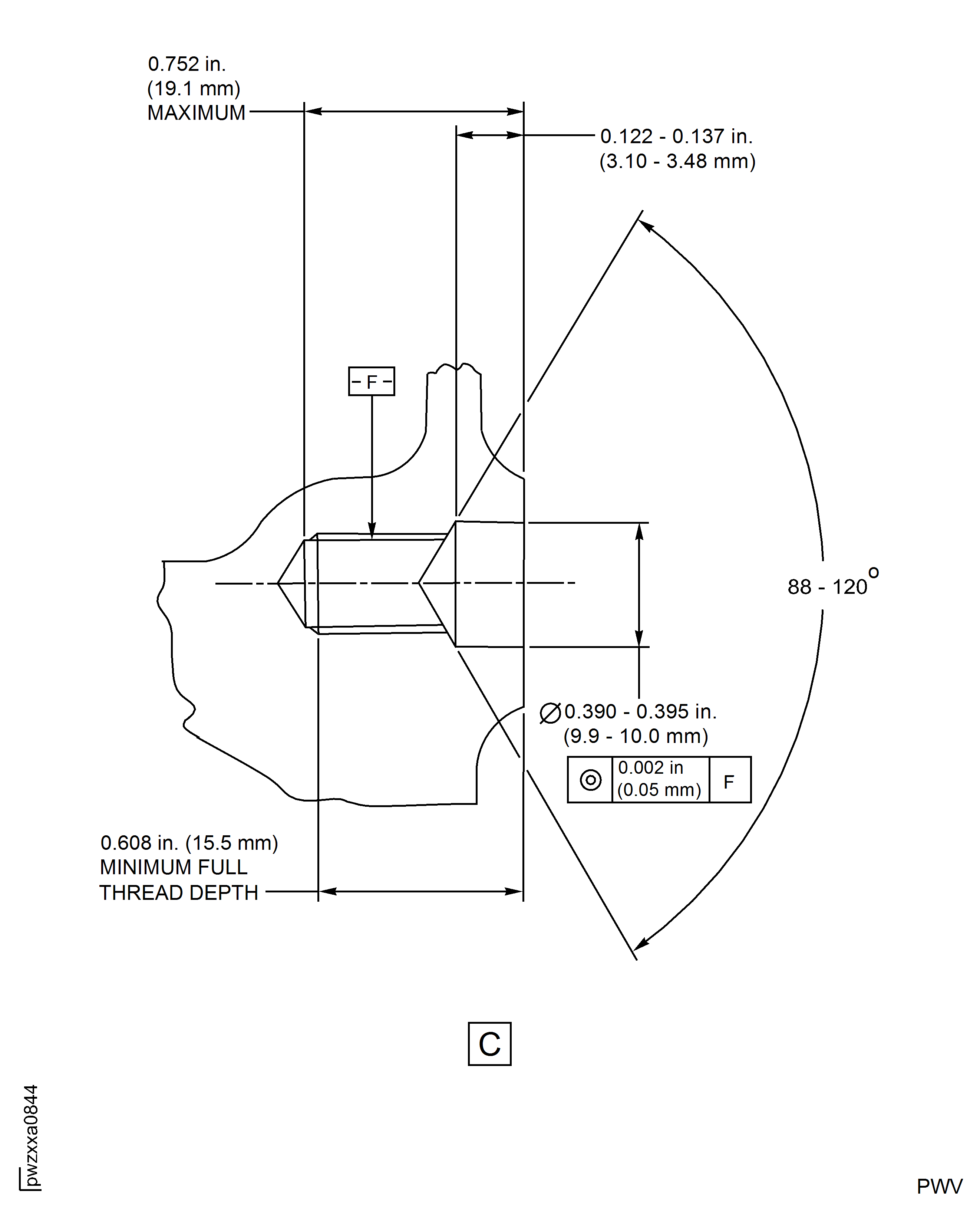

Figure: Threading

Threading

Figure: Installation Of Stud

Installation Of Stud

Figure: Drill Guide

Drill Guide

Drill Guide