Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-61-49-300-004 Gearbox Breather Outlet Oil Duct - Weld Repair A Patch, Repair-004 (VRS7503)

General

This repair can be done on the gearbox breather outlet duct during overhaul.

Price and availability - none.

Related repairs - none.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Argon-arc welding equipment | LOCAL | Argon-arc welding equipment | ||

| Wire brush | LOCAL | Wire brush |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 | Local supply material: MIL-T-8808B Type 347 0.032 in. (0.81 mm). |

Spares

NONESafety Requirements

NONEProcedure

Refer to Cleaning-001 TASK 72-61-49-100-101.

WARNING

KEEP FLAMES AND ELECTRICAL EQUIPMENT WHICH IS NOT FLAMEPROOF AWAY FROM THE WORK AREA. THE CLEANING FLUID IS FLAMMABLE.

WARNING

DO NOT GET CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GOGGLES AND A MASK. USE THE FLUID IN A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET THE FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.Clean the gearbox breather outlet duct.

SUBTASK 72-61-49-110-001 Clean the Gearbox Breather Outlet Duct

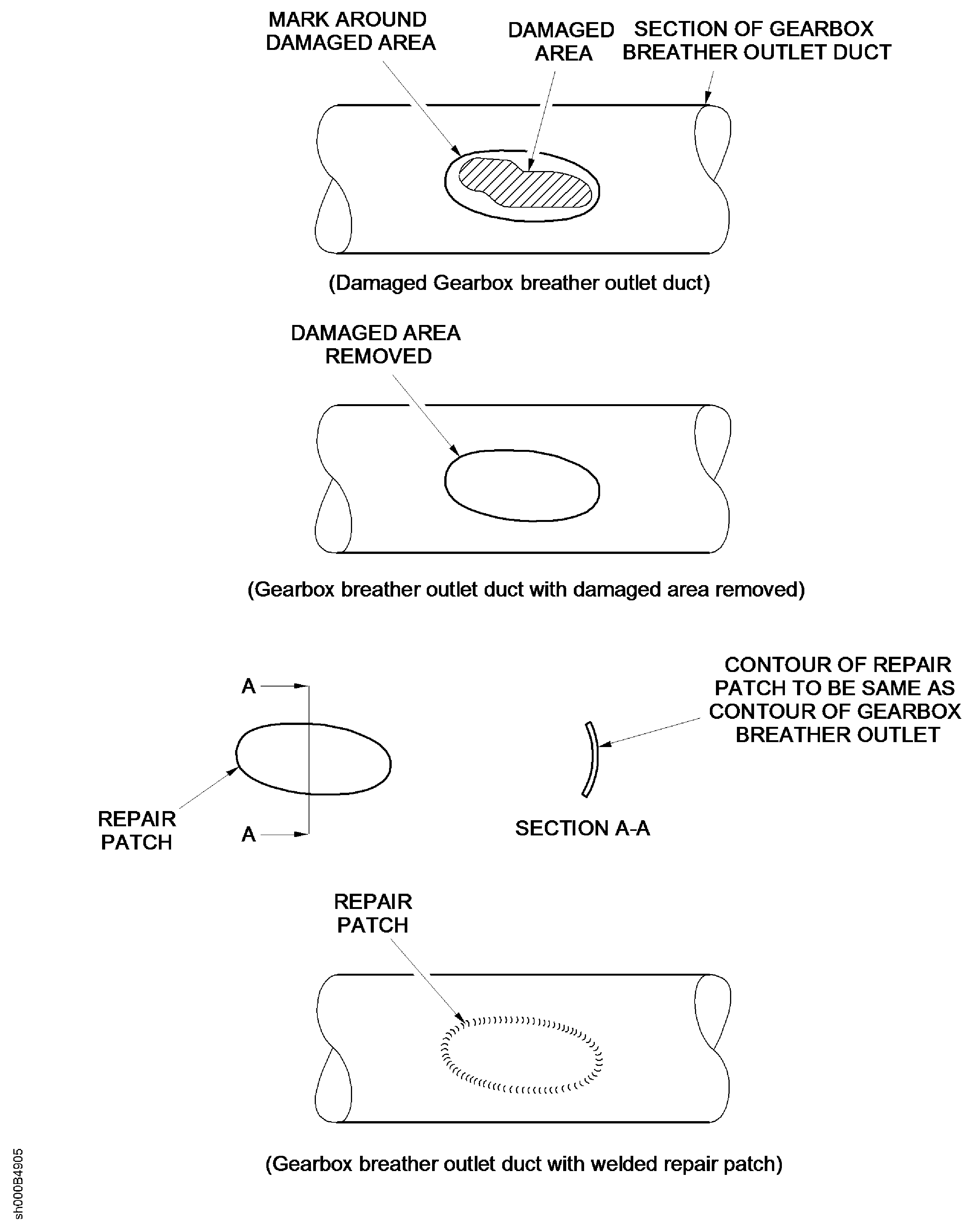

Refer to Figure.

Make sure that the mark is symmetrical in shape and larger all around than the damaged area.

Identify the area to be removed.

Use the standard workshop tools and cut along the mark around the damaged area. Remove the damaged area.

Removed the damaged area.

Use the standard workshop tools.

Remove all the sharp edges from the cut-out in the gearbox breather outlet duct.

SUBTASK 72-61-49-350-001 Prepare the Damaged Area

Use the standard workshop tools and either a section of used gearbox breather outlet duct or the applicable repair material.

Make the repair patch to the same dimensions as the cut-out in the gearbox outlet duct.

Roll the material until the contour of the repair patch and the gearbox breather outlet duct are the same.

Make a repair patch.

Use the standard workshop tools.

Remove the sharp edges from the repair patch.

SUBTASK 72-61-49-350-002 Make a Repair Patch

Refer to Cleaning-001 TASK 72-61-49-100-101.

WARNING

KEEP FLAMES AND ELECTRICAL EQUIPMENT WHICH IS NOT FLAMEPROOF AWAY FROM THE WORK AREA. THE CLEANING FLUID IS FLAMMABLE.

WARNING

DO NOT GET CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GOGGLES AND A MASK. USE THE FLUID IN A WELL VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET THE FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.Clean the gearbox breather outlet duct.

SUBTASK 72-61-49-110-002 Clean the Gearbox Breather Outlet Duct

If necessary, tack weld the repair patch into position.

Put the repair patch into the correct position for installation.

Refer to SPM TASK 70-31-02-310-501-001.

The welding data is as follows:

Type - Argon-arc D.C Torch - B.O.C W200 or equivalent

Electrode - 2% ceriated tungsten with 0.0625 in. (1.54 mm) diameter

Weld the repair patch.

NOTE

The argon backing flow, the argon torch flow and the current flow must be determined by experiment on suitable test pieces.Let the repair cool.

SUBTASK 72-61-49-310-001 Install the Repair Patch

Use the Wire brush to remove unwanted materials caused by the repair.

Clean the repaired area.

SUBTASK 72-61-49-120-001 Clean the Repaired Area

Refer to SPM TASK 70-31-02-310-501-001.

Make sure that the repair is satisfactory.

Visually examine the repaired area of the gearbox breather outlet duct.

SUBTASK 72-61-49-220-009 Examine the Repair

Refer to SPM TASK 70-31-02-310-501-001.

Do the dye-penetrant test of the repair.

SUBTASK 72-61-49-230-003 Examine the Repair

Refer to SPM TASK 70-31-02-310-501-001.

Do the X-ray inspection of the repair.

SUBTASK 72-61-49-260-001 Examine the Repair

Refer to Testing-001 TASK 72-61-49-700-101.

Do a pressure test of the gearbox outlet duct.

SUBTASK 72-61-49-780-001 Pressure Test the Gearbox Breather Outlet Duct

Refer to SPM TASK 70-09-00-400-501.

Put the repair number VRS7503 on the gearbox breather outlet duct adjacent to the part number using electro-etch method.

SUBTASK 72-61-49-850-001 Put the Repair Number on the Gearbox Breather Outlet Duct

Figure: Repair Details and Dimensions

Repair Details and Dimensions