Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-22-41-300-006 No. 4 Bearing Compartment Cooler (ACAC) Air Ducts - Weld Repair The Outlet Duct, Repair-006 (VRS1649)

General

This TASK gives the procedure for repair by welding of crack on the ACAC outlet duct.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Welders must be fully approved by the applicable regulatory authority.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| TIG welding equipment | LOCAL | TIG welding equipment | ||

| Sealed welding chamber | LOCAL | Sealed welding chamber | ||

| Heat Treatment Equipment | LOCAL | Heat Treatment Equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 01-124 ISOPROPYL ALCOHOL | LOCAL | CoMat 01-124 | ||

| CoMat 03-348 WELDING WIRE | LOCAL | CoMat 03-348 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 | ||

| CoMat 06-063 FLUORESCENT PENETRANT (POST-EMULSIFIED MEDIUM SENSITIVITY) | LOCAL | CoMat 06-063 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Refer to Inspection-001 TASK 75-22-41-200-101.

Write down the crack location and dimension.

Repair cracks which begin only from the welded joints and are not more than 1.0 in. (25.4 mm) in length.

Do the crack test.

SUBTASK 75-22-41-230-057 Examine the ACAC Outlet Duct (01-400) for Damaged Area

Refer to Figure.

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Do again Step

Cracked in the damaged area.

Crack test on the damaged area.

SUBTASK 75-22-41-230-058 Examine the ACAC Outlet Duct (01-400) for Damaged Area

Roughen the damaged area.

Refer to SPM TASK 70-11-26-300-503.

Clean the damaged area.

SUBTASK 75-22-41-350-059 Prepare the Damaged Area for Welding

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Routed out with CoMat 03-348 WELDING WIRE and TIG welding equipment with Sealed welding chamber.

CAUTION

SURFACES FOR REPAIR MUST BE FULLY CLEANED AND DO NOT TOUCH BY HAND. CLEAN COTTON OR POLYTHENE GLOVES MUST BE WORN.Weld to repair the crack.

SUBTASK 75-22-41-310-002 The Procedure to Weld the Damaged Area

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Do again Step

Cracked.

Crack test on the repaired area.

SUBTASK 75-22-41-230-059 Examine the Repaired Area

Refer to SPM TASK 70-37-17-370-501.

Heat treat the outlet duct, in a controlled argon gas chamber.

Heat to a temperature of 1099 deg F (593 deg C) plus or minus 18 deg F (10 deg C) for 2 hours.

Cool down to room temperature with fan cool in argon gas.

Heat Treat Data.

SUBTASK 75-22-41-370-001 Heat Treat the ACAC Outlet Duct

Cracks or unwanted material are not permitted.

Pores larger than 0.006 in. (0.13 mm) diameter are not permitted. Pores with a distance of less than 0.200 in. (5.10 mm) between them, are not permitted.

Surfaces broken by pores are not permitted.

Use radiographic equipment.

Table 3. X-Ray Data Source

Beryllium window

Source to film distance (SFD)

27.56 in. (700.0 mm) minimum

Kilovoltage

86 KV

Tube current

5 mA

Exposure time

30 seconds

Thickness and type of screens

0.00012 in. (0.03 mm) Lead foi

Type of film

KODAK INDUSTREX M100 film (Refer to ASTM E 1815-96 Class I)

Penetrameter

Ti 0.010 in. (0.25 mm)

Radio graphically examine the welded area.

SUBTASK 75-22-41-260-001 Examine the Outlet Duct

Refer to SPM TASK 70-23-05-230-501.

Do the crack test.

Do again Step

Cracked in the damaged area.

Crack test on the damaged area.

SUBTASK 75-22-41-230-060 Examine the Outlet Duct

Make sure the bolt hole(s) are to the dimensions given.

Make sure there is no distortion of the outlet duct.

Use workshop inspection equipment.

Visually examine and measure the dimension of the bolt hole(s) in the ACAC outlet duct.

Reject the outlet duct.

If the bolt hole(s) are more than the given limits.

SUBTASK 75-22-41-220-072 Examine the Outlet Duct

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Mark the number of times this repair has been completed on the duct.

Vibro-engrave the number of times in a triangle adjacent to the part number.

Make a mark VRS1649 adjacent to the assembly number.

SUBTASK 75-22-41-350-060 Identify the Repair

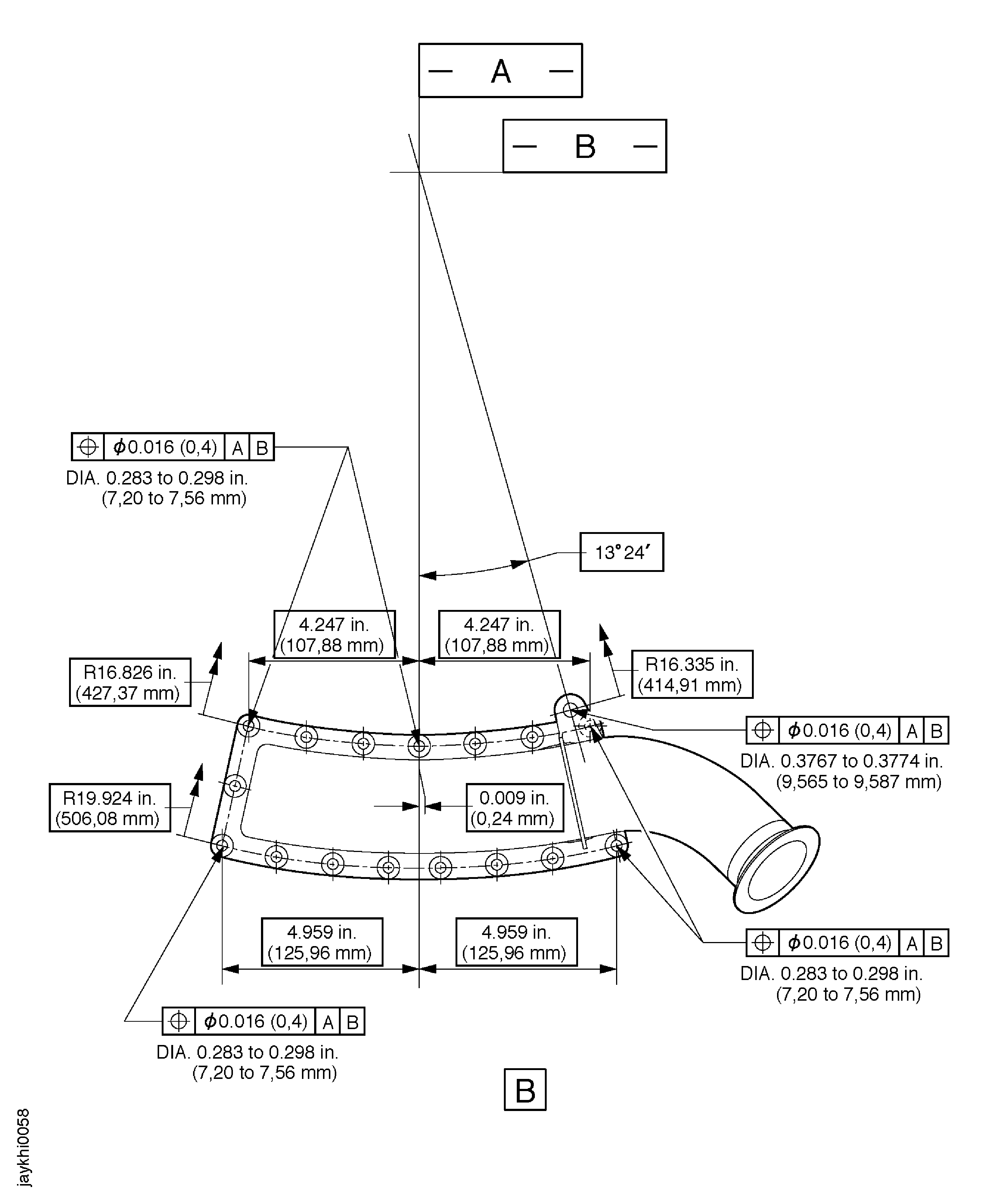

Figure: Air Cooled Air Cooler (ACAC) Outlet Duct

Air Cooled Air Cooler (ACAC) Outlet Duct

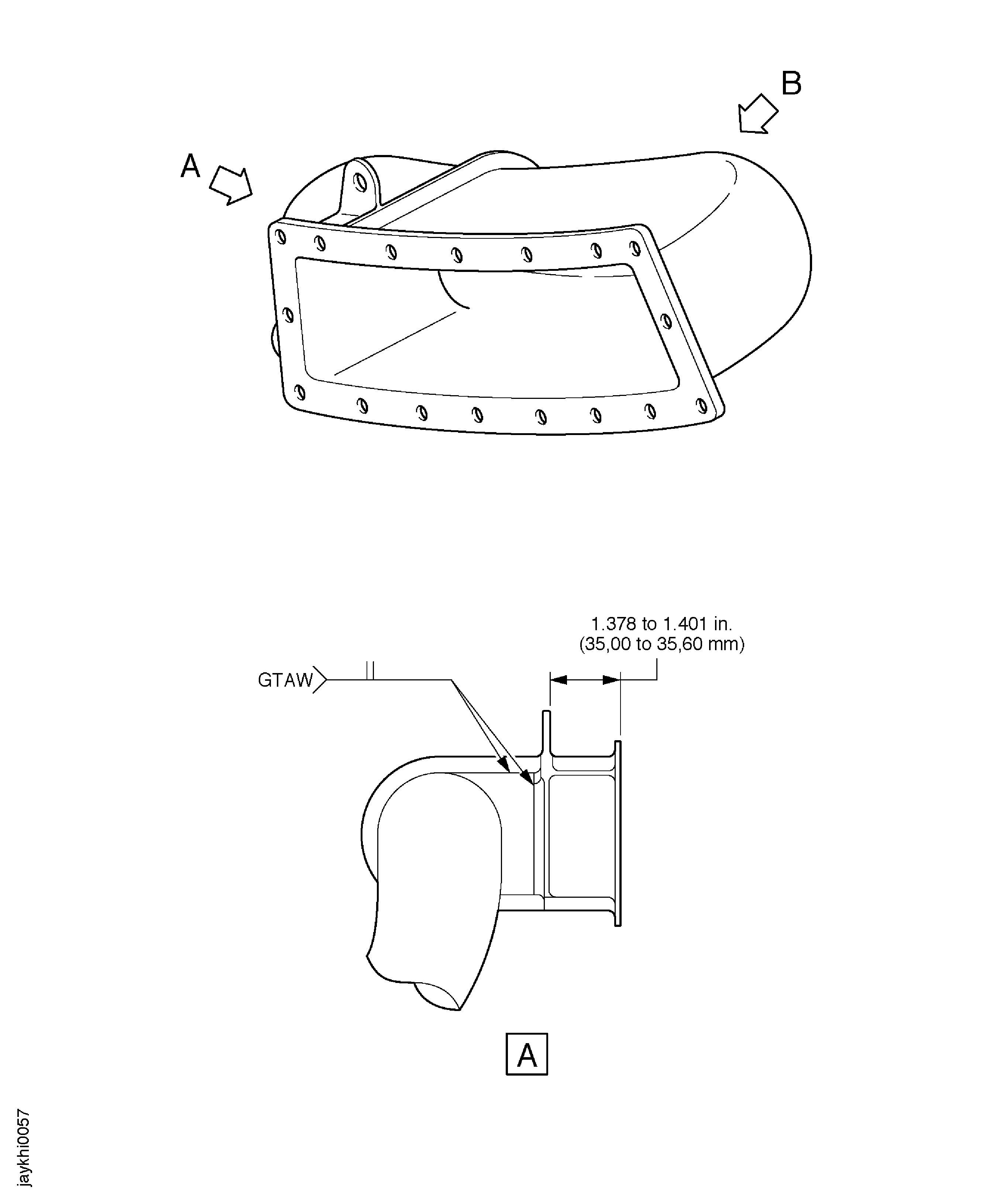

Figure: Detail Dimensions of the Repair Part

Detail Dimensions of the Repair Part