Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

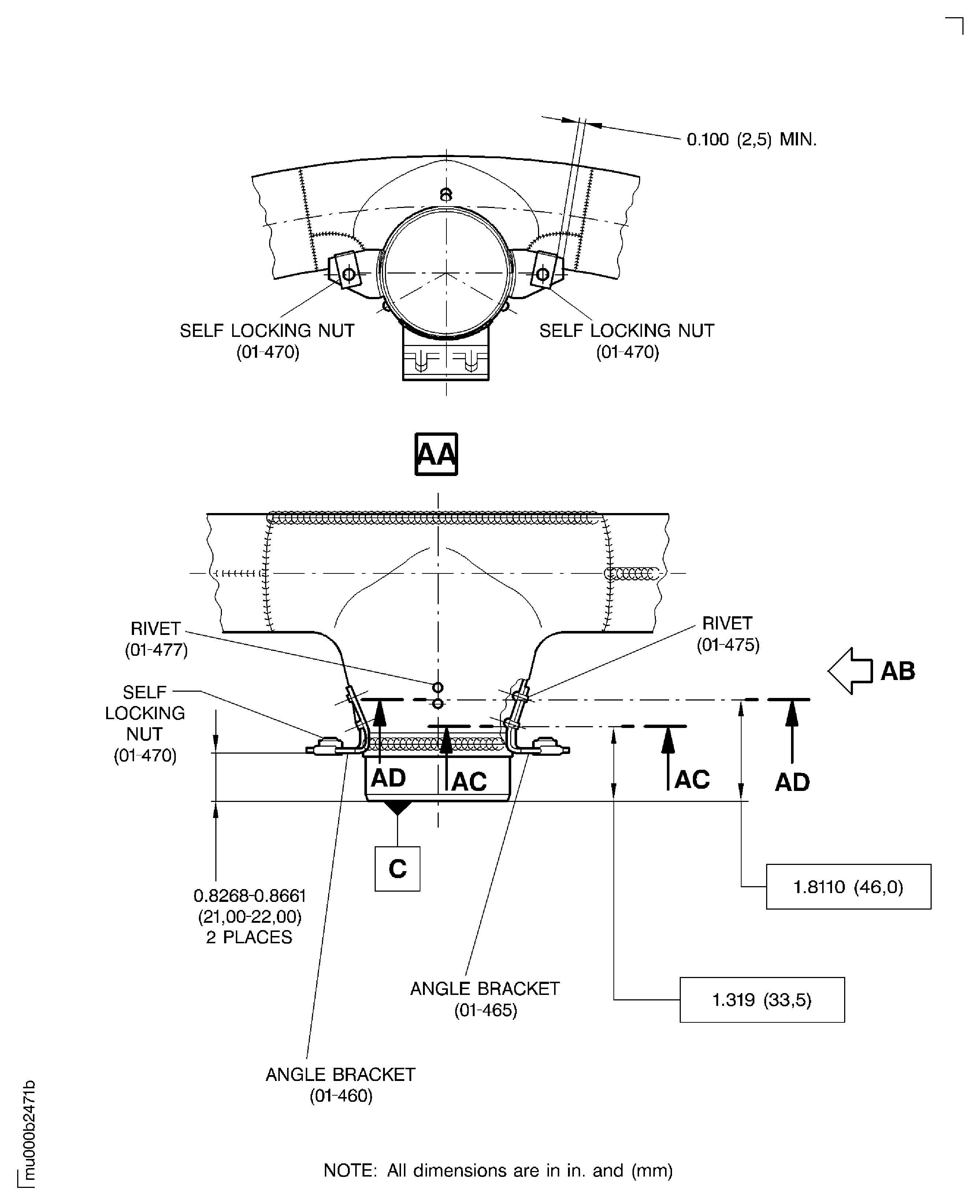

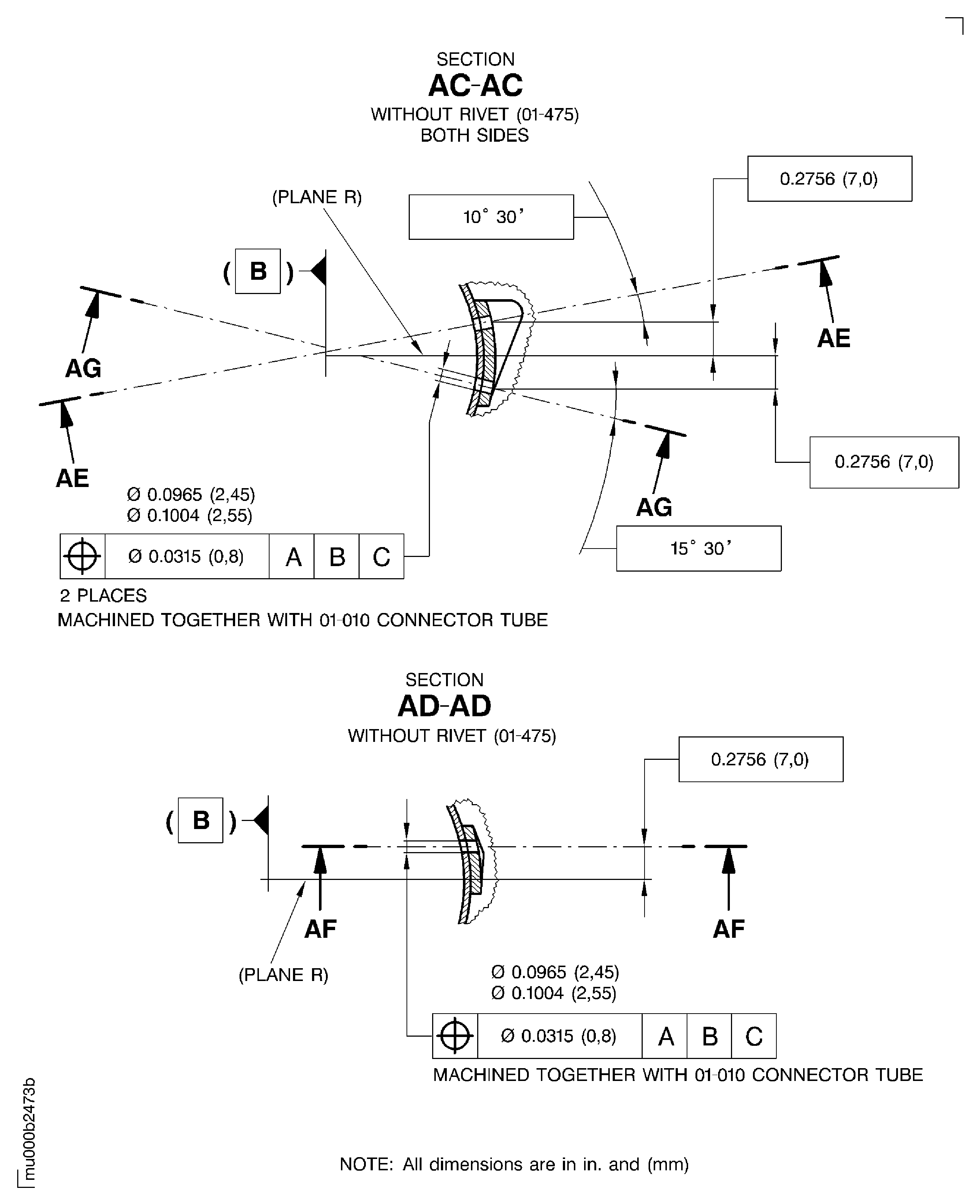

TASK 75-24-49-840-001 LPT ACC Connector Air Tube - Install New Angle Brackets, Rework-001 - SBE 75-0051

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Hand held grinder | LOCAL | Hand held grinder |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Put the connector tube on a suitable workbench.

Use Hand held grinder.

Grind off (01-400 or 01-401) carefully.

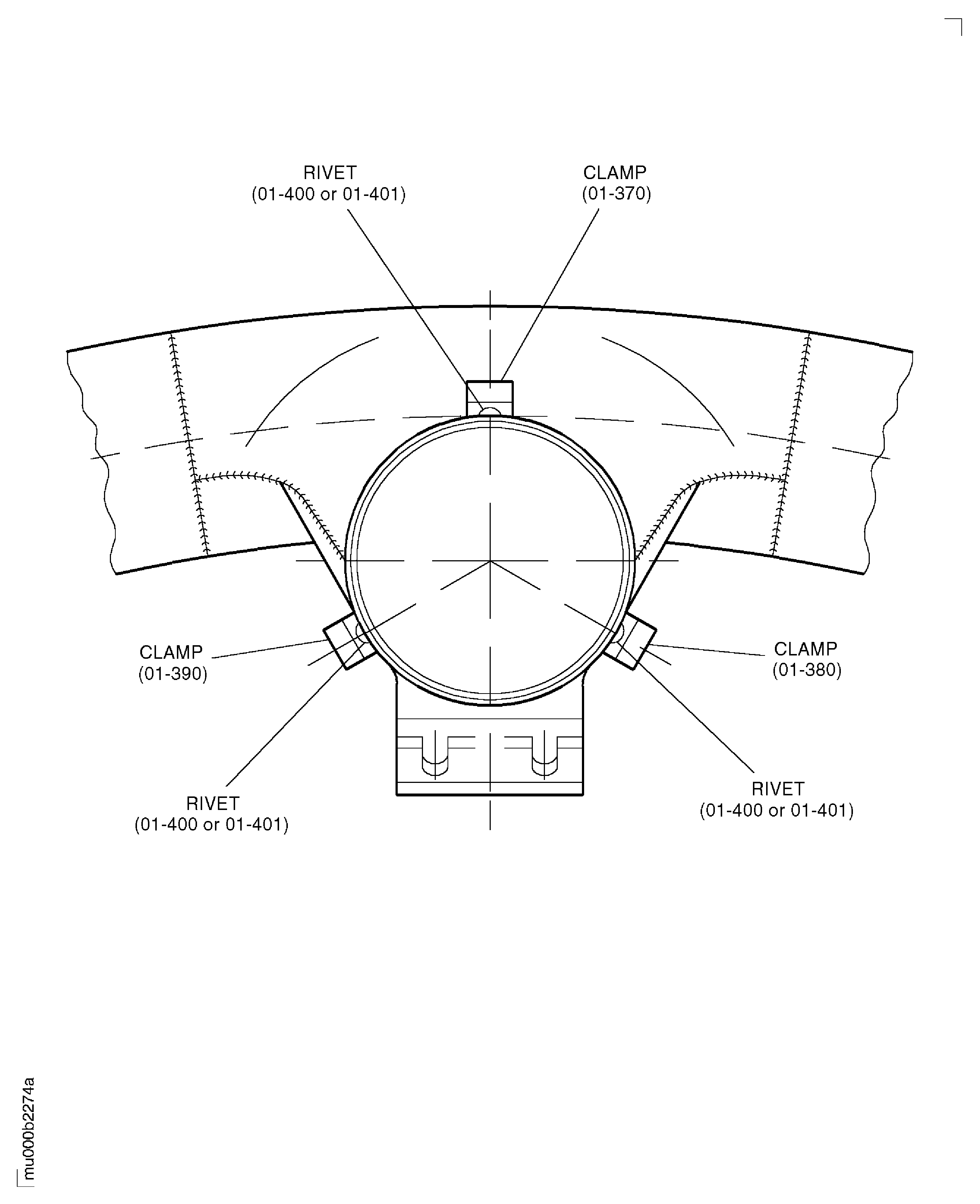

Remove the rivets and the clamps.

SUBTASK 72-24-49-320-054 Remove the Clamps

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Repair the cracks.

Refer to Repair, VRS4251 (Repair-007) TASK 75-24-49-300-007.

Examine the local surface for cracks.

SUBTASK 75-24-49-230-164 Do a Crack Test at the ACC Connector Tube

Refer to SPM TASK 70-11-06-300-503.

Clean the surfaces around the rivet holes.

SUBTASK 75-24-49-110-138-001 Clean the Connector Tube

Refer to SPM TASK 70-11-26-300-503.

Clean the surfaces around the rivet holes.

SUBTASK 75-24-49-110-138-002 Clean the Connector Tube

Refer to Figure.

Refer to SPM TASK 70-39-03-390-501. The rivets must be tight.

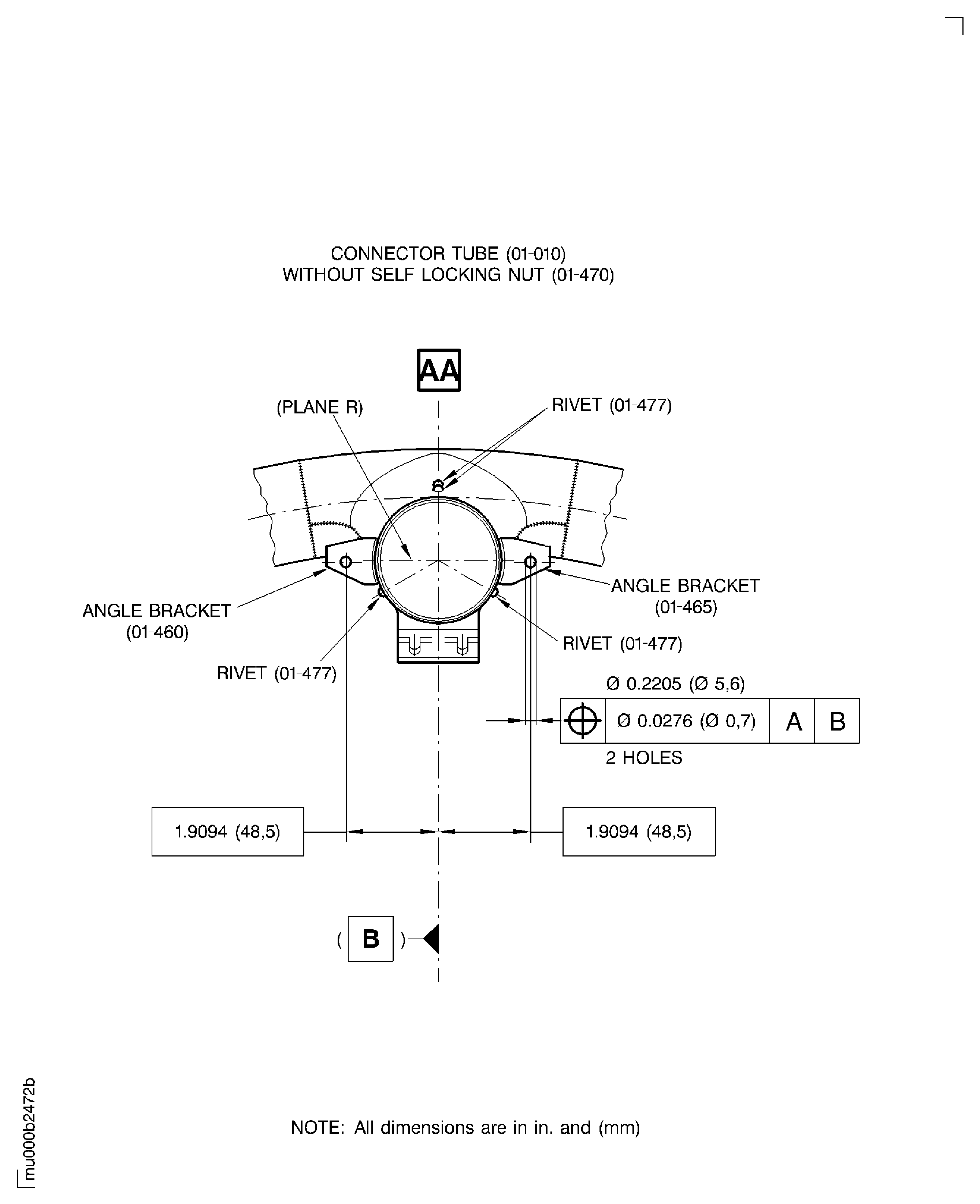

Blank off the six existing rivet holes with blind rivets (01-477). Use replacement blind rivets with part number ST1086-01 or AN123168.

SUBTASK 75-24-49-390-051 Blank off the Existing Rivet Holes

Refer to Figure.

Oversize diameter must be between 0.1275 to 0.1315 in. (3.24 to 3.34 mm).

Drill initial rivet holes to oversize diameter.

Refer to SPM TASK 70-39-03-390-501. The rivet holes must be tight.

Blank off the oversize rivet holes with blind rivets (01-477). Use replacement blind rivets with part number AN123184 or NAS1398C4-1.

SUBTASK 75-24-49-390-053 Blank off the Existing Rivet Holes with Oversize Rivets

Refer to Figure.

Use Hand held grinder.

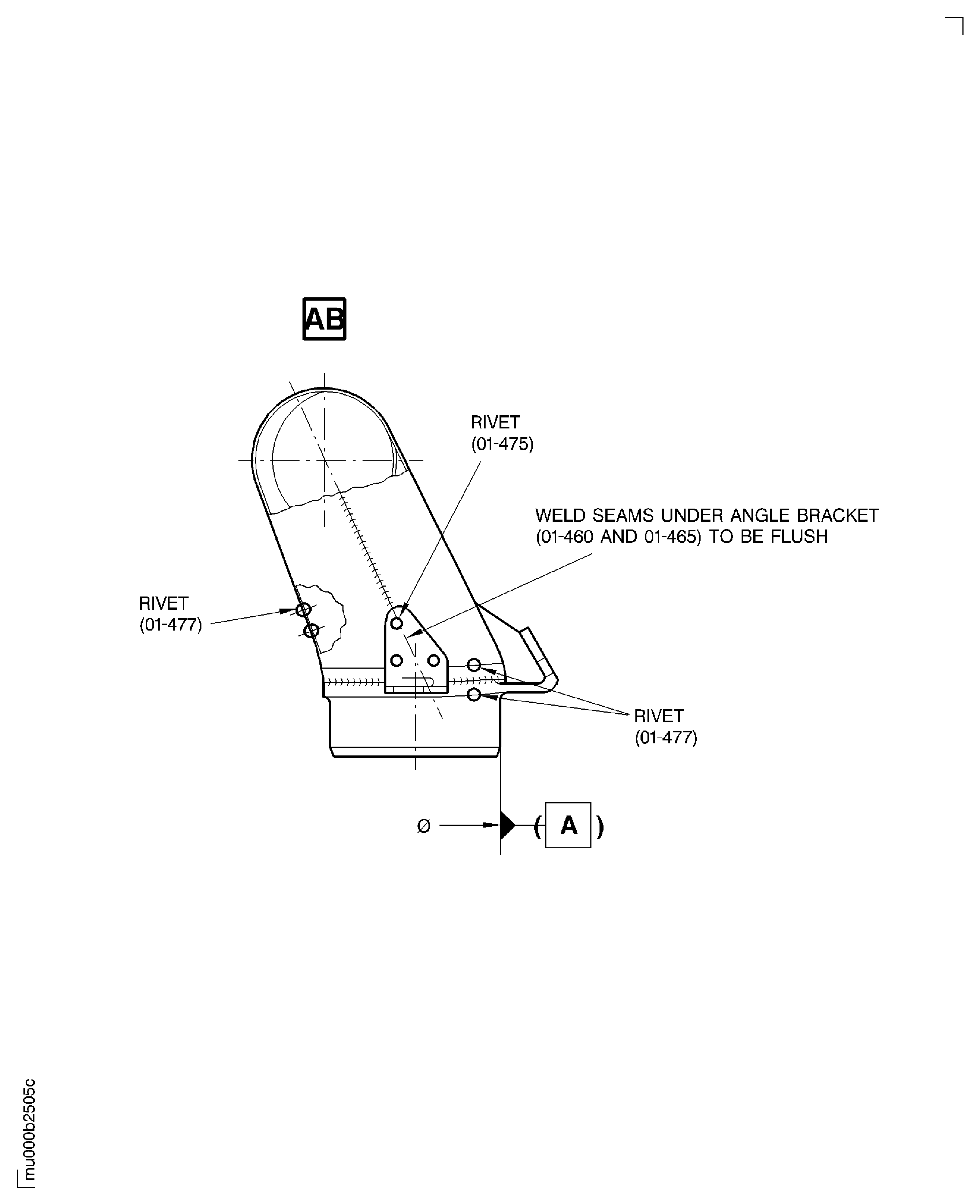

Remove the weld build up at the weld seams.

SUBTASK 75-24-49-320-055 Prepare the Connector Tube for Installation of the Angle Brackets

CAUTION

KEEP MATERIAL REMOVAL TO THE MINIMUM TO AVOID DAMAGE TO THE CONNECTOR TUBE.Refer to SPM TASK 70-23-05-230-501.

Cracks are not permitted except linear indications not more than 0.008 in. (0.2 mm) in weld seams

Do the test for cracks at the dressed areas.

SUBTASK 75-24-49-230-077 Do a Crack test at the ACC Connector Tube

Refer to SPM TASK 70-39-03-390-501.

Install the angle brackets with six rivets (01-475).

Install the self locking nuts (01-470).

SUBTASK 75-24-49-390-052 Install the Angle Brackets

Refer to SPM TASK 70-39-03-390-501 for acceptance standards.

Examine the quality of the machine riveting and safety of joints.

SUBTASK 75-24-49-220-232 Examine the Rivets

Refer to Figure.

Install the self locking nuts.

SUBTASK 75-24-49-430-001 Install the Self Locking Nuts

Use shallow electrochemical marking method. Refer to SPM TASK 70-09-00-400-501.

NUMBER BEFORE - 3A0494

NEW NUMBER - 3A2335

NUMBER BEFORE - 3A1549

NEW NUMBER - 3A2316

Identify the connector tube with the new part number.

SUBTASK 75-24-49-320-056 Identify the ACC Connector Tube (01-010) with the New Part Number

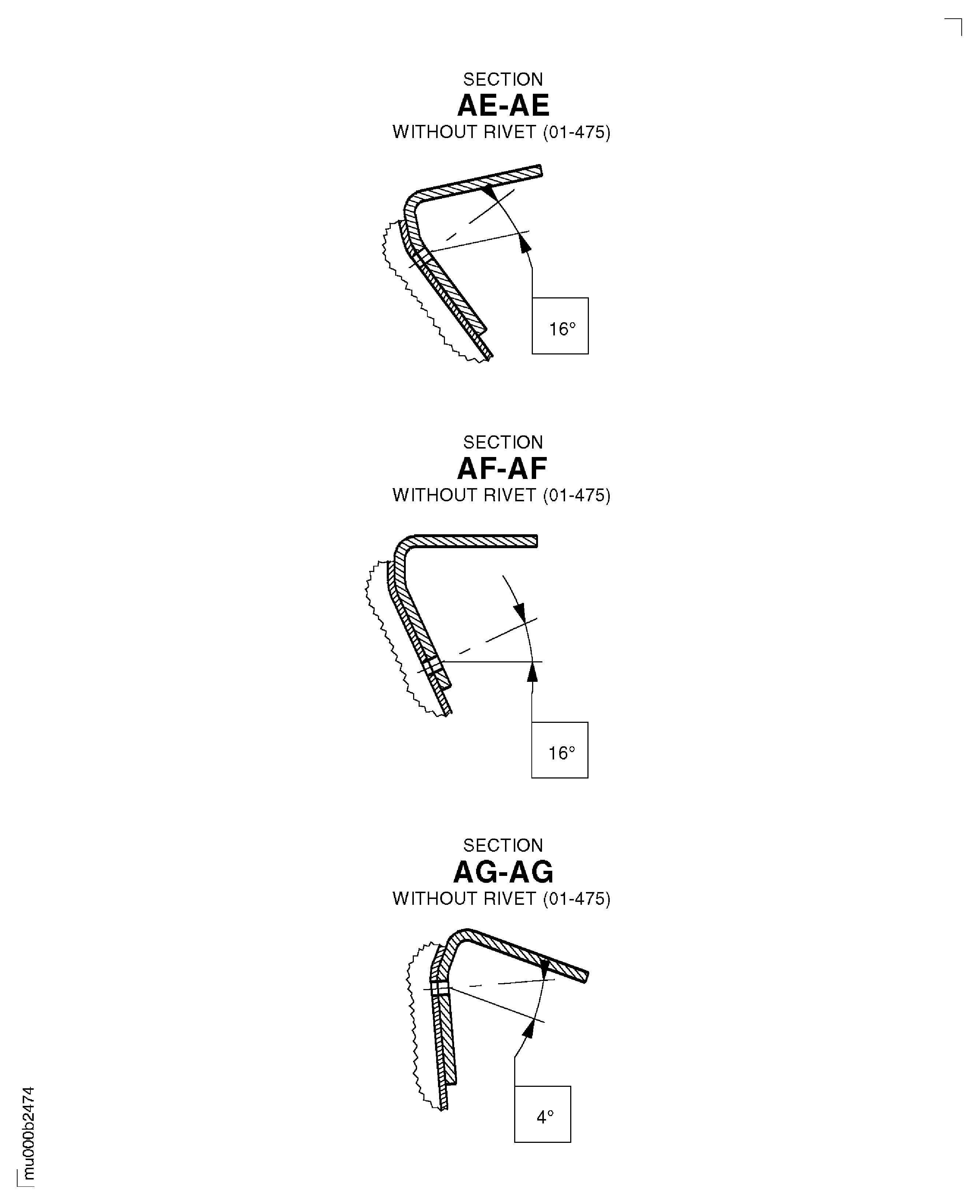

Figure: Rework of the ACC Connector Tube

Rework of the ACC Connector Tube

Rework of the ACC Connector Tube

Rework of the ACC Connector Tube

Rework of the ACC Connector Tube

Rework of the ACC Connector Tube

Rework of the ACC Connector Tube