Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-31-42-300-005 LPC Bleed Master Actuator - Related Parts - Weld Repair Cracks To The LPC Bleed Master Actuator Bracket Assembly, Repair-005 (VRS6627)

Material of component

PART IDENT | SYMBOL | MATERIAL |

LPC Bleed Master Actuator Bracket Assembly | EAK | Modified 12 percent Chromium Steel |

EBQ | 11 percent Chromium 1 percent Molybdenum Steel |

General

This Repair must only be done when the instruction to do so is given in 75-31-42 Inspection/Check.

The practices and processes referred to in the procedures by the TASK/SUBTASK numbers, are in the SPM.

Price and availability.

Refer to International Aero Engines.

Related repairs.

LPC Bleed Master Actuator Bracket Assembly - Replace Surface Protection, refer to VRS6628, (Repair-006) TASK 75-31-42-300-006.

Equivalent materials or equipment can be used.

More equipment and materials necessary to do this Repair are in the SPM TASKS given below:

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Chemical cleaning equipment | LOCAL | Chemical cleaning equipment | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Argon-arc welding equipment | LOCAL | Argon-arc welding equipment | ||

| Heat-treat equipment | LOCAL | Heat-treat equipment | ||

| Penetrant Crack Test Equipment | LOCAL | Penetrant crack test equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Vibro-engraving equipment | LOCAL | Vibro-engraving equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-181 WELDING WIRE 12% Cr. STEEL | LOCAL | CoMat 03-181 | ||

| CoMat 06-018 FLUORESCENT PENETRANT (POST-EMULSIFIED HIGH SENSITIVITY) | 37676 | CoMat 06-018 | ||

| CoMat 06-022 FLUORESCENT PENETRANT (POST-EMULSIFIED ULTRA HIGH SENSITIVITY) | LOCAL | CoMat 06-022 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-11-05-300-503.

Remove the paint from the LPC Bleed Master Actuator Bracket Assembly.

SUBTASK 75-31-42-110-053 Chemically Remove the Paint

Refer to Figure.

Make sure the paint has been completely removed from the weld area(s).

Visually examine the area(s) to be welded.

SUBTASK 75-31-42-220-069 Examine the Bracket

Chemically clean the LPC Bleed Master Actuator Bracket Assembly. Refer to SPM TASK 70-11-03-300-503, SUBTASK 70-11-03-300-002.

SUBTASK 75-31-42-110-054 Chemically Clean

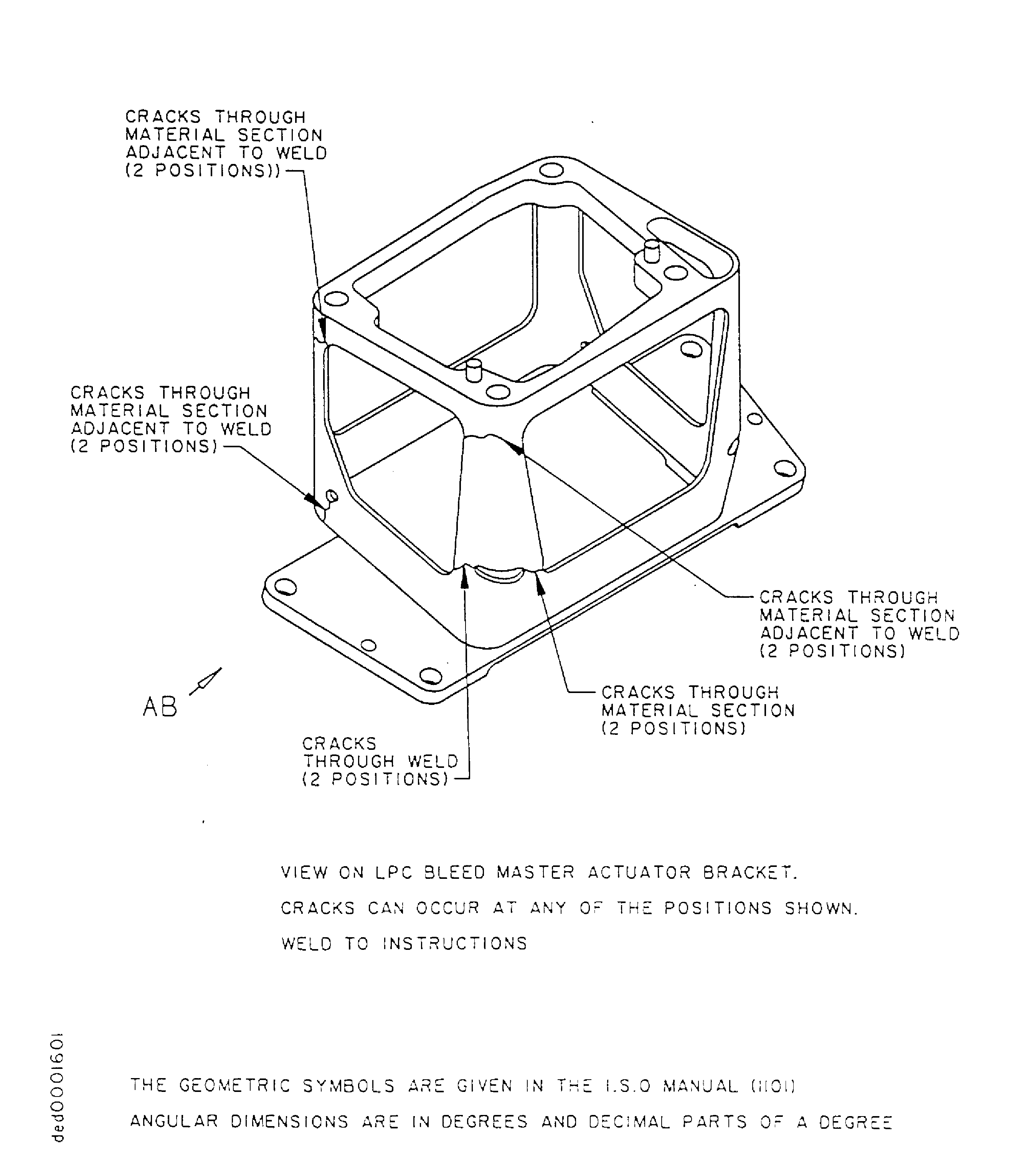

Refer to Figure.

Lightly vee-groove the area(s) for welding.

SUBTASK 75-31-42-350-052 Prepare the Bracket for Welding

Refer to Figure.

Chemically clean the area(s) to be welded. Refer to SPM TASK 70-31-02-310-501-001, SUBTASK 70-31- 02-120-001.

SUBTASK 75-31-42-110-055 Clean the Area(s) to be Welded

Refer to Figure.

CAUTION

DO NOT USE COPPER, ALUMINUM AND/OR ZINC BASE ALLOY TOOLS TO HOLD THE COMPONENT.Weld the crack(s) in the LPC Bleed Master Actuator Bracket Assembly. Refer to SPM TASK 70-31-02-310-501-001.

SUBTASK 75-31-42-310-051 Weld the Bracket

Use Heat-treat equipment.

Heat-treat the LPC Bleed Master Actuator Bracket Assembly. Refer to SPM TASK 70-31-02-310-501-004.

Heat to a temperature of 1202 deg F (650 deg C) and hold for 30 minutes.

Cool down to room temperature in air.

Heat-treat data

SUBTASK 75-31-42-370-051 Heat-treat the Bracket

Cracks are not permitted.

Do a local penetrant crack test of the welded area(s). Refer to SPM TASK 70-23-05-230-501.

SUBTASK 75-31-42-230-053 Do a Crack Test

Chemically clean the repaired area(s) to remove fluorescent penetrant. Refer to SPM TASK 70-11-26-300-503.

SUBTASK 75-31-42-110-056 Chemically Clean

Refer to Figure.

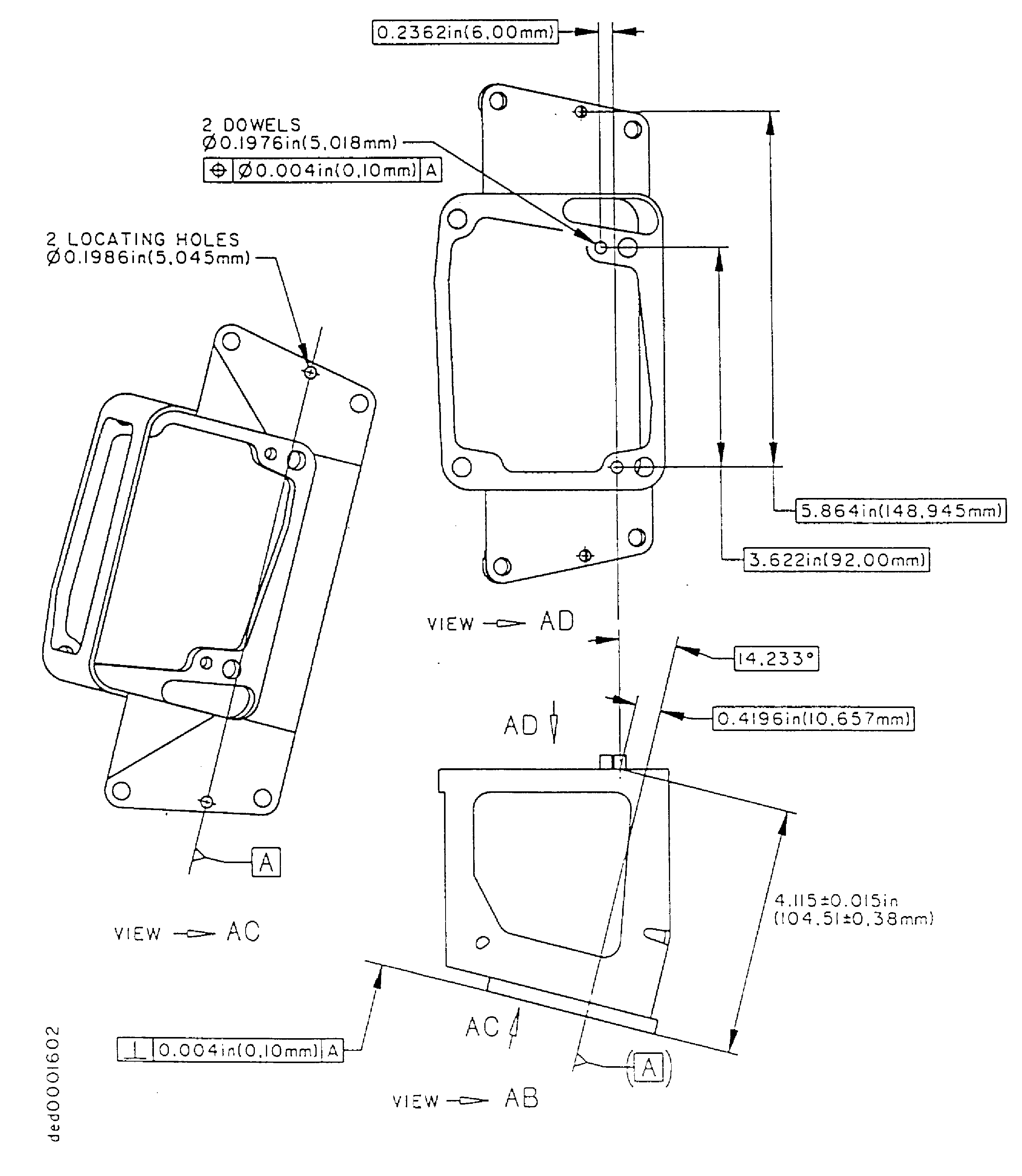

Check the bracket to make sure that critical dimensions are kept.

Visually examine and measure the dimensions of the LPC Bleed Master Actuator Bracket Assembly.

SUBTASK 75-31-42-220-070 Examine the Bracket

Refer to Figure.

NOTE

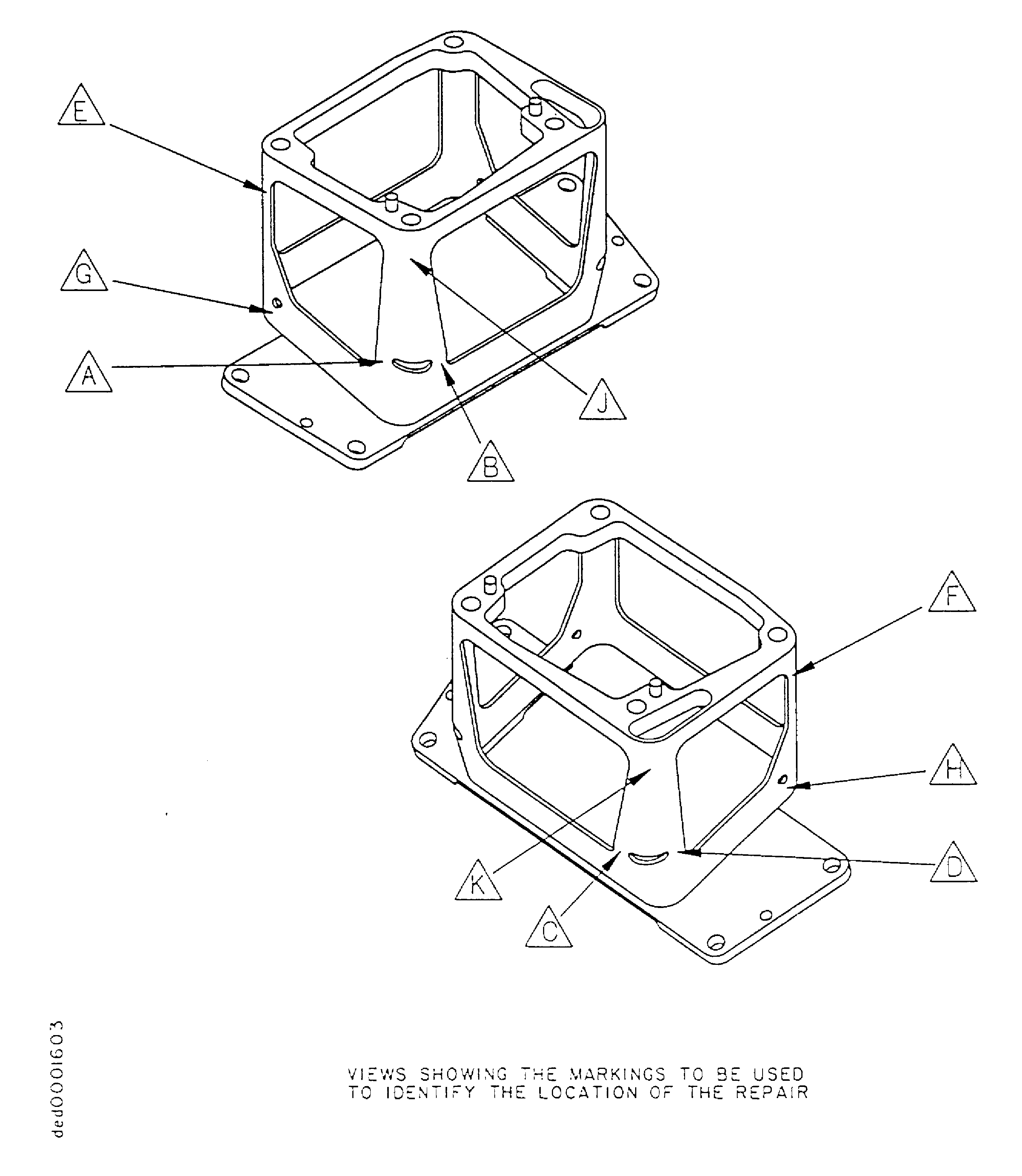

The code symbol tells you the area(s) that have been repaired.

Mark a mark VRS6627 and a code symbol adjacent to the part number. Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400- 001.

SUBTASK 75-31-42-350-053 Identify the Repair

Figure: Repair Details And Dimensions

Repair Details And Dimensions

Figure: Repair Details And Dimensions

Repair Details And Dimensions

Figure: Repair Details And Dimensions

Repair Details And Dimensions