Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-50-30-440-005-A00 LPT Stage 7 Rotor Assembly - Assemble, Assembly-005

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to the SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to the SPM TASK 70-63-02-380-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Refer to TASK 72-50-00-990-501 for a sectional view of the LP turbine module.

The abbreviation Intf. shows an interference or light fit. This cause REJECT IF MORE THAN to become REJECT IF LESS THAN. The abbreviation Clear shows a clearance fit.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Balancing machine | LOCAL | Balancing machine | ||

| Blade distribution system | LOCAL | Blade distribution system | ||

| Feeler gage | LOCAL | Feeler gage | ||

| IAE 1M14015 Blade holder | 0AM53 | IAE 1M14015 | 1 | |

| IAE 1M14019 Mounting adapter | 0AM53 | IAE 1M14019 | 1 | |

| IAE 1M14020 Balancing base plate | 0AM53 | IAE 1M14020 | 1 | |

| IAE 1M14025 Balancing fixture disk | 0AM53 | IAE 1M14025 | 1 | |

| IAE 1M14026 Balancing fixture sleeve | 0AM53 | IAE 1M14026 | 1 | |

| IAE 1M14030 Assembly trolley | 0AM53 | IAE 1M14030 | 1 | |

| IAE 1M14079 Plastic wedge | 0AM53 | IAE 1M14079 | 1 | |

| IAE 1M14091 Position retainer | 0AM53 | IAE 1M14091 | 1 | |

| IAE 1M14132 Guide pin | 0AM53 | IAE 1M14132 | 1 | |

| IAE 1M14153 Assy/disassy stand | 0AM53 | IAE 1M14153 | 1 | |

| IAE 1M14154 Assy/disassy stand | 0AM53 | IAE 1M14154 | 1 | |

| IAE 1M14155 Clamping ring | 0AM53 | IAE 1M14155 | 1 | |

| IAE 1M14156 Lifting fixture | 0AM53 | IAE 1M14156 | 1 | |

| Mallet | LOCAL | Mallet | Soft head | |

| Moment weighing equipment | LOCAL | Moment weighing equipment | ||

| Oven | LOCAL | Oven | ||

| Rack pallet | LOCAL | Rack pallet | ||

| Torch light | LOCAL | Torch light |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-069 DISPOSABLE CLEANING TISSUES | 33591 | CoMat 02-069 | ||

| CoMat 02-129 MARKER | IAE28 | CoMat 02-129 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Calculate the clearance at location 3364.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3364

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

19.1417

19.1378

Intf

0.0157

Intf

0.0177

Air seal dia

19.1299

19.1260

0.0079

0.0020

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3364

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

486.2

486.1

Intf

0.4

Intf

0.45

Air seal dia

485.9

485.8

0.2

0.05

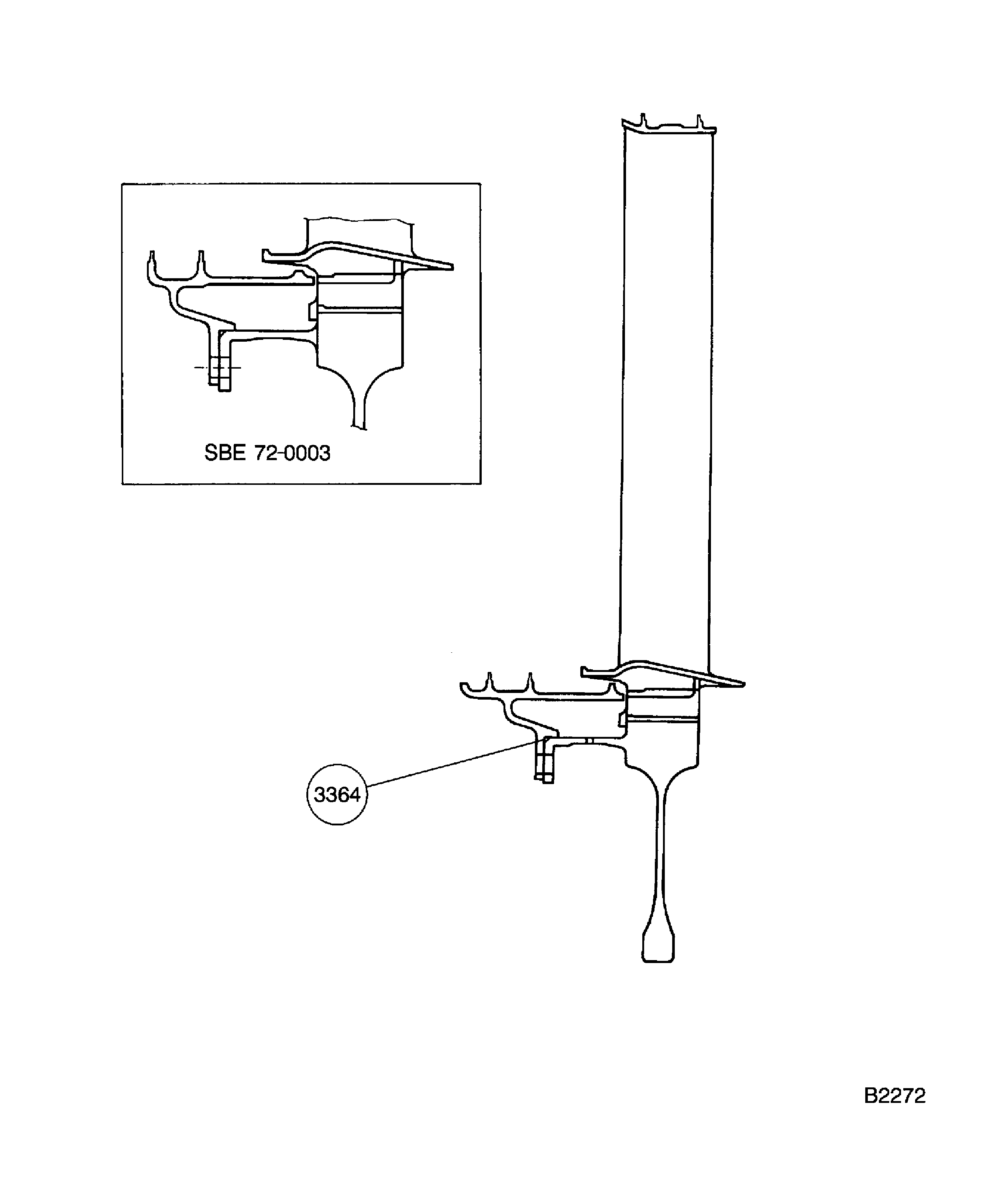

SUBTASK 72-50-30-220-055-A00 Make sure that the Fits and Clearances between the Stage 7 Disk and the Stage 7 Air Seal are in the Limits given at Location 3364 (Pre SBE 72-0003 and Pre SBE 72-0138)

Refer to Figure.

SBE 72-0003: Introduce a Weight Reduced Stage 7 LPT Air Seal

Calculate the clearance at location 3364.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3364

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

19.1417

19.1378

Intf

0.0236

Intf

0.0255

Air seal dia

19.1221

19.1181

0.0157

0.0119

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3364

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

486.2

486.1

Intf

0.6

Intf

0.65

Air seal dia

485.7

485.6

0.4

0.30

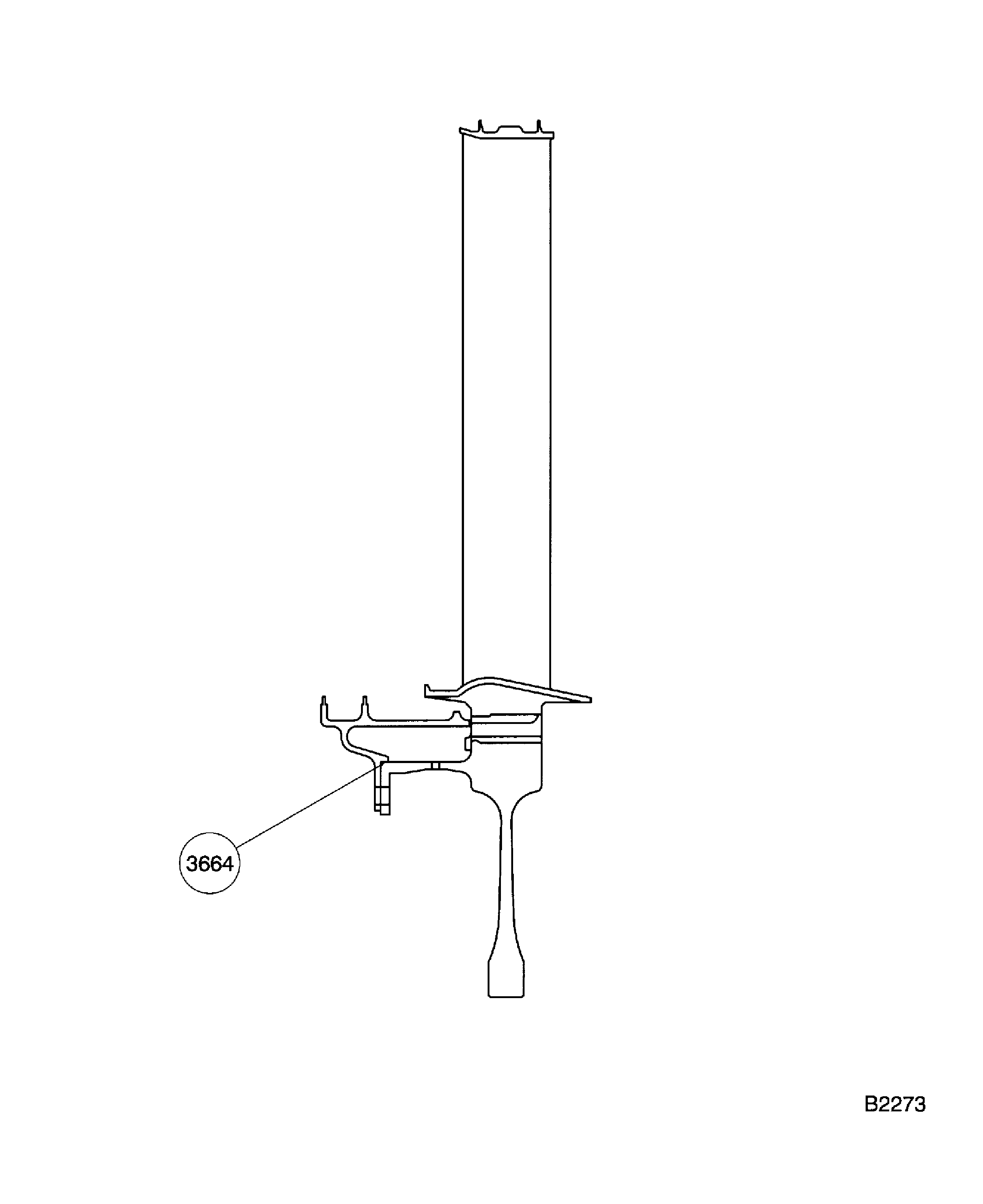

SUBTASK 72-50-30-220-055-B00 Make sure that the Fits and Clearances between the Stage 7 Disk and the Stage 7 Air Seal are in the Limits given at Location 3364 (SBE 72-0003 and Pre SBE 72-0138)

Refer to Figure.

SBE 72-0138: Rotor and stator assembly introduce new LP turbine blades and vanes

Calculate the clearance at location 3664.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3664

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

19.1417

19.1378

Intf

0.0236

Intf

0.0255

Air seal dia

19.1221

19.1181

0.0157

0.0119

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3664

Stage 7 air seal ENGINE-LP TURBINE ROTATING SEALS (72-50-33,01-010)

to stage 7 turbine disk

ENGINE-LP TURBINE DISCS (72-50-31,01-010)

Disk dia

486.2

486.1

Intf

0.6

Intf

0.65

Air seal dia

485.7

485.6

0.4

0.30

SUBTASK 72-50-30-220-055-C00 Make Sure that the Fits and Clearances between the Stage 7 Disk and the Stage 7 Air Seal are in the Limits given at Location 3664 (SBE 70-0707, SBE 72-0003 and SBE 72-0138)

Refer to Figure.

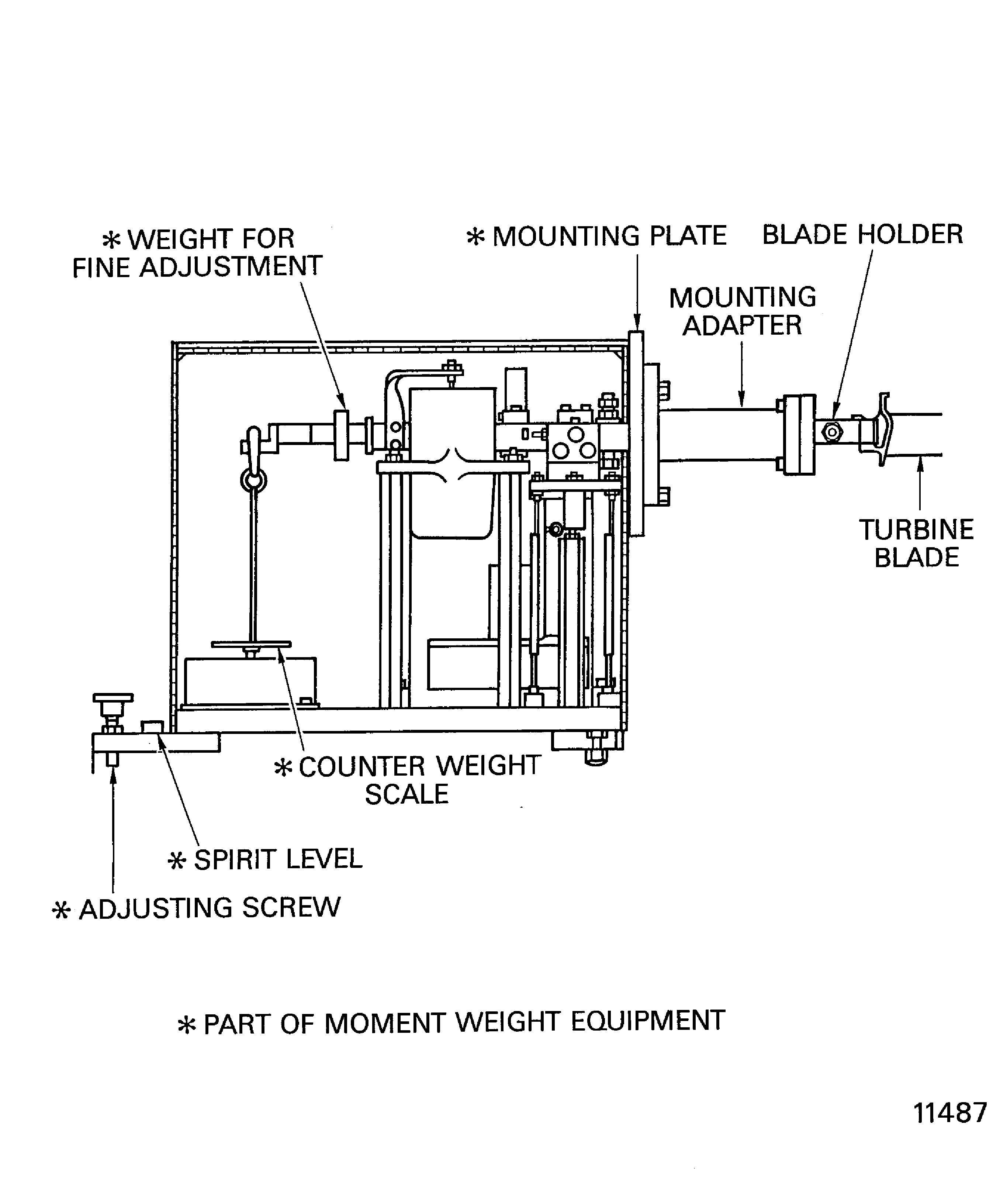

Install the IAE 1M14019 Mounting adapter 1 off with the four screws on to the mounting flange of the moment weight equipment.

Install the IAE 1M14015 Blade holder 1 off with the four screws on to the mounting adapter.

SUBTASK 72-50-30-440-091 Calibrate the Moment Weight Equipment

Refer to Figure.

Identify the stage 7 turbine blades with number one to 89. Use CoMat 02-129 MARKER.

SUBTASK 72-50-30-440-092 Weigh the Stage 7 Turbine Blades

NOTE

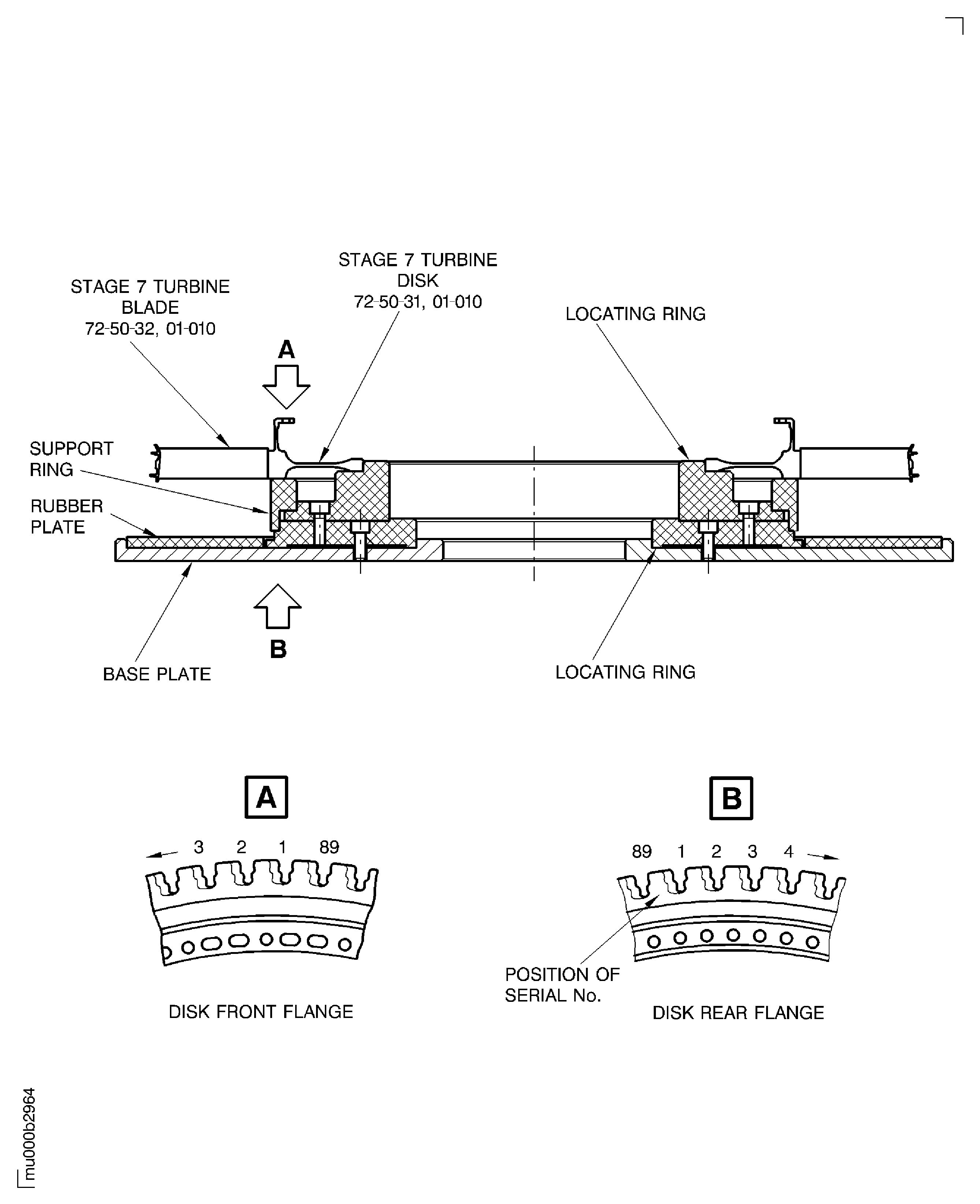

The IAE 1M14153 Assy/disassy stand 1 off must only be used for stage 7 turbine disk with P/N 3A0717.

Make sure that you use the correct locating ring and support ring of the IAE 1M14153 Assy/disassy stand 1 off for the stage 7 disk.

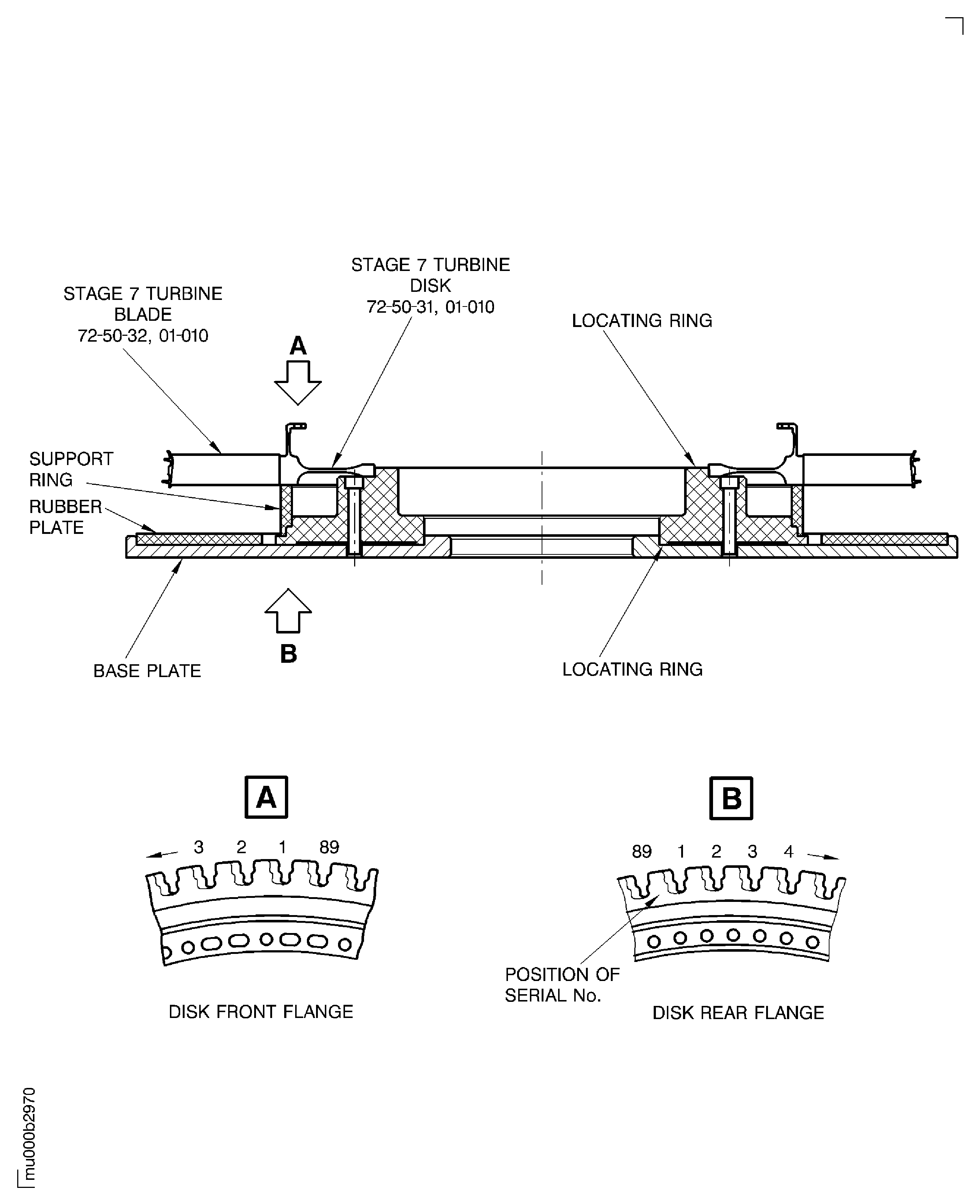

Put the stage 7 turbine disk on the assy/disassy stand, turbine disk front flange upwards.

NOTE

The IAE 1M14154 Assy/disassy stand 1 off must only be used for stage 7 turbine disk with P/N 3A2514.

Make sure that you use the correct locating ring and support ring of the IAE 1M14154 Assy/disassy stand 1 off for the stage 7 disk.

Identify the disk slot with the disk serial number. The serial number is vibrograved on the front face of the disk. The groove number one is the first groove at the left side of the serial number. Make a mark to the number one. Use CoMat 02-129 MARKER.

Lightly hit the blades at the blade roots. Operate stepwise and in counter clockwise direction to engage the blades. Move stepwise the support of the assy/disassy stand upwards. Use the IAE 1M14079 Plastic wedge 1 off and a soft headed mallet.

Repeat Step until all the blades are fully engaged in to the grooves of the disk. Make sure that the hook from each turbine blade root is in contact with the turbine disk front face.

SUBTASK 72-50-30-440-093 Install the Stage 7 Turbine Blades to the Stage 7 Turbine Disk

Refer to Figure.

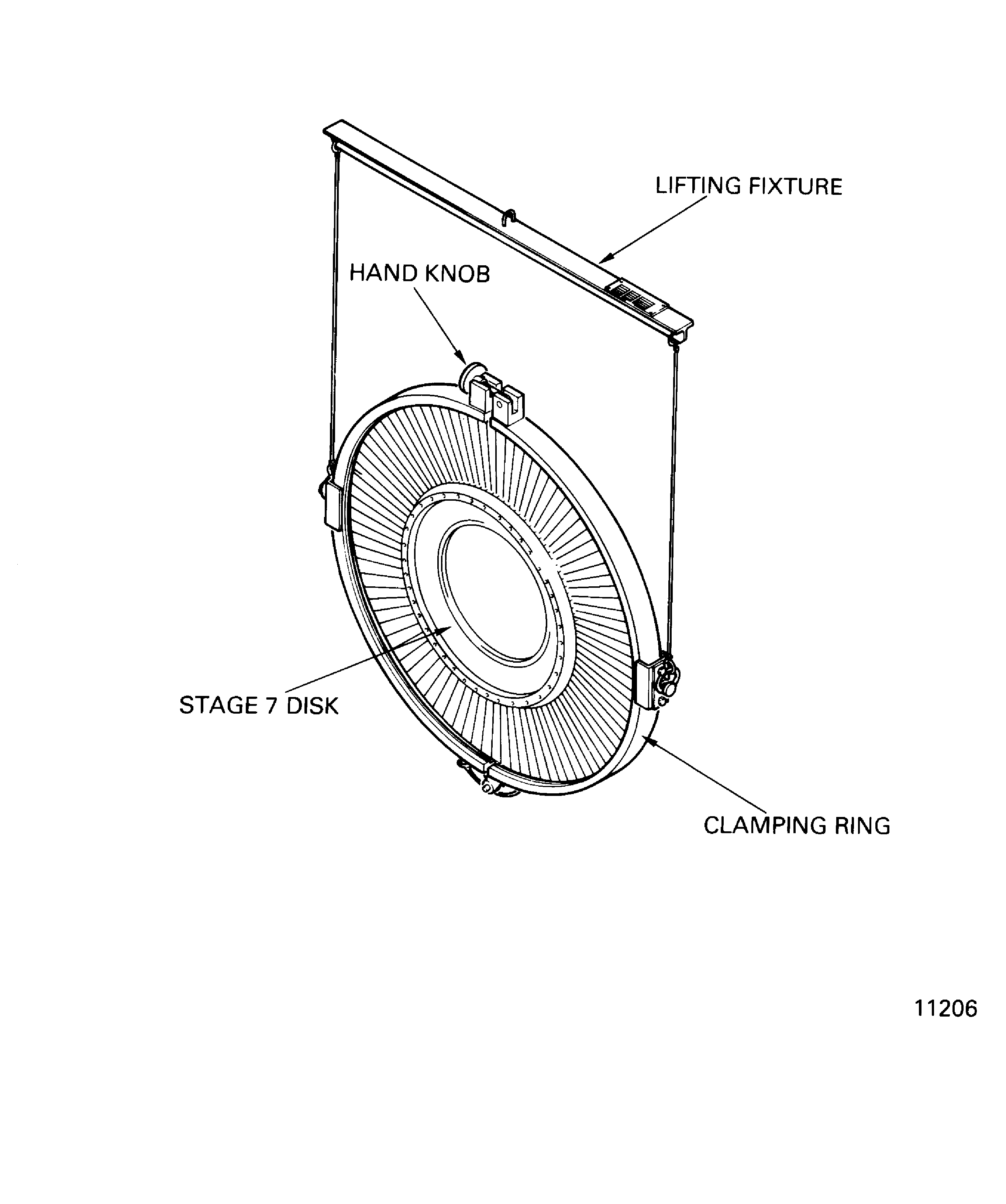

Install the two halves of the IAE 1M14155 Clamping ring 1 off to the stage 7 turbine disk.

SUBTASK 72-50-30-440-094 Install the Clamping Ring on to the Stage 7 Turbine Disk

Refer to Figure.

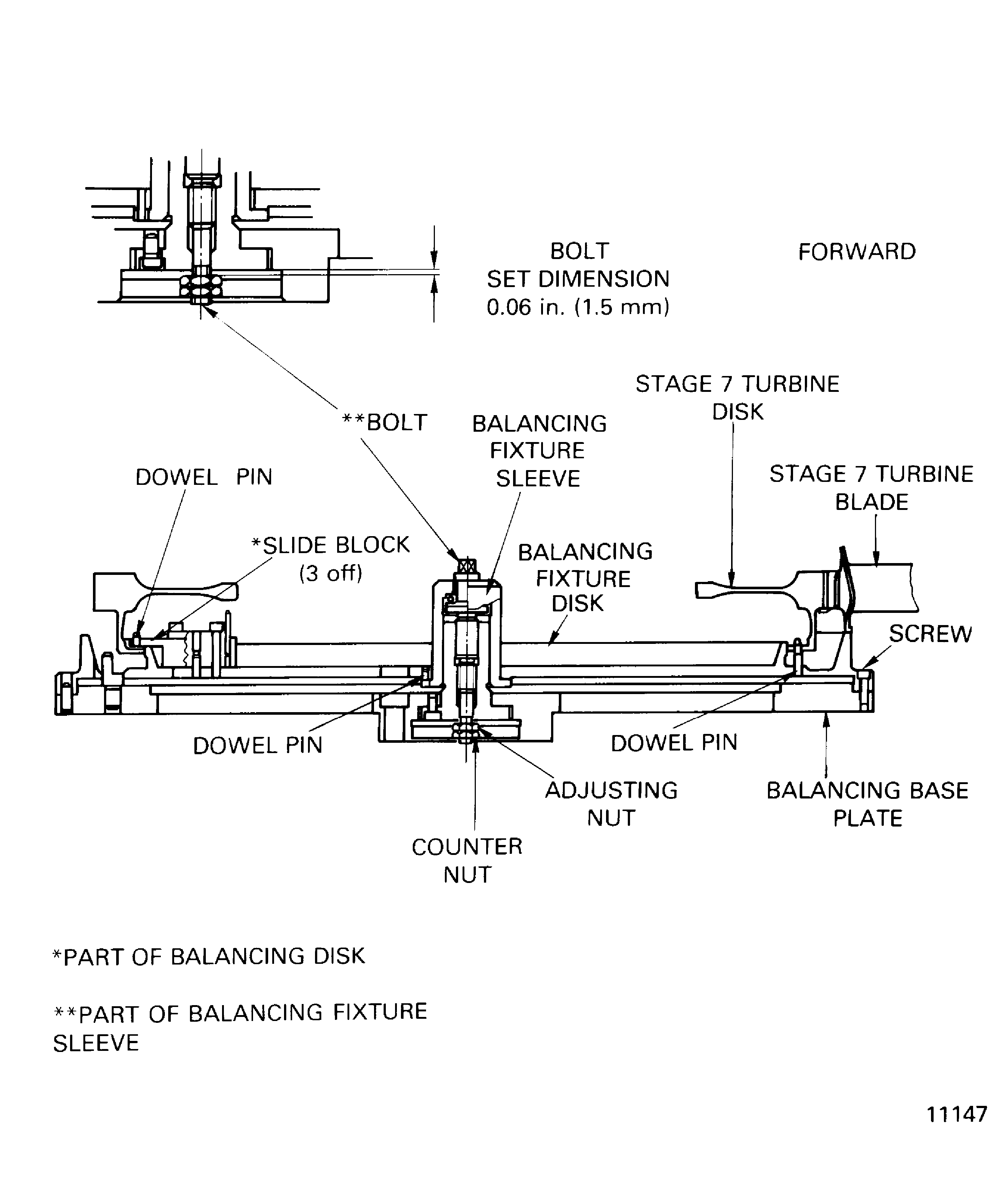

Use hoist equipment. Lower the balancing base plate on rack pallet. Remove hoist equipment.

NOTE

The balancing fixture sleeve is used to safety the LP turbine rotor assembly in radial position. This is achieved when the balancing fixture disk is pulled at the inner diameter from the balancing base plate. The caused increase of the balancing fixture disk goes to a small diameter reduction at the abutment face to the LPT rotor disk front snap diameter. Correct adjustment of the adjusting nut, part of the balancing fixture sleeve prevents overstressing.

Do not tighten the balancing fixture sleeve bolt at this moment.

Remove the set screw on the balancing baseplate. Install the IAE 1M14026 Balancing fixture sleeve 1 off to the IAE 1M14020 Balancing base plate 1 off. Install the adjusting nut and the counter nut. Make sure that the set dimension of the adjusting nut, part of the balancing fixture sleeve is correct adjusted.

Use hoist equipment. Install the IAE 1M14025 Balancing fixture disk 1 off above the balancing fixture sleeve on to the balancing base plate. Align the TOP marks.

Install the IAE 1M14156 Lifting fixture 1 off to hoist equipment.

Attach the lifting fixture to the IAE 1M14155 Clamping ring 1 off. Lift the stage 7 turbine disk carefully above the installed balancing tool assembly. Turn the stage 7 turbine disk front flange down. Lower it carefully on to the installed balancing fixture disk.

SUBTASK 72-50-30-440-095 Install the Stage 7 Turbine Disk on to the Balancing Machine

Refer to Figure.

SUBTASK 72-50-30-440-096 Remove the Clamping Ring from the Stage 7 Turbine Disk

Install the IAE 1M14155 Clamping ring 1 off on to the stage 7 turbine disk. Refer to Step.

Install the IAE 1M14156 Lifting fixture 1 off to the clamping ring. Use hoist equipment.

Remove the lifting fixture from the clamping ring. Remove the clamping ring. Refer to Step.

Repeat Step.

Use CoMat 02-129 MARKER to mark the unbalance and the position on the blades.

Lightly hit the blades at the blade roots. Operate stepwise and in clockwise direction to disengage the blades. Use the IAE 1M14079 Plastic wedge 1 off and soft headed mallet.

Install the clamping ring to the stage 7 turbine disk. Refer to Step. Remove the quick acting knob and the bar.

Install the stage 7 turbine disk to the balancing machine. Refer to Step.

Remove the clamping ring. Refer to Step.

Remaining unbalance must not be more than 1.0 ozin (720 gmm). If the unbalance is within the limits, continue with Step. If not, correct the unbalance by blade selection as follows:

SUBTASK 72-50-30-440-097 Balance the Stage 7 Turbine Disk

Remove the identification numbers from the turbine blades and the mark on the disk groove number one. Use CoMat 02-069 DISPOSABLE CLEANING TISSUES or clean cloth or clean cloth and CoMat 01-031 ACETONE (CH3)2CO.

Install the IAE 1M14155 Clamping ring 1 off to the stage 7 turbine disk. Refer to Step.

Install the IAE 1M14156 Lifting fixture 1 off to the clamping ring. Use hoist equipment.

SUBTASK 72-50-30-440-098 Remove the Stage 7 Turbine Disk from the Balancing Machine

Refer to Figure.

SUBTASK 72-50-30-440-099 Remove the Tools from the Balancing Machine

Refer to Figure.

Lift the stage 7 turbine disk above the IAE 1M14030 Assembly trolley 1 off. Use the IAE 1M14156 Lifting fixture 1 off with hoist equipment.

Remove the clamping ring from the stage 7 turbine disk. Refer to Step.

Install the IAE 1M14132 Guide pin 1 off in to a bolt hole of the stage 7 turbine front flange. Safety the guide pin with the IAE 1M14091 Position retainer 1 off.

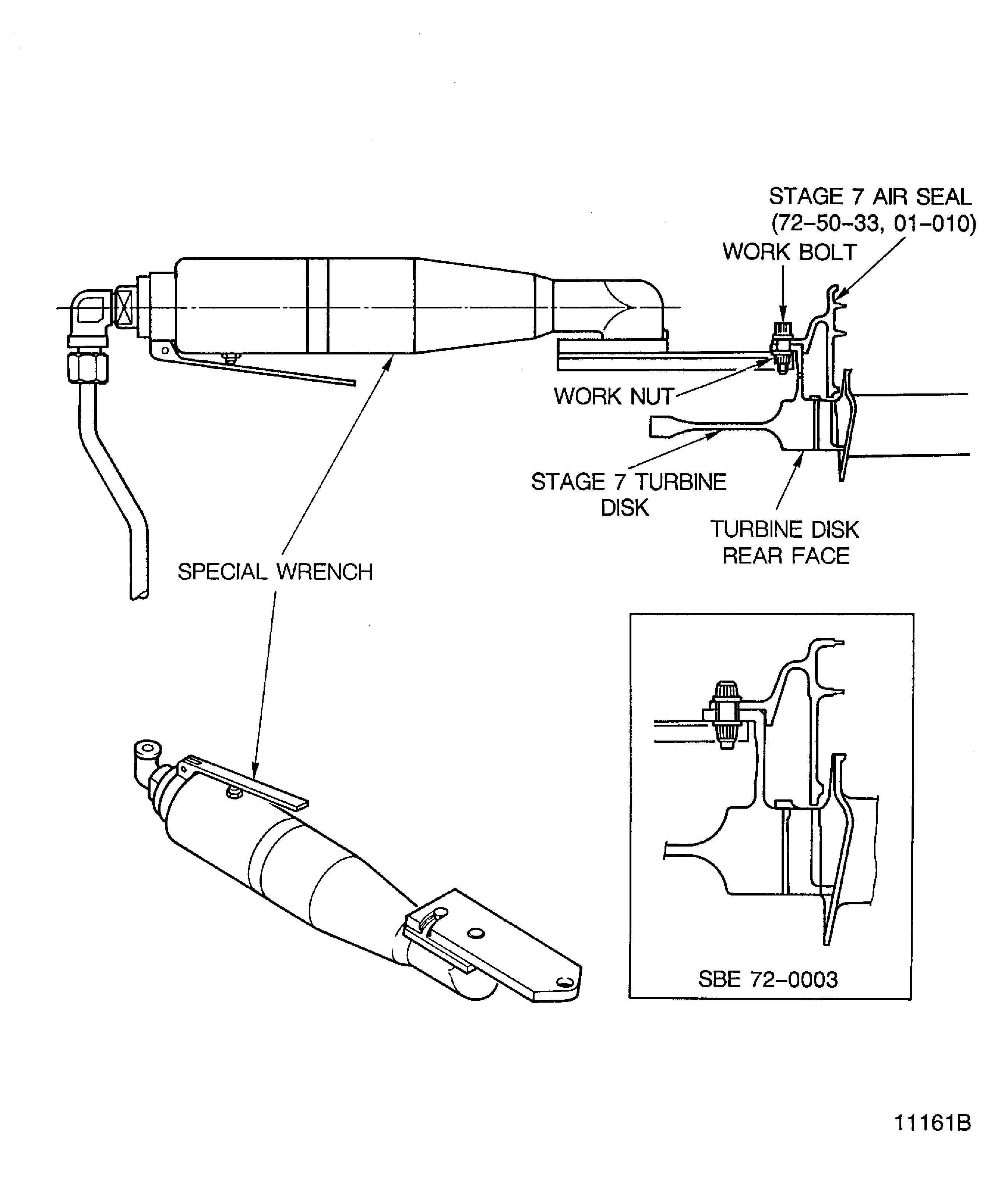

WARNING

USE PROTECTIVE GLOVES.NOTE

The high point of the parts are identified by the delta symbol in a circle.

The turbine disk stage 7 and the air seal stage 7 must be assembled so that the high points of the parts are 180 degrees apart.

If the stage 7 air seal has the correct temperature remove it from the oven.

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU INSTALL THE NUTS ON TO THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FROM MOVEMENTS. THE DISK-/INNER AIR SEAL FLANGES AND/OR THE BOLTS CAN BE DAMAGED BY SCORES.Install six work bolts and work nuts to safety the air seal on the disk. Tighten the nuts.

Let the temperature of all parts decrease to room temperature. Install the IAE 1M14155 Clamping ring 1 off to the stage 7 turbine disk. Refer to Step.

Use CoMat 02-129 MARKER and mark a dash in a circle on the disk hub at the caused high point location at the stage 7 turbine disk hub.

Install the IAE 1M14156 Lifting fixture 1 off to the installed clamping ring. Use hoist equipment.

Remove the clamping ring. Refer to Step.

SUBTASK 72-50-30-440-100 Install the Stage 7 Air Seal to the Stage 7 Turbine Disk

Figure: Pre SBE 72-0138: The stage 7 Turbine Disk and the Stage 7 Air Seal - Fits and Clearances

Sheet 1

Figure: SBE 72-0138: The Stage 7 Turbine Disk and the Stage 7 Air Seal - Fits and Clearances

Sheet 2

Figure: Calibrate the Moment Weight Equipment

Calibrate the Moment Weight Equipment

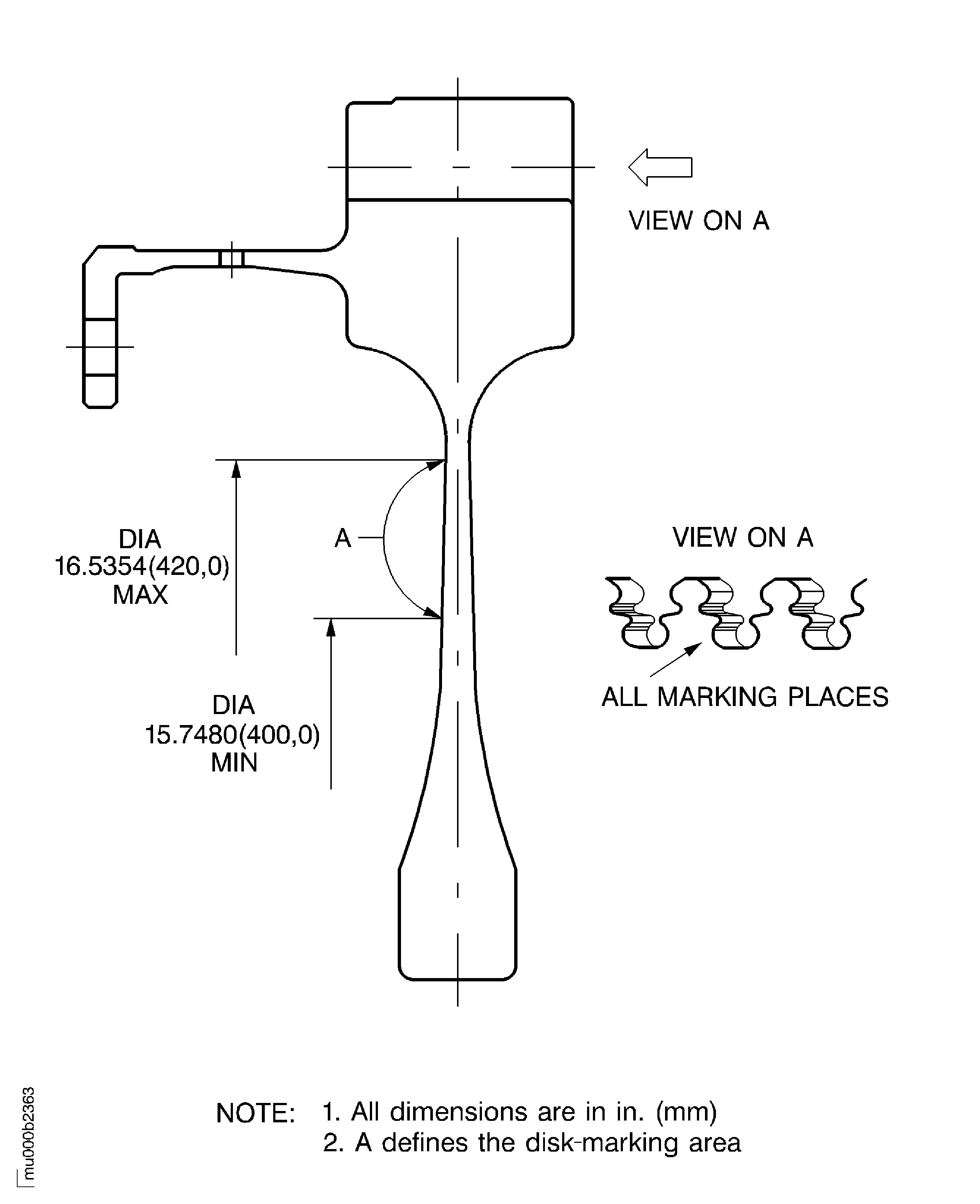

Figure: Disk-marking Areas of the Stage 7 Turbine Disk

Disk-marking Areas of the Stage 7 Turbine Disk

Figure: Install the Stage 7 Turbine Blades

Install the Stage 7 Turbine Blades

Figure: Turn the Stage 7 Turbine Disk with the Clamping Ring

Turn the Stage 7 Turbine Disk with the Clamping Ring

Figure: Install the Stage 7 Turbine Disk to the Balancing Tool Assembly

Install the Stage 7 Turbine Disk to the Balancing Tool Assembly

Figure: Install the Stage 7 Air Seal to the Stage 7 Turbine Disk

Install the Stage 7 Air Seal to the Stage 7 Turbine Disk

Figure: Install the Stage 7 Turbine Blades to the Stage 7 Turbine Disk with P/N 3A0717

Install the Stage 7 Turbine Blades to the Stage 7 Turbine Disk with P/N 3A0717

Figure: Install the Stage 7 Turbine Blades to the Stage 7 Turbine Disk with P/N 3A2514

Install the Stage 7 Turbine Blades to the Stage 7 Turbine Disk with P/N 3A2514