Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 71-00-02-400-027-B00 (A5-PPBU) - Install The Core Fire Detectors, Installation-027

General

Fig/Item numbers in parenthesis in the procedure agree with those used in the IPC. Only the primary Fig/Item numbers are used. For service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/Item number.

Special torque data is identified with the symbol * after the torque value.

For the torque tightening procedures refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL or CoMat 10-077 APPROVED ENGINE OILS unless other lubricants are referred to in the procedure.

Transportation covers/blanks must be removed immediately before installation of the components.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attaching parts. Use the correct color of air drying enamel. Refer to SPM TASK 70-38-21-380-501.

Do not remove the special plastic caps from the electrical connections until immediately before they are installed. This will give protection from unwanted fluids and materials.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 07-038 AIR DRYING ENAMEL | 00BB6 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 | ||

| CoMat 10-094 ANTI-SEIZE COMPOUND, PURE Ni-SPECIAL | K2147 | CoMat 10-094 |

Spares

NONESafety Requirements

NONEProcedure

NOTE

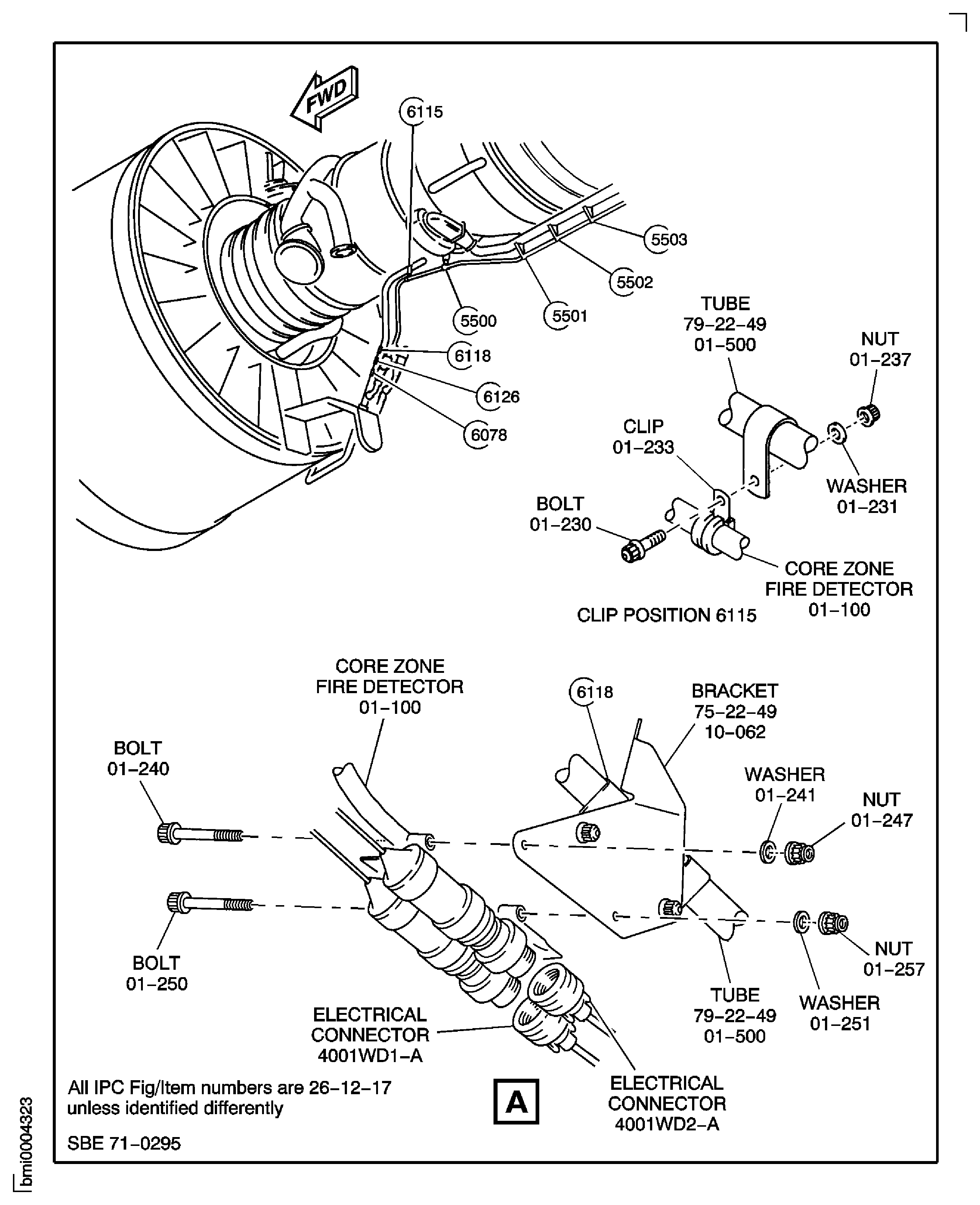

Make sure that the fire detector has a minimum clearance of 0.25 in. (6.35 mm) with adjacent pipes and structure.Refer to Figure.

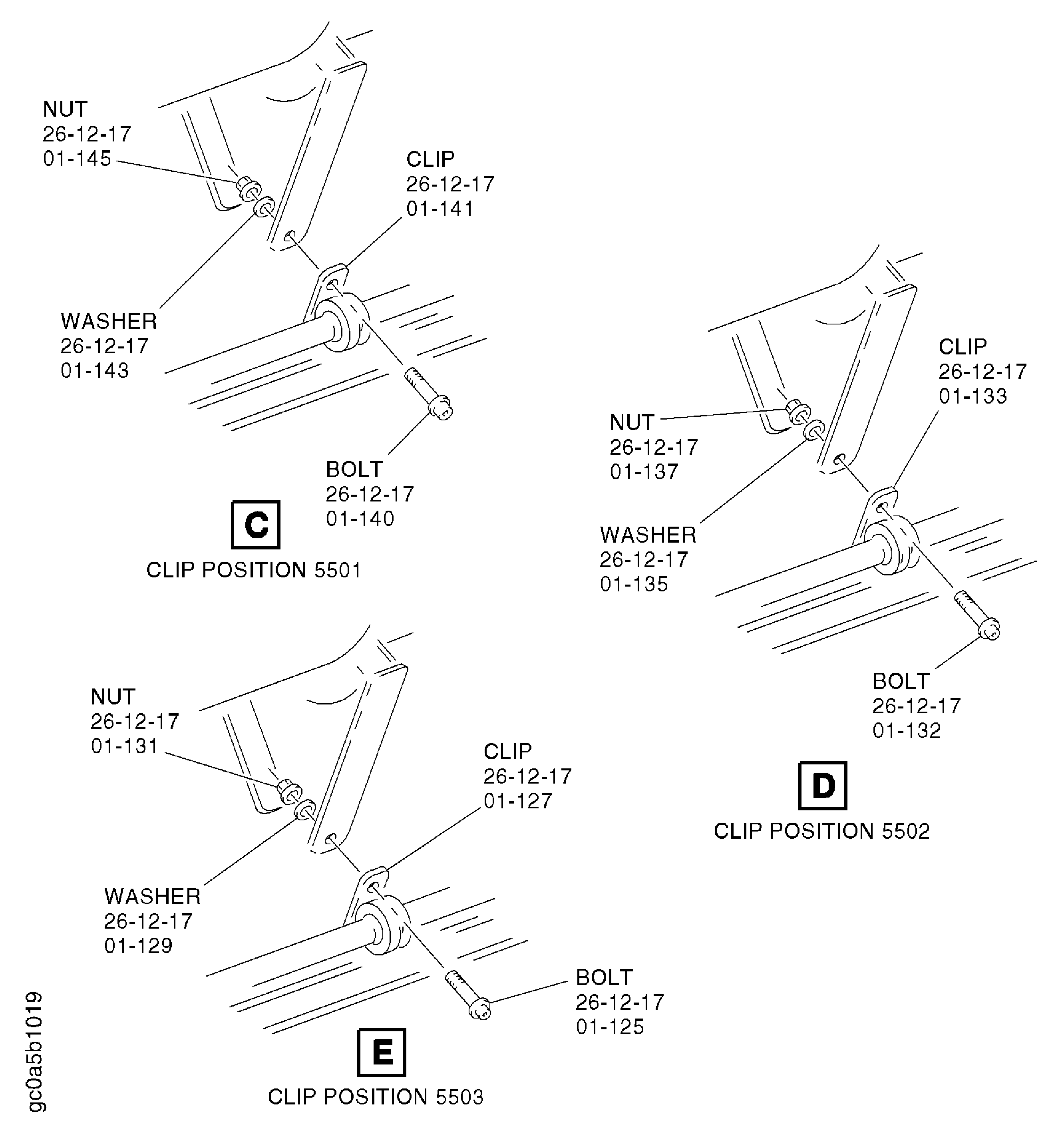

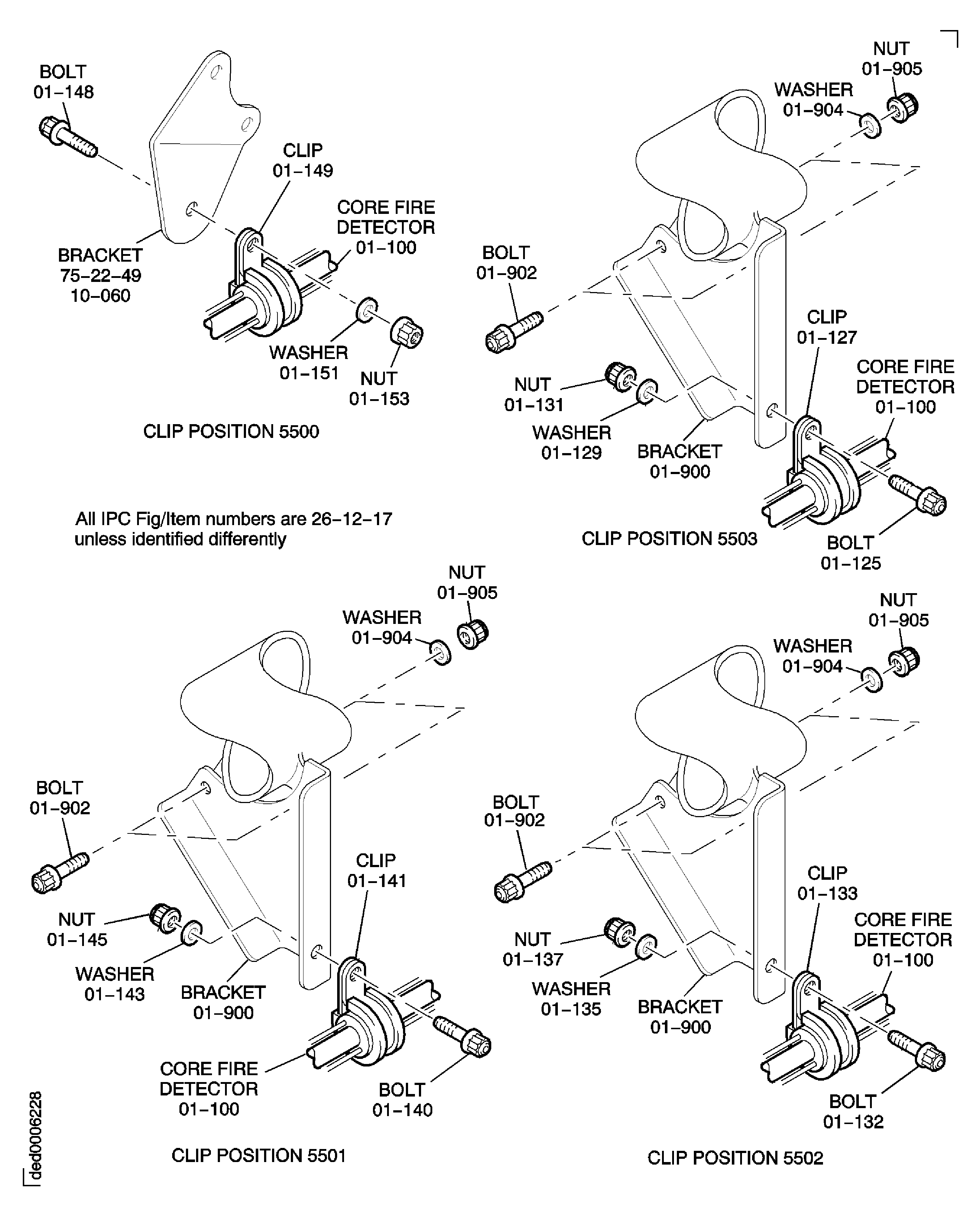

Apply the CoMat 10-077 APPROVED ENGINE OILS engine oil to the threads of the bolts FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-125), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-132) and FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-140).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-127) at clip position 5503 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-129), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-125), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-131).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-137) at clip position 5502 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-135), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-132), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-137).

Install the clip FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-141) at clip position 5501 on the ACAC exhaust duct ACAC Exhaust Duct And Housing (75-22-48, 01-010) with the washer FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-143), bolt FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-140), and nut FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-145).

Torque the nuts FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-131), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-137), FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-145) to 40 lbf.in (4.5 Nm).

SUBTASK 71-00-02-420-028 Install the Core Cowl Fire Detector on the ACAC Exhaust Duct

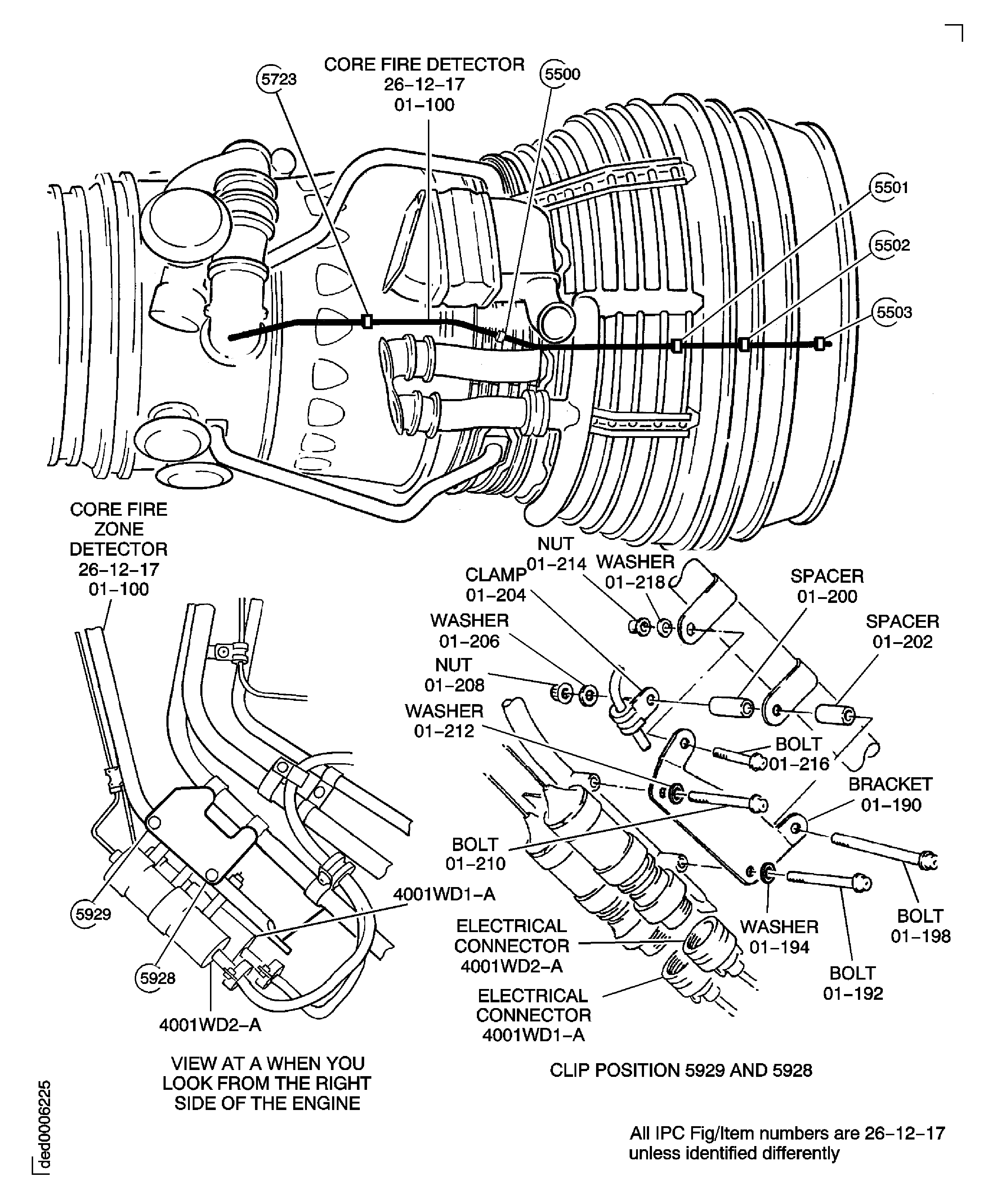

Put the core fire detector FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-100) in to position.

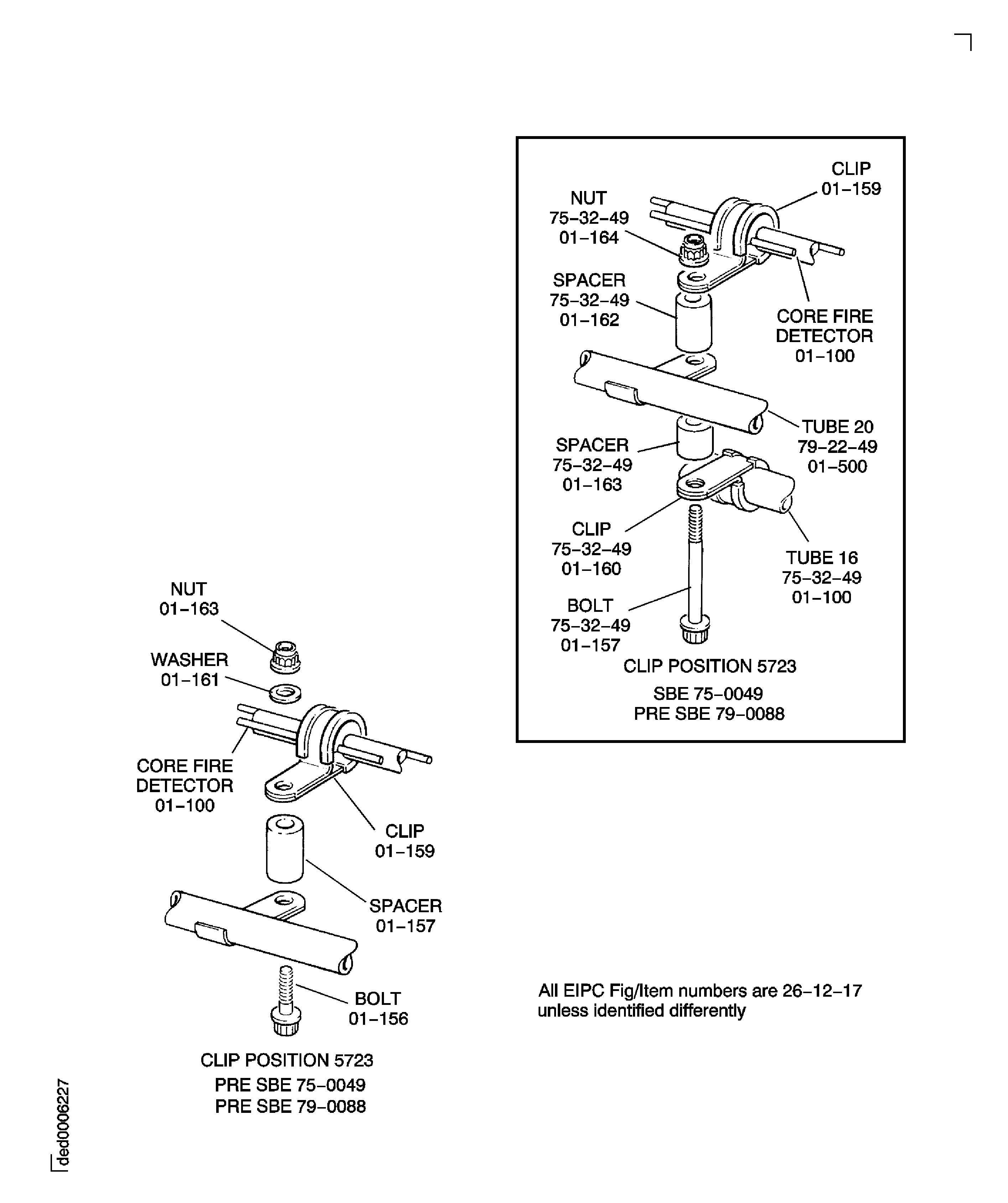

Pre SBE 75-0049: Install the clip, the washer, the spacer, the bolt and the nut at the clip position 5723.

SBE 75-0049: Install the two clips, the two spacers, the bolt and the nut at the clip position 5723.

SUBTASK 71-00-02-420-029-A00 Install the Core Zone Fire Detector (Pre SBE 79-0088)

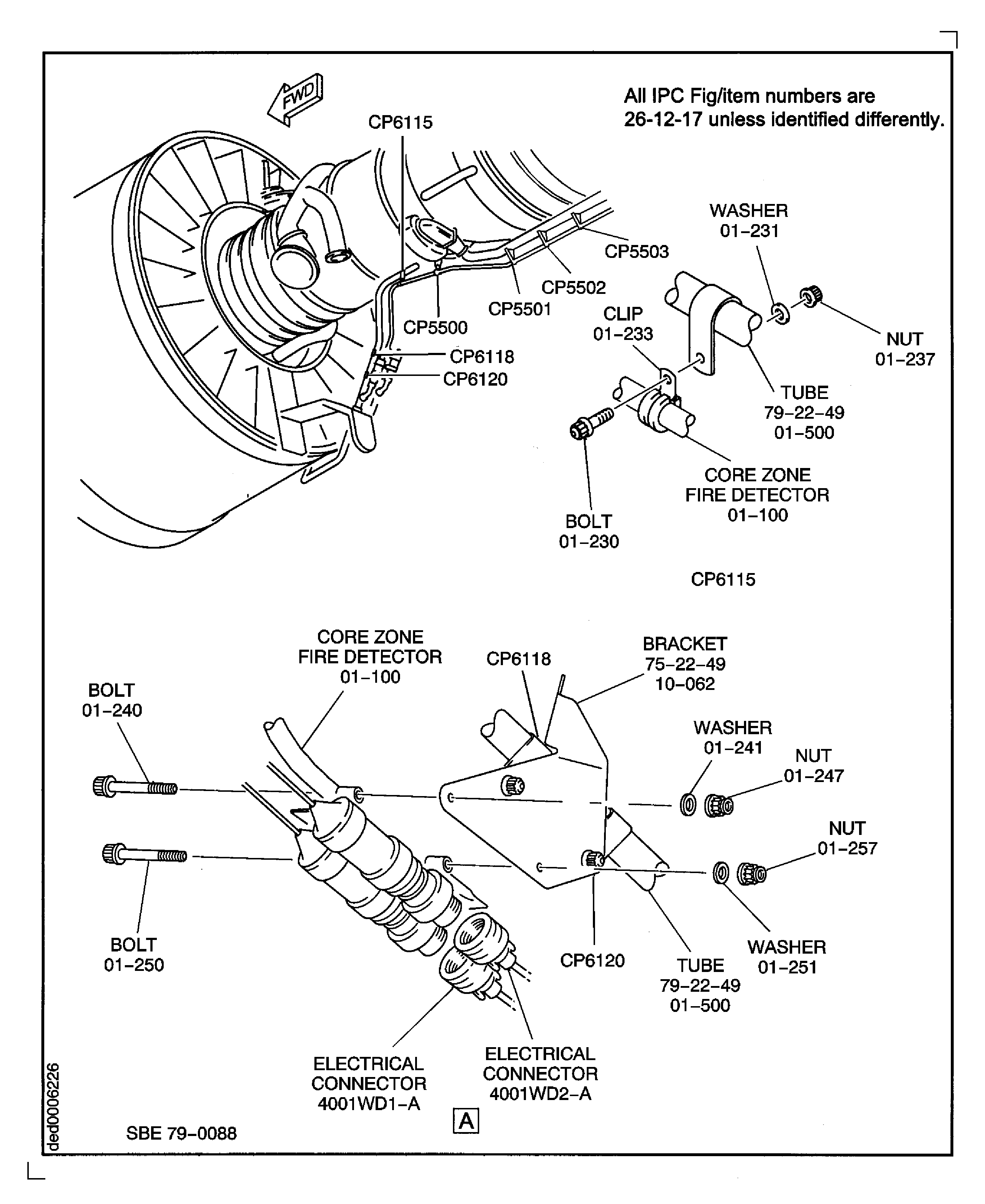

Put the core fire detector FIRE PROTECTION-CORE ZONE FIRE DETECTOR (26-12-17, 01-100) in to position.

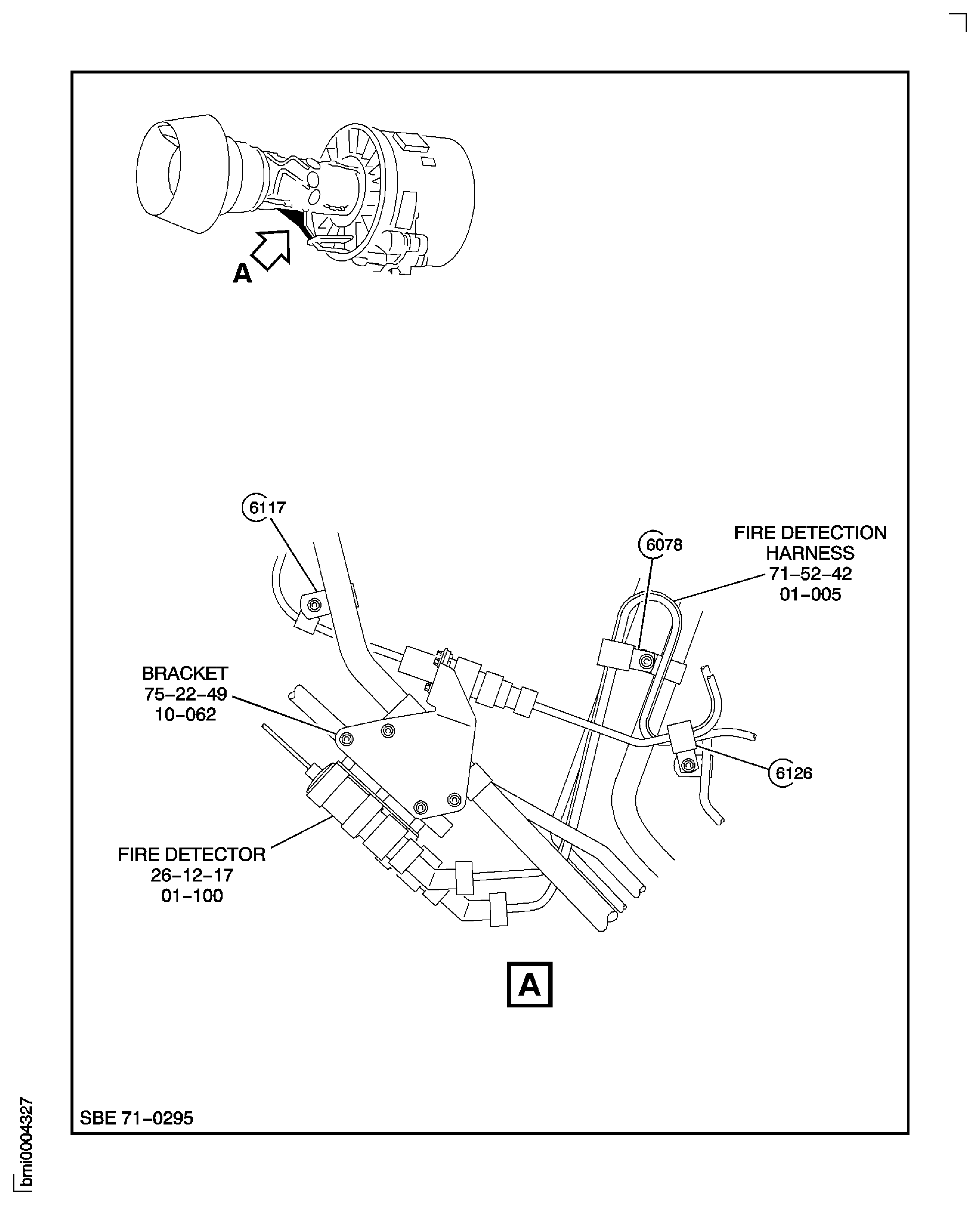

Install the nuts, the washers, the bolts to attach the core zone fire detector support tube to the bracket AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49, 10-062).

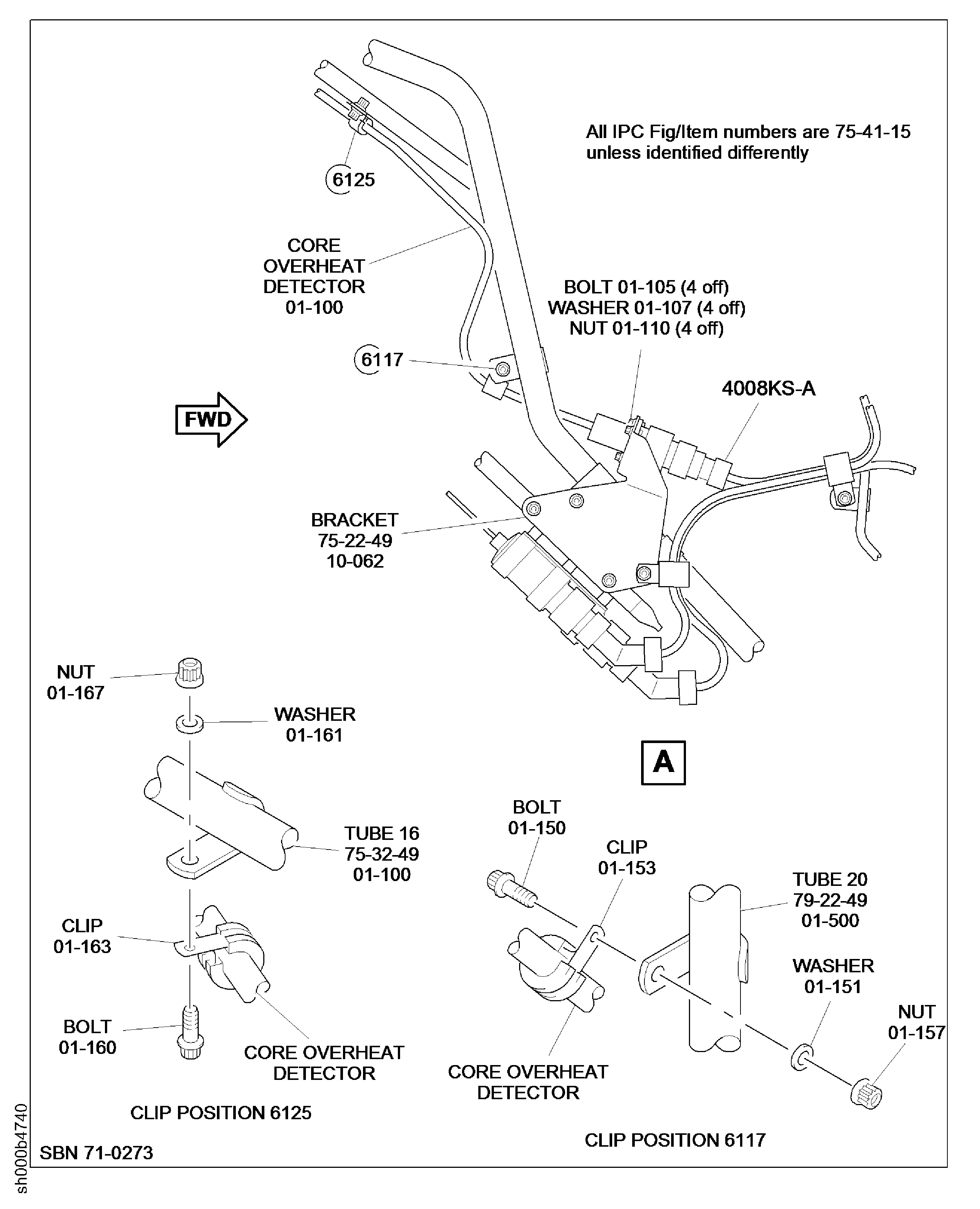

SUBTASK 71-00-02-420-029-B00 Install the Core Zone Fire Detector (SBE 79-0088, Pre SBE 71-0295 and SBE 71-0295)

Refer to Figure.

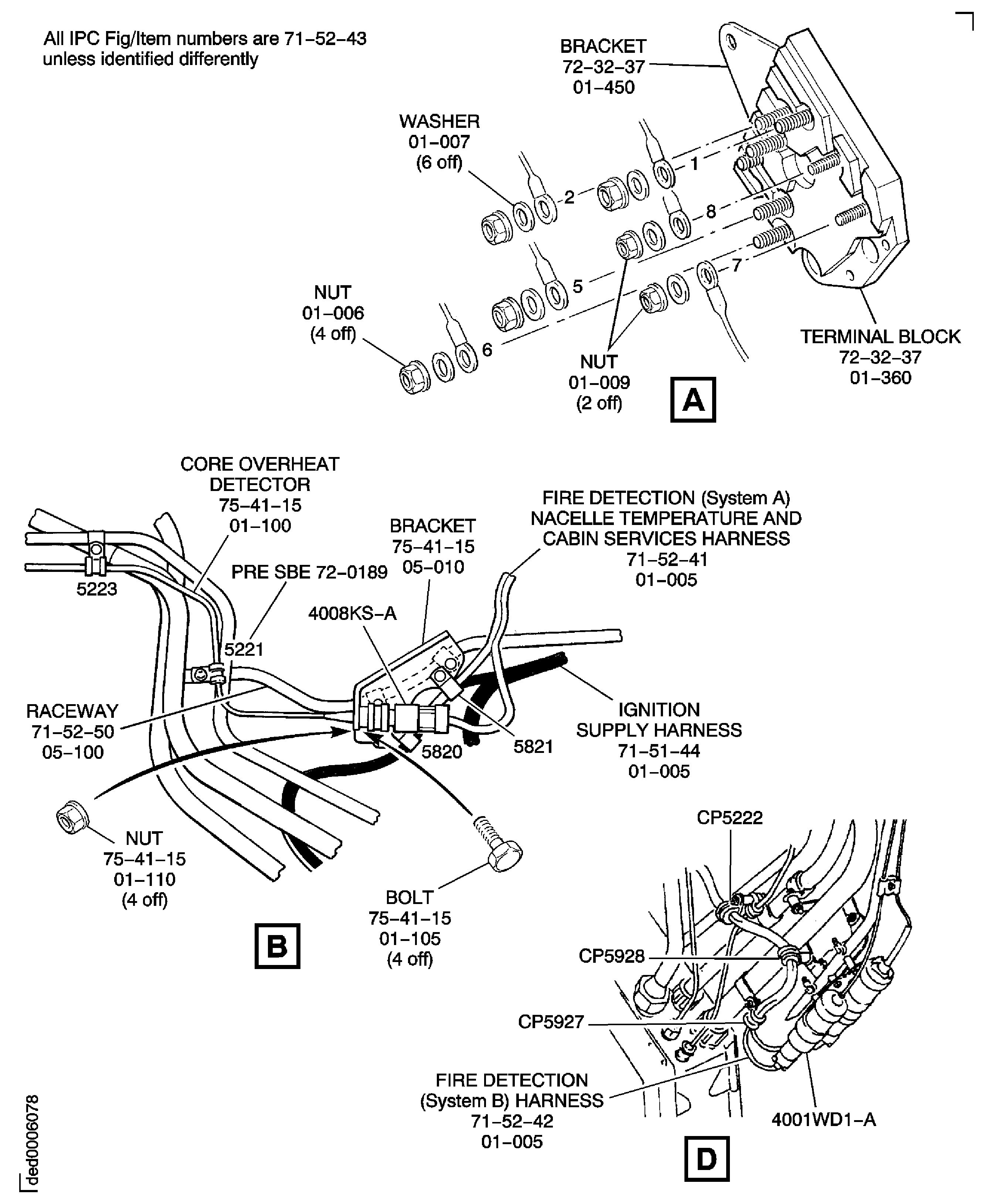

Attach the bracket NACELLE TEMPERATURE SENSOR (75-41-15, 05-010) to the raceway Core Harness Support Raceways (71-52-50, 05-100) with the two bolts NACELLE TEMPERATURE SENSOR (75-41-15, 05-015), the two washers NACELLE TEMPERATURE SENSOR (75-41-15, 05-020) and the two nuts NACELLE TEMPERATURE SENSOR (75-41-15, 05-025) at the clip positions 5802 and 5803. Torque the nuts to 36 lbf.in to 45 lbf.in (4 Nm to 5 Nm).

Attach the core overheat detector to the bracket with the four bolts NACELLE TEMPERATURE SENSOR (75-41-15, 01-105) and the four nuts NACELLE TEMPERATURE SENSOR (75-41-15, 01-110). Torque the nuts to 6 lbf.in to 8 lbf.in (0.68 Nm to 0.90 Nm).

Install the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100).

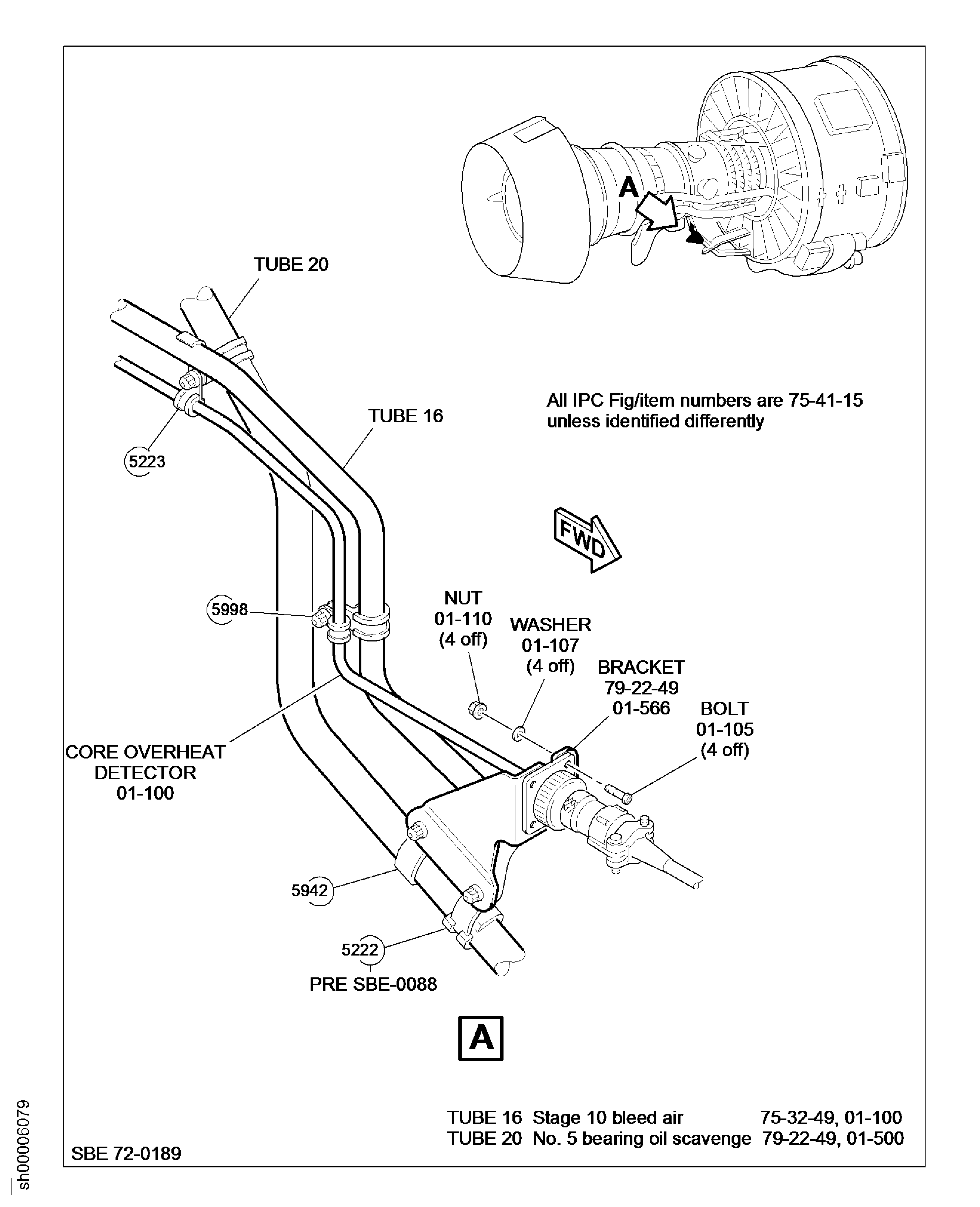

SUBTASK 71-00-02-420-030-A00 Install the Core Overheat Detector (Pre SBE 72-0189)

Attach the bracket Engine Scavenge Oil Tubes (79-22-49,01-566) at the clip position 5222 and with the bolt, washer and nut NACELLE TEMPERATURE SENSOR (75-41-15,05-030), NACELLE TEMPERATURE SENSOR (75-41-15,05-035) and NACELLE TEMPERATURE SENSOR (75-41-15,05-040). Torque the nuts to 36 lbf.in to 45 lbf.in (4 Nm to 5 Nm).

Attach the core overheat detector to the bracket with the four bolts NACELLE TEMPERATURE SENSOR (75-41-15, 01-105), the four washers NACELLE TEMPERATURE SENSOR (75-41-15, 01-107) and the four nuts NACELLE TEMPERATURE SENSOR (75-41-15, 01-110). Torque the nuts to 6 lbf.in to 8 lbf.in (0.68 Nm to 0.90 Nm).

Connect the electrical connector 4008KS-A and torque to 14 * lbf.in (1.6 Nm).

Install the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100).

Attach the core overheat detector to the bracket AIR-BEARING COMPARTMENT COOLING & SEALING TUBES (75-22-49,10-062) with the four bolts NACELLE TEMPERATURE SENSOR (75-41-15, 01-105), the four washers NACELLE TEMPERATURE SENSOR (75-41-15, 01-107), and the four nuts NACELLE TEMPERATURE SENSOR (75-41-15, 01-110). Torque the nuts to 6 lbf.in to 8 lbf.in (0.68 Nm to 0.90 Nm).

Install the core overheat detector NACELLE TEMPERATURE SENSOR (75-41-15, 01-100).

SUBTASK 71-00-02-420-030-B00 Install the Core Overheat Detector (SBN 71-0273 and SBE 72-0189)

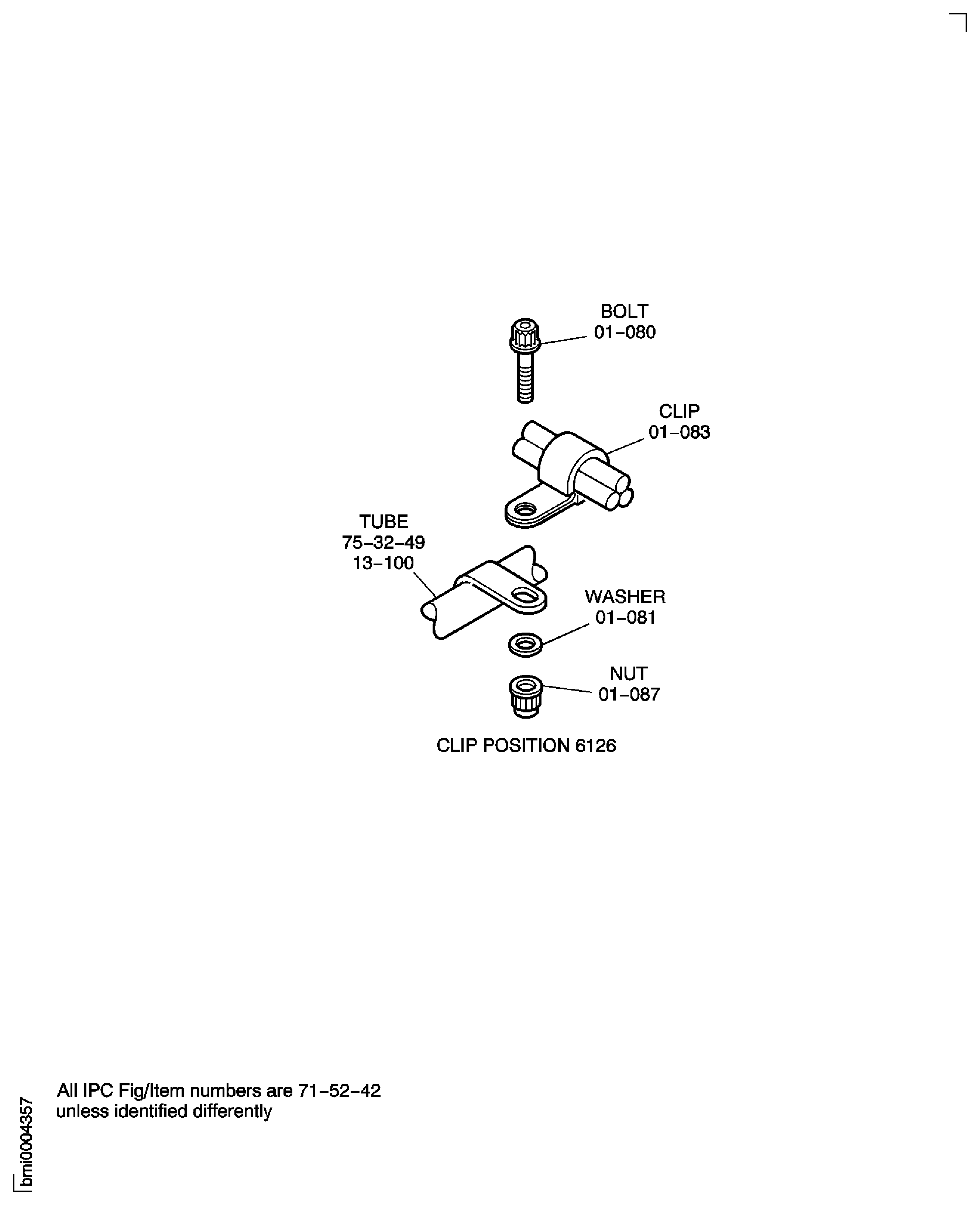

Figure: Core Cowl Fire Detector

Core Cowl Fire Detector

Figure: Install the Core Zone Fire Detector

Sheet 1

Figure: SBE 79-0088 and Pre SBE 71-0295: Install the Core Zone Fire Detector

Sheet 2

Figure: SBE 71-0295: Install the Core Zone Fire Detector

Sheet 3

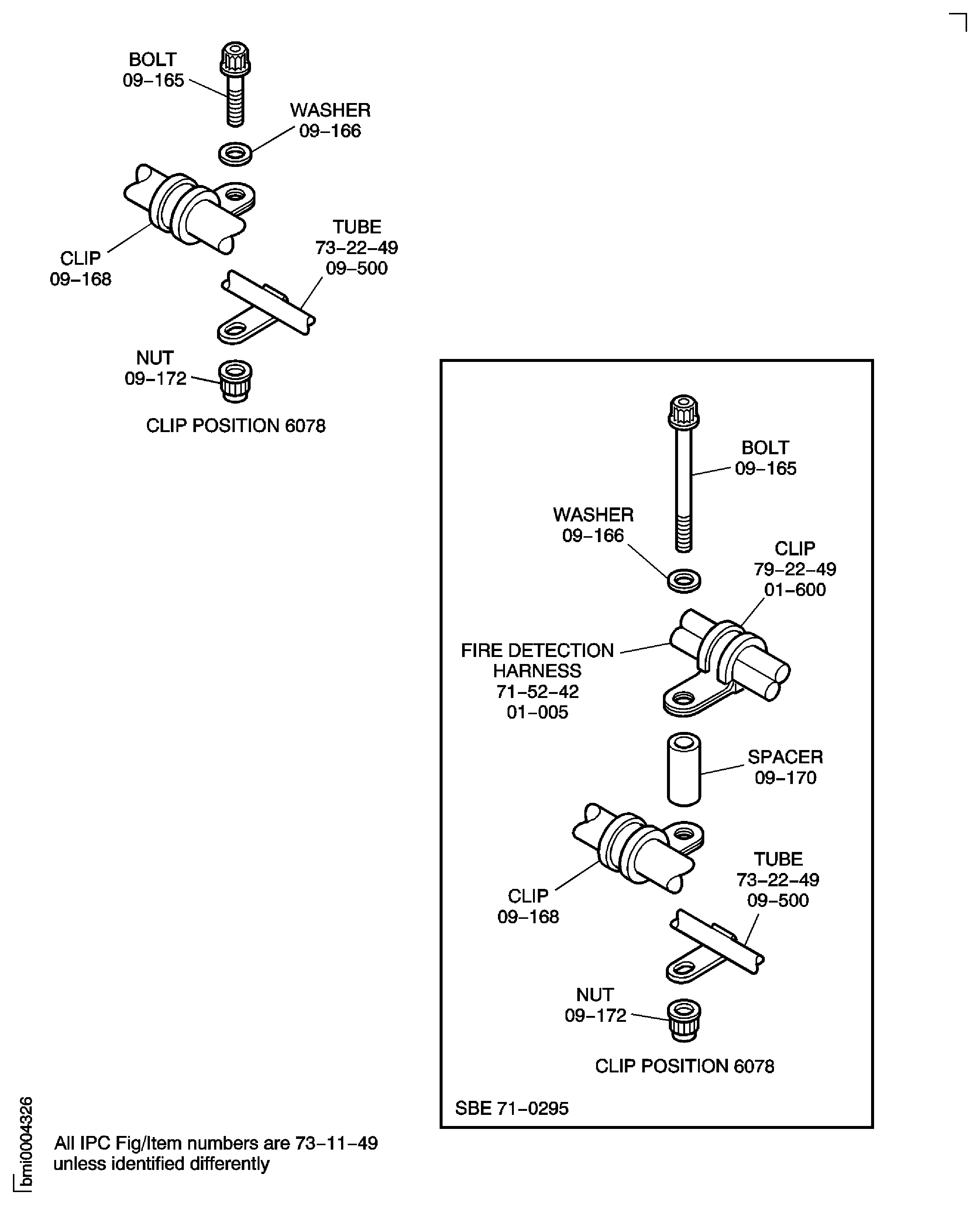

Figure: Install the Core Zone Fire Detector

Sheet 4

Figure: Install the Core Zone Fire Detector

Sheet 5

Figure: Install the Core Overheat Detector

Sheet 1

Figure: Install the Core Overheat Detector

Sheet 2

Figure: Install the Core Overheat Detector

Sheet 3

Figure: SBE 71-0295: Install the Core Overheat Detector

Sheet 4

Figure: Pre SBE 71-0295 and SBE 71-0295: Install the Core Overheat Detector

Sheet 5

Figure: SBE 71-0295: Install the Core Overheat Detector

Sheet 6