Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A5

Common Information

TASK 72-00-32-020-001-B00 LPC/Intermediate Case Module - Remove The Hydraulic Tubes, Thermal Anti-ice Duct, Thermal Anti-Ice Insulation, And Starter Air Duct, Removal-001

General

This TASK also gives the TASKS to remove the air intake cowl and the external gearbox module. Refer to the TASKS which follow for the other related procedures.

Remove the LP compressor/intermediate case electrical harnesses by TASK 72-00-32-020-002.

Remove the LP compressor/intermediate case tubes and the electrical harness raceways by TASK 72-00-32-020-003.

Remove the LP compressor/intermediate case components by TASK 72-00-32-020-004.

Remove the LP compressor/intermediate case brackets and the bifurcation panel by TASK 72-00-32-020-005.

Fig/item numbers in parentheses in the procedure agree with those used in the EIPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts. Let the parts soak before removal.

Discard all rubber seal rings, split cotter pins and gaskets removed in this procedure.

Remove and discard the lockwire and keywashers before the tube, connector or component is disconnected.

All the tubes, hoses and ducts removed in this procedure must have their maintenance completed, as given in the Component Maintenance Manual (CMM-THD-V2500-1IA) or the Aeroquip Maintenance Manual (29-11-49) as specified.

Seal all openings when the tubes and components are disconnected to prevent contamination from unwanted material.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-058 PENETRATING OIL | LOCAL | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

CAUTION

MAKE SURE THAT THE CUT LOCKWIRE DOES NOT FALL INTO THE ENGINE.Remove and discard the lockwire from the inner and outer venturi duct insulation halves Anti-Ice Ducts (30-21-49, 01-220) and Anti-Ice Ducts (30-21-49, 01-225).

Remove and discard the lockwire from the inner and outer pipe insulation halves Anti-Ice Ducts (30-21-49, 01-210) and Anti-Ice Ducts (30-21-49, 01-215).

Remove the installed clamps that attach the inner and outer venturi duct insulation halves Anti-Ice Ducts (30-21-49, 01-220) and Anti-Ice Ducts (30-21-49, 01-225) to the venturi duct. Remove the inner and outer venturi duct insulation halves.

Remove the installed clamps that attach the inner and outer pipe insulation halves Anti-Ice Ducts (30-21-49, 01-210) and Anti-Ice Ducts (30-21-49, 01-215) to the duct assembly. Remove the pipe insulation halves.

Remove the TAI insulation.

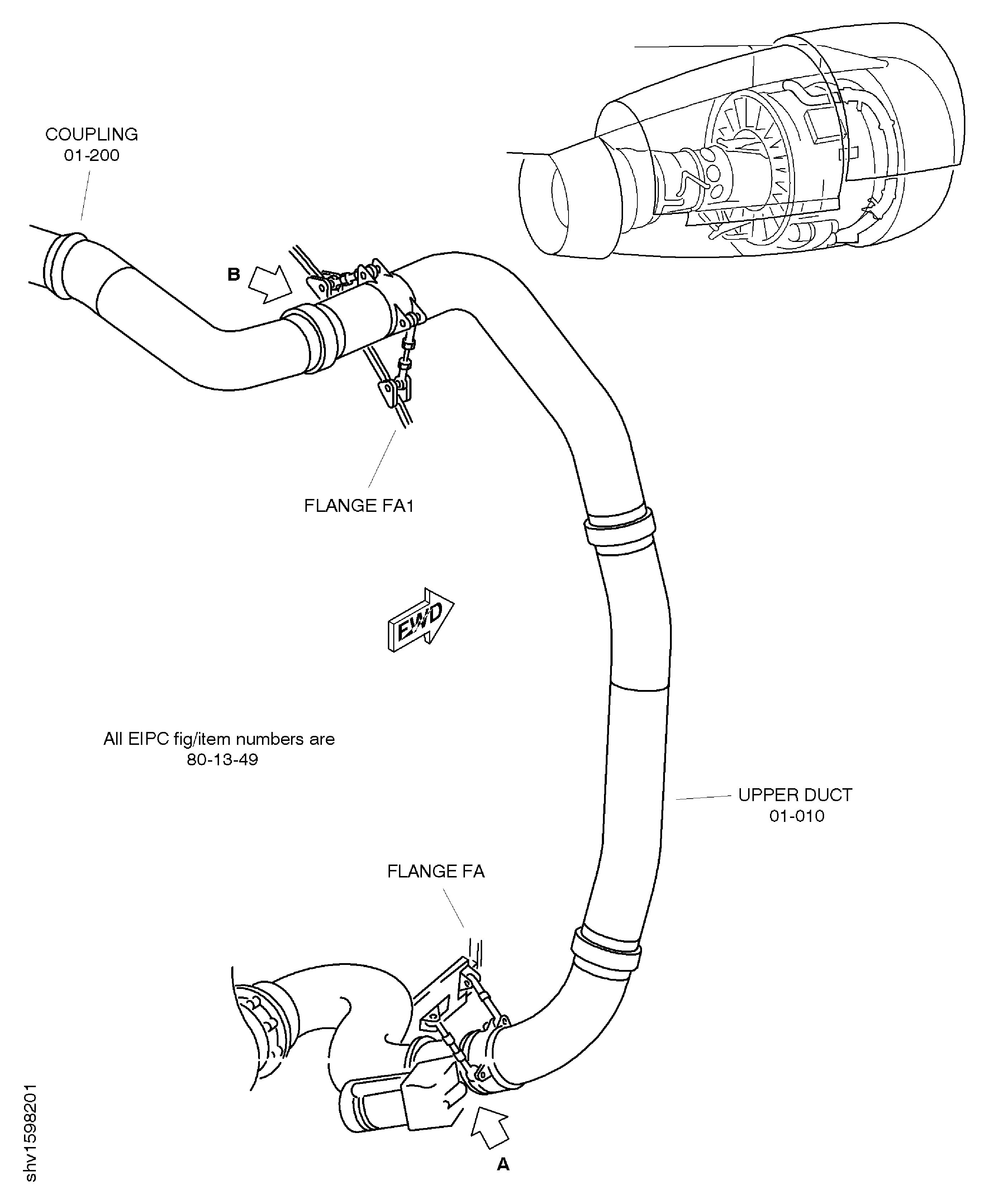

Attach temporary ties to the rear of the duct Anti-Ice Ducts (30-21-49, 01-070), to hold it in safety. Refer to Figure and Figure.

Safety the TAI duct.

Remove the air intake cowl and the TAI duct. Refer to TASK 71-11-11-020-001 and CMM-AIC-V2500-1IA.

Remove the air intake cowl and the TAI duct.

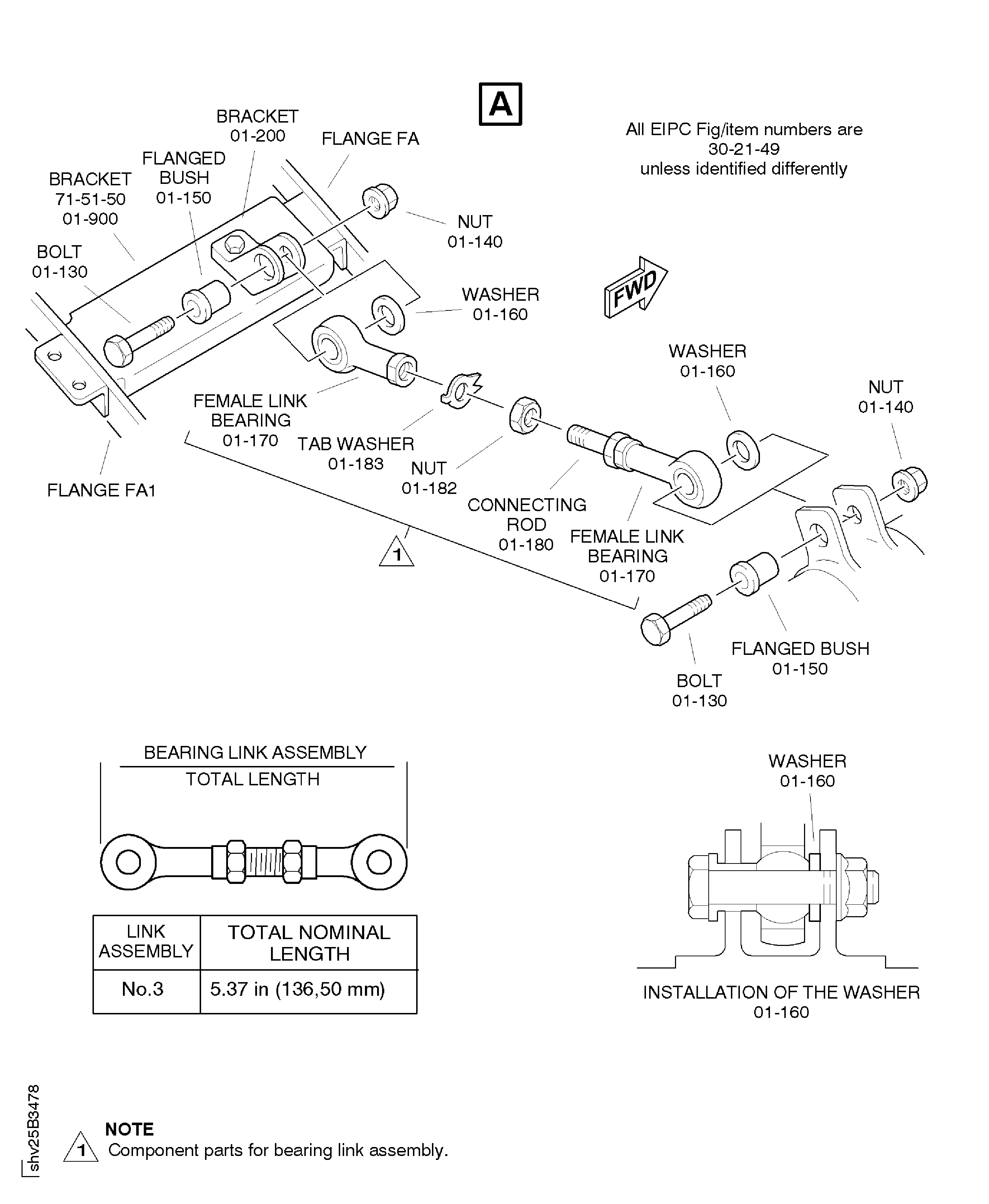

Remove the bolt, the flanged bush, the washer and the nut which attach the turnbuckle link assembly to the duct. Refer to the detail on A.

SBE80-0022

NOTE

The procedure for the remaining TAI ducts (7th stage offtake) is given in TASK 72-00-40-020-003.Remove the temporary ties. Remove the duct and the attached coupling.

Remove the duct Anti-Ice Ducts (30-21-49, 01-070). Refer to Figure, Figure and Figure

Remove the female link bearings and the connecting rod.

Remove the bolt, the flanged bush, the washer and the nut which attach the turnbuckle link assembly to the bracket. Remove the female link bearings from the connecting rod. Refer to the detail on A.

SBE80-0022

SUBTASK 72-00-32-020-189 Remove the Air Intake Cowl, the Thermal Anti-Ice (TAI) Duct and the Thermal Anti-Ice (TAI) Insulation

Remove the tubes and harnesses from the external gearbox module. Refer to TASK 72-00-60-020-001 and TASK 72-00-60-020-002.

SUBTASK 72-00-32-020-190 Remove the Tubes and Harnesses from the External Gearbox Module

Remove the external gearbox module as given in TASK 72-00-60-020-003-001.

SUBTASK 72-00-32-020-191 Remove the External Gearbox Module

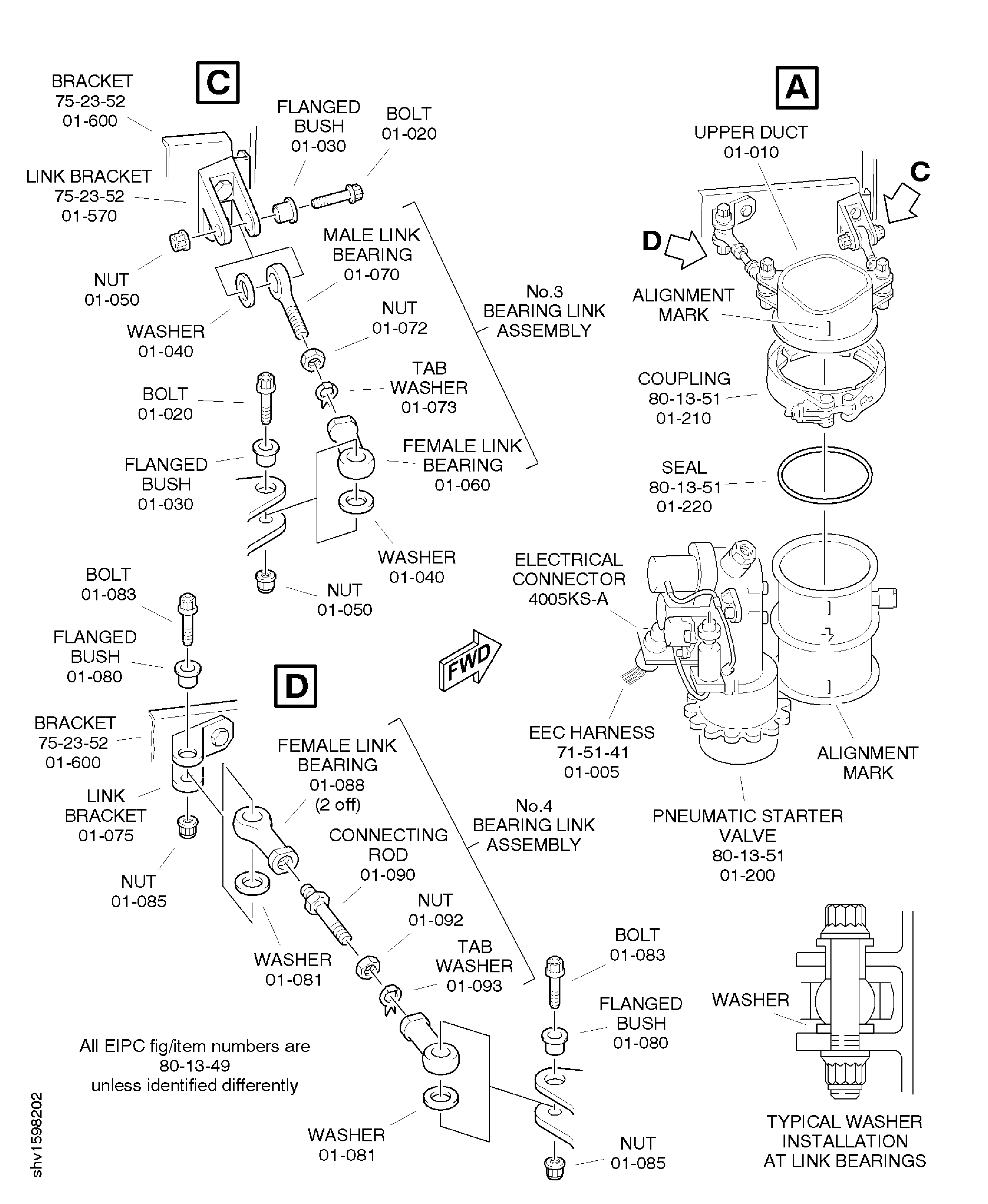

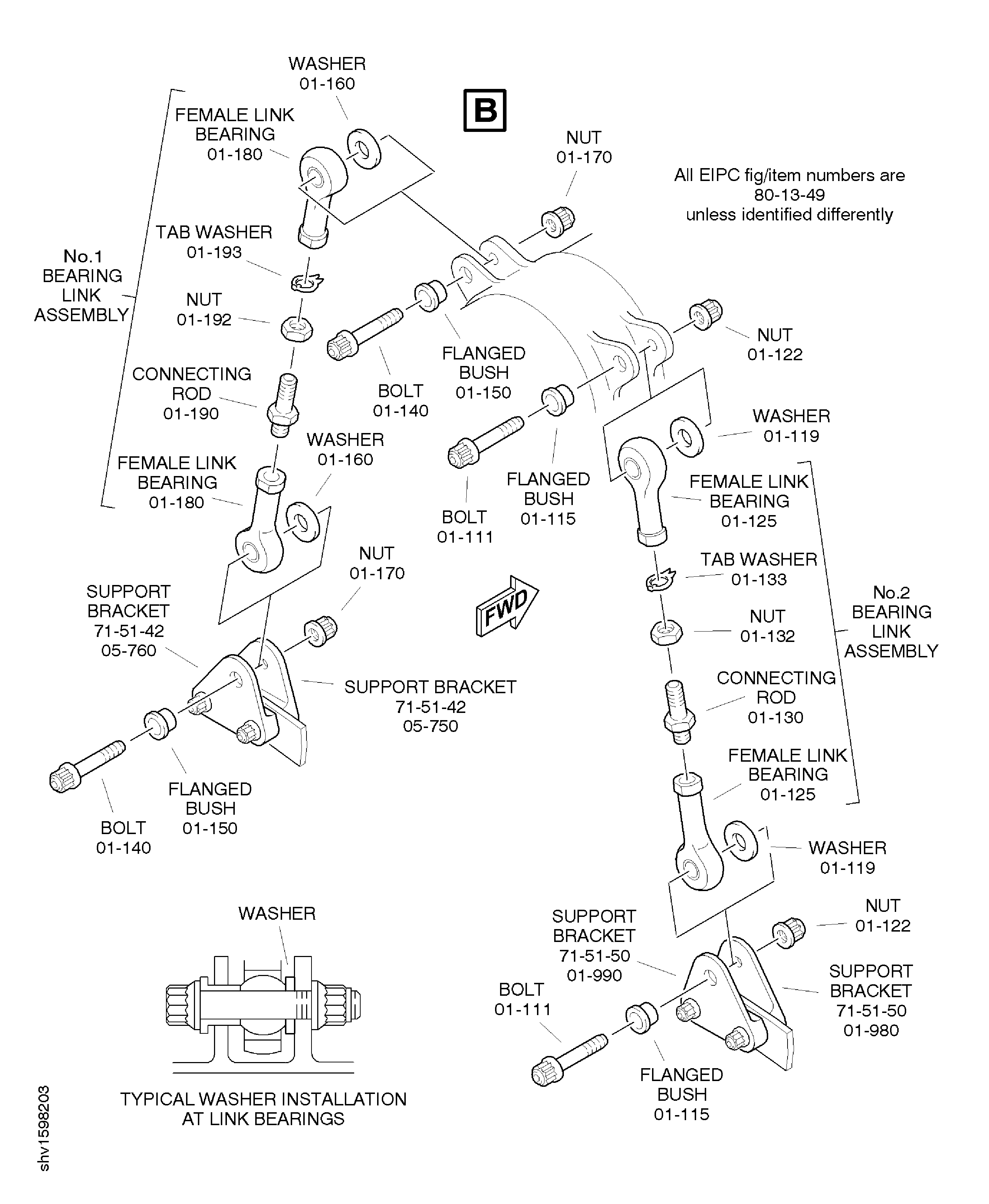

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing STARTING-STARTER DUCT (80-13-49, 01-060) to the upper duct. Refer to the detail on A. Temporarily install the bolt and the nut to hold the upper duct to the female link bearing.

Disconnect the female link bearing STARTING-STARTER DUCT (80-13-49, 01-088) from the upper duct. Do the procedure in Step. Temporarily attach the upper duct to the female link bearing.

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing STARTING-STARTER DUCT (80-13-49, 01-180) to the upper duct. Refer to the detail on B. Temporarily install the bolt and the nut to hold the upper duct the female link bearing.

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing STARTING-STARTER DUCT (80-13-49, 01-125) to the upper duct.

Hold the upper duct and remove the three bolts and the three nuts temporarily installed in Step to Step. Remove the upper duct and the coupling STARTING-STARTER DUCT (80-13-49, 01-200).

PRE SBE80-0022

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing (80-13-49, 01-180) to the upper duct. Refer to the detail on B. Temporarily install the bolt and the nut to hold the upper duct the female link bearing.

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing (80-13-49, 01-125) to the upper duct.

SBE80-0022

Remove the upper duct.

Remove the bolt, the flanged bush, the washer and the nut which attach the male link bearing STARTING-STARTER DUCT (80-13-49, 01-070) to the link bracket. Remove the male link bearing from the female link bearing. Refer to the detail on A.

Do the procedure given in the previous step and remove the female link bearings STARTING-STARTER DUCT (80-13-49, 01-088) from the connecting rod.

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing STARTING-STARTER DUCT (80-13-49, 01-180) to the flange FA1 support brackets. Remove the female link bearings from the connecting rod. Refer to the detail on B.

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing STARTING-STARTER DUCT (80-13-49, 01-125) to the flange FA1 support brackets. Remove the female link bearings from the connecting rod.

PRE SBE80-0022

Remove the bolt, the flanged bush, the washer and the nut which attach the female link bearing (80-13-49, 01-180) to the flange FA1 support brackets. Remove the female link bearings from the connecting rod. Refer to the detail on B.

Remove the bolt, the flanged bush, the washer and the nut which attach the female turnbuckle link bearing (80-13-49, 01-125) to the flange FA1 support brackets. Remove the female link bearings from the connecting rod.

SBE80-0022

Remove the link bearings and the connecting rods.

SUBTASK 72-00-32-020-192 Remove the Pneumatic Starter Duct

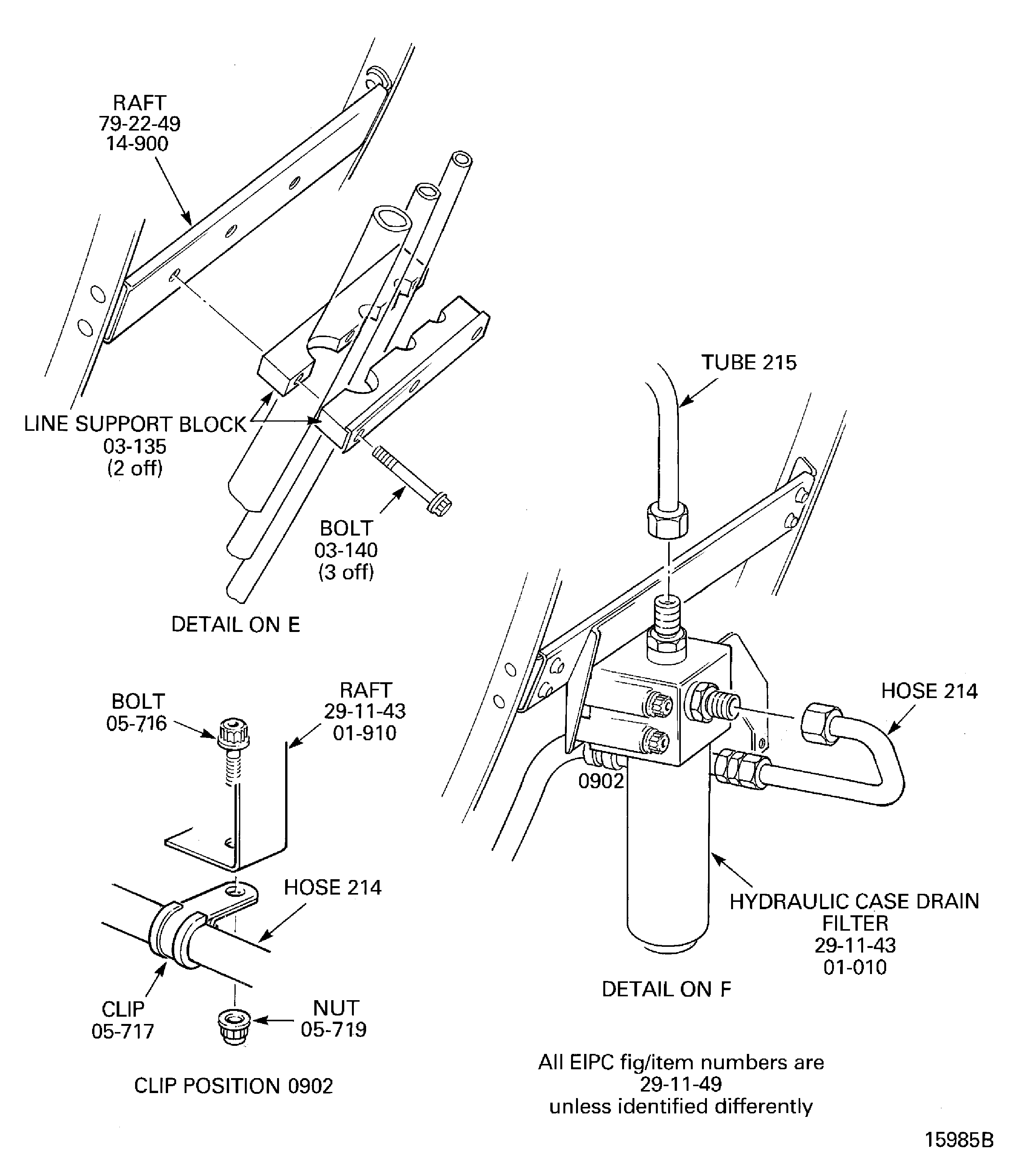

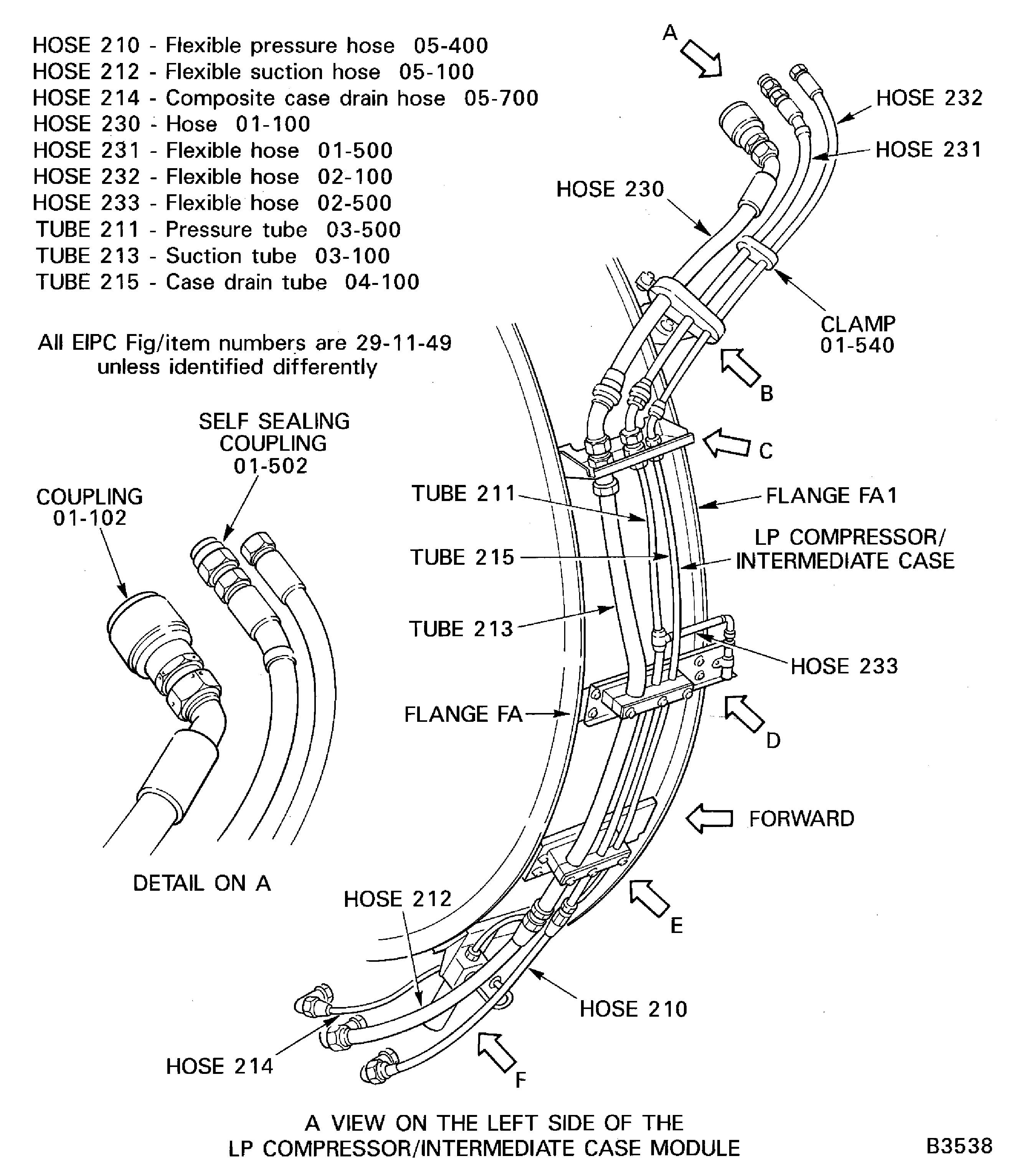

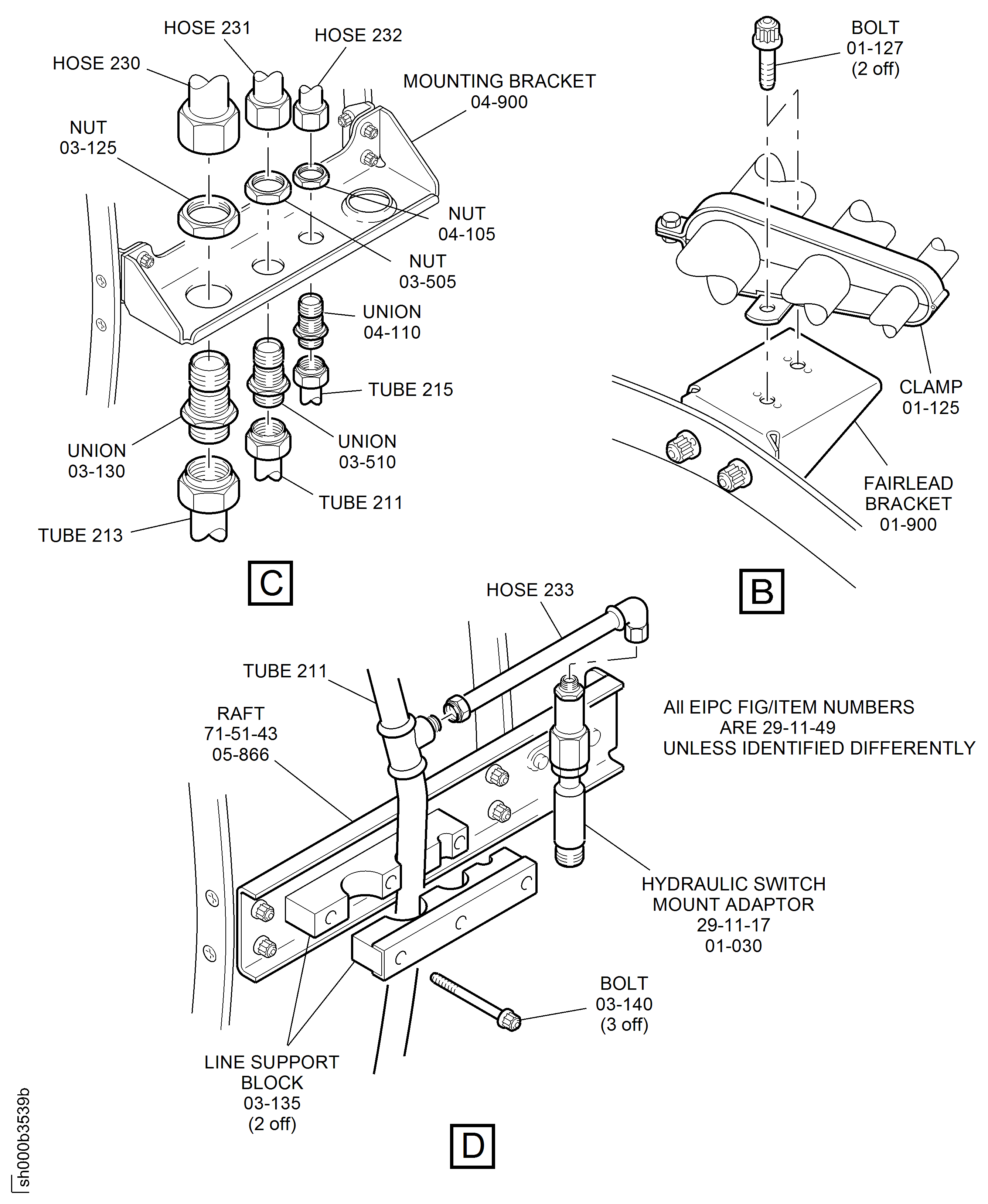

Hold the hose assemblies and remove the two bolts which secure the clamp HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-125) to the fairlead bracket. Remove the hose assemblies. Refer to the detail on B.

Remove the two clamps HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-125 and HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES 01-540) from the hose assemblies.

Remove the coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-102) and the self sealing coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-502) from the hoses 230 and 231. Refer to the detail on A.

WARNING

THE AIRCRAFT HYDRAULIC FLUID AND THE VAPOR ARE DANGEROUS THROUGH ABSORPTION AND INGESTION. THE HYDRAULIC FLUID CAN CAUSE EYE, NOSE AND SKIN IRRITATION. DO NOT BREATHE THE VAPOR.DO NOT GET HYDRAULIC FLUID ON YOUR SKIN OR IN YOUR EYES. YOU MUST USE PROTECTIVE GOGGLES AND GLOVES. YOU MUST OBEY THE MAKERS SPECIAL SAFETY INSTRUCTIONS.CLEAN YOUR EYES IMMEDIATELY WITH CLEAN COLD WATER IF HYDRAULIC FLUID GETS INTO THEM AND GET MEDICAL AID. USE SOAP AND HOT WATER TO IMMEDIATELY CLEAN THE AREA OF SKIN TOUCHED BY THE HYDRAULIC FLUID.

CAUTION

REMOVE HYDRAULIC FLUID IMMEDIATELY WITH A DRY CLOTH AND WASH THE AREA OF CONTAMINATION WITH MILD CLEANER, REFER TO THE SPM TASK 70-11-03-300-503. THE HYDRAULIC FLUID USED IN THIS SYSTEM WILL CAUSE DAMAGE TO A LARGE RANGE OF MATERIALS SUCH AS RUBBER, COPPER, DIFFERENT PLASTICS AND PAINT.KEEP LEAKAGE TO A MINIMUM AND INSTALL CLEAN CAPS TO ALL OPEN TUBES AND COMPONENTS AFTER YOU DISCONNECT THEM.Remove the hoses 230, 231 and 232.

Coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-102) and self sealing coupling HYDRAULIC POWER-ENGINE MOUNTED HYDRAULIC TUBES (29-11-49, 01-502) must have their maintenance completed as given in the Aeroquip Maintenance Manual (29-11-49).

Complete the tube and hose maintenance.

SUBTASK 72-00-32-020-193 Remove the Hydraulic Tubes

Figure: Remove the Thermal Anti-Ice (TAI) Duct

Sheet 1

Figure: Remove the Thermal Anti-Ice (TAI) Duct

Sheet 2

Figure: Remoce Thermal Anti.Ice (TAI) Duct Insulation

Sheet 3

Figure: Remove Thermal Anti.Ice (TAI) Duct Insulation

Sheet 4

Figure: Remove the Pneumatic Starter Duct

Sheet 1

Figure: Remove the Pneumatic Starter Duct

Sheet 2

Figure: Remove the Pneumatic Starter Duct

Sheet 3

Figure: Remove the Pneumatic Starter Duct

Sheet 4

Figure: Remove the Pneumatic Starter Duct

Sheet 5

Figure: Remove the Pneumatic Starter Duct

Sheet 6

Figure: Remove the Hydraulic Tubes

Sheet 1

Figure: Remove the Hydraulic Tubes

Sheet 2

Figure: Remove the Hydraulic Tubes

Sheet 3